Patents

Literature

82results about How to "Air dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

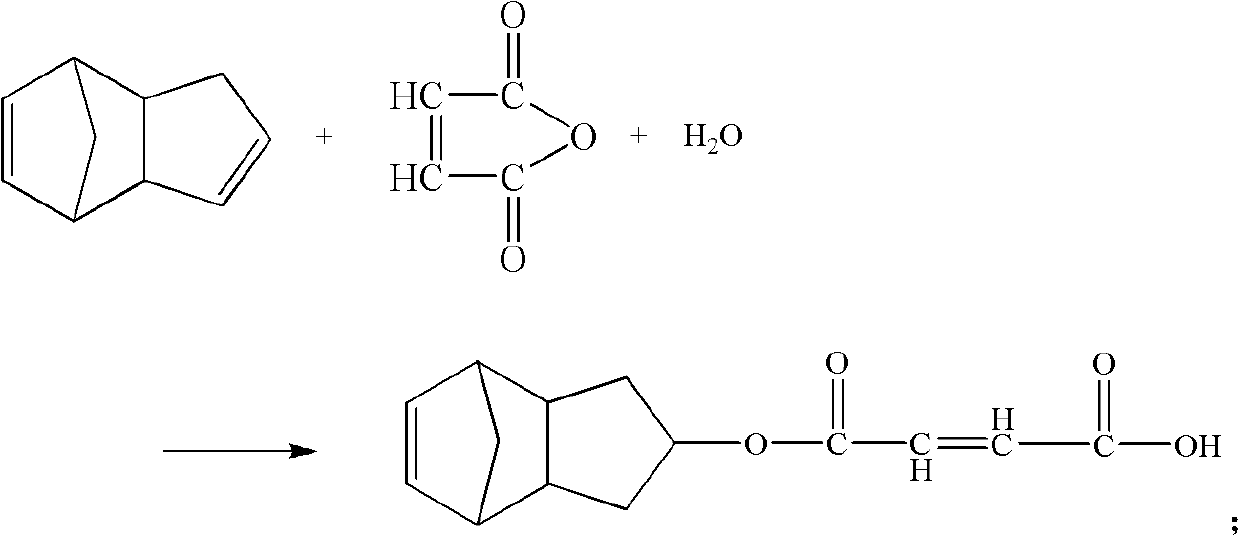

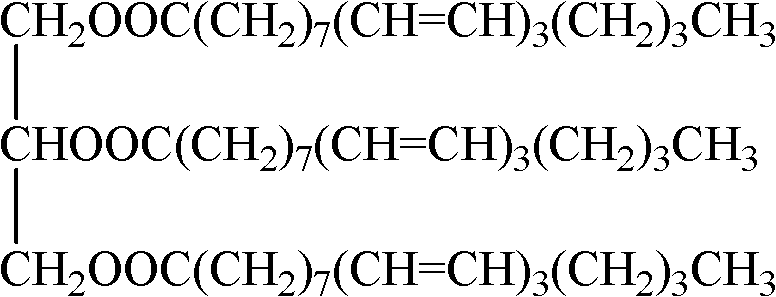

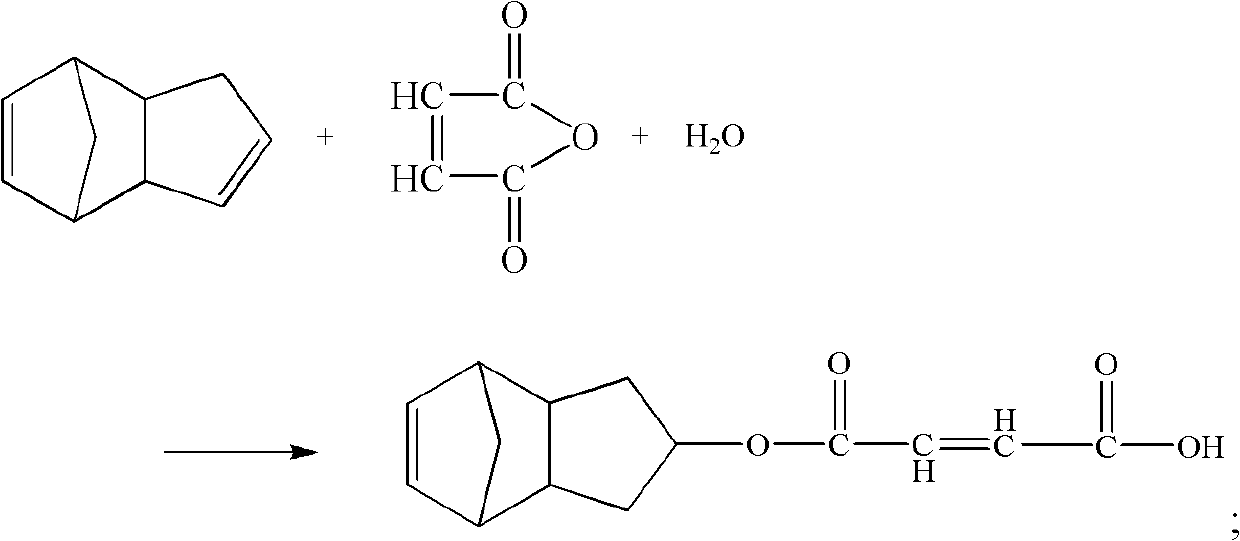

Dicyclopentadiene type unsaturated polyester modified by tung oil, and preparation method and application thereof

InactiveCN102115534AEasy to operateImprove product qualityPlastic/resin/waxes insulatorsOther chemical processesAlcoholAcid value

The invention discloses a dicyclopentadiene type unsaturated polyester modified by tung oil, and a preparation method and application thereof. The method comprises the following steps: reacting raw materials maleic anhydride and dicyclopentadiene under the action of a catalyst to obtain dicyclopentadiene semi-maleate; adding dihydric alcohol, dibasic acid and polymerization inhibitor, and heatingto 190-210 DEG C for dehydration and esterification; when the acid value reaches 50-120 mg KOH / g, cooling to 120-180 DEG C, adding a certain amount of tung oil, and heating to 200-210 DEG C to continue the reaction; and after the acid value reaches 20-35 mg KOH / g under the action of esterification, cooling to 100-120 DEG C, diluting with styrene dissolved with a small amount of polymerization inhibitor, and uniformly dispersing to obtain the product. The dicyclopentadiene type unsaturated polyester modified by tung oil according to the method has the advantages of favorable air-drying property, aging resistance, biodegradability and the like. The product is suitable to be used as an unsaturated polyester paint for corrosion protection, insulation and binding.

