Egg cleaning machine

A cleaning machine and egg technology, applied in the field of egg cleaning, can solve the problems of reducing production efficiency, high difficulty and high cost, and achieve the effects of ensuring factory quality, reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

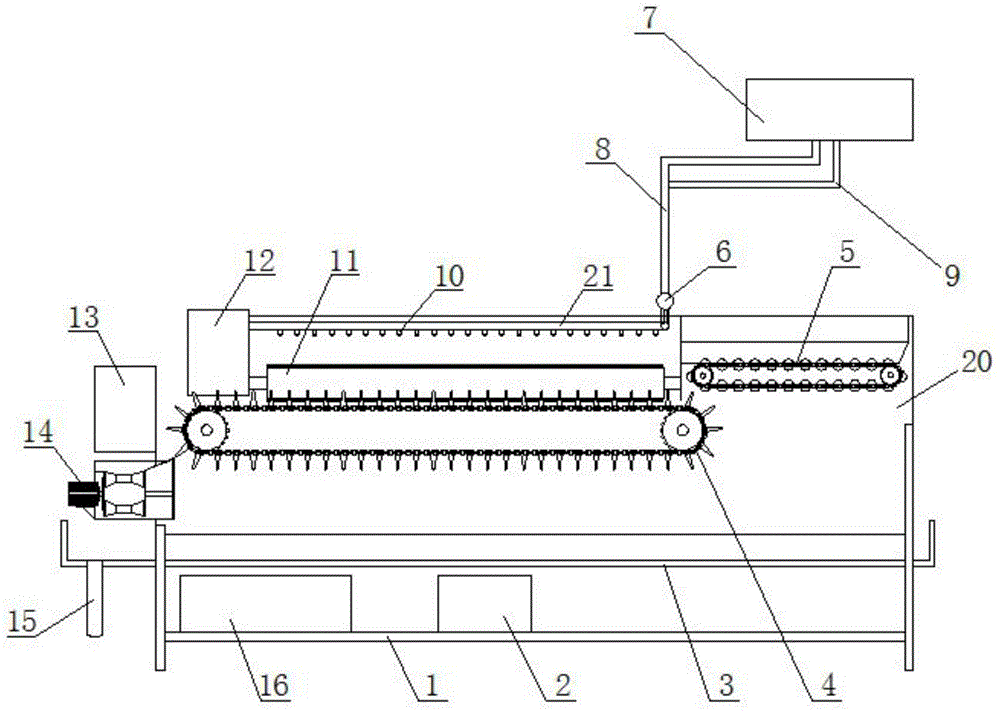

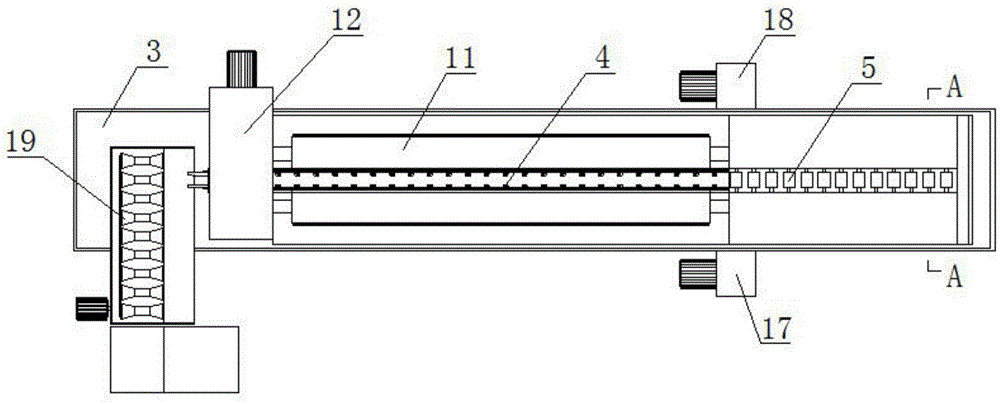

[0028] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0029] Such as Figure 1-7 As shown, a kind of egg washing machine of the present invention, comprises the frame 1 that is welded by angle steel, is used to control the electric control box 2 of each motor start-stop, and body 20, and described body 20 and electric control box 2 are respectively installed on the frame 1, the body 20 includes a feeding mechanism 5, an egg cleaning conveyor belt 4 and a discharging mechanism 19, the transmission mode of which is a chain drive, each motor output end is equipped with a reduction box, and the output of the reduction box The end drives the chain to work through the sprocket.

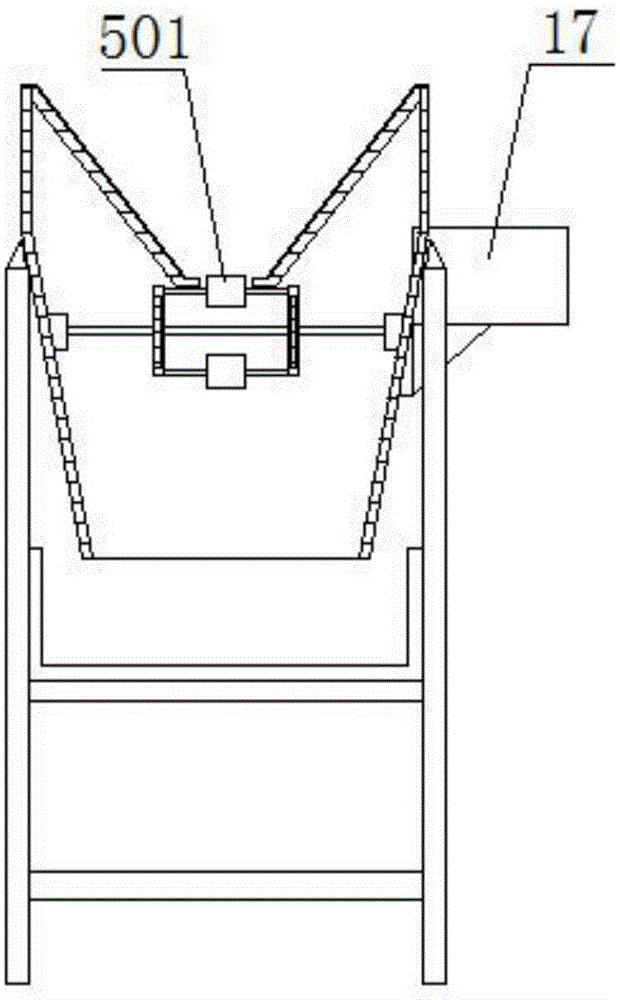

[0030] The feeding mechanism 5 is funnel-shaped with three sides inclined and one side open, and a number of feeding rollers 501 are arranged at the bottom. Material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com