Vacuum-freeze-dried vegetable and egg product and preparation method

A vacuum freeze-drying and egg technology is applied in the direction of drying and preserving eggs, food ingredients as colors, and food ingredients as taste improvers, etc. Rich nutritional structure, convenient to eat and carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

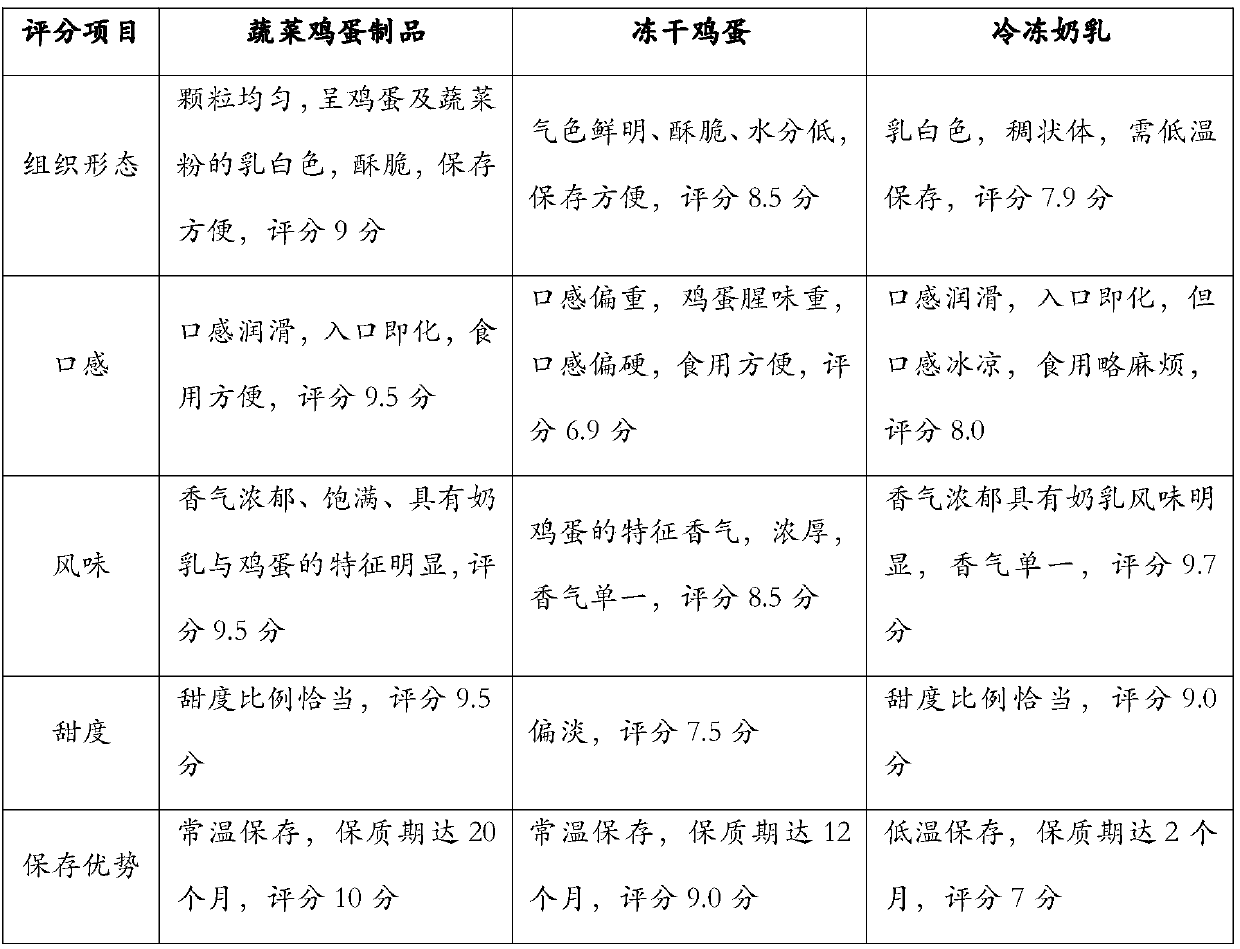

[0024] A vacuum freeze-dried vegetable and egg product provided by the present invention and its preparation method are further explained through the following examples.

[0025] The eggs selected in the following examples all use fresh eggs within five days. The vegetable powder used in the vegetable egg products is purple sweet potato powder and carrot powder, proportioned in a weight ratio of 1:1, and the white granulated sugar is refined table sugar, low Fructose is fructooligosaccharide. The above raw materials selected, eggs meet the requirements of GB21710-2016, white sugar meets GB / T317-2018, fructooligosaccharides meet the requirements of relevant national standards such as GB / T23528-2009.

[0026] S1. Acceptance of raw and auxiliary materials: After the incoming raw materials are checked and accepted according to the acceptance standards of raw and auxiliary materials, the raw and auxiliary materials used on the day are prepared according to the requirements of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com