Owner:山东中洋新创复合材料有限公司

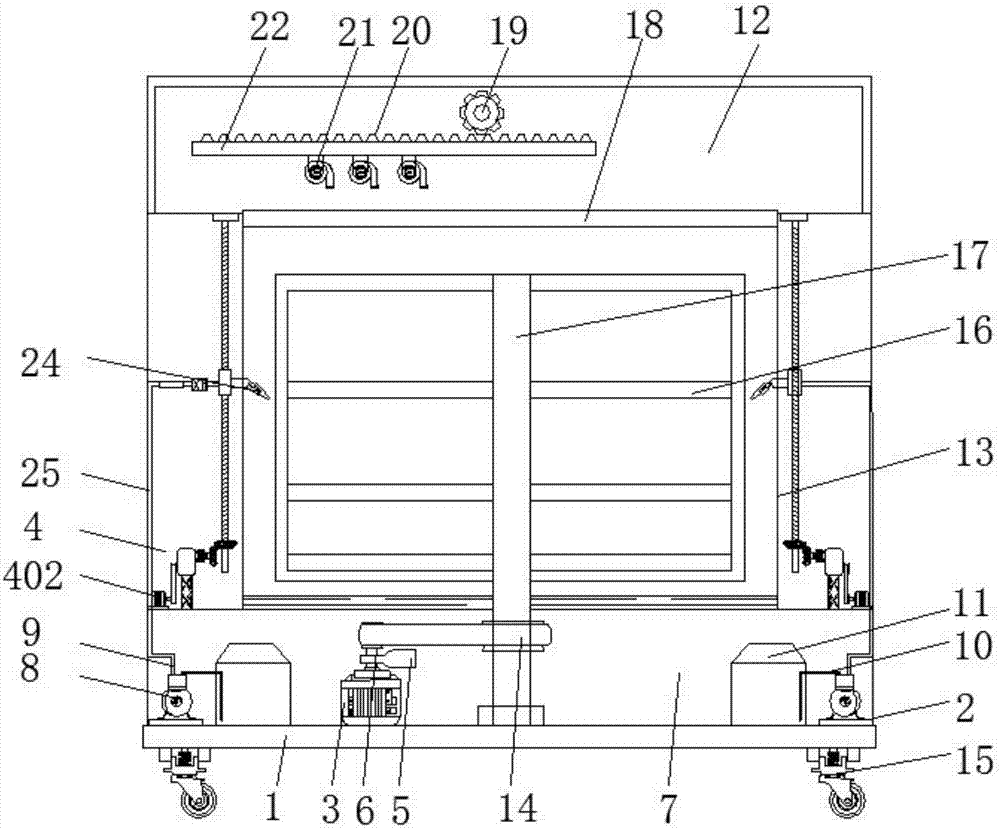

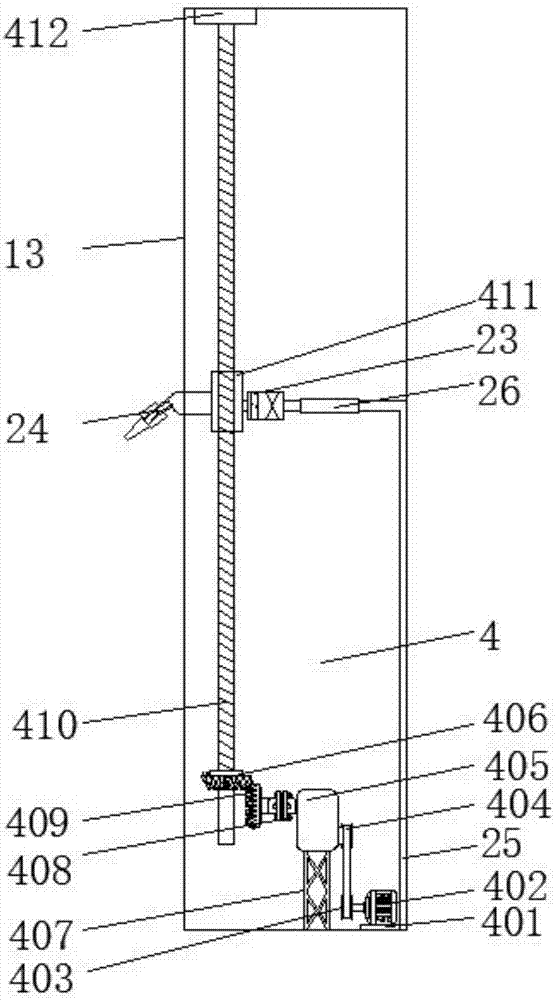

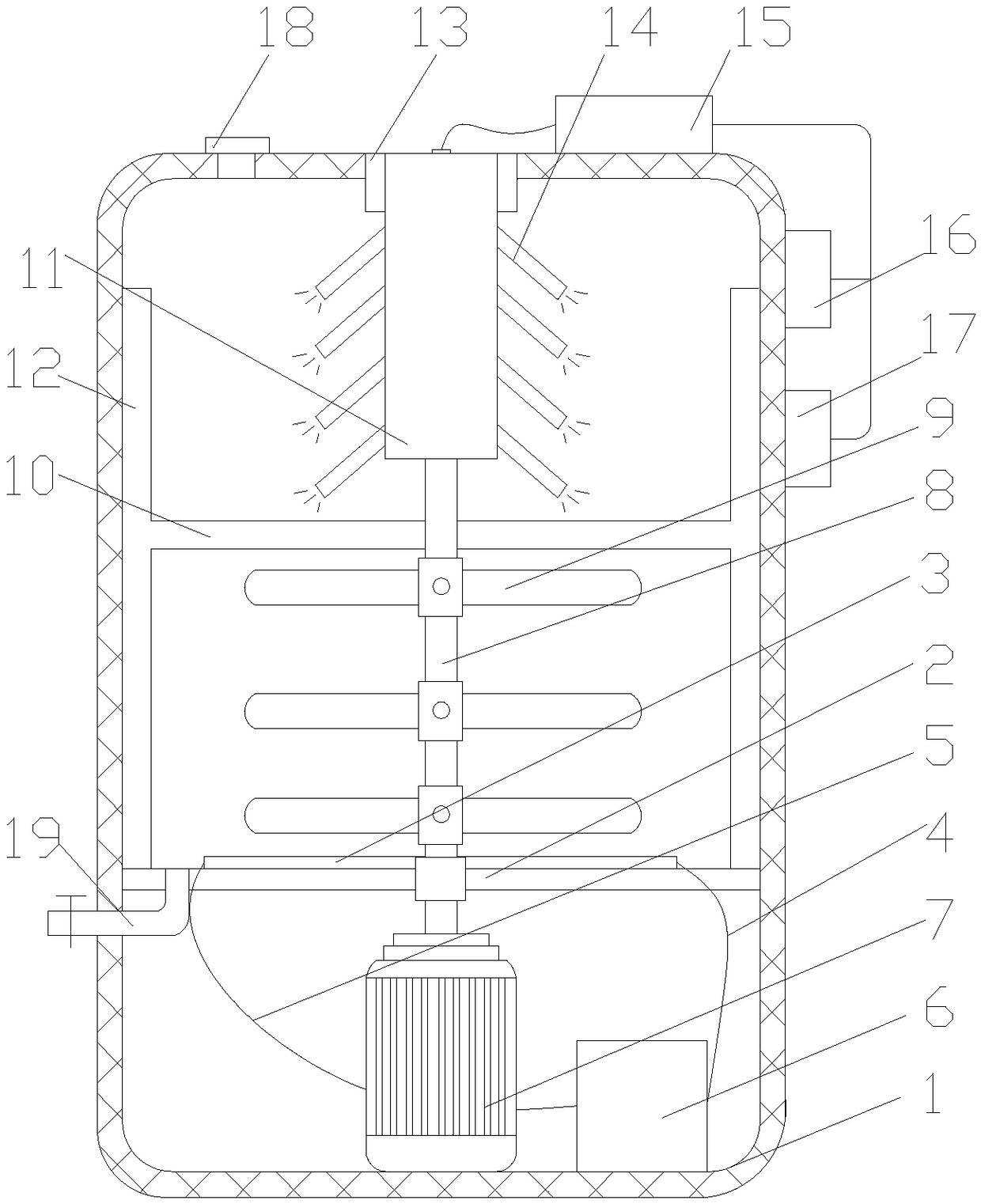

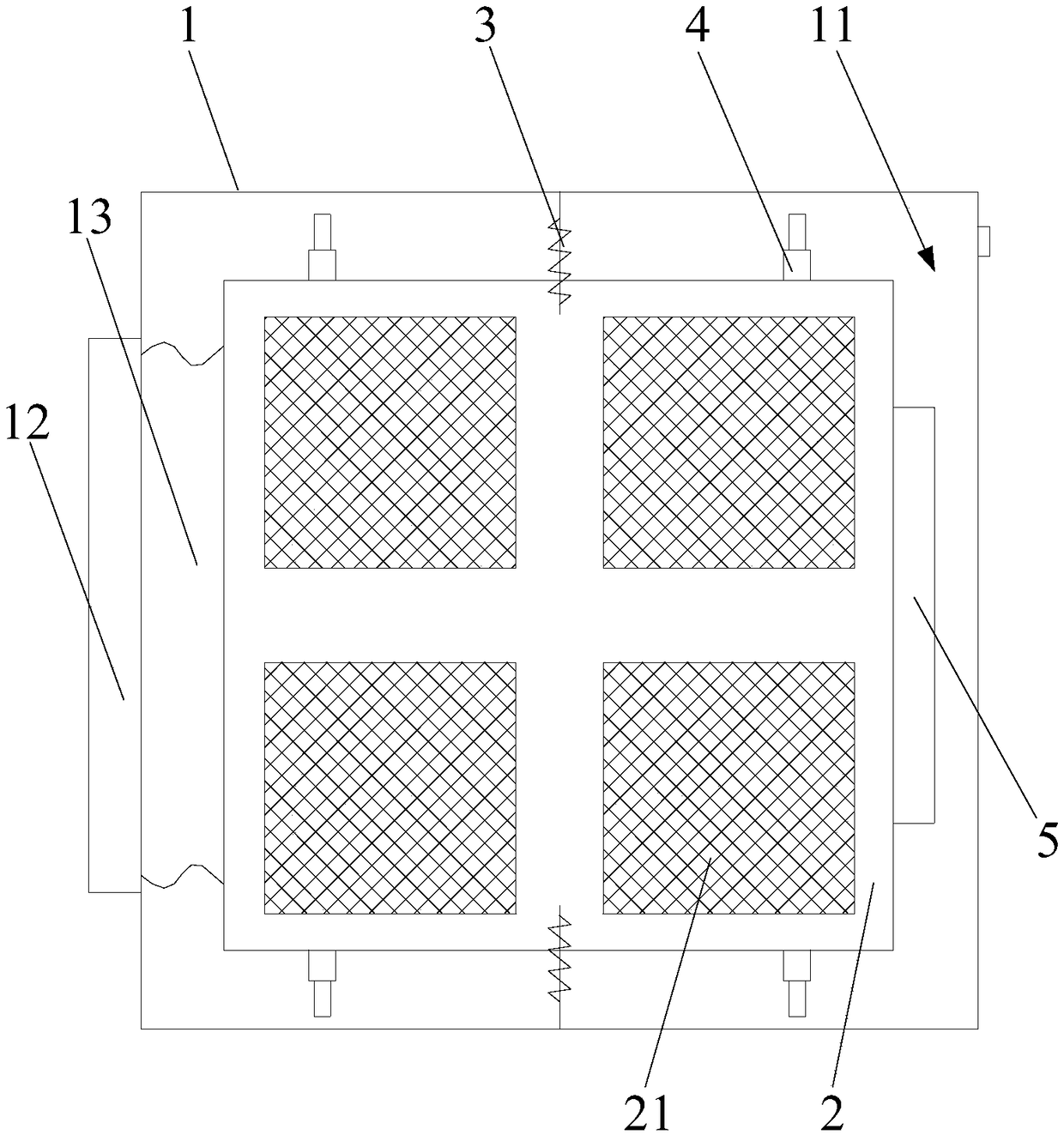

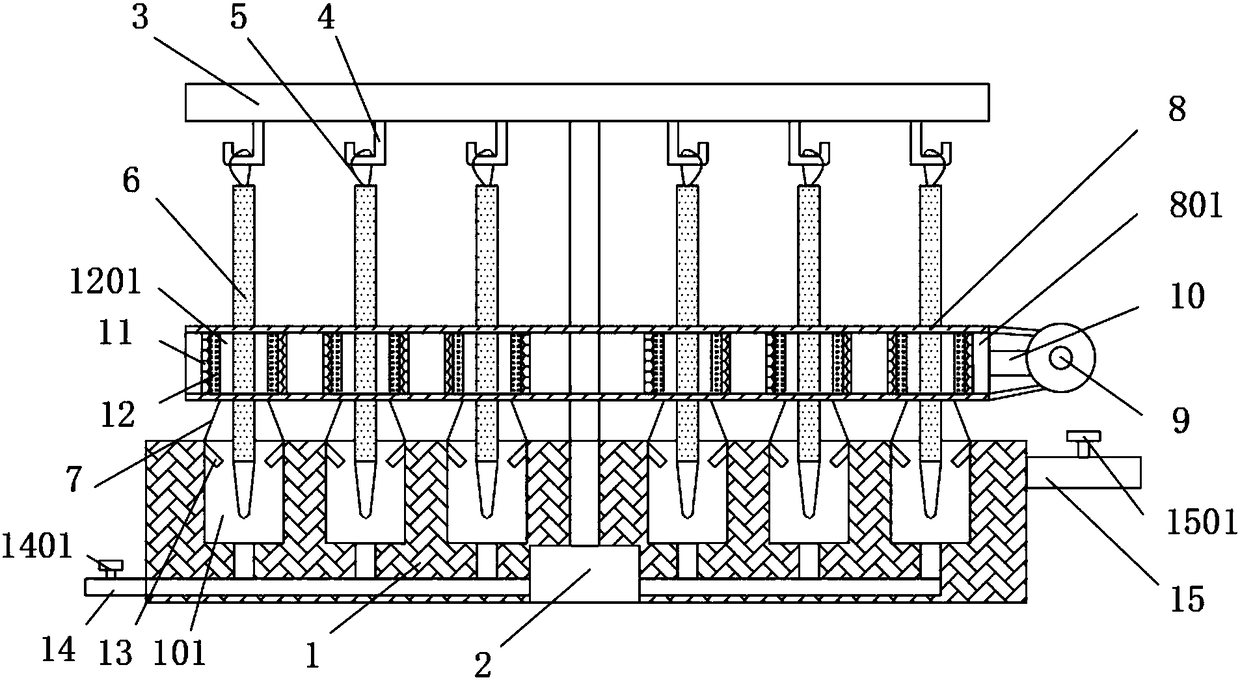

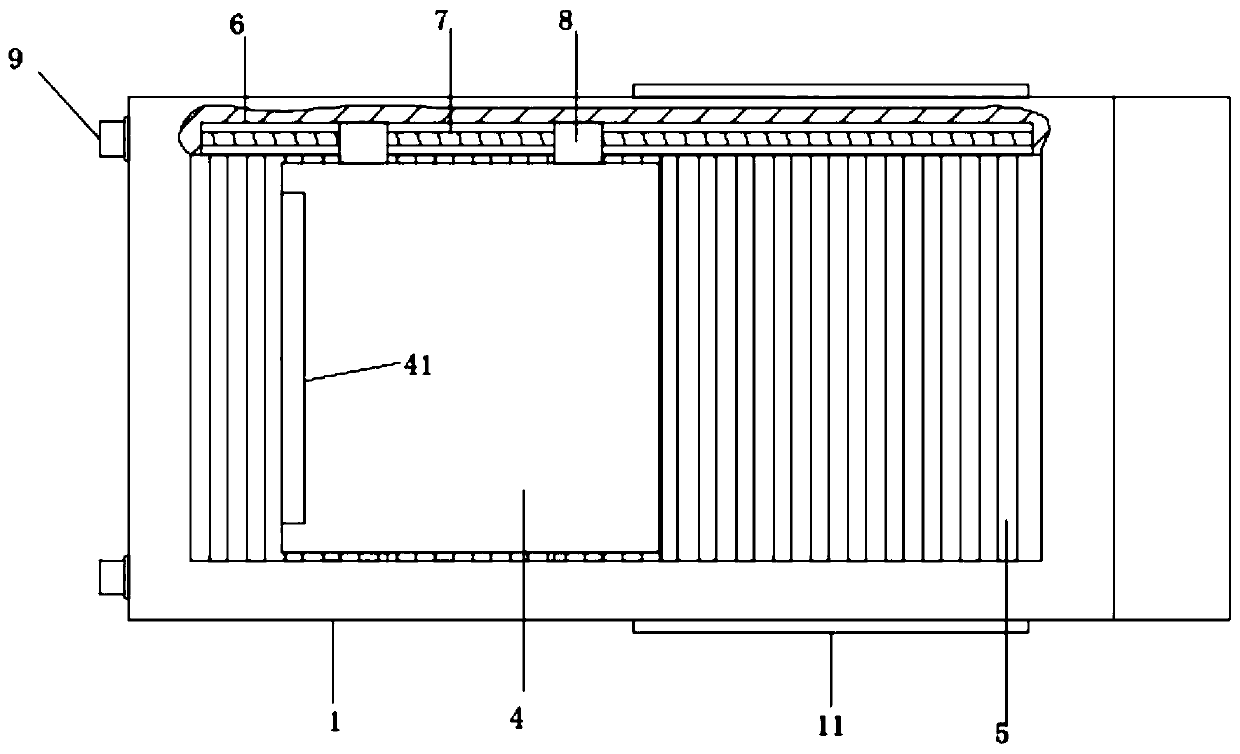

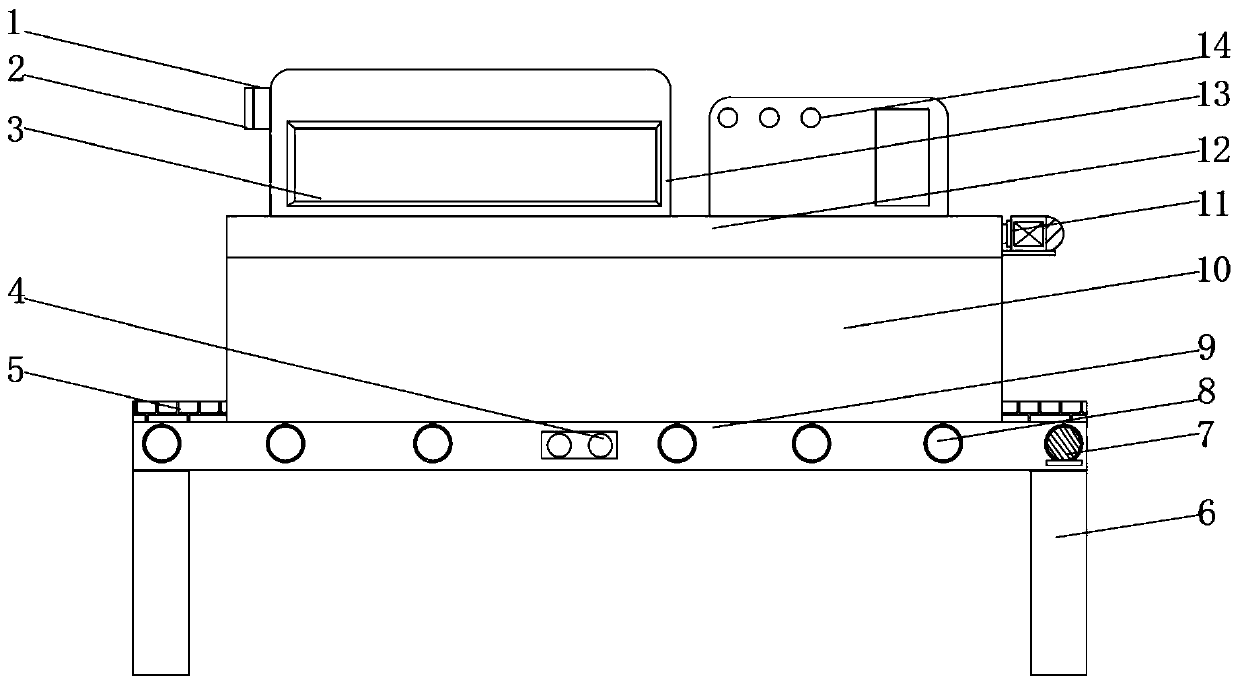

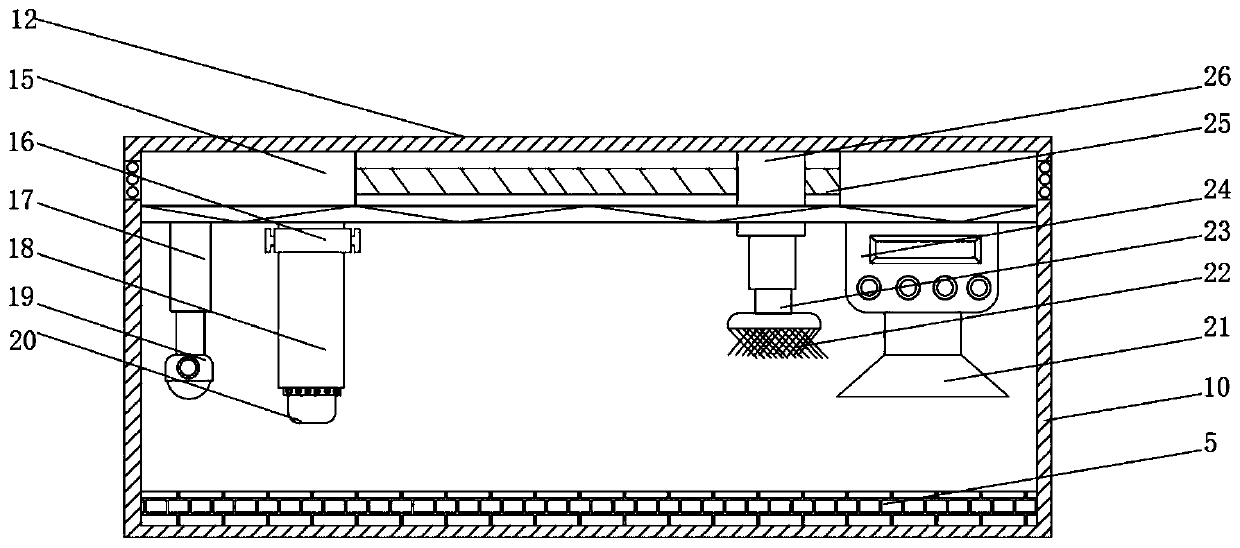

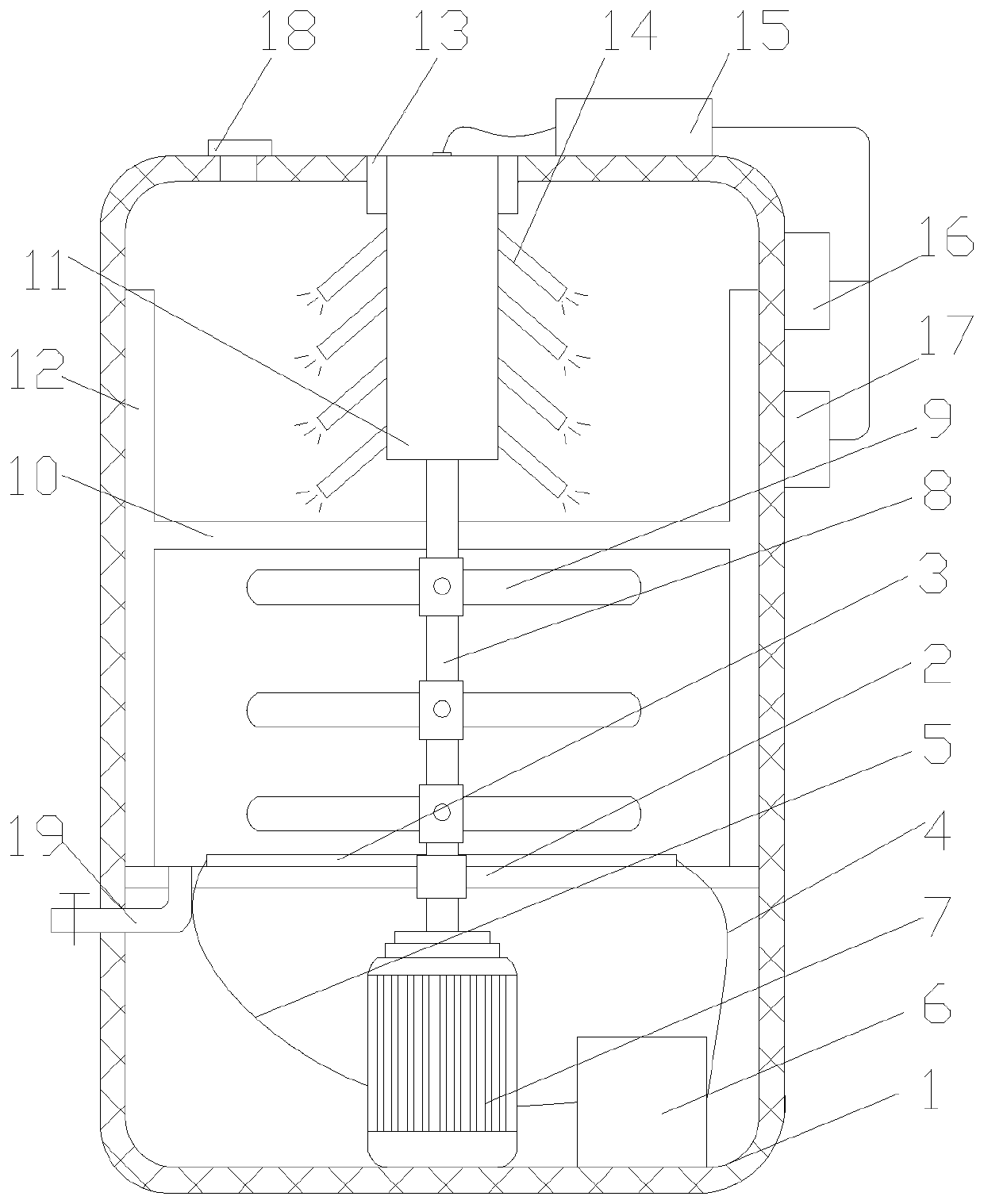

Quick cleaning and air drying device for mechanical parts

InactiveCN107175230AAchieve intelligenceReduce workloadDrying gas arrangementsCleaning using liquidsMechanical equipmentEngineering

The invention discloses a quick cleaning and air drying device for mechanical parts, and relates to the technical field of mechanical equipment. The quick cleaning and air drying device comprises a bottom plate; a working box is fixedly connected to the top of the bottom plate; a water pump motor box is fixedly connected to the bottom of the inner wall of the working box; a first motor is fixedly connected to the bottom of the inner wall of the water pump motor box and rotationally connected with a speed reducing connector through an output shaft; a first belt wheel is fixedly connected to the output shaft of the speed reducing connector; a second belt wheel is rotationally connected to the first belt wheel through a belt; and a rotary shaft is fixedly connected to the second belt wheel through a flat key. Through the quick cleaning and air drying device for the mechanical parts, the parts are intelligently cleaned, the cleaning efficiency and cleanness are ensured, the purposes that a high-pressure spray head moves up and down, and an air blower moves left and right are achieved, the high efficiency of cleaning and air drying is achieved, workers do not need to get the parts out of water after the parts are cleaned, the working amount of the workers is decreased, and the production efficiency is improved.

Owner:合肥全套机械科技有限公司

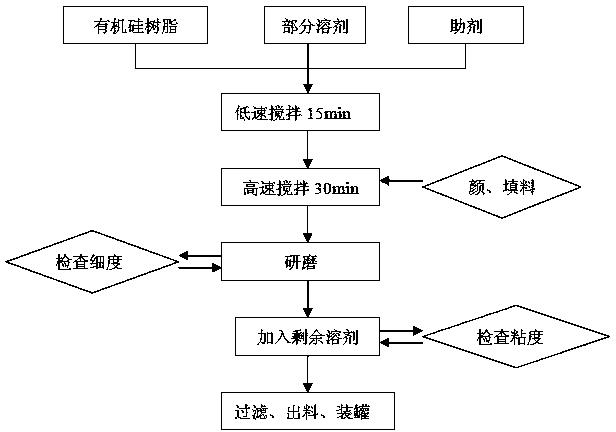

800DEG C resistant organosilicon anticorrosion coating for outer wall of pipeline, and preparation method thereof

ActiveCN103614071AAir dryAchieve high temperature corrosion protectionAnti-corrosive paintsSolventMaterials science

A 800DEG C resistant organosilicon anticorrosion coating for the outer wall of a pipeline is obtained by adding a glass frit having a low melting point of 370-430DEG C to an organosilicon resin base material which is a hydroxy-containing methyl phenyl silicone resin SM1056, and concretely comprises, by mass, 30-35% of the organosilicon resin base material, 10-20% of the glass frit having a low melting point of 370-430DEG C, 10-15% of micaceous iron oxide red, 2-4% of an assistant, 10-18% of a solvent and 20-27% of a filler. The 800DEG C resistant organosilicon anticorrosion coating for the outer wall of a ship pipeline can be a normal temperature dry-to-touch single-component coating, and has the advantages of good heat resistance, convenient construction, and large area construction. The coating can be used on the external surface of a ship thermal pipeline to realize the high temperature anticorrosion effect, so the corrosion rupture of the ship pipeline, caused by the bad corrosive environment, is avoided.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

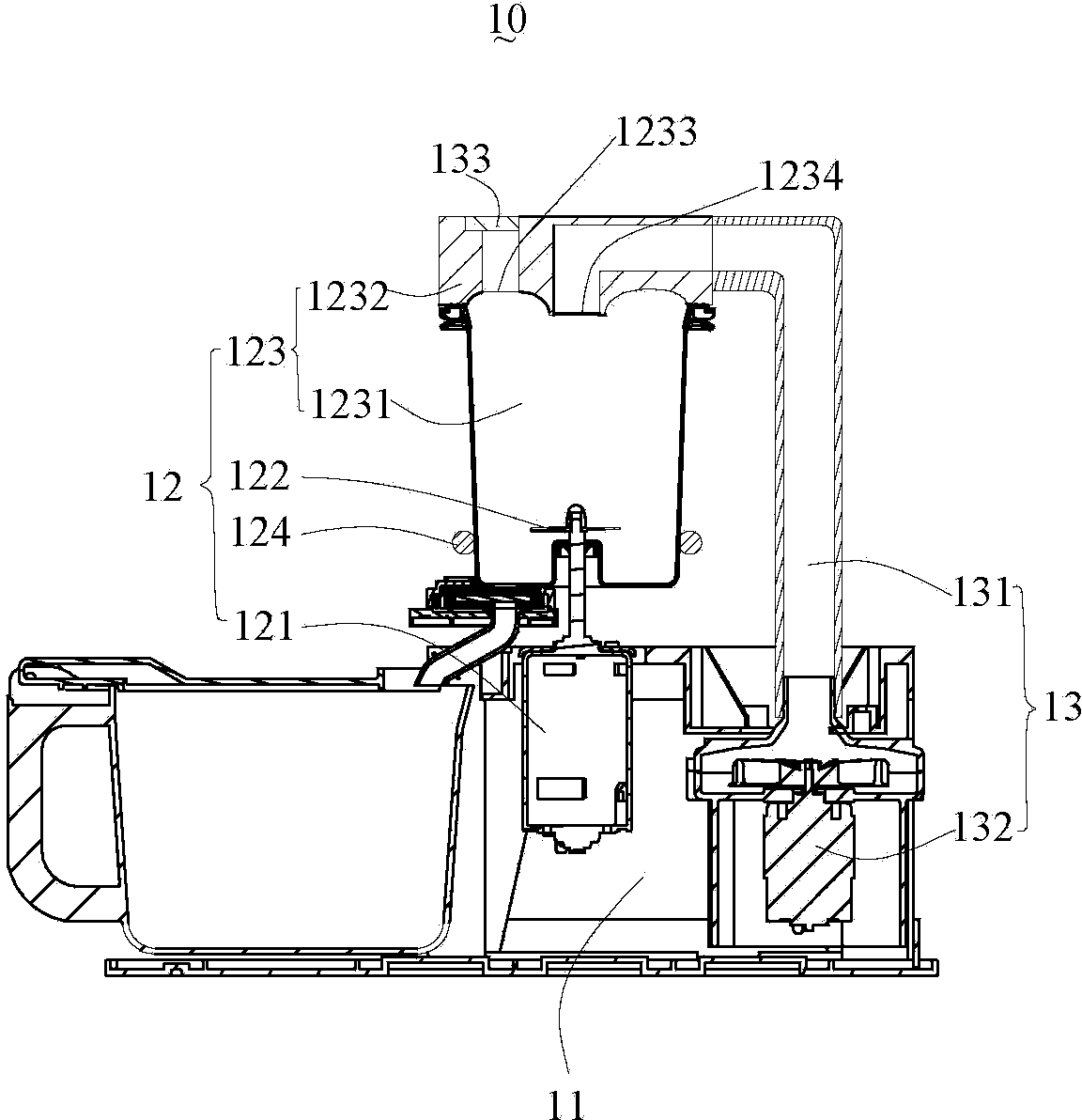

Rapid soybean milk making method of soybean milk maker

ActiveCN104545455AReduce the temperatureShorten the timeBeverage vesselsMilk substitutesCold airEngineering

The invention relates to a rapid soybean milk making method of a soybean milk maker. A cooking stage also includes the step of overflow prevention, the hot air in a pulverizer is sucked away by a sucking pump, the outside cold air rapidly enters the pulverizer via an air inlet under the difference between the outside air pressure and the air pressure in the pulverizer, the air which flows at high speed breaks rising soybean milk bubbles and decreases the surface temperature of the soybean milk liquid, so that overflow is prevented, consequently, the hot steam of cooking is sucked away by the sucking pump, the surface temperature of the soybean milk bubbles is decreased, the bubbles rapidly expand and break according to the principle of thermal expansion and contraction when the gas temperature in the bubbles is higher than the outside temperature, negative pressure is generated in the pulverizer as the hot steam is sucked away, the outside air is formed into high-speed airflow under the effect of pressure difference and is rapidly replenished into the pulverizer, the high-speed airflow also can break the bubbles of the soybean milk liquid, and thereby the efficiency of overflow prevention is increased greatly.

Owner:JOYOUNG CO LTD

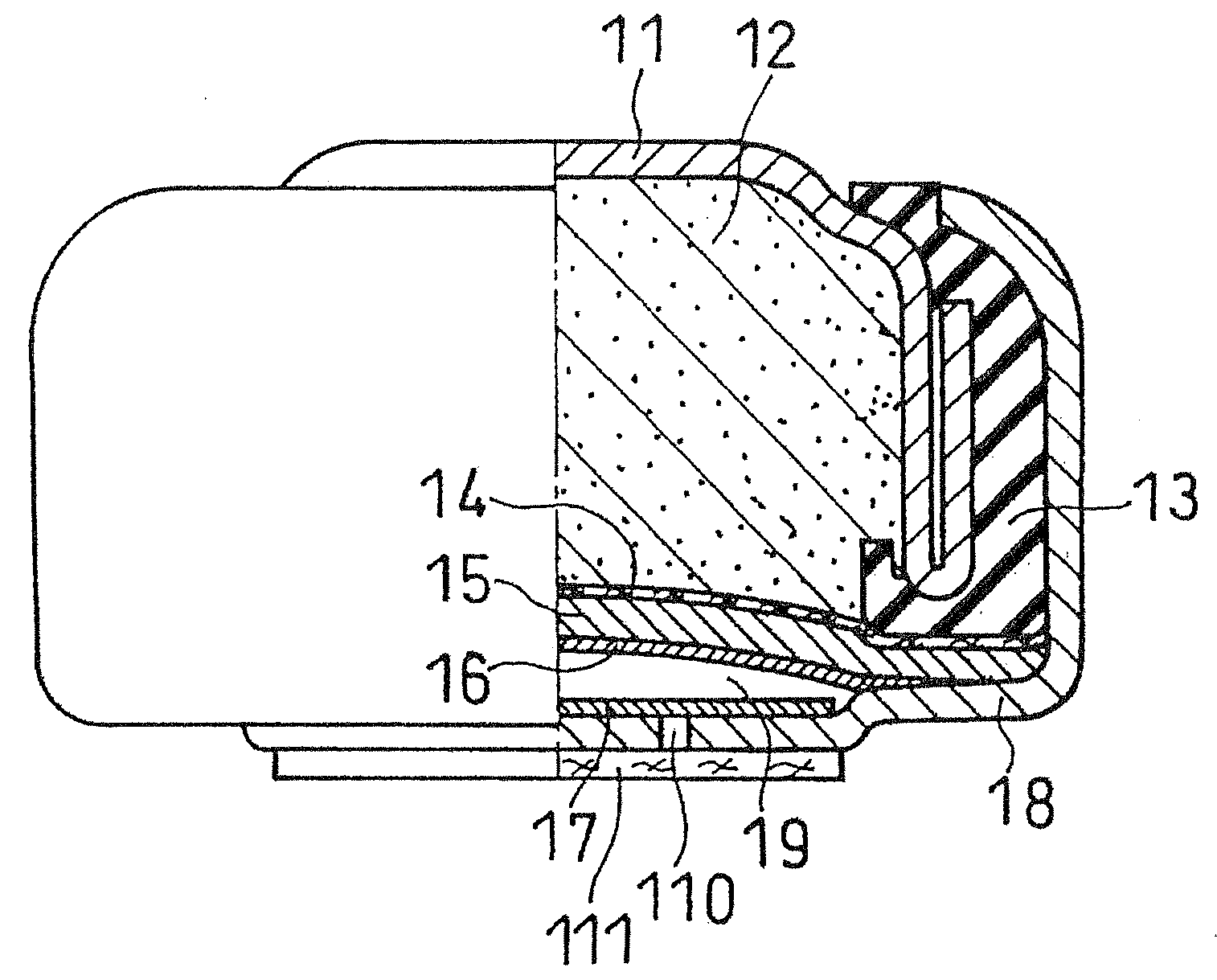

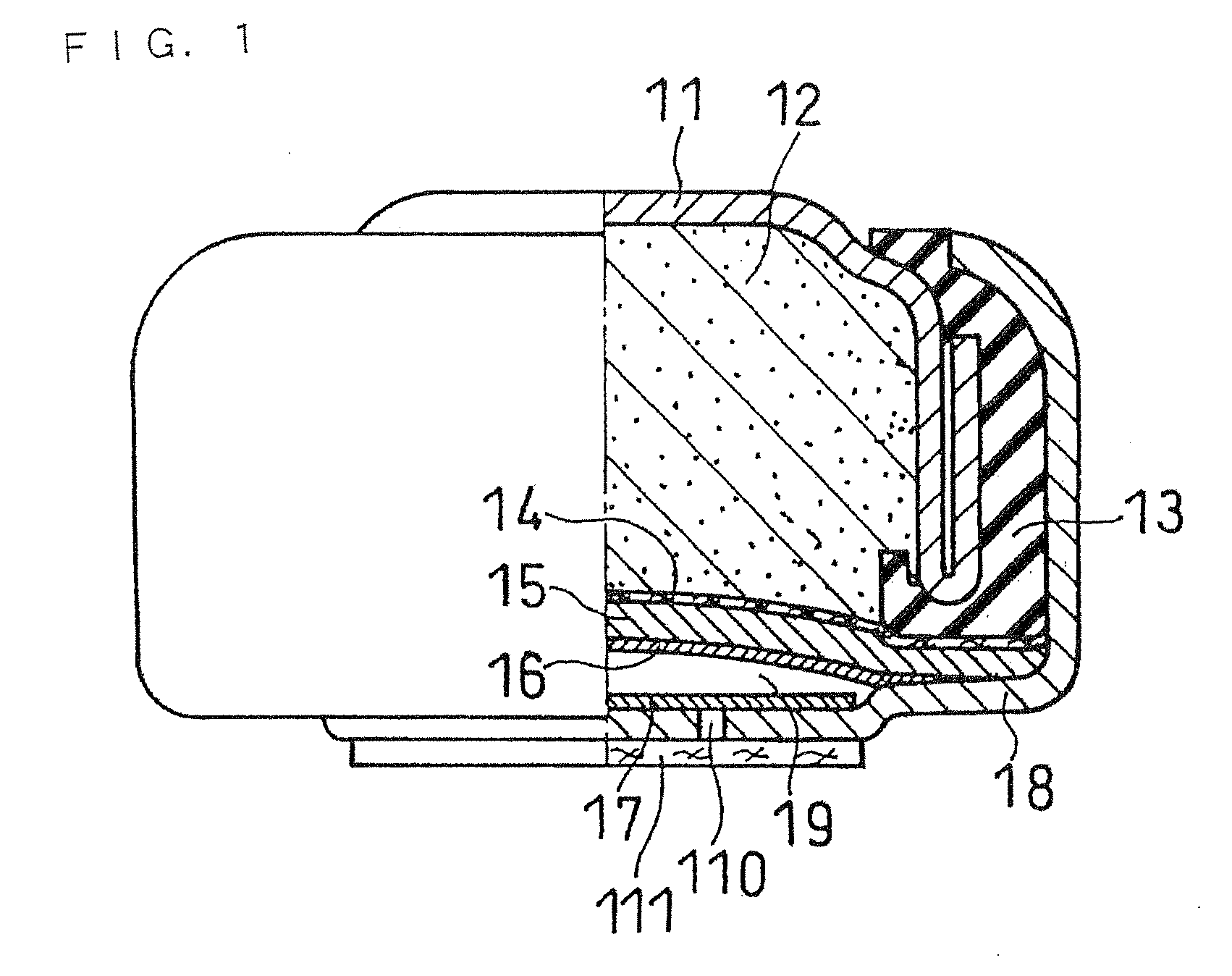

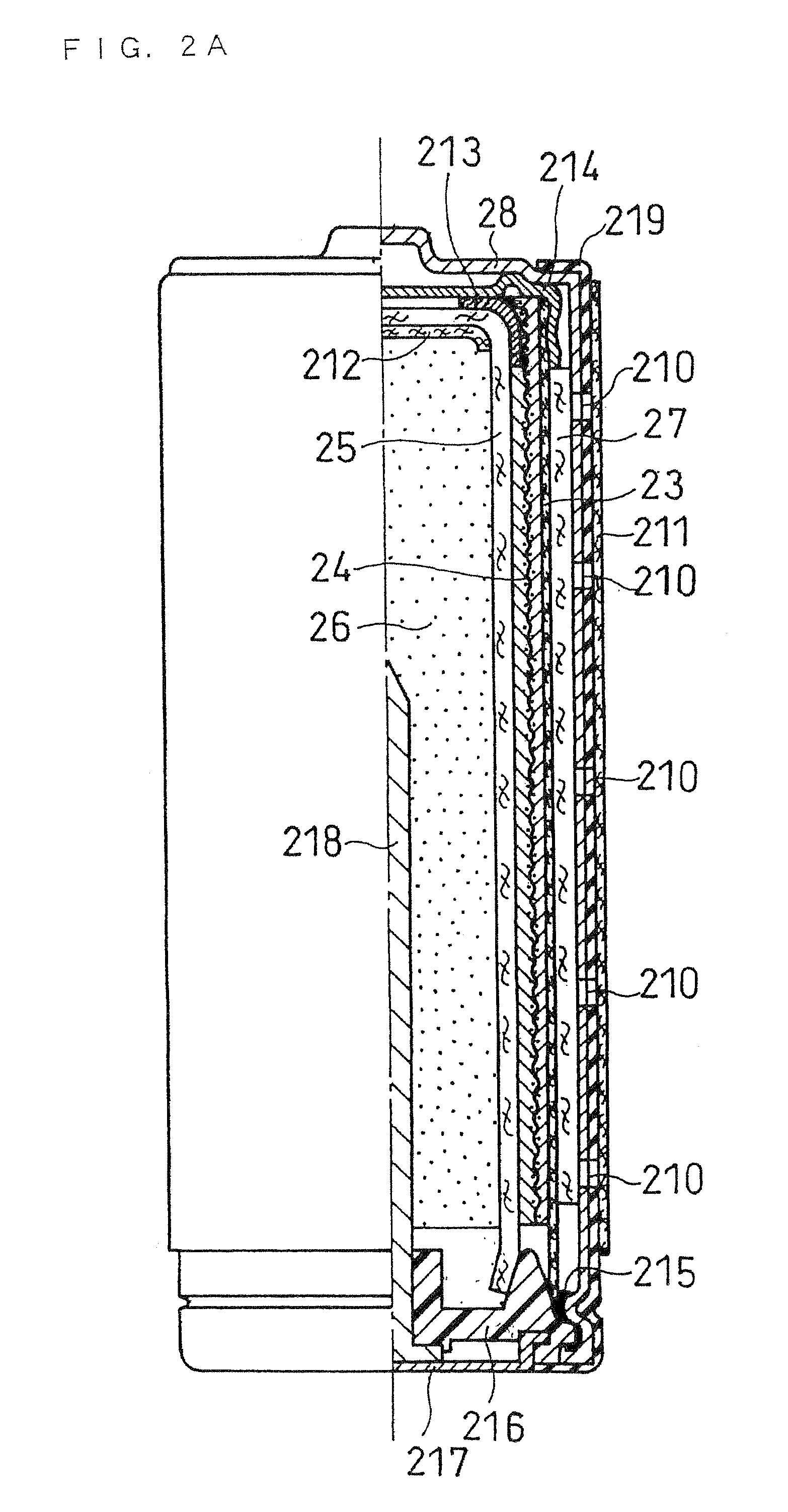

Oxygen permeable film, oxygen permeable sheet, and cell including these

InactiveUS20090202876A1Favorable high rate discharge characteristicExpanding allowable operation rangeFuel and primary cellsCell electrodesWater vaporPolyvinylidene difluoride

An oxygen permeable film including an aggregate of water-repellent particles and having an average particle size of the particles of 0.01 to 50 μm has a contact angle with water of not less than 120° and super water repellency, and therefore has an excellent water vapor permeation inhibiting capability. As the particles, fluorocarbon resins such as polytetrafluoroethylene, polyvinyl fluoride and polyvinylidene fluoride are suitable. The specific surface area of the oxygen permeable film is preferably not less than 0.1 m2 / g and not more than 500 m2 / g.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

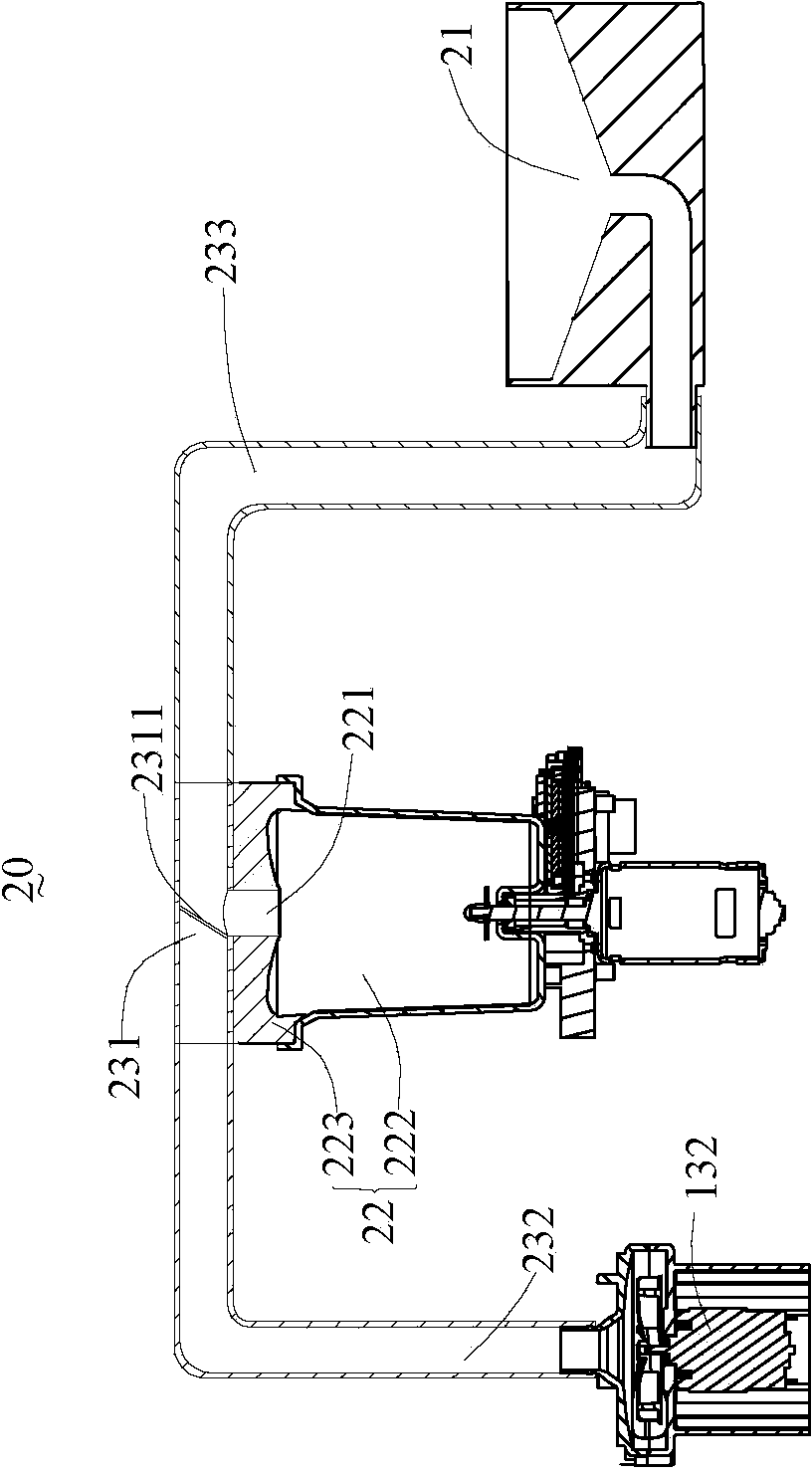

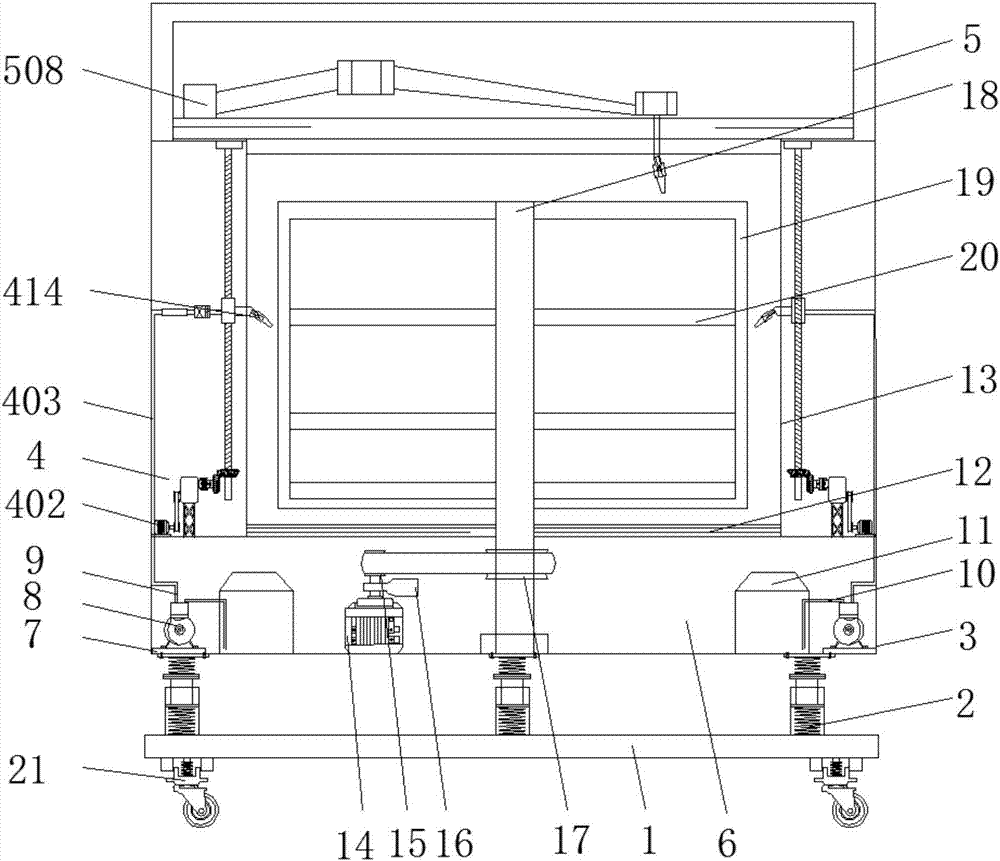

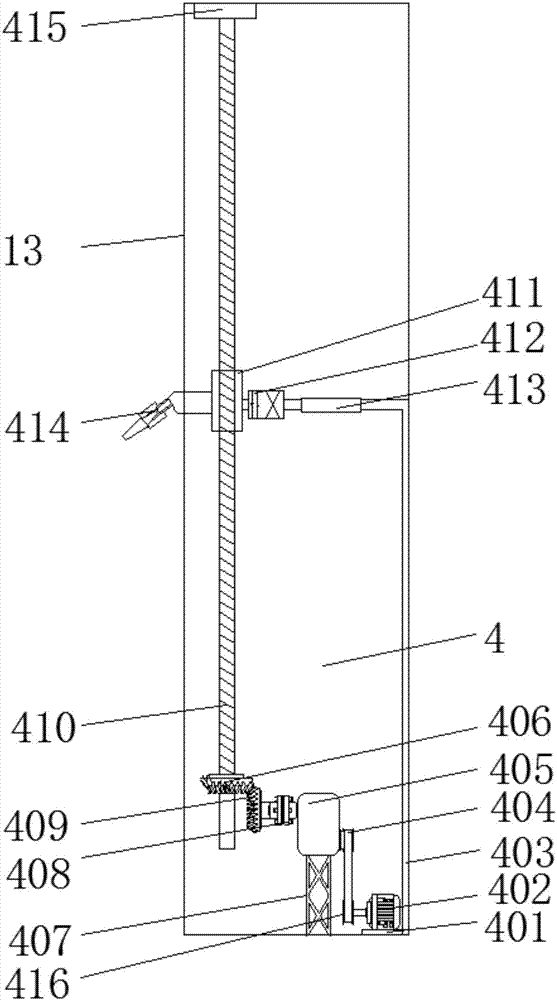

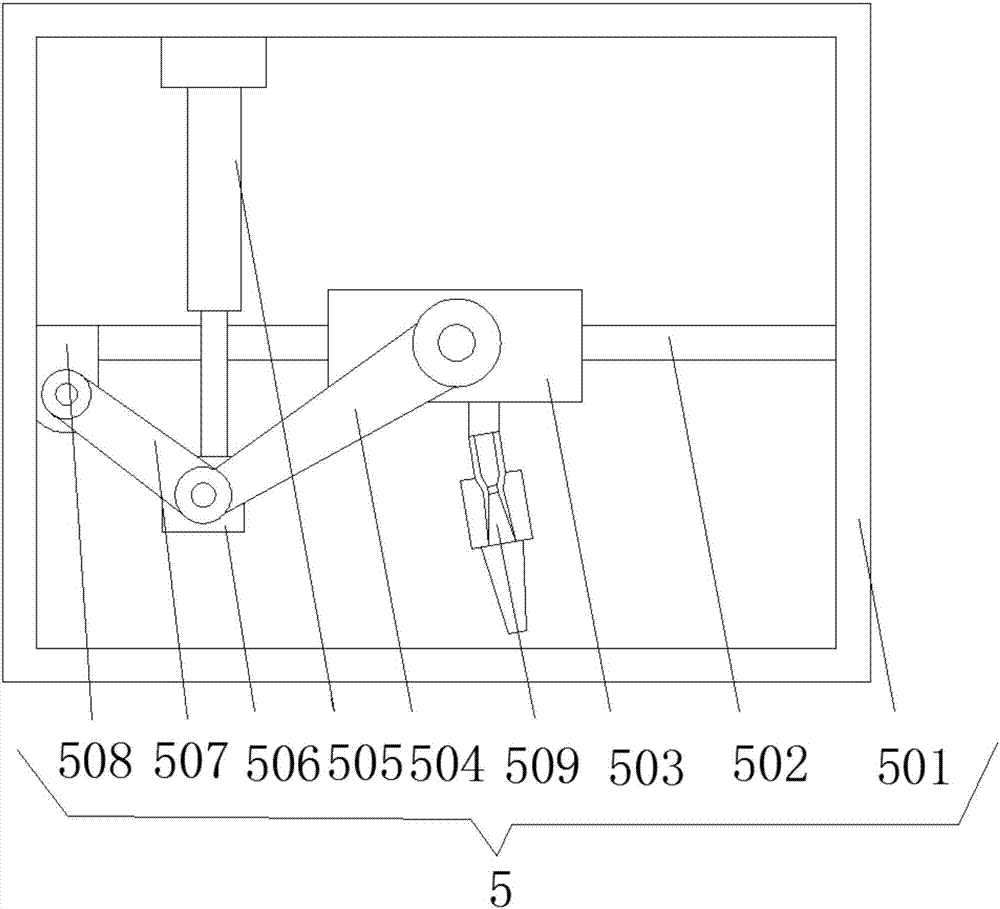

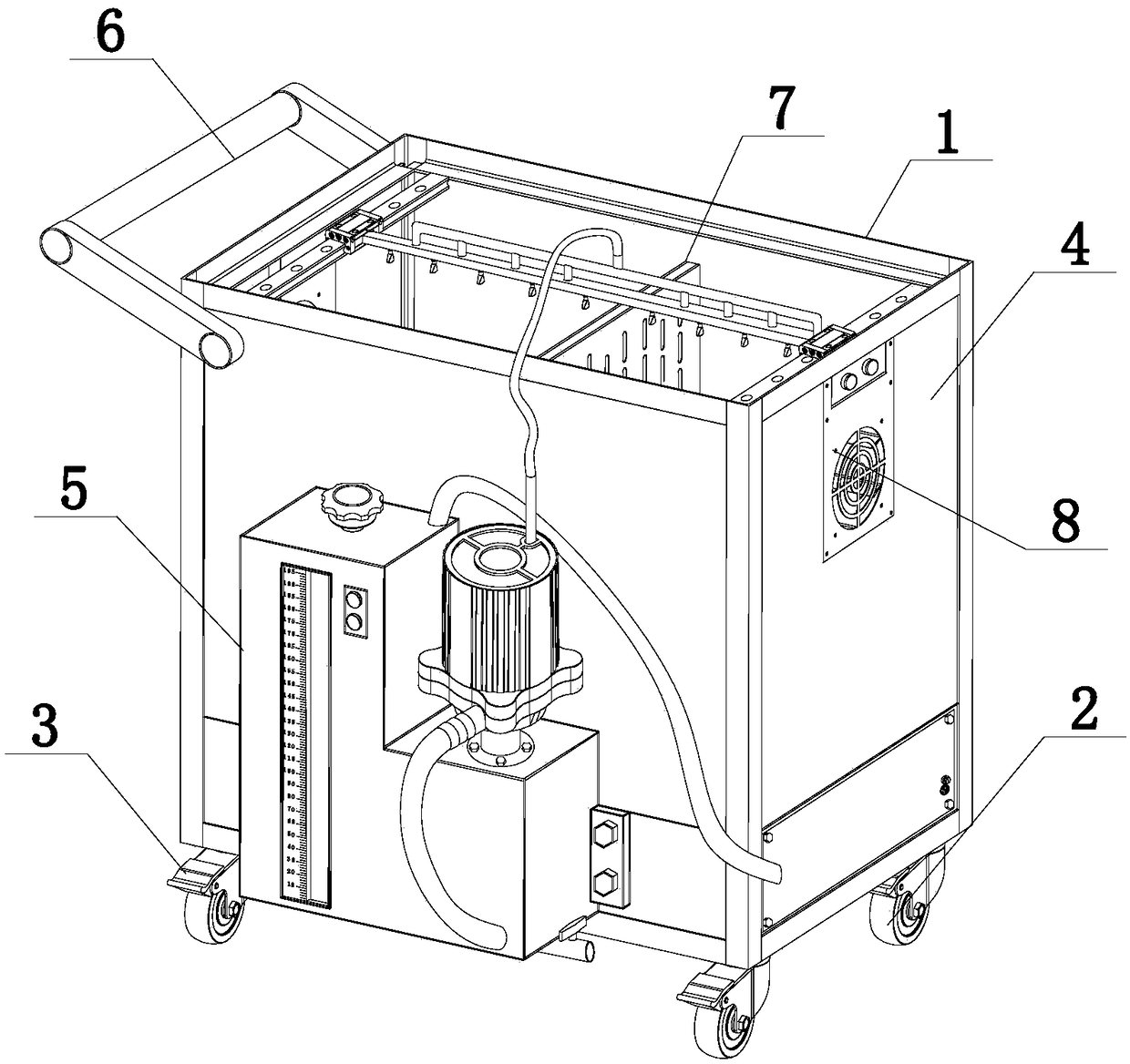

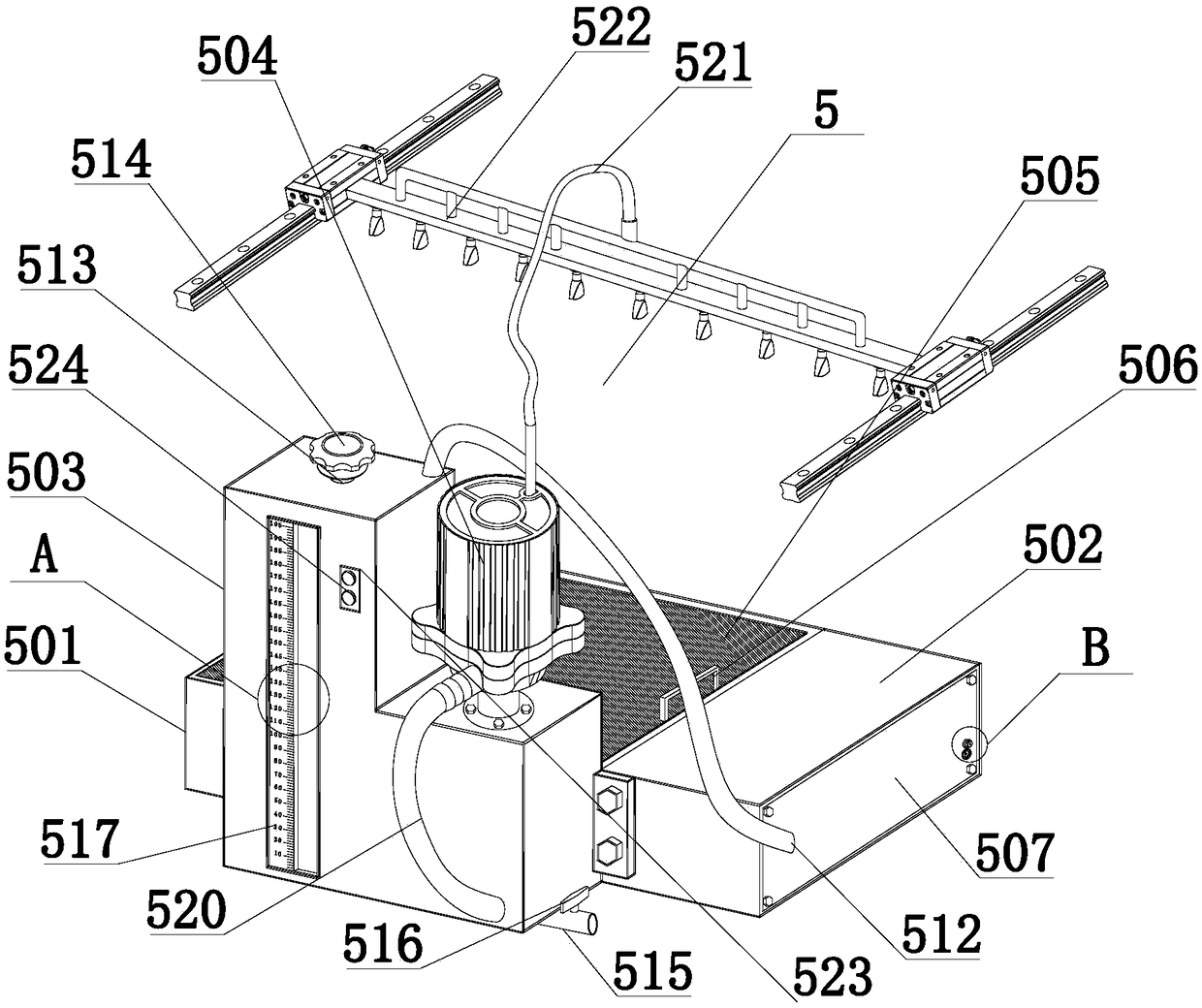

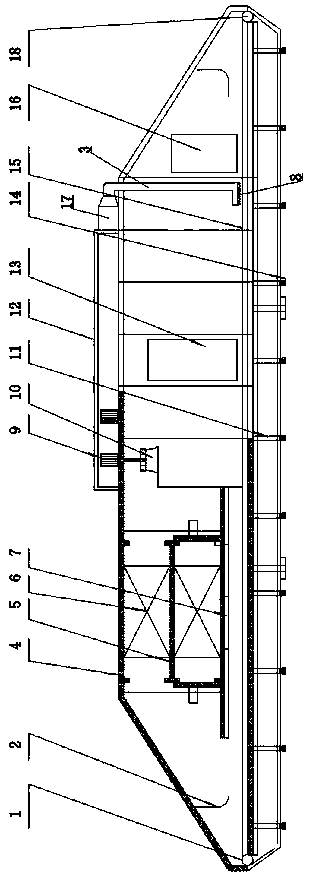

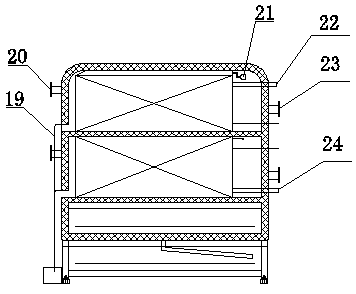

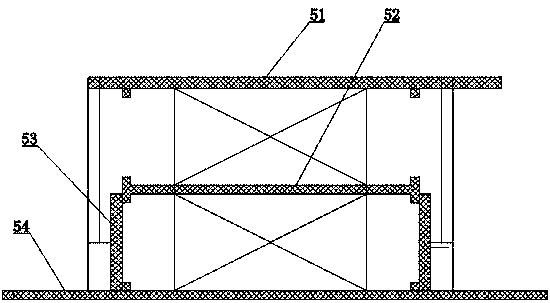

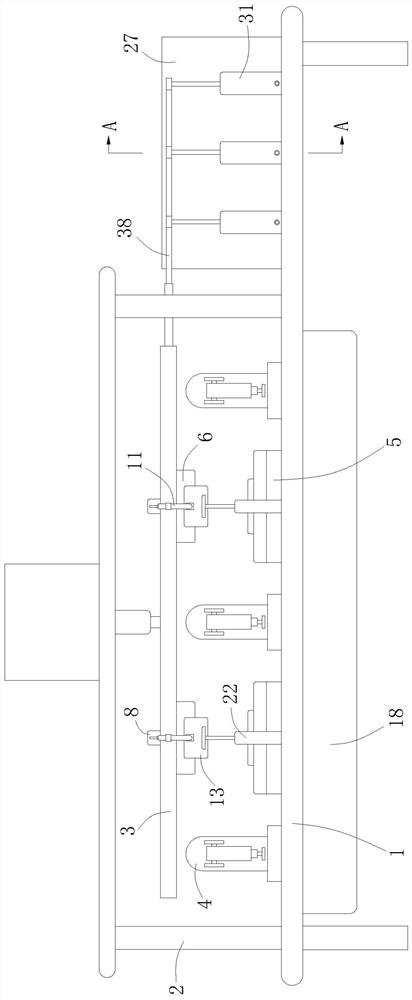

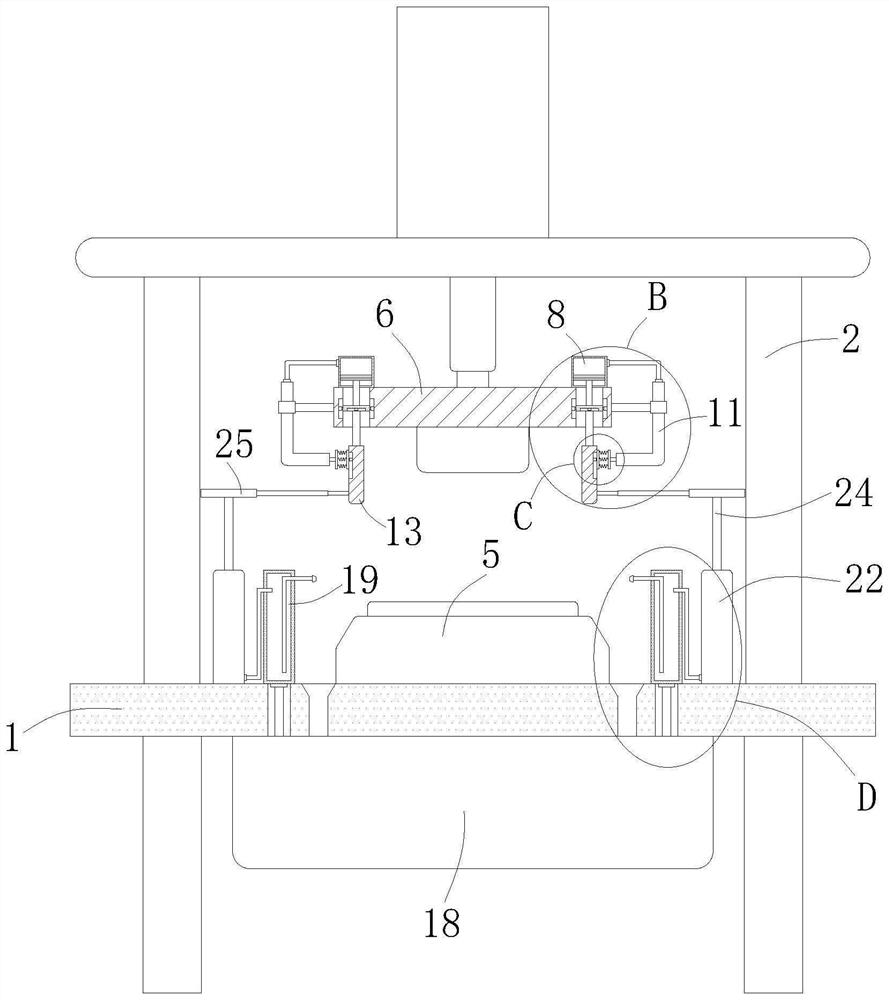

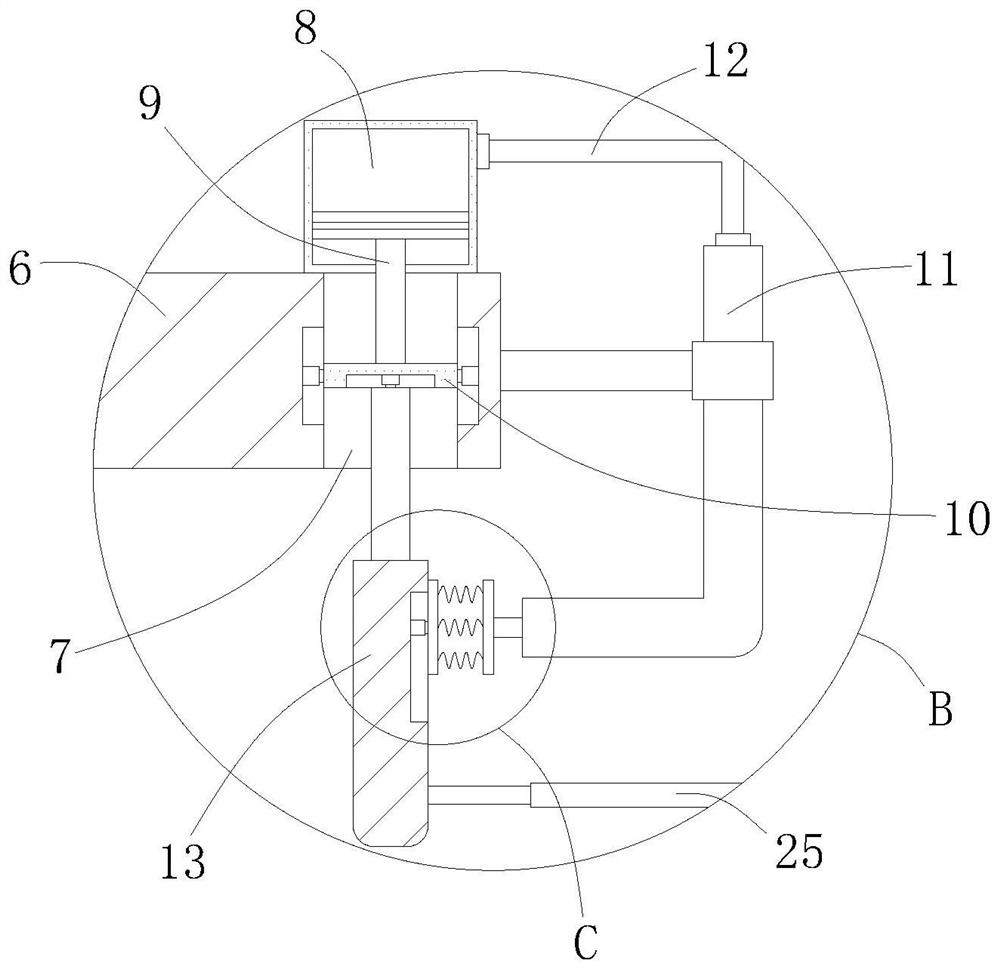

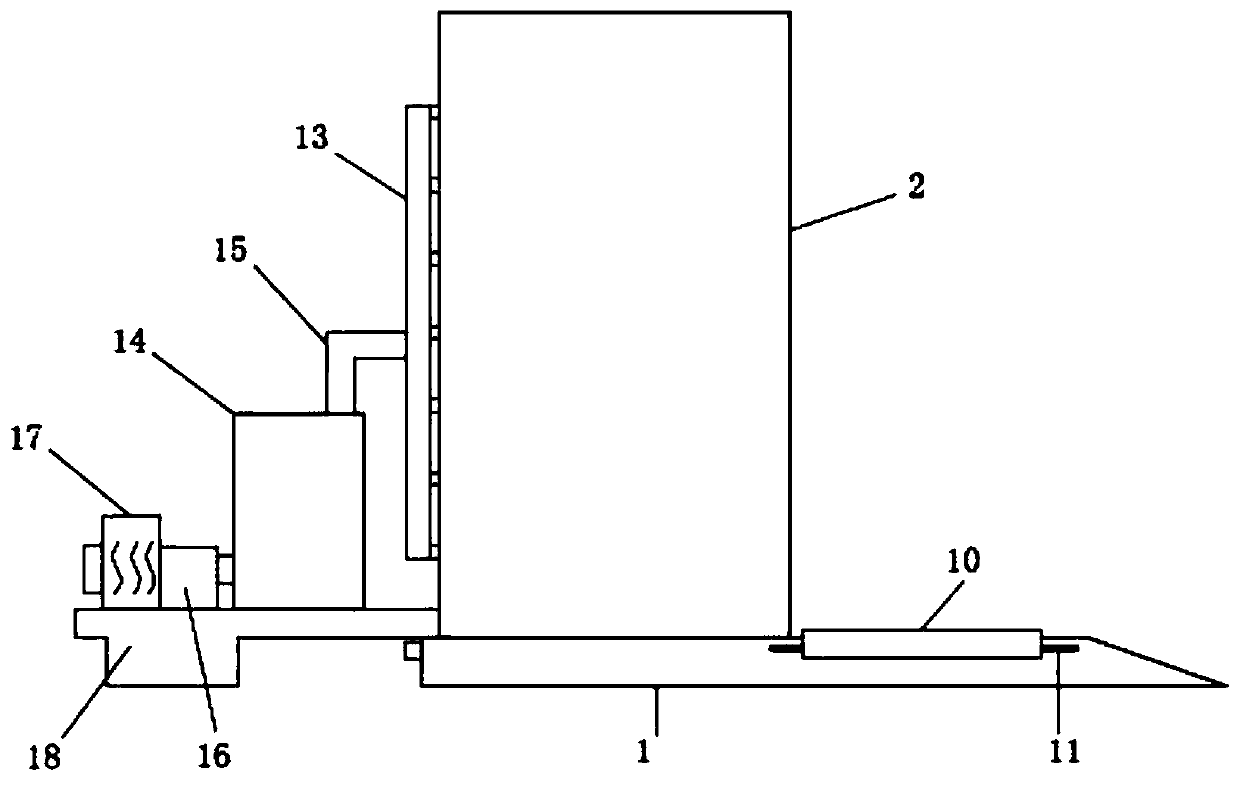

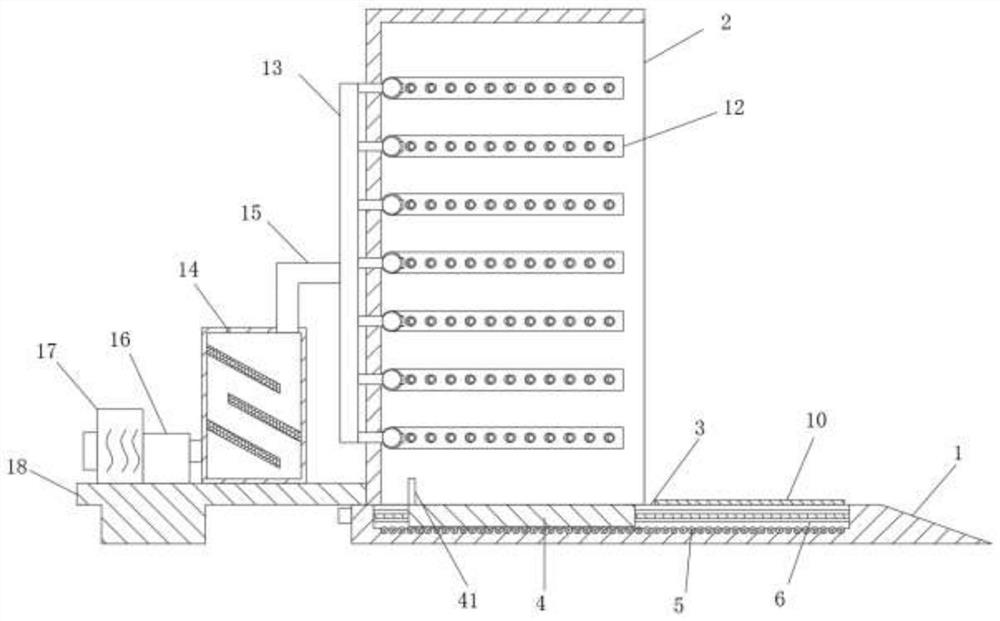

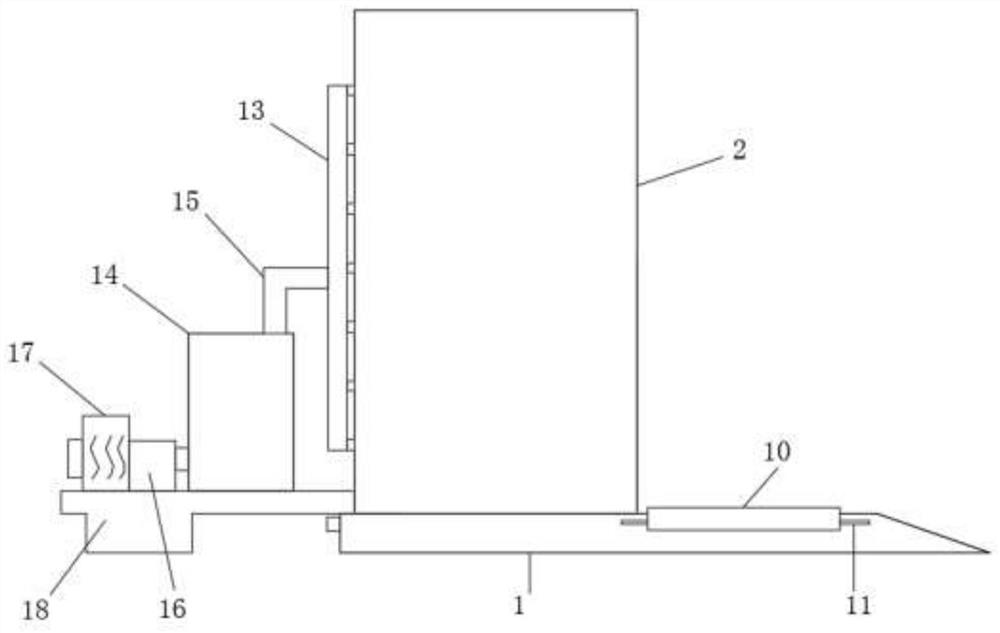

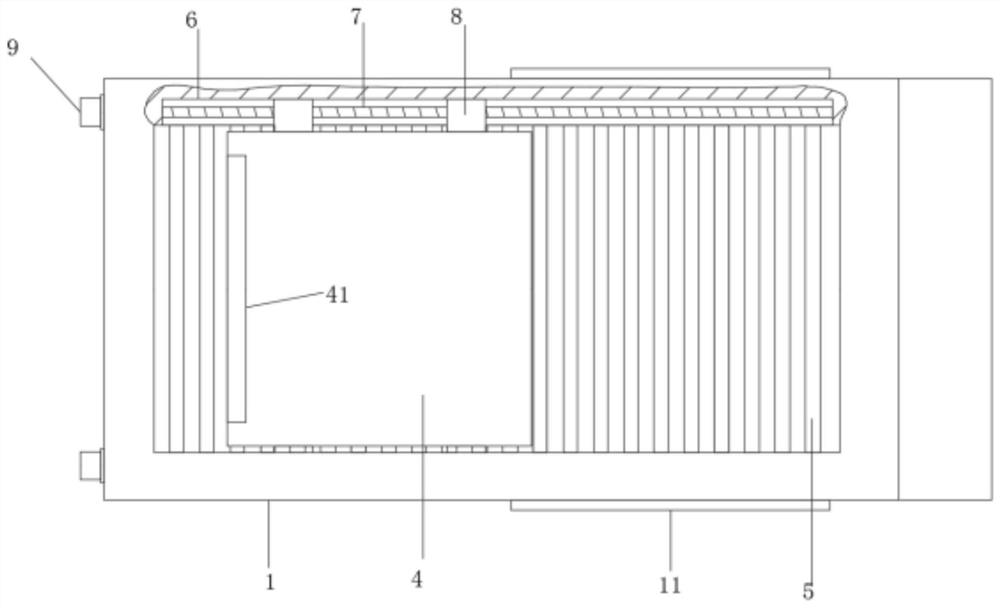

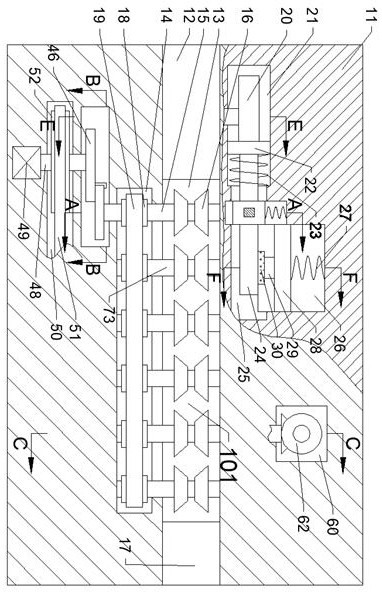

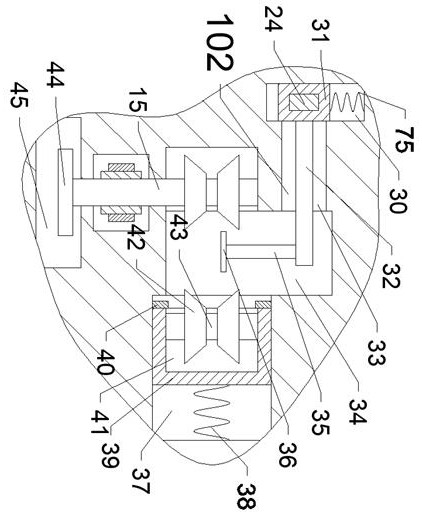

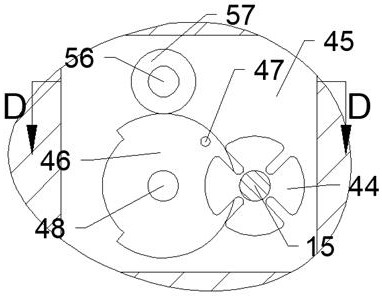

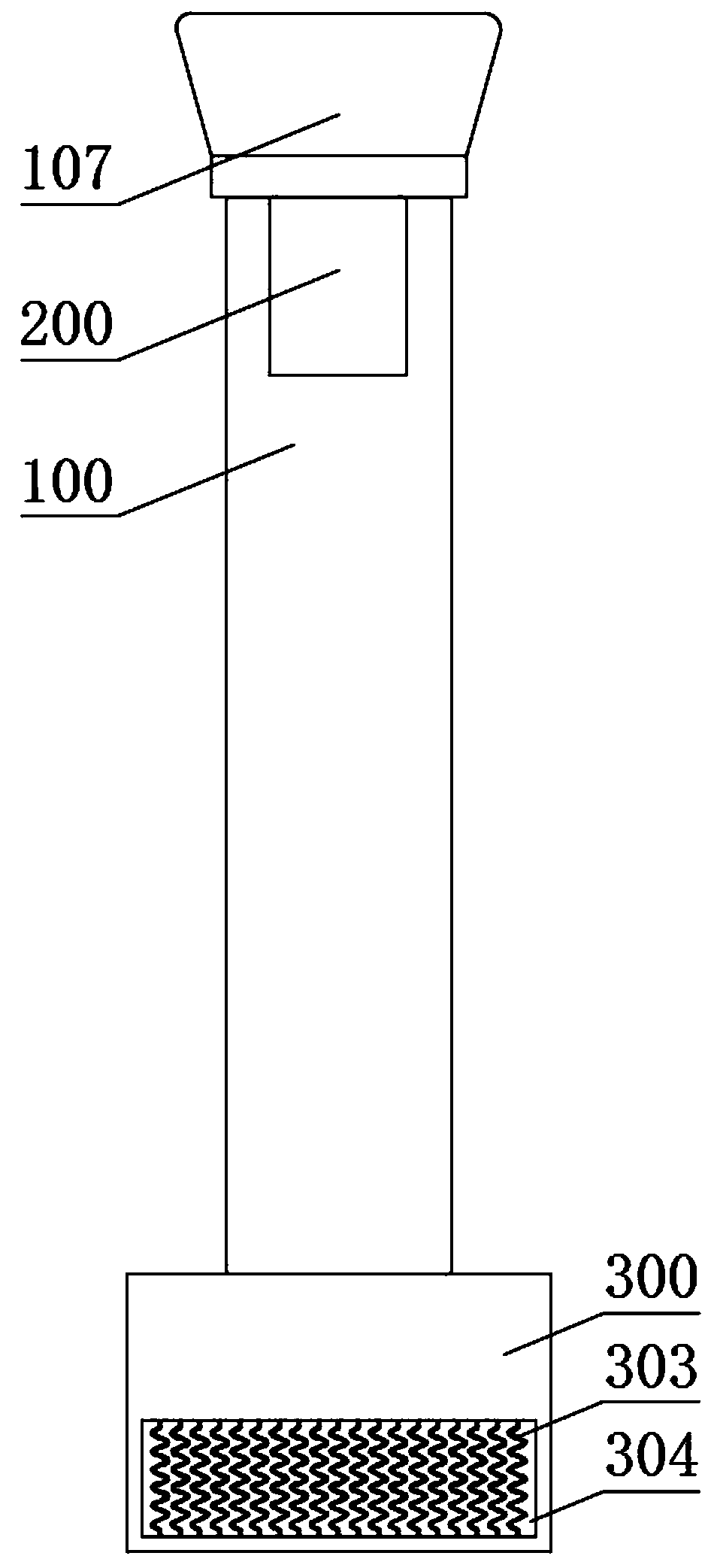

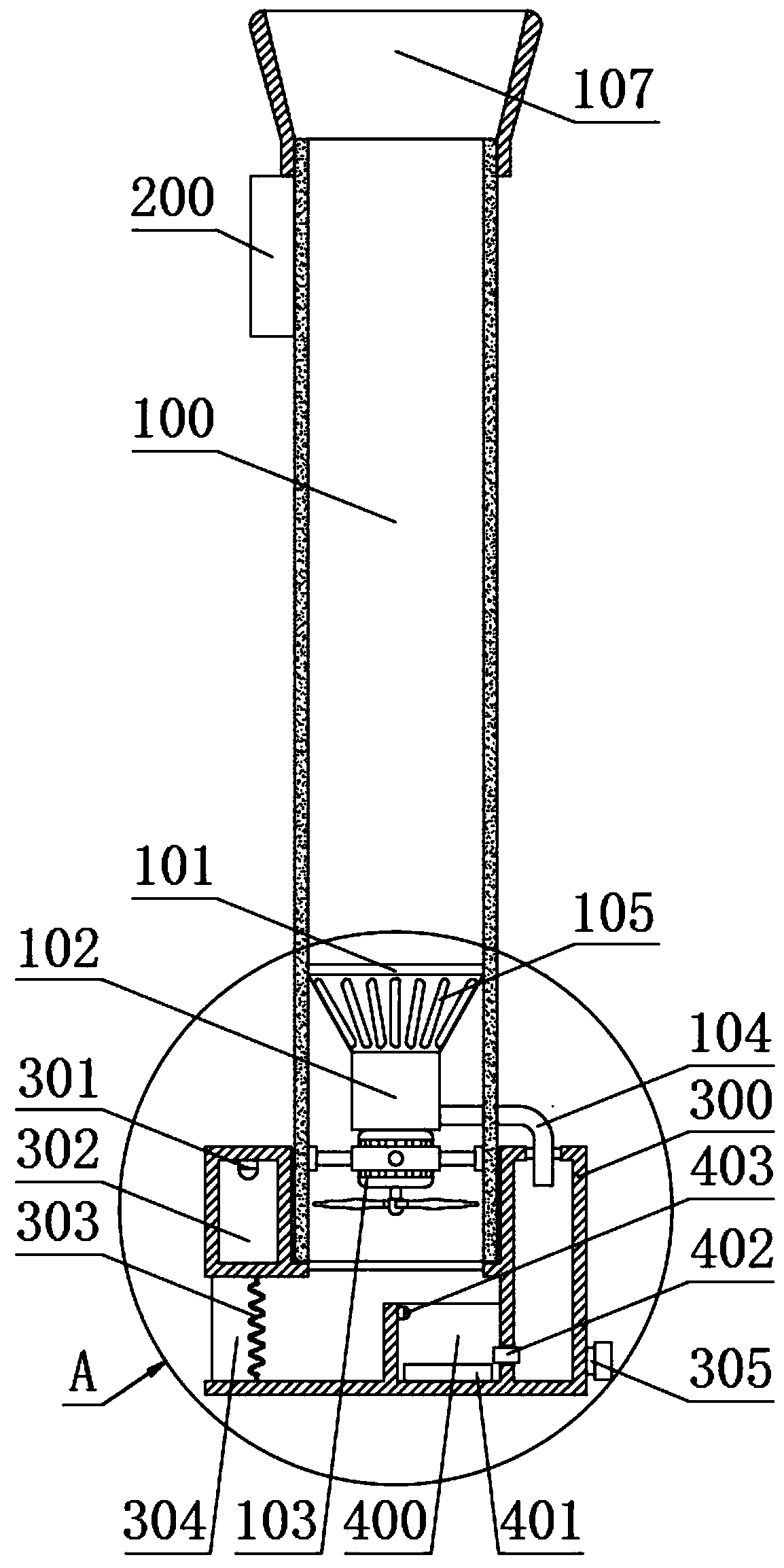

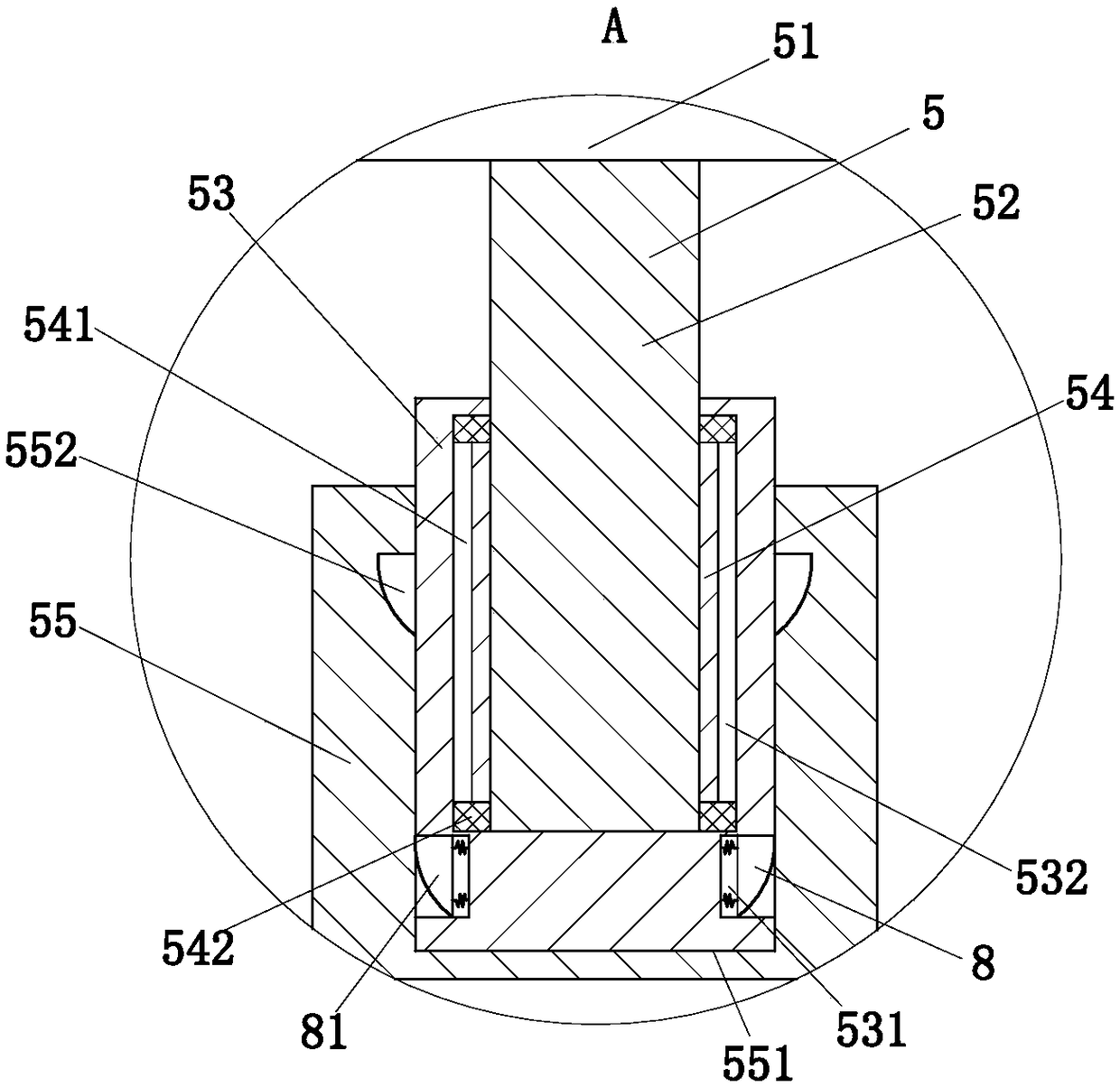

Rapid cleaning and air-drying device for automobile parts

InactiveCN107377485AImprove efficiencyGuaranteed high efficiencyCleaning using liquidsEngineeringLeather belt

The invention discloses a rapid cleaning and air-drying device for automobile parts, and relates to the technical field of automobile part processing machinery. The rapid cleaning and air-drying device comprises a bottom plate, the top of the bottom plate is fixedly connected with a working box through a damping device, the bottom of the inner wall of the working box is fixedly connected with a motor water pump box, and the motor water pump box is fixedly connected with a first motor; an output shaft of the first motor is rotatably connected with a reducer, the first reducer is rotatably connected with a first belt pulley through the output shaft, and the first belt pulley is rotatably connected with a second belt pulley through a belt; the first reducer is rotatably connected with a rotating shaft through the first belt pulley and the second belt pulley. The rapid cleaning and air-drying device for the automobile parts has the advantages that the purposes are achieved that a high-pressure nozzle moves up and down, and a fixation and installation frame can conduct cleaning and rapid air drying in a rotating mode; the device can also be moved, it is ensured that the device works efficiently, and the working efficiency is improved.

Owner:HUZHOU WUXING HUALONG MACHINERY CO LTD

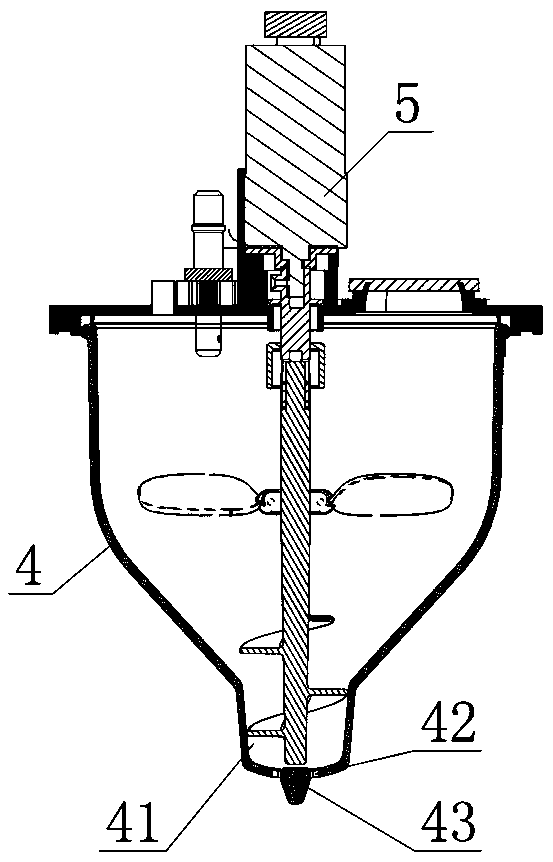

Reaction kettle used for producing lubricating oil and easy to clean

ActiveCN108201830AEasy to cleanImprove solubilityTransportation and packagingRotary stirring mixersEngineeringReaction chamber

The invention relates to a reaction kettle used for producing lubricating oil and easy to clean. According to the invention, a heat dissipation coil is arranged on and connected with a partition plate, and l is connected with a steam generator through a steam inlet pipe and a steam outlet pipe; the steam generator and a motor are both located in an electrical cavity; the output shaft of the motoris in driving connection with one end of a stirring shaft; the other end of the stirring shaft penetrates the partition plate and extends into a reaction chamber; a water tank is rotatably connected with the top of the reaction chamber through a sleeve, connected with a plurality of nozzles and communicated with a mixer through a pipeline; the mixer has an air inlet and a water inlet; the water inlet is connected with a water pump through a water inlet pipe; the air inlet is connected with a heating box through an air inlet pipe; and the heating box is internally provided with a fan. The reaction kettle of the invention has the advantages of sufficient material dissolving, high dissolving efficiency and low energy consumption; and after a reaction is completed, the body of the kettle can be cleaned without opening the kettle body, so the reaction kettle is simple to operate and convenient to maintain.

Owner:TOILX TIANJIN

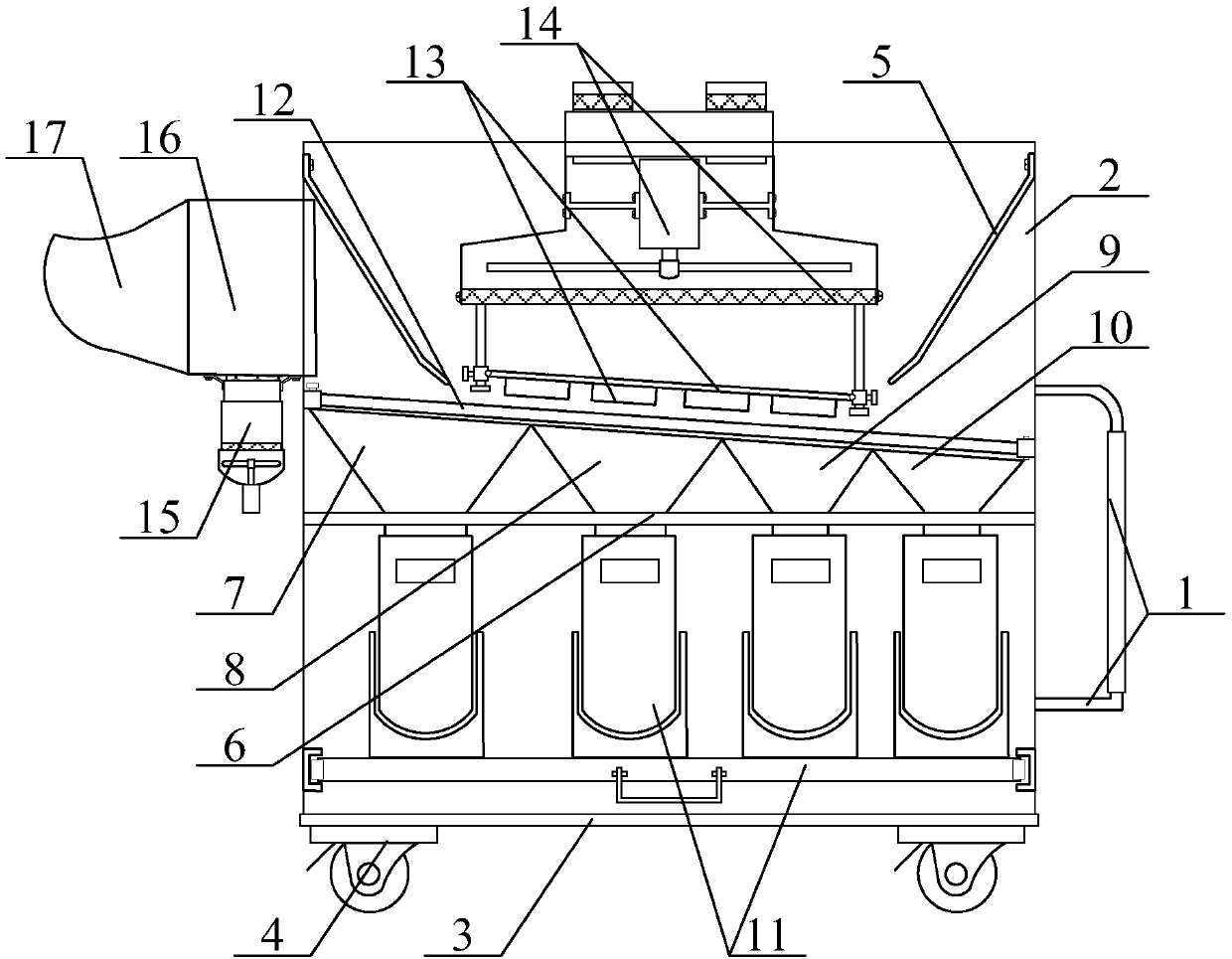

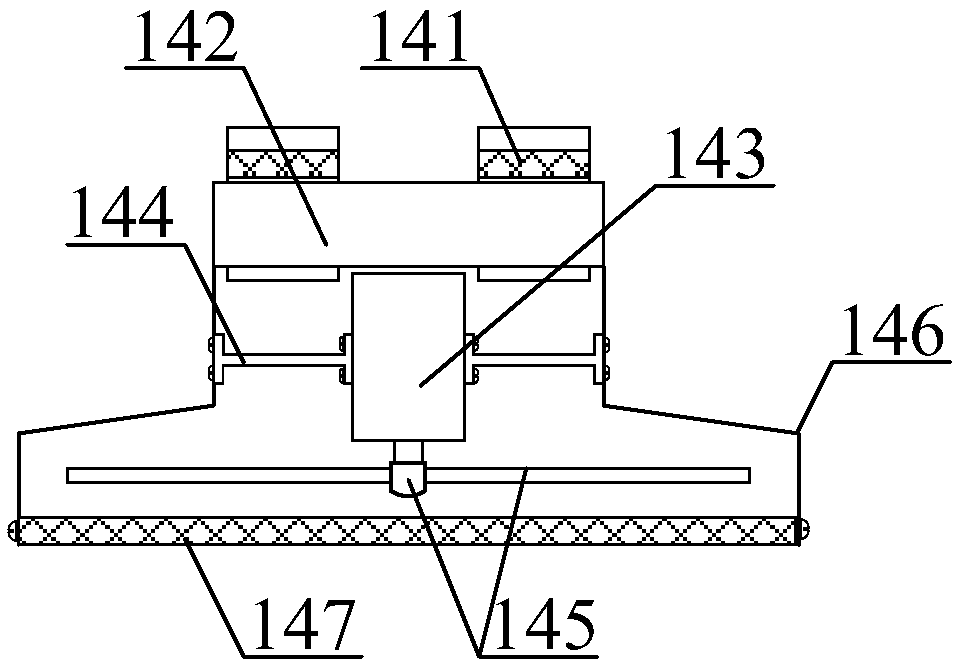

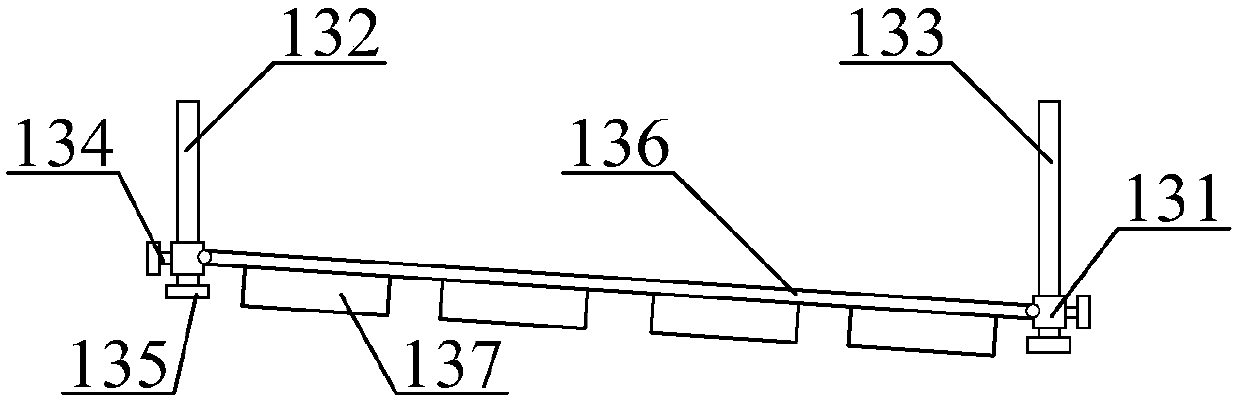

Sports goods moving vehicle

InactiveCN109349832AEasy to cleanAir dryDrying gas arrangementsBall sportsMobile vehicleVehicle frame

The invention discloses a sports goods moving vehicle. A vehicle frame is arranged on an outer frame of the moving vehicle; four corners at the bottom end of the vehicle frame are vertically connectedwith universal wheels in a bolted manner; and the top ends of the universal wheels are connected with brakes in a rotary manner. The vehicle has the following advantages: when in use, water in a water tank can be pumped into a water disc through a first water pump, the sports goods can be sprayed and cleaned by the water through a 6-point flat-mouth sprinkler head, the water can be recycled intoa water collecting tank after being filtered through a filter screen plate, and can be pumped back into the water tank through a second water pump; and meanwhile, an electric motor in an air-drying device can drive a fan to rotate to generate air flow, and thus the sporting goods in a placing frame are subjected to air-drying treatment, so that the problem that the physical and mental health of users is damaged caused by the fact that bacteria are easily generated on the surfaces of the ball sports goods and unpleasant smell is generated due to the fact that the existing sports goods moving vehicle cannot better clean and air-dry the used ball sports goods during use is solved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

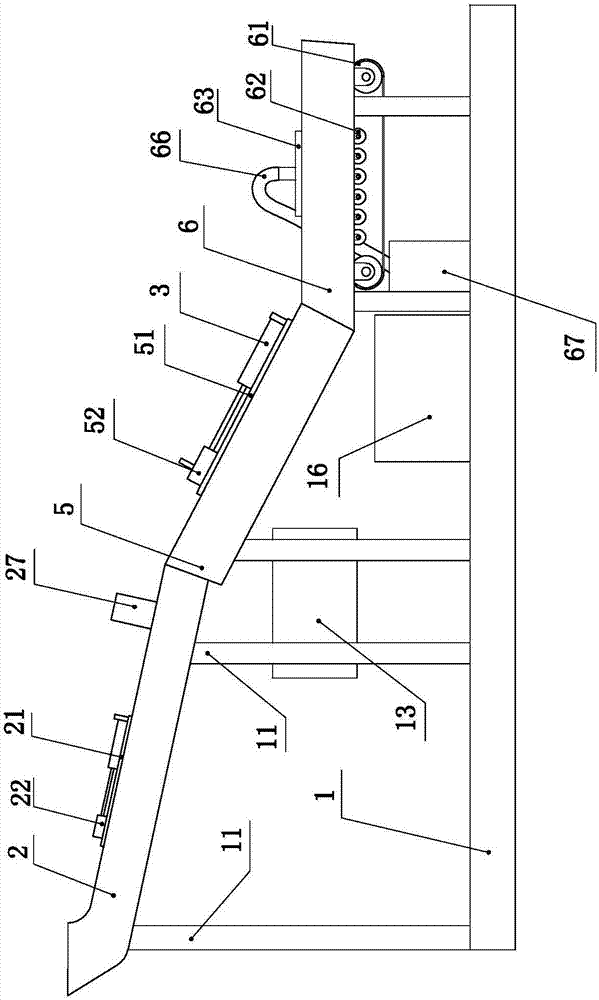

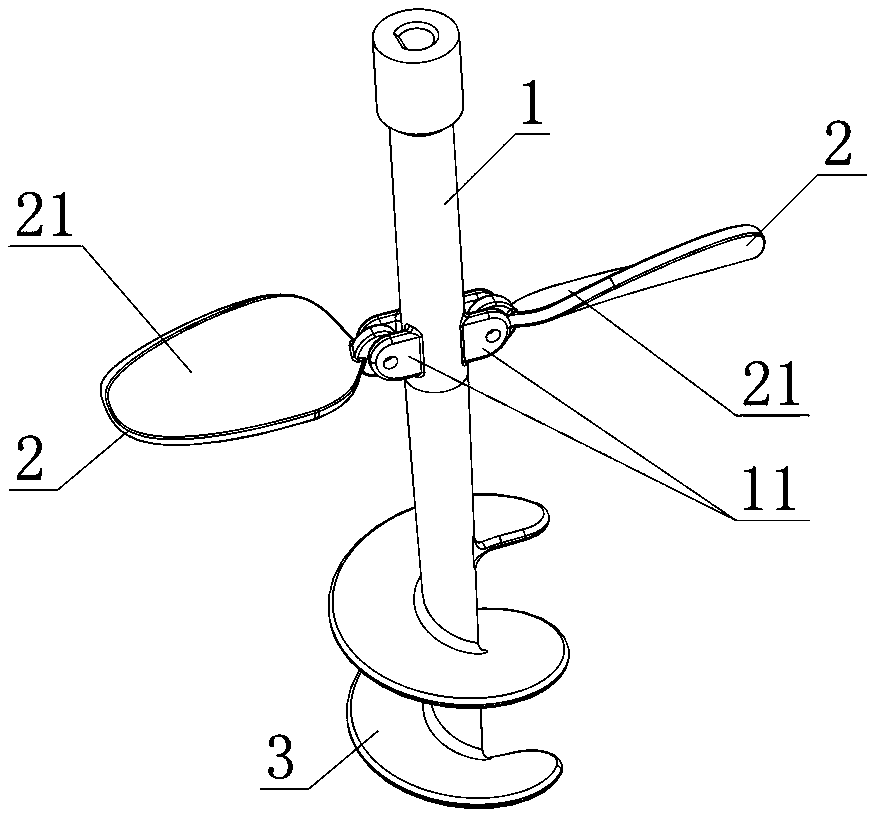

Bituminous concrete building stone cleaning and airing device

InactiveCN107537823AReduce deliveryQuality improvementDrying gas arrangementsCleaning using liquidsAcute angleEngineering

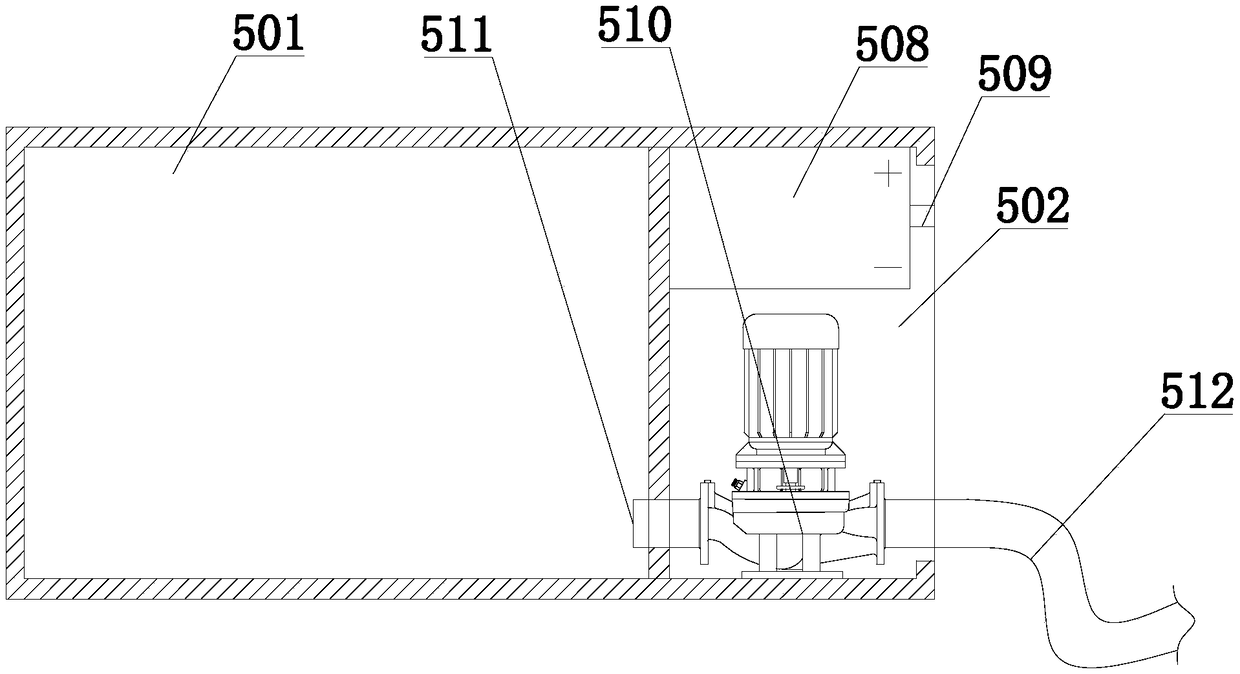

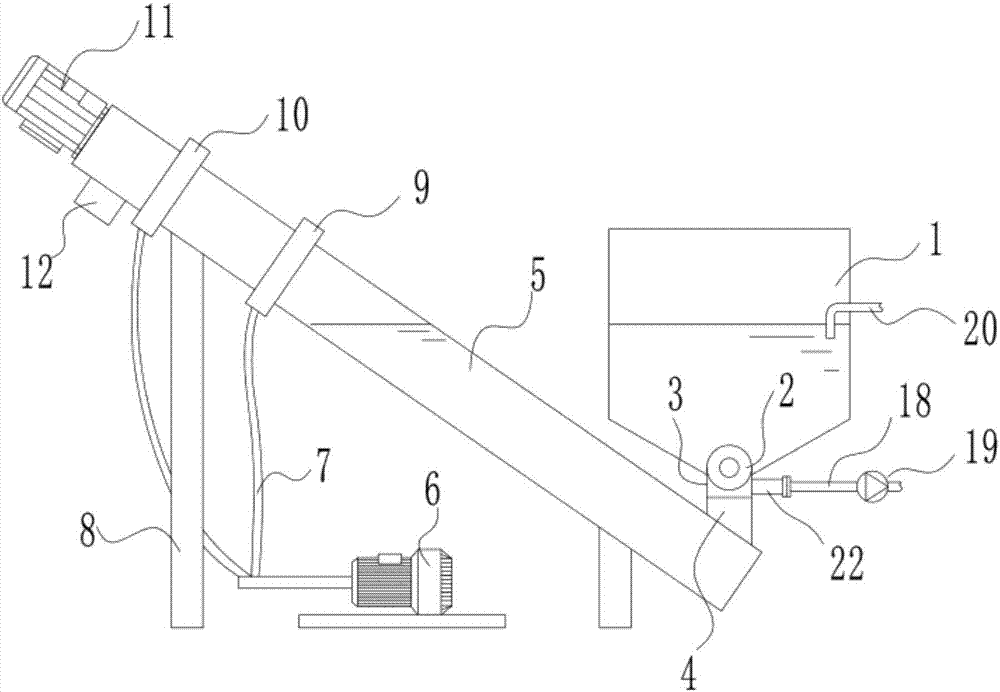

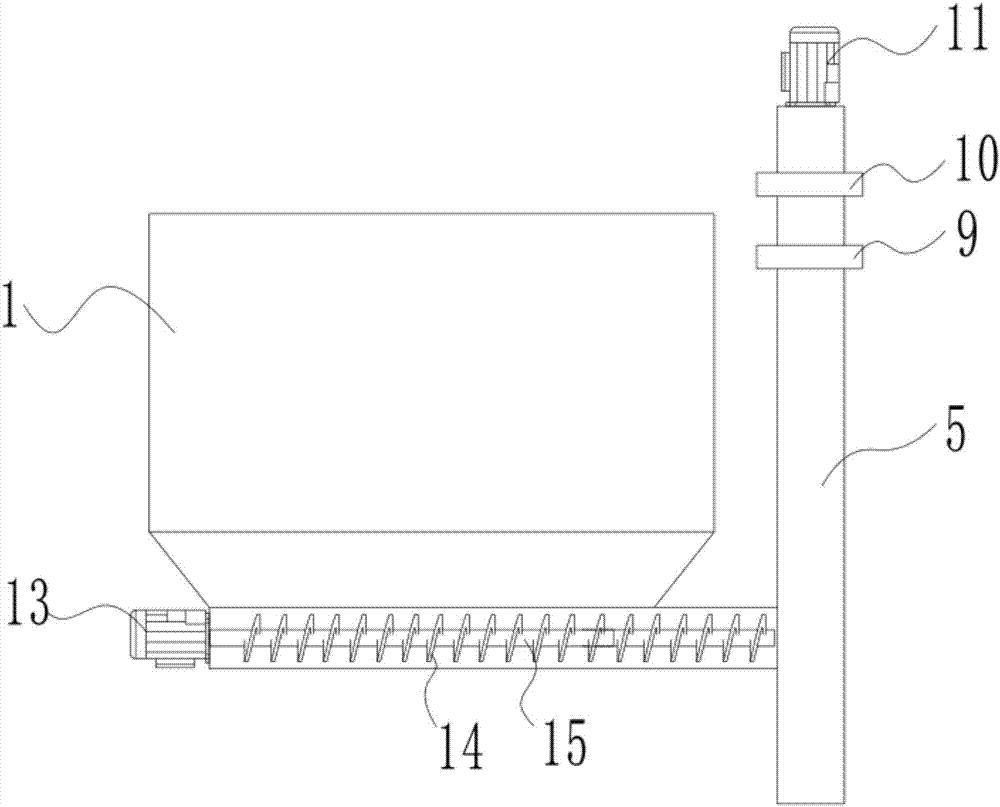

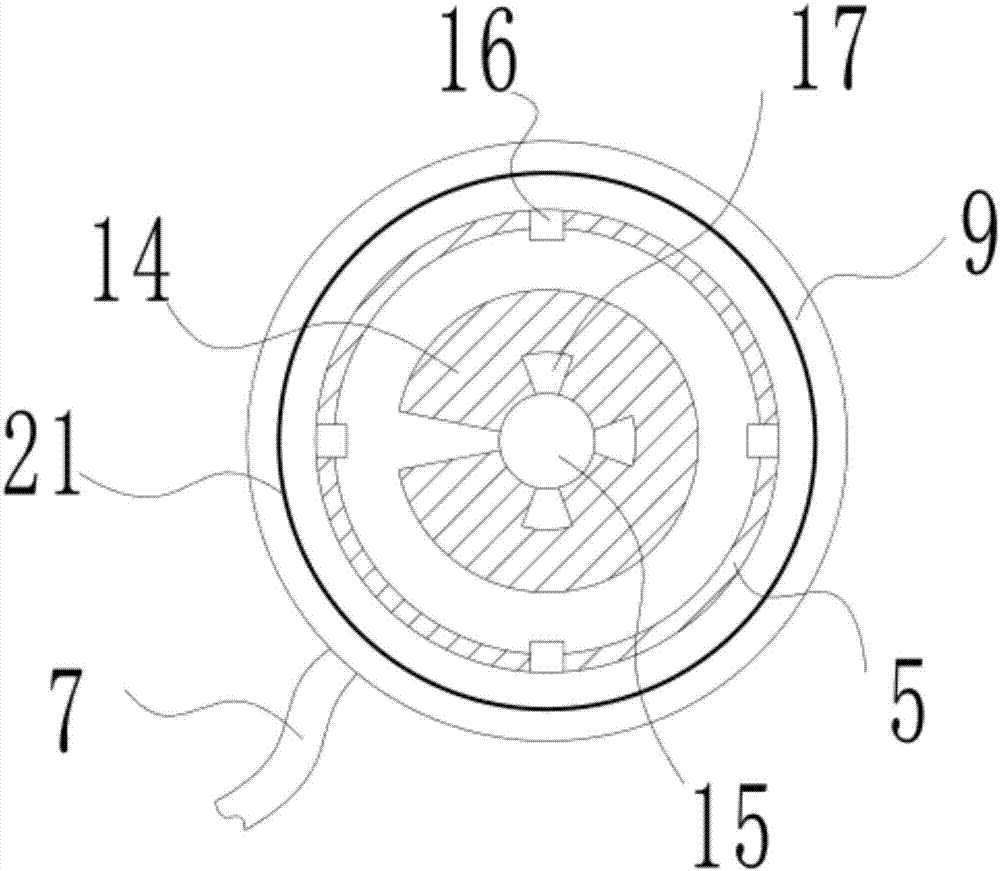

The invention discloses a bituminous concrete building stone cleaning and airing device. The device comprises a cleaning pond, a first feeding packing auger, a cleaning tank and a second feeding packing auger, a water inlet pipe which is used for adding water into the cleaning pond is further arranged at the top of the cleaning pond, the bottom of the cleaning pond gradually shrinks inwards to form the cleaning tank, the first feeding packing auger is installed in the cleaning tank and is composed of feeding blades and a rotary shaft, the spiral feeding blades are fixed to the outer part of the rotary shaft, the rotary shaft is driven by a first motor which is installed at one side of the cleaning tank, and the end of the cleaning tank is connected with the second feeding packing auger through an adaption pipe. The bituminous concrete building stone cleaning and airing device has the advantages that both cleaning and airing of building stones can be automatically completed, the efficiency of the device is high, the automated degree is high, and in the process, manual participation is basically not needed; meanwhile, the included angle of the air outlet direction of air outlet pipesand the axial direction of the second feeding packing auger is an acute angle, the airing effect is played, delivery of the building stones can also be promoted, and the work load of the second feeding packing auger is reduced.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

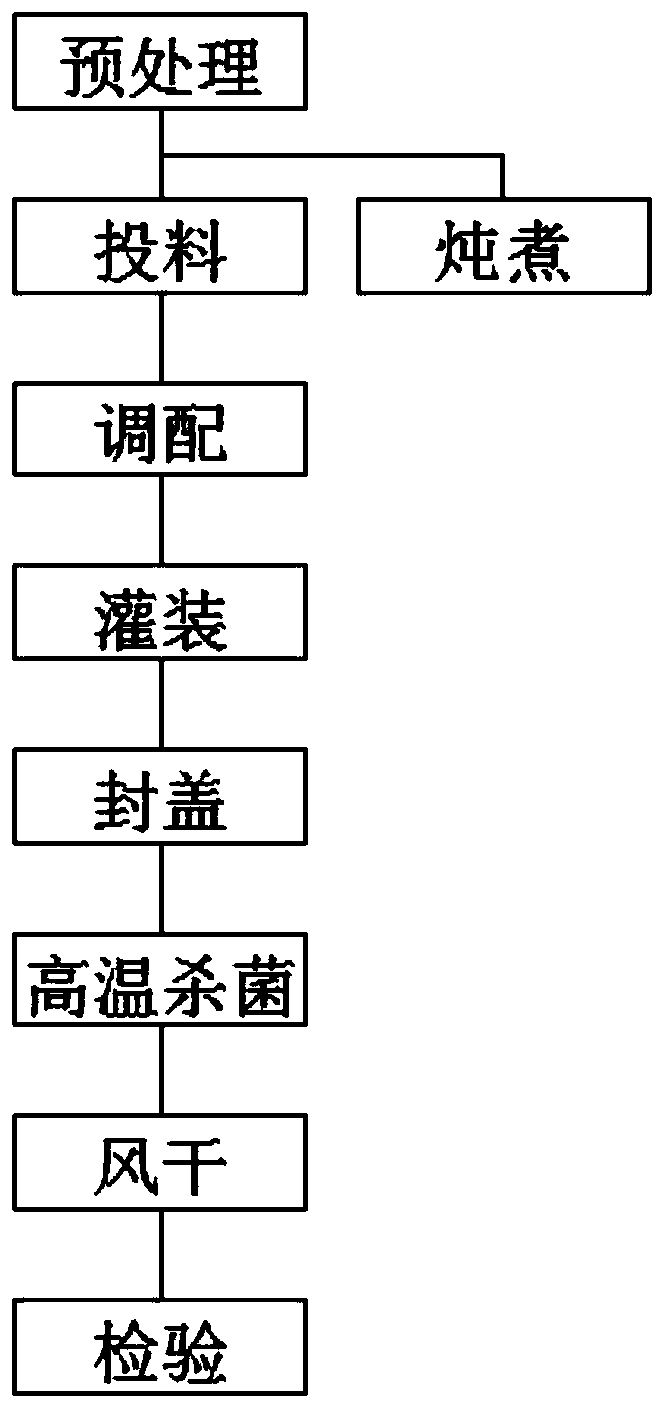

Preparation method of instant bird's nest

The invention discloses a preparation method of instant bird's nest, and belongs to the technical field of food processing. The preparation method comprises the steps of pretreatment, feeding, blending, filling, sealing, high-temperature sterilization, air-drying and inspection to complete the preparation of the instant bird's nest. In the blending process, a 100-mesh filter sieve is adopted for filtration, and a filter sieve with higher density is selected for screening of impurities and precipitates, thus guaranteeing a better screening effect. In addition, the air-drying step is added in the process, i.e. the air-drying of the outer surface of the whole bottle body is realized, so as to avoid the residue of water stains and further guarantee the overall quality and the integrity of thequality.

Owner:镇江市皇巢食品有限公司

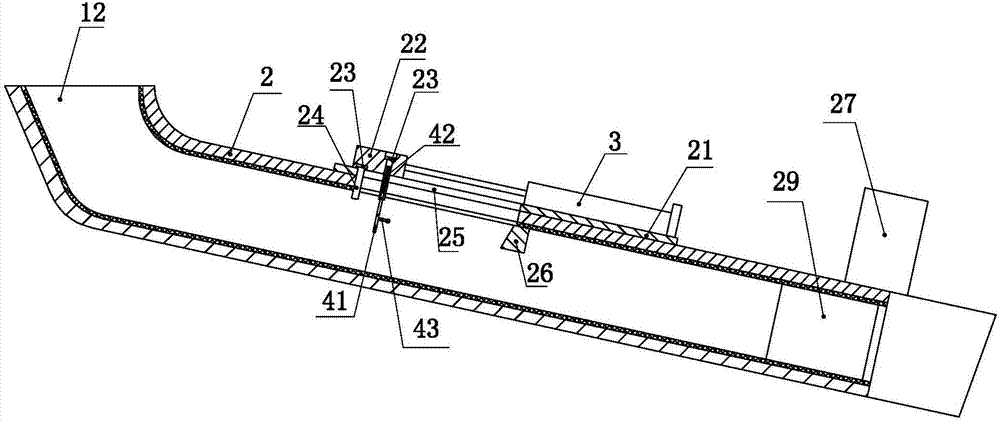

Treatment equipment and treatment method before fruit sorting and purification

The invention discloses treatment equipment and a treatment method before fruit sorting and purification, for realizing pre-treatment for fruits. The treatment equipment comprises a sieving pipe, a cleaning pipe and an air-drying pipe which are sequentially arranged on a base, wherein a first slide block is slidably installed at the top of the sieving pipe, an industrial camera located at the inner side of the sieving pipe is arranged at the front side of the first slide block, and a stopping mechanism is arranged at the rear side of the first slide block; a separation pipe is connected to the lower end of the sieving pipe, and a sieving mechanism sealing the sieving pipe or the separation pipe is arranged at the junction of the sieving pipe and the separation pipe; the cleaning pipe which is arranged slantwise is butted to the lower end of the sieving pipe, and a second slide block is slidably installed at the top of the cleaning pipe; a water washing mechanism is arranged at the front side of the second slide block; and the air-drying pipe which is horizontally placed is butted to the lower end of the cleaning pipe, a belt conveyer is arranged below the air-drying pipe, an air nozzle is fixed to the inner wall of the upper side of the air-drying pipe, and the air nozzle is connected with an air duct through a connection pipe. The equipment is capable of effectively realizing earlier-stage pre-treatment for the fruits.

Owner:SHANDONG CROP GERMPLASM CENT

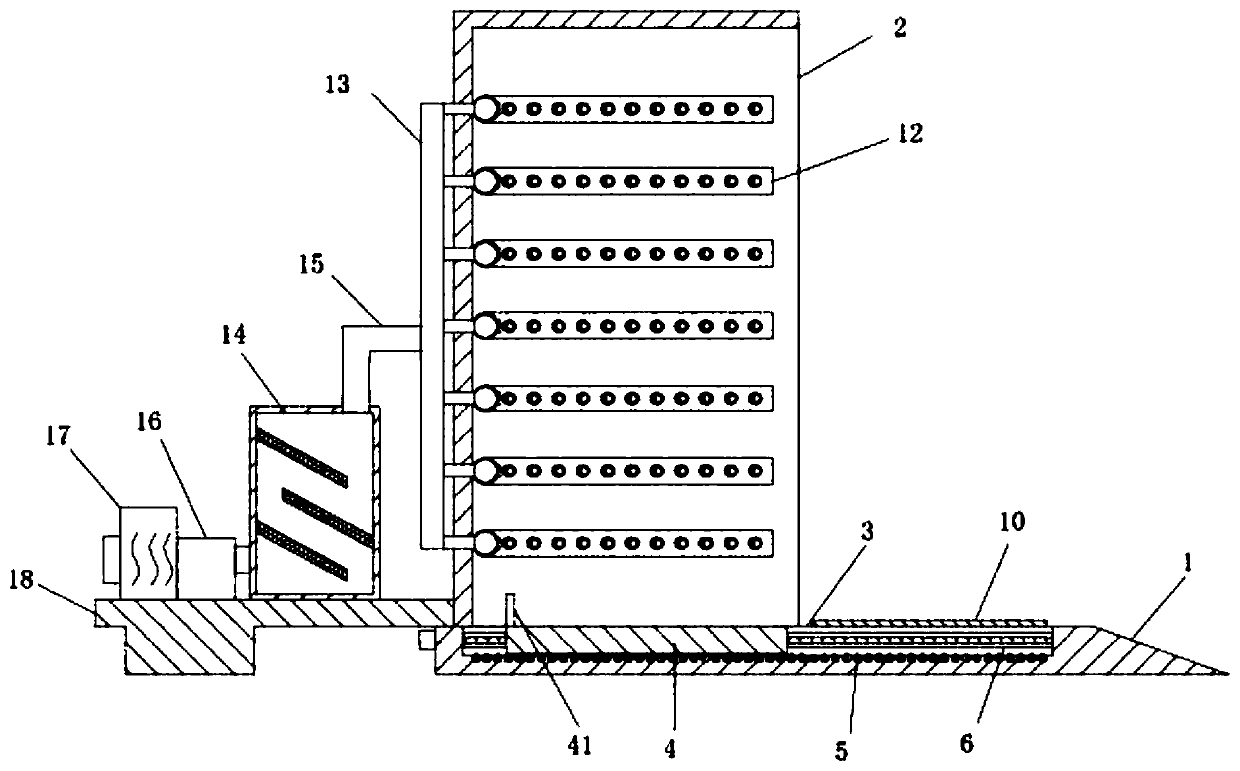

Intelligent instant freezer

PendingCN108562094AAutomatic defrosting is achievedAutomatic defrost avoidanceLighting and heating apparatusStationary refrigeration devicesPulp and paper industryCentrifugal force

The invention relates to an intelligent instant freezer, which comprises a freezer body and an outer support frame arranged at the lower end of the freezer body, wherein a refrigeration mechanism is arranged in the machine body and comprises two evaporators, an evaporator separation plate, evaporator door plates and an air return baffle plate, wherein the two evaporators are arranged in a separated way at upper side and lower side through the evaporator separation plate; the evaporator door plates are movably arranged at the two sides of one of the two evaporators; the upper end of the machinebody is provided with a dismounting type centrifugal fan; the lower end of the centrifugal fan is connected with an air return air collecting cover positioned inside the machine body; an externally-mounted fan over is arranged at the outer side of the dismounting type centrifugal fan, and is communicated with the lower end of the machine body through a hot air pipeline; a pipeline fan is arrangedon the hot air pipeline. The instant freezer has the advantages that the defrosting on the instant freezer can be realized under the condition without machine halt; the continuity of the freezing isensured; the freezing effect is ensured; through a fan externally-installation technology, the freezing effect is not influenced; the recovery and utilization of the fan heat is realized; the production cost is reduced.

Owner:山东滨州冰天制冷设备有限公司

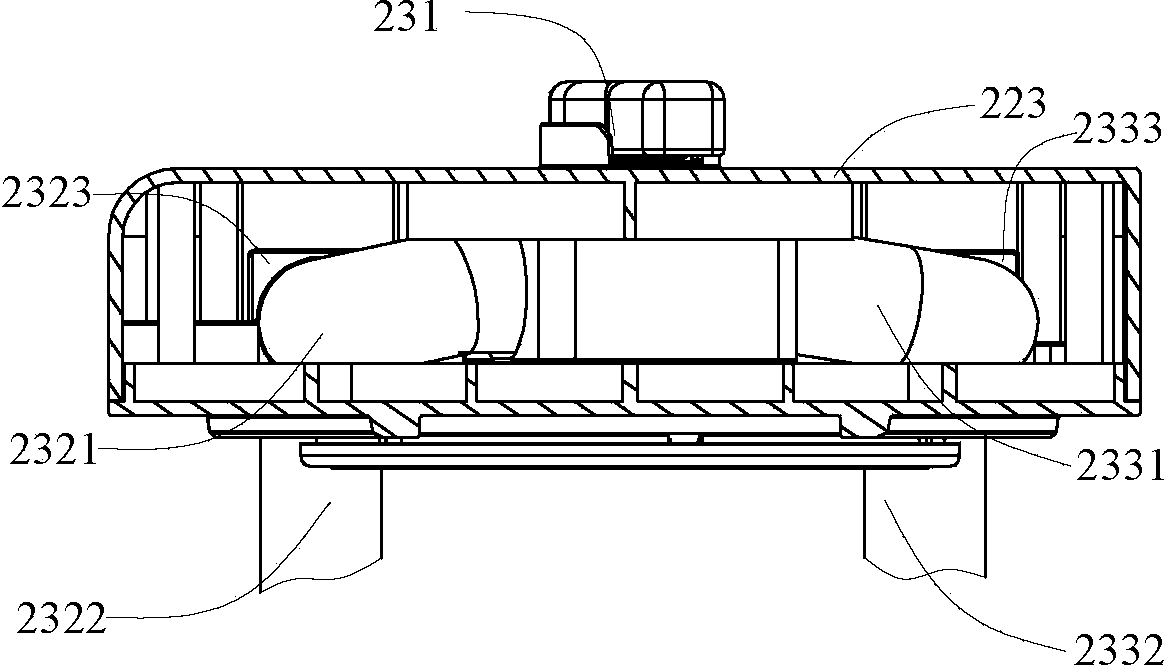

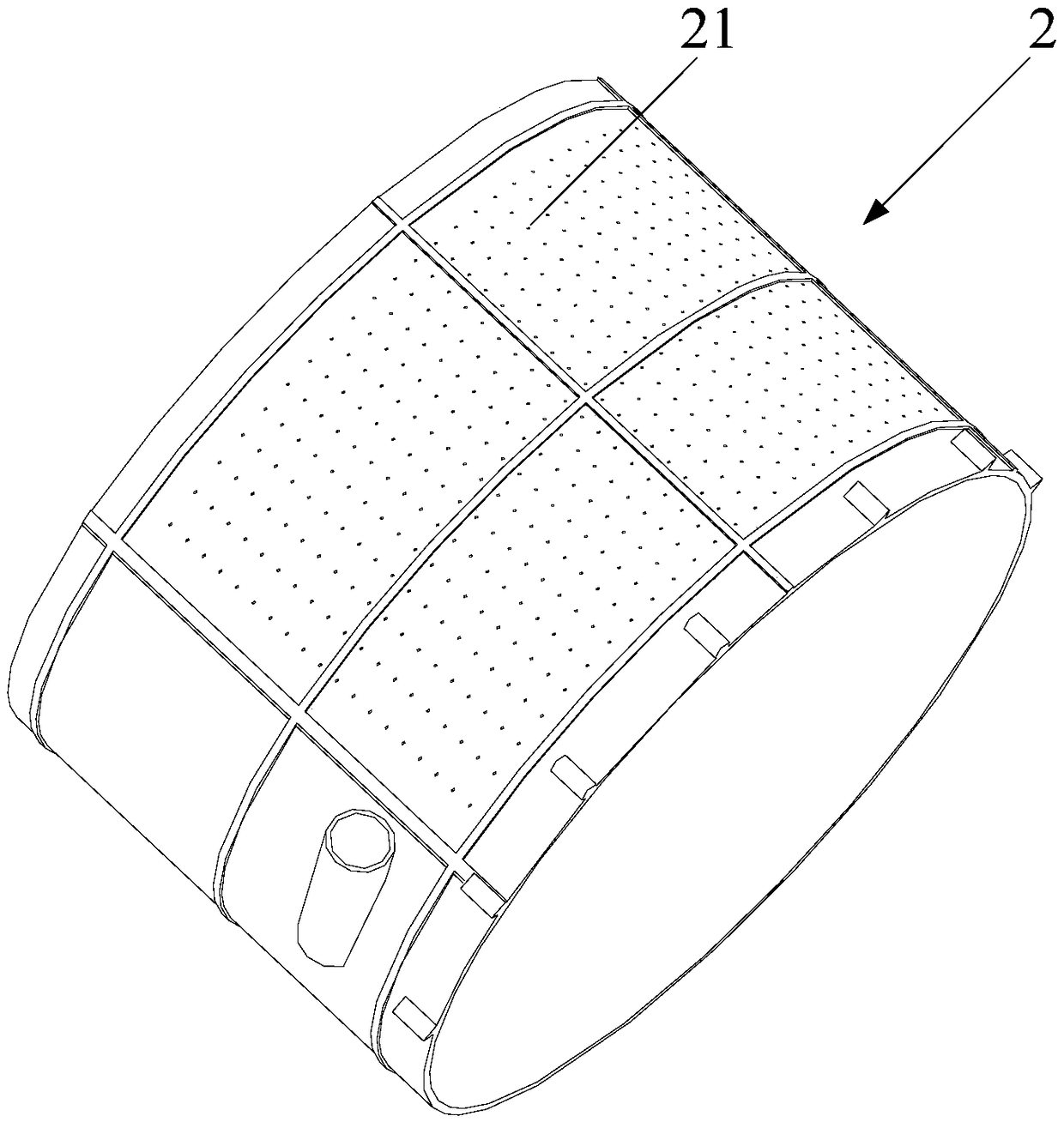

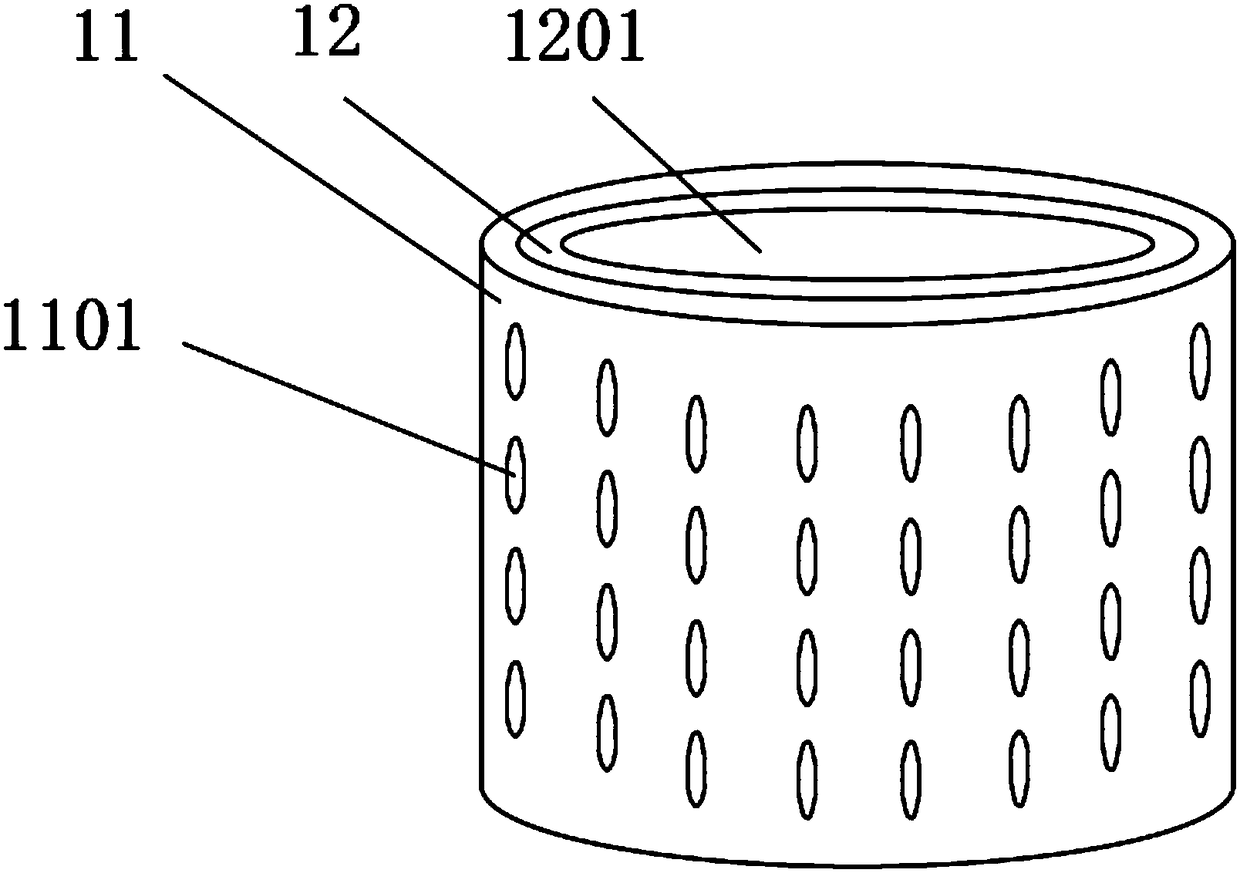

Washing machine

InactiveCN109355856AGuaranteed breathableAir dryOther washing machinesWashing machine with receptaclesWater blockEngineering

The invention relates to the technical field of laundry equipment, in particular to a washing machine. The washing machine includes a casing, water-blocking air-permeable members, an inner drum and anouter drum sleeving the inner drum; the outer drum is provided with at least one opening communicated with an accommodating cavity, each opening is provided with the corresponding water-blocking air-permeable member, and the water-blocking air-permeable members can prevent water in the accommodating cavity from flowing out of the outer drum and can also allow an airflow outside the outer drum toenter the accommodating cavity so that air in the accommodating cavity can be circulated. Therefore, internal ventilation of the inner drum is maintained, and the situation that the interior of the inner drum is moist for a long time is avoided. In addition, through the high-speed rotation of the inner drum, the air in the inner drum can be driven to form an airflow, the airflow is discharged through the water-blocking air-permeable members, and air-drying of clothes can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

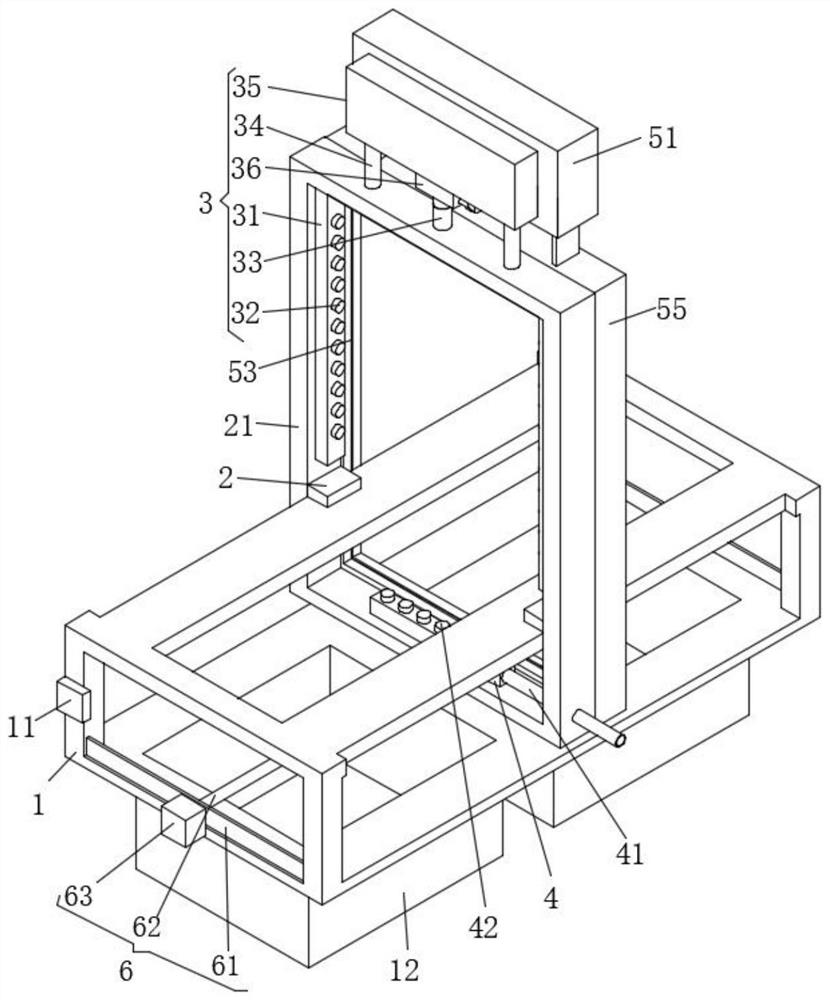

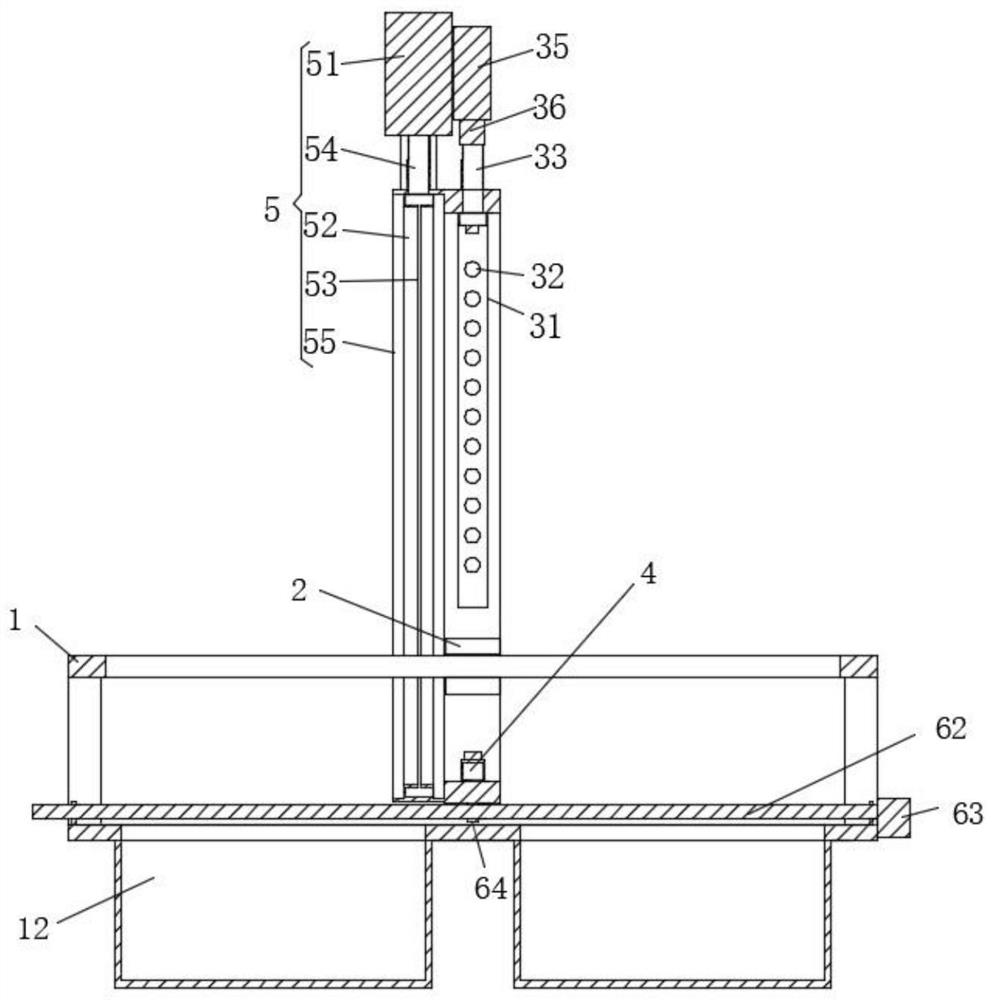

Single-punch multi-die sheet metal part stamping machining automatic line

PendingCN114011983AHigh precisionReduce manufacturing costShaping toolsMetal-working feeding devicesEngineeringSheet metal stamping

The invention relates to the technical field of sheet metal stamping, in particular to a single-punch multi-die sheet metal part stamping machining automation line which comprises a workbench, a mounting frame, a lifting frame, a mechanical arm, an objective table and a pressing part; a first piston cylinder is fixedly arranged at the upper end of each mounting hole, and an automatic clamping mechanism is arranged between each first piston cylinder and a clamping plate; an automatic lubricating mechanism acting on the storage tank is arranged between a third piston cylinder and the clamping plate; and an air drying and cooling mechanism is arranged on the top plate. The air pressure in the first piston cylinder is changed through the descending action of the lifting frame, the two clamping plates are driven to get close to each other, and then the machining precision is improved; under the condition that no extra driving part exists, the lubricating procedure is completed, so that the production cost is saved, and the production quality is improved; and the lifting frame moves up and down to drive the fourth piston rod to move, so that air in the fourth piston cylinder and the fifth piston cylinder is used for blowing, air drying and cooling of workpieces are achieved, and the production efficiency is improved.

Owner:夏俊豪

Stationery frame convenient to use by writing brush

The invention discloses a stationery frame convenient to use by a writing brush. The stationery frame comprises a base, a cleaning tank, an electric hydraulic push rod, a top plate, a hook, a hangingrope, a writing brush, a connecting shell, a drying shell, an inner cavity, a fan, an air inlet pipe, an annular electric heating plate, an air inlet hole, an annular heat conduction silica gel sheet,a placing hole, a spray head, a water outlet pipe, a water outlet valve, a water inlet pipe and a water inlet valve. The stationery frame convenient to use is reasonable in structure and novel in design, cleaning of the used writing brush is achieved, cleanness of a writing brush head is guaranteed, and the situation that the writing brush head is damaged due to the fact that ink is arranged on the writing brush head is avoided; and meanwhile, the service life of the writing brush is guaranteed, the writing brush is conveniently used by a user next time, the writing brush can be convenientlyplaced, multiple writing brushes can be cleaned and aired, the brush head of the cleaned writing brush can be subjected to air drying, the drying time of the writing brush is saved, the airing efficiency of the writing brush head is improved, the normal use of the writing brush is guaranteed, the use value is high, and the writing brush is suitable for popularization and use.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

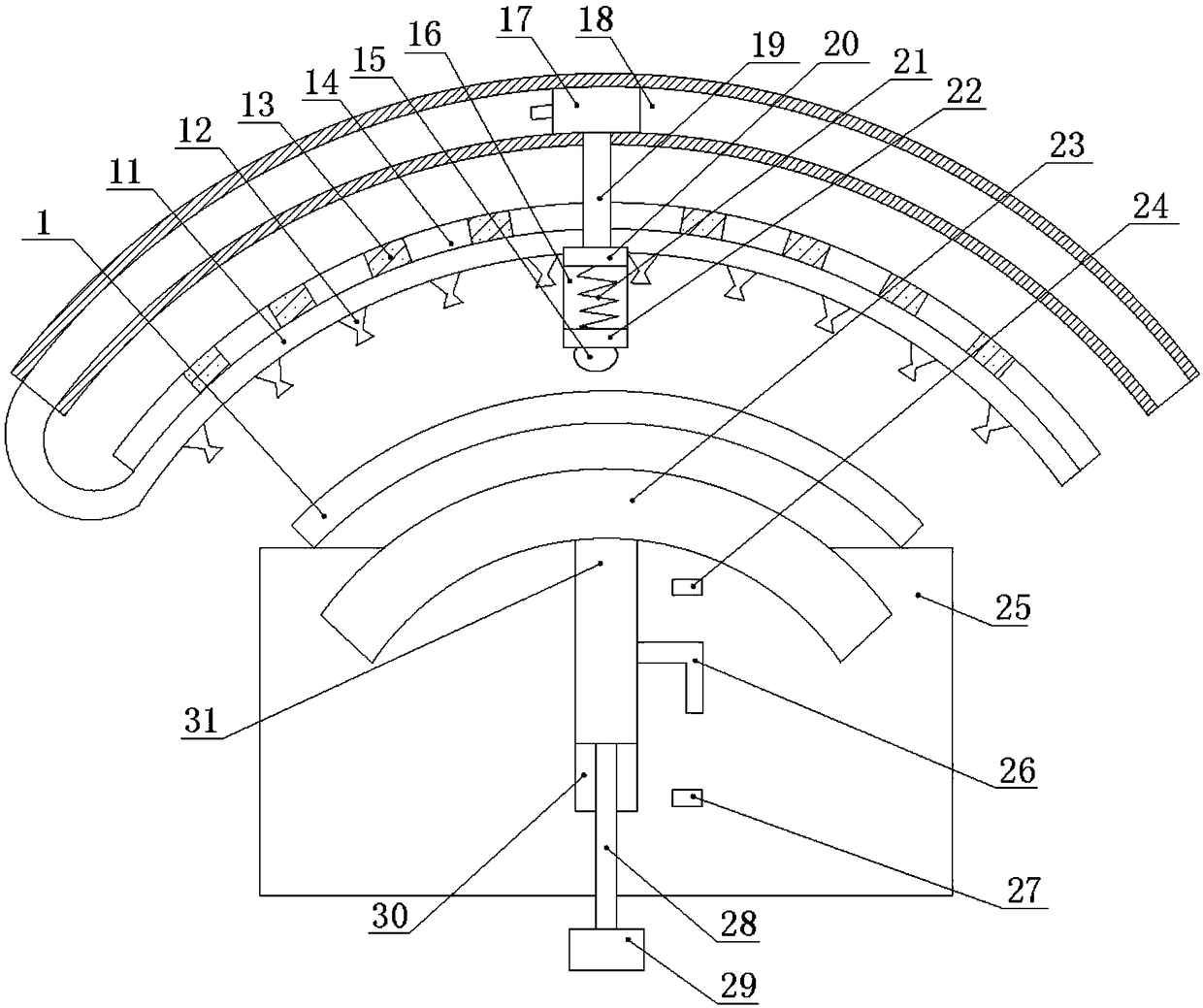

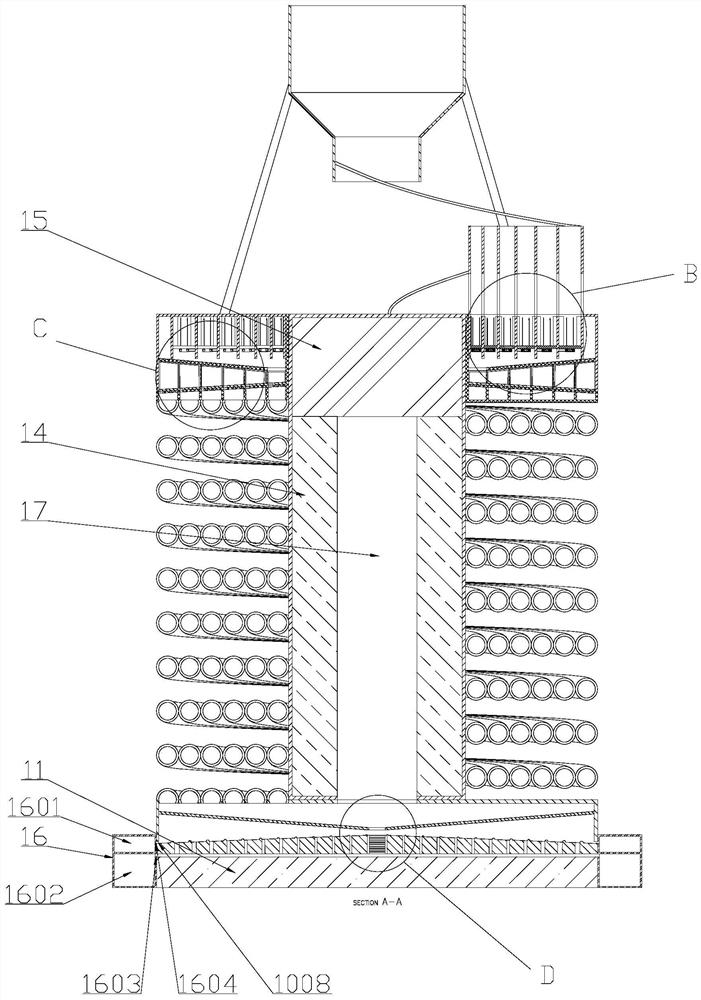

Raw material yard heavy vehicle washing platform

PendingCN113415261AAchieve flushingAir dryVehicle drying apparatusCleaning apparatus for vehicle exteriorsAgricultural engineeringStructural engineering

The invention discloses a heavy vehicle washing platform for a raw material yard. The heavy vehicle washing platform comprises a stand and a spray washing assembly, wherein two water collecting grooves are symmetrically formed in a bottom face of the stand, sliding blocks are slidably connected to the two sides of a surface of the stand, a sliding frame is arranged on the sliding blocks, an air drying assembly is arranged on the sliding frame, and a moving assembly is arranged at the bottom of the stand; the spraying assembly comprises a spraying frame, nozzles, a water inlet pipe and supporting rods, the spraying frame is arranged on an inner side face of the sliding frame, the nozzles are evenly arranged on the inner side face of the spraying frame, the water inlet pipe penetrates through the middle of a surface of the sliding frame and communicates with the spraying frame, the supporting rods are symmetrically arranged on a surface of the sliding frame, the spraying assembly further comprises a PLC, the PLC is arranged on an end face of the rack table, and an input end of the PLC is electrically connected with an output end of an external power supply. According to the raw material yard heavy vehicle washing platform, rotary washing of heavy vehicles can be achieved, labor intensity is reduced, working efficiency is improved, washing is more comprehensive, and practicability is high.

Owner:衡阳市广源线路器材有限公司

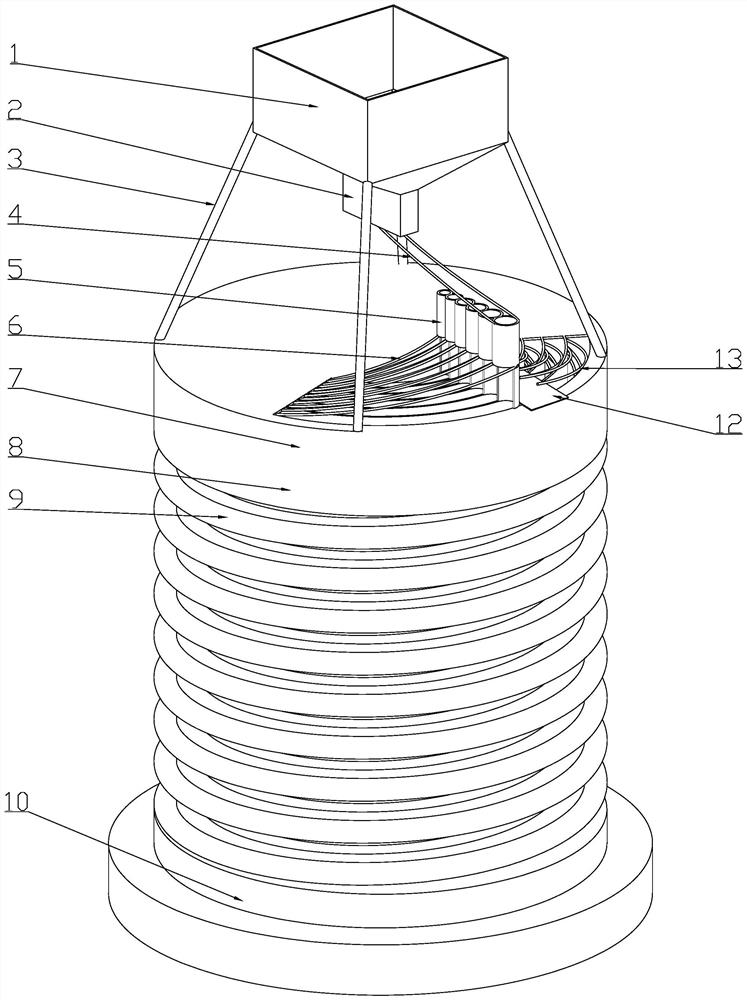

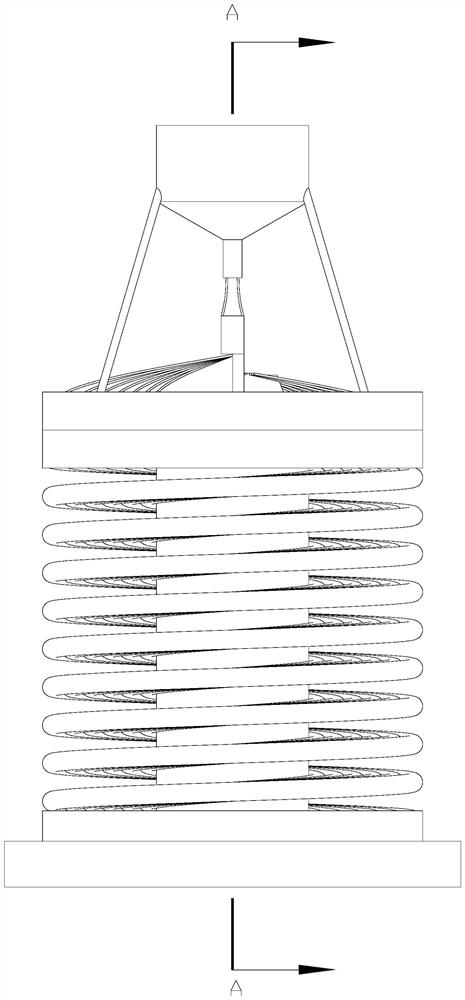

Combined type soybean impurity removal and air-drying device

InactiveCN109092682AEasy to cleanIncreased quick drying efficiencyGas current separationDrying gas arrangementsEngineeringGuide tube

The invention provides a combined type soybean impurity removal and air-drying device. The combined type soybean impurity removal and air-drying device comprises a push rod with a rubber sleeve, a concentric-square-shaped impurity removal and air-drying box, a base, universal wheels with brake pads, soybean anti-jump boards, a center seat, a small grain funnel, a medium grain funnel, a large grainfunnel, a super large grain funnel, a draggable mobile collection barrel structure, a soybean adjustable selection type picking rod structure, a soybean iron impurity inclination adjustable adsorption rod structure, a rapid air intake air-drying tube structure, a detachable dust and fine impurity collection tube structure, a soybean flow guiding tube and a soybean feed hopper. The push rod with the rubber sleeve is installed on the lower right side of the concentric-square-shaped impurity removal and air-drying box in a bolt mode. The concentric-square-shaped impurity removal and air-drying box is mounted on the upper surface of the base in a bolt mode. The combined type soybean impurity removal and air-drying device increases a soybean selection function, realizes the combination function of integrating the removal of iron impurities in soybeans with air drying, and can collect the impurities removed and increases a storage classification function after the soybean sorting.

Owner:郑制强 +4

Heat dissipation protection device for electromechanical equipment

ActiveCN111511134AThe installation process is simple and labor-savingAvoid moisture damageDispersed particle separationCasings/cabinets/drawers detailsPhysicsDry box

The invention discloses an electromechanical equipment heat dissipation protection device, and belongs to the technical field of heat dissipation protection devices. The device comprises a base, wherein a protective cover is arranged on the left side of the top end of the base, the right side of the protective cover is open, a groove is formed in the top end of the base, a supporting plate is arranged in the inner cavity of the groove in a sliding manner, sliding grooves are formed in the groove in a front-back symmetry mode, and a driving mechanism is arranged in the sliding groove. Accordingto the invention, a groove is formed in the surface of a base, and a movable supporting plate is arranged in the groove, so that when electromechanical equipment is supported, raising operation is not required, and the mounting process of the electromechanical equipment is simple and labor-saving; by arranging a drying box, dehumidification operation can be conducted on air entering a protectivecover, so that airflow blown to the electromechanical equipment is dry, and the electromechanical equipment is prevented from being affected with damp damage; the resistance generated when the supporting plate moves in a loaded mode is reduced through the arranged roller column; and the groove can be covered through the arranged cover plate, so that personnel can stand in front of the equipment tooperate conveniently.

Owner:山东水利职业学院

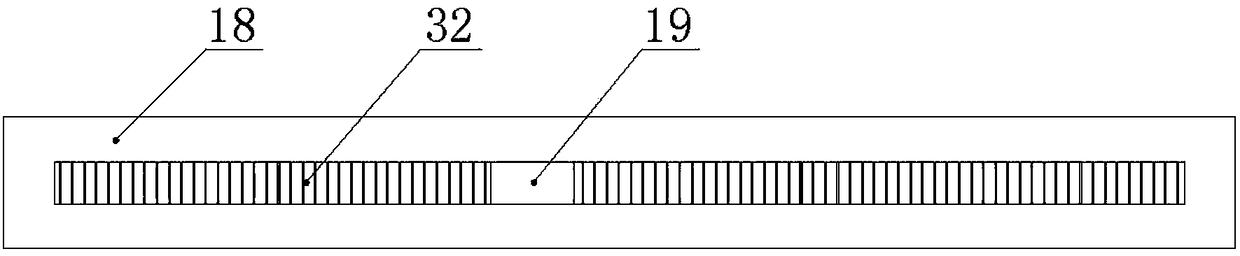

Decoration panel embossing device

The invention relates to the field of mechanical manufacturing, in particular to a decoration panel embossing device. The decoration panel embossing device comprises a processing platform; a sliding cavity is formed in the processing platform; a supporting column is arranged in the sliding cavity in a sliding way; the top end of the supporting column is connected with a top plate; the supporting column is connected with a supporting rod; a first switch is arranged above the supporting rod; an arc-shaped sliding way matched with the shape of the panel is arranged on the processing platform; thecentral line of the arc-shaped sliding rail is superposed with the central line of the top plate; a plurality of clamping grooves are formed in the arc-shaped sliding rail; a connecting rod capable of being clamped into a clamping groove is arranged in the arc-shaped sliding rail in a sliding way; one end of the connecting rod is connected with a sliding mechanism; a second magnet is arranged atthe other end of the connecting rod; an electromagnet is arranged below the second magnet in a sliding way; the electromagnet is electrically connected with the first switch; the opposite sides of theelectromagnet and the second magnet have the same magnetic pole; a spring is connected with the part between the electromagnet and the second magnet; and an embossing head is arranged below the electromagnet. The decoration panel embossing device can solve the problem that the existing pattern has inconsistent shape, color and depth.

Owner:SHANDONG STREET MOBILE SHOP NEW ENERGY TECH CO LTD

A heat dissipation protection device for electromechanical equipment

ActiveCN111511134BReduce resistanceEasy to installDispersed particle separationCasings/cabinets/drawers detailsEngineeringActive support

The invention discloses a heat dissipation protection device for electromechanical equipment in the technical field of heat dissipation protection devices. It includes a base. A protective cover is provided on the left side of the top of the base. The inner cavity of the groove is slidably provided with a support plate, and the groove is symmetrically opened with a chute in front and back, and a driving mechanism is arranged in the chute. The present invention places the movable support plate on the surface of the base by slotting In the groove, so that when carrying the electromechanical equipment, there is no need to carry out the lifting operation, which makes the installation process of the electromechanical equipment easier and labor-saving. The airflow of the equipment is relatively dry to avoid damage to the electromechanical equipment due to moisture. The set rollers reduce the resistance of the support plate when the load moves, and the set cover plate can cover the grooves, which is convenient for personnel to operate in front of the equipment.

Owner:山东水利职业学院

Graphene oxide/unsaturated polyester composite material and preparation method thereof

The invention discloses a graphene oxide / unsaturated polyester composite material and a preparation method of the composite material. The composite material comprises the raw materials: dihydric alcohol, graphene oxide, saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride, vinyl monomer, and normal polymerization inhibitor, initiator and accelerant, wherein the content of the graphene oxide is 0.06-0.5wt%. The preparation method of the graphene oxide / unsaturated polyester composite material comprises the following steps of: adding the graphene oxide into the dihydric alcohol to directly and ultrasonically disperse, or adding the dihydric alcohol into graphene oxide water solution to ultrasonically disperse and remove water in a fractional distillation way so as to obtain graphene oxide / dihydric alcohol solution which is evenly dispersed; performing polycondensation between the obtained graphene oxide / dihydric alcohol solution and the saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride and polymerization inhibitor with metering ratio, and diluting by adding the vinyl monomer after the polymerization so as to prepare graphene oxide / unsaturated polyester resin; and adding the initiator and the accelerant, and curing and crosslinking to prepare the graphene oxide / unsaturated polyester composite material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

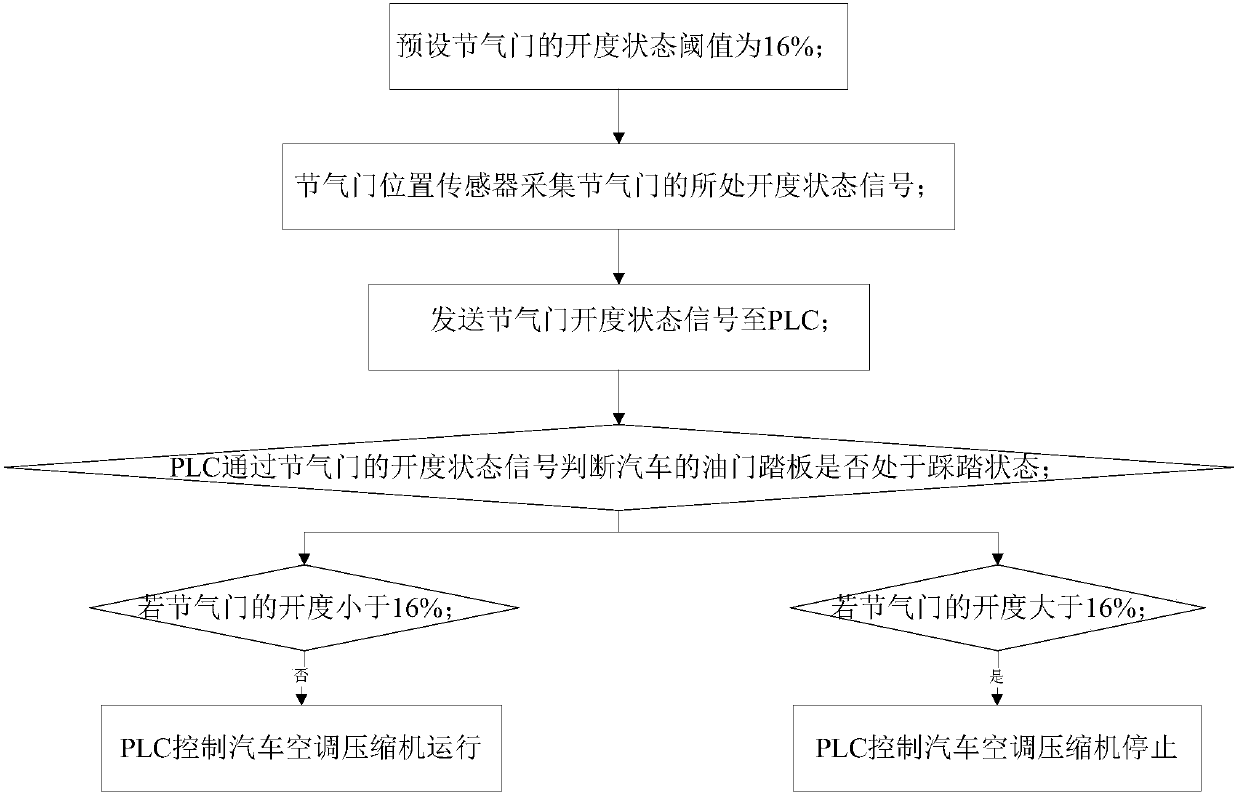

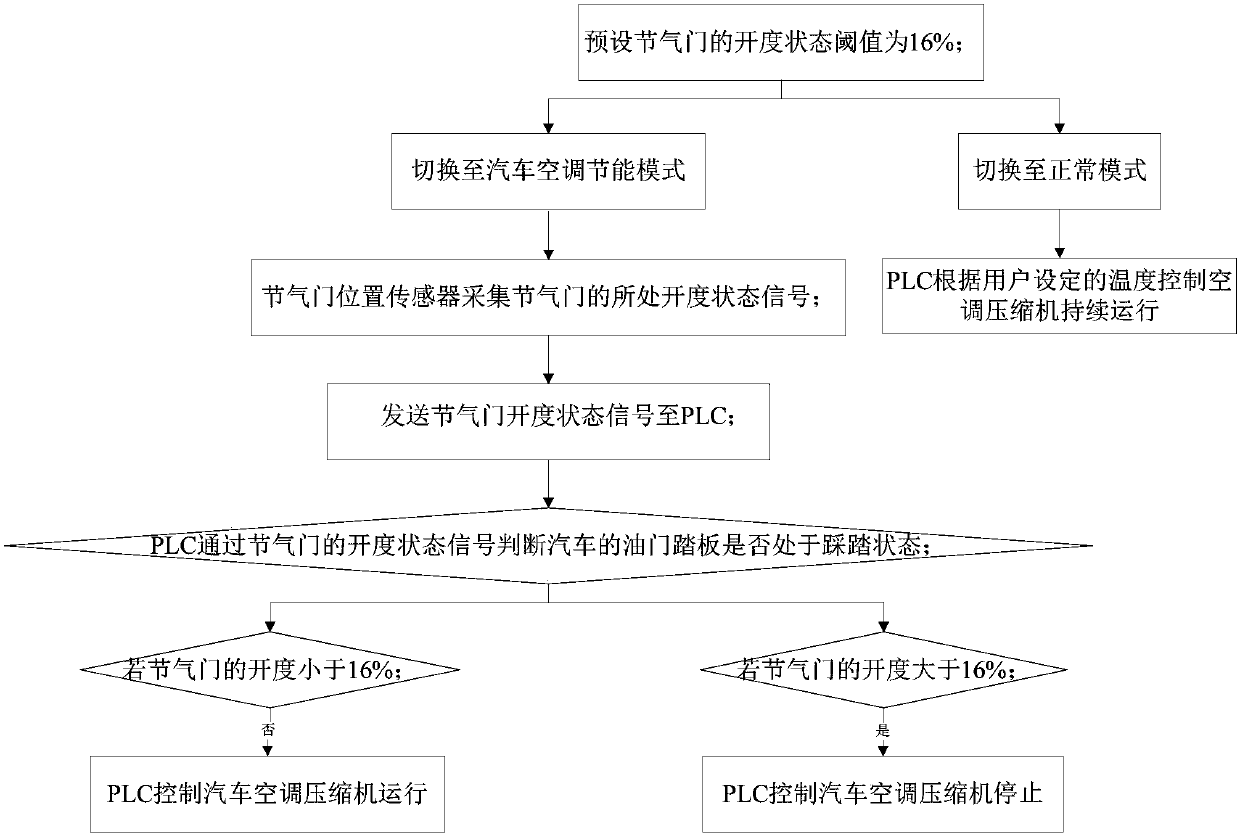

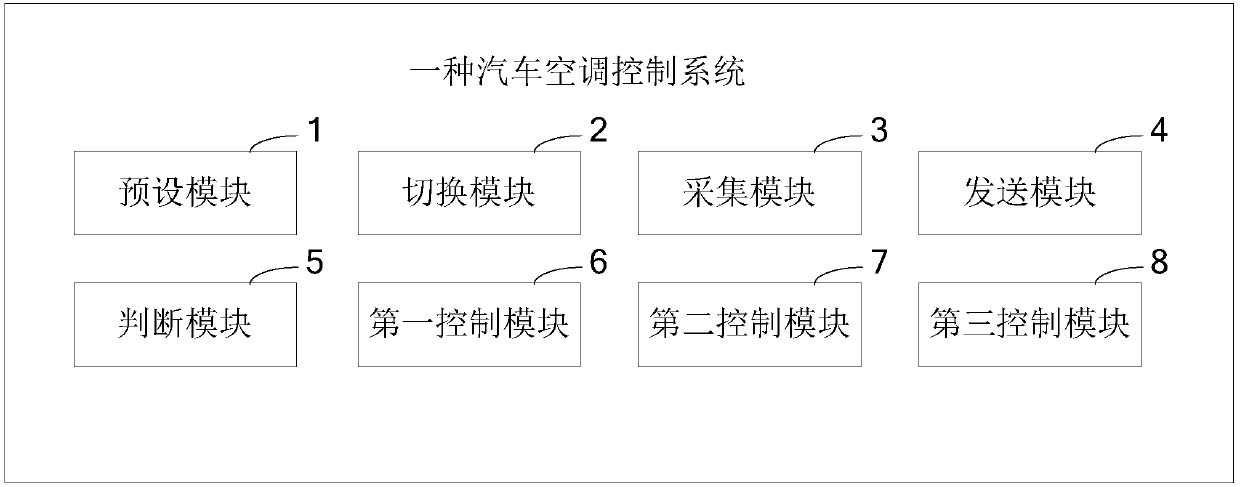

Automobile air conditioner control method and system thereof

InactiveCN107639997AAchieve zero lossExtended service lifeAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningAutomotive engineering

The invention relates to an automobile air conditioner control method. The method includes the steps of judging whether an accelerator pedal of an automobile is in a stamped state; if the acceleratorpedal is in the stamped state, controlling an automobile air conditioner compressor to be shut down; if the accelerator pedal is not in the stamped state, controlling the automobile air conditioner compressor to run. Whether the automobile air conditioner compressor runs or shuts down is controlled by judging whether the accelerator pedal of the automobile is in the stamped state; when a driver accelerates driving by treading on the automobile accelerator pedal, it can be ensured that the power of the automobile is not reduced and a remarkable fuel saving effect is achieved; when the driver loosens the accelerator pedal, inertia energy of the automobile and sliding energy under the gravity during the downhill driving are made full use of to make the air conditioner compressor run, the inertia of the automobile is subjected to greater resistance and weakened, thus prolonging the service life of a brake disc. Through testing, the automobile air conditioner control method can save fuel bymore than 10%.

Owner:李伟

Device for cleaning LED screen

InactiveCN112246710AAchieve cleaningAir dryDrying gas arrangementsCleaning using toolsElectric machineEngineering

The invention discloses a device for cleaning an LED screen. The device comprises a machine body, wherein an inlet cavity with a leftward opening is formed in the left end of the machine body, the right side of the inlet cavity communicates with a working cavity, the right side of the working cavity communicates with an outlet cavity with a rightward opening, a motor is arranged on the lower sideof the inlet cavity, a motor belt cavity is formed in the upper side of the motor, an intermittent cavity is formed in the upper side of the motor belt cavity, and the upper end of the motor is in power connection with a motor shaft which penetrates through the motor belt cavity and extends into the intermittent cavity. According to the device for cleaning the LED screen, the LED screen can be automatically cleaned and air-dried, the device can be used for cleaning the LED screens with different thicknesses and widths and is simple in structure and convenient to operate, the full-automatic operation is realized, all the procedures are matched with one another and do not influence one another, the labor loss is greatly reduced, and the practicability of the device is improved.

Owner:兰溪米雪电子科技有限公司

Efficient wax coating device for shoemaking processing fabric

InactiveCN110965228AUniform wax application is more comprehensive and reliableImprove the efficiency of wax applicationLiquid/gas/vapor removalTextile treatment machine arrangementsElectric machineryControl valves

The invention discloses an efficient wax coating device for a shoemaking processing fabric. The device comprises a rack, a support plate, a drive plate, a threaded rod, a sliding block, a guide pipe,a spray plate, an electric telescopic rod and an applying brush. When shoemaking wax coating processing needs to be performed, firstly the shoemaking fabric that needs to be coated with wax can be placed on a conveyor belt and fixed, and the fabric is automatically moved and conveyed through the conveyor belt; then the wax inside a storage tank can be heated by an electric heating wire, and a control valve is opened to export the wax through the guide pipe; finally the wax is applied to the shoemaking fabric through the spray plate. The threaded rod is driven to rotate for driving the slidingblock to move through a stepping motor, and lifting adjustment is carried out through the electric telescopic rod, so that the applying brush can perform contact application on the surface of the shoemaking fabric, the wax can be spread and applied to the surface of the fabric, application is more uniform and more comprehensive and reliable, workers are replaced to perform the manual wax coating procedure, the wax coating efficiency is improved, and the wax coating effect is better.

Owner:含山县华侨鞋业有限公司

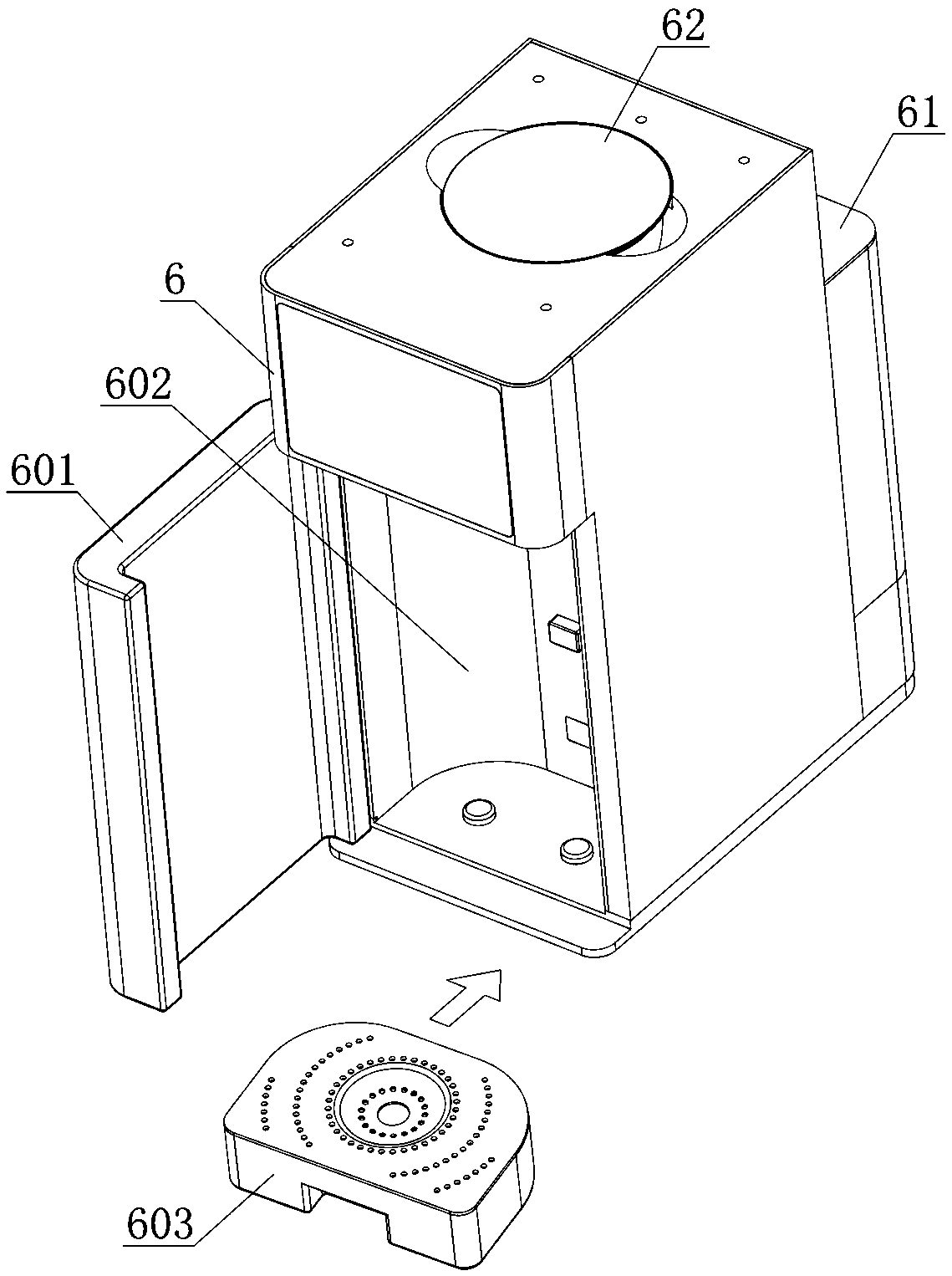

Powder dissolving mixer and mixing cabin, powder dissolving mixing device and control method of powder dissolving mixing device

PendingCN110150981AReduced sealing structureSimple structureBeverage vesselsRadiationMaterials scienceControl unit

The invention discloses a powder dissolving mixer and mixing cabin, a powder dissolving mixing device and a control method of the powder dissolving mixing device. The powder dissolving mixer includesa main shaft and stirring blades, and the end part of the main shaft is provided with a section of stirring spiral; the upper part of a cabin body of the powder dissolving mixing cabin is provided with a stirring motor and the powder dissolving mixer, the lower side of the inner part of the cabin body is provided with a spiral seal accommodation hole which has a bottom with a liquid outlet, and the stirring spiral is arranged in the spiral seal accommodation hole in an inserting mode; a housing of the powder dissolving mixing device is provided with a control unit, a water supplying assembly,a powder supplying assembly and the powder dissolving mixing cabin; and the control method includes the following steps of powder dissolving mixing, cleaning and air drying operation. According to thepowder dissolving mixer and mixing cabin, the powder dissolving mixing device and the control method of the powder dissolving mixing device, a sealing structure at the bottom of the mixing cabin is omitted, the product structure is simplified, the production cost is decreased, the problem that the bottom of the sealing structure is prone to breeding bacteria is solved, by a spiral structure of the stirring spiral combined with the stirring blades, the problem of single action on milk powder and water is solved, evenly powder dissolving is ensured, and powder clumping is prevented.

Owner:桃江银卓智能科技有限公司

Breeding method for increasing goat milk yield of milk goats

InactiveCN110036972AHigh activityLight intensityFood processingAnimal feeding stuffAnimal scienceEvery Evening

The invention discloses a breeding method for increasing goat milk yield of milk goats. The method includes the following steps: (1) selecting excellent varieties; (2) selecting and distributing breeding sites; (3); (4) adult goat management; (5) careful feeding: driving pregnant ewes after mating into a waiting room to be fed, feeding each ewe with 2-3 kg of coarse feeds, 0.2-0.3 kg of fine feedsand sufficient nutrient water at fixed points every day, feeding each ewe with 0.2-0.3 kg of fine feeds every day during the first 1-2 months before the ewe is produced, feeding each ewe with 0.5-1 kg of green feeds after the ewe is produced, opening a fence every morning for grazing for 5-6 hours, milking the ewe once every morning and every evening after the ewe is milked, and massaging the ewe's mammary gland for 5-8 minutes before milking; and (6) early weaning: after a lamb is born for 10-15 days and the weight increases to 1.5-2 kg, feeding the lamb with whole milk, at the same time, eating, by the lamb, a small amount of easily-digestible high-quality fine and coarse feeds, after 40-80 days, feeding the lamb with milk, grass and feeds, and after 80-120 days, mainly feeding the lambwith grass and feeds.

Owner:董建芬

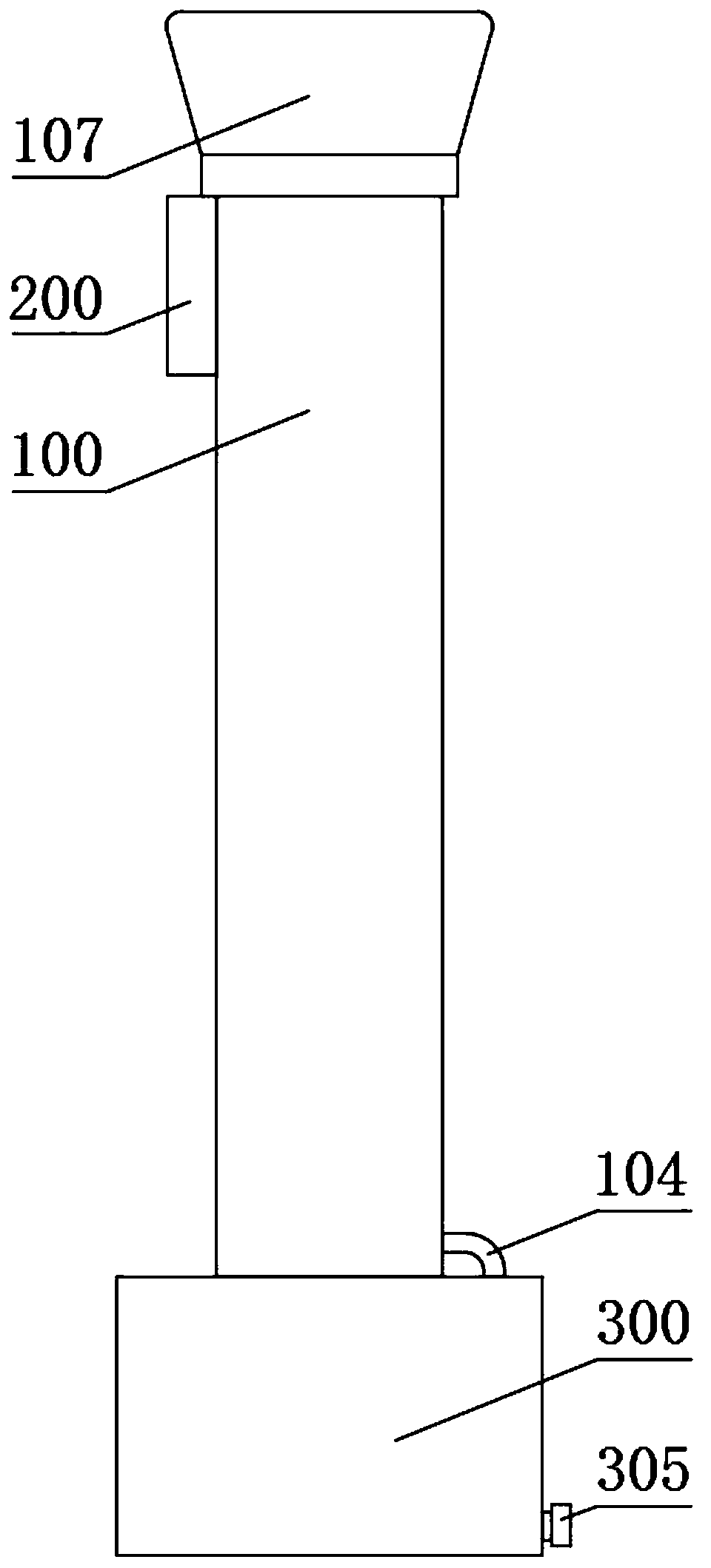

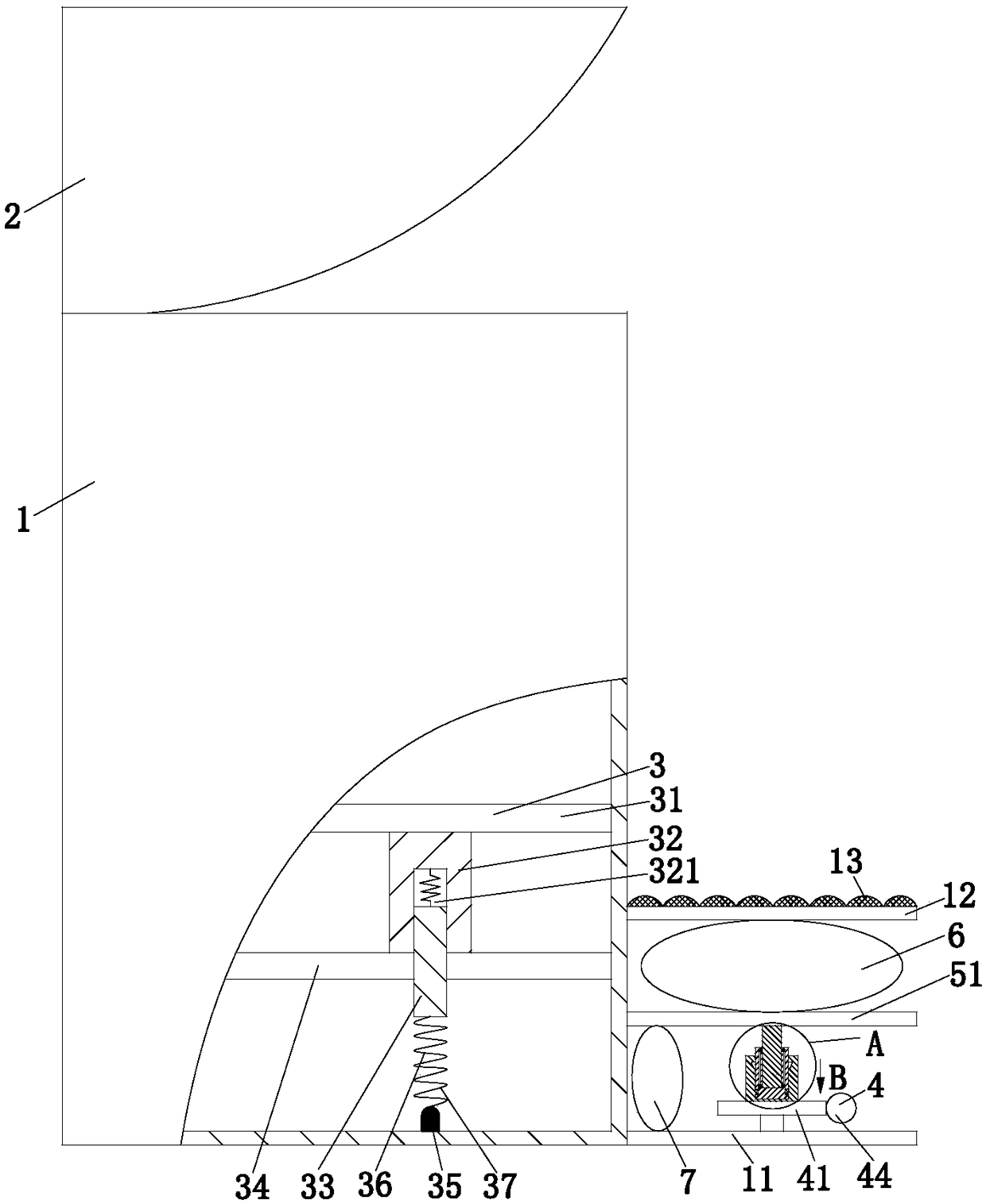

Rapid umbrella air-drying machine convenient and rapid to use

ActiveCN111006455AImprove air drying effectEasy to dripDrying gas arrangementsDrying chambers/containersElectric machineryEnvironmental engineering

The invention discloses a rapid umbrella air-drying machine convenient and rapid to use. The rapid umbrella air-drying machine convenient and rapid to use comprises an air-drying cylinder. The air-drying cylinder is provided with a gathering hopper, a water collecting box, an air blowing motor and a water discharging pipe. The gathering hopper is fixedly welded to the inner wall of the bottom of the air-drying cylinder. The water collecting box is fixedly welded to the center of the bottom of the gathering hopper. The gathering hopper is used for gathering the umbrella and guiding the umbrellainto the water collecting box. The water collecting box is used for collecting rainwater on the surface of the umbrella. The water discharging pipe is inserted and connected into the outer surface ofone side of the bottom of the water collecting box in an penetrating manner. The water discharging pipe discharges rainwater in the water collecting box. According to the rapid umbrella air-drying machine convenient and rapid to use, the air blowing motor blows air upwards or downwards, so that air can pass through the air-drying cylinder, air can conveniently conduct air drying on the umbrella when passing through the air-drying cylinder; besides, an electric heating wire is installed, so that when air is blown downwards, the blown-out air can be heated, the heated air can achieve air dryingof the ground, and therefore the indoor ground is guaranteed to be dry.

Owner:ANHUI JINWAN PUMP TECH CO LTD

Refined corn flour processing equipment and corn processing method

PendingCN114158359AThrift threshingEfficient threshingGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention belongs to the field of agricultural product fine processing, and particularly relates to refined corn flour processing equipment and a corn processing method.The refined corn flour processing equipment comprises a feeding box, a discharging opening is formed in the lower portion of the feeding box, the feeding box and the discharging opening are fixed through four supporting frames, the discharging opening is provided with two sorting guide rails, and the sorting guide rails are downwards connected with sorting feeding openings; a threshing mechanism is connected below the sorting feed inlet, a press-in rail and a separation rail are connected between the sorting feed inlet and the threshing mechanism, a sorting mechanism is arranged below the threshing mechanism, a ventilator is arranged at the center of circle of the middle of the threshing mechanism, a dryer is arranged below the ventilator, and a plurality of spiral pipelines are arranged on the outer side of the dryer and located below the sorting mechanism. A plurality of small protrusions are arranged in the spiral pipeline, a peeling and sorting mechanism is arranged below the drying mechanism, a grinding mechanism is connected below the peeling and sorting mechanism, and a collecting box is arranged on the outer side of the grinding mechanism. According to the invention, direct production from corn cobs to corn flour is realized more efficiently and quickly.

Owner:王志民

An easy-to-clean reaction kettle for lubricating oil production

ActiveCN108201830BEasy to cleanImprove solubilityTransportation and packagingRotary stirring mixersElectric machineProcess engineering

In the easy-to-clean lubricating oil production reaction kettle proposed by the present invention, the heat dissipation coil is connected to the partition plate, and the heat dissipation coil is connected to the steam generator through the steam inlet pipe and the steam outlet pipe, and the steam generator and the motor are both located in the electrical cavity. The output shaft of the motor is connected to one end of the stirring shaft, and the other end of the stirring shaft passes through the partition and extends into the reaction chamber. The water tank is connected to the top of the reaction chamber through the rotation of the sleeve. There are multiple nozzles connected to the water tank and communicated with the mixer through pipes. The mixer has an air inlet and a water inlet, the water inlet is connected to the water pump through the water inlet pipe, the air inlet is connected to the heating box through the air inlet pipe, and a fan is arranged in the heating box. The easy-to-clean reaction kettle for lubricating oil production proposed by the present invention has sufficient material dissolution, high dissolution efficiency, and low energy consumption; after the reaction is completed, the kettle body can be cleaned without opening the kettle body, and the operation is simple and the maintenance is convenient .

Owner:TOILX TIANJIN

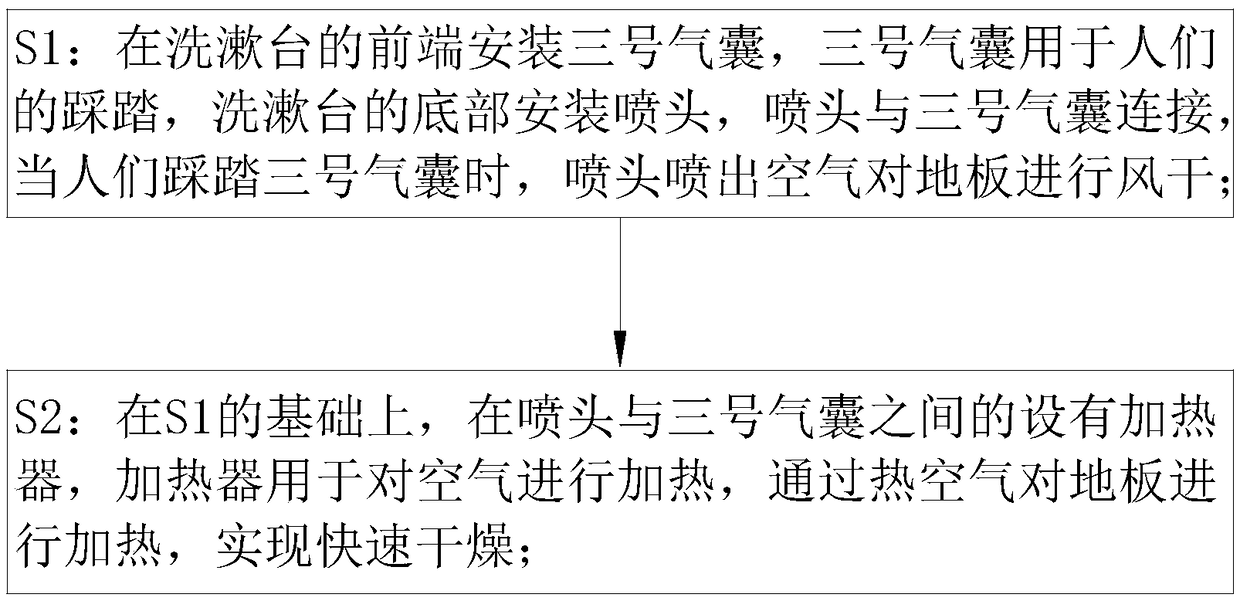

Floor dehumidifying and dampproof method

ActiveCN109186244APrevent fallingImprove securityDrying gas arrangementsDomestic plumbingEngineeringTread

The invention belongs to the technical field of dehumidifying and drying, in particular to a floor dehumidifying and dampproof method. According to the method, a washing table is adopted; and the washing table comprises a washing cabinet and a washing stand, and further comprises a control unit, a driving unit, an automatic lifting unit, a first air bag, a second air bag, a fixing plate and a controller. After people has washed, on one hand, people tread a third air bag, through the mutual cooperation between the third air bag and a spray head, the spray head sprays the air which is blown outthrough the tread by people on the third air bag to a floor, so that air drying of the floor is realized; on the other hand, by arranging a heater, through the heating of the heater, the temperature of the air is increased, the floor is heated by utilizing the hot air, so that rapid drying of the floor is realized.

Owner:嘉兴市金鹭喷织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com