800DEG C resistant organosilicon anticorrosion coating for outer wall of pipeline, and preparation method thereof

A technology for pipeline outer walls and anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor feedback from users, and achieve the effects of avoiding corrosion and cracking of piping systems, good heat resistance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

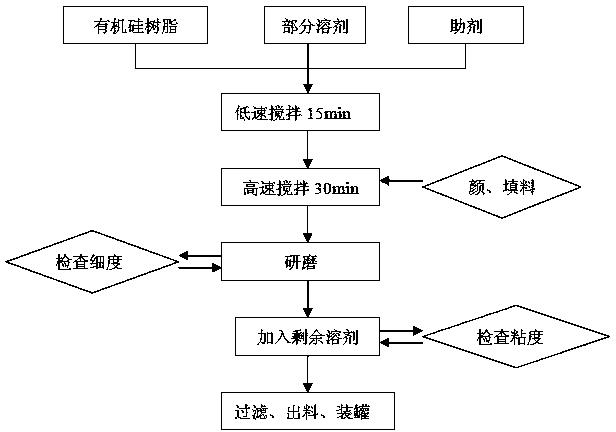

Method used

Image

Examples

Embodiment Construction

[0025] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

[0026] The 800°C high-temperature resistant organosilicon anticorrosion coating for the outer wall of the ship pipeline of the present invention is a normal temperature finger-dry single-component heat-resistant coating, and the coating can be sprayed, brushed, rolled and other processes, and the dry film thickness of each coating is 50μm, 2 coats are recommended. Examples are shown in Table 4.

[0027] Table 4: Examples

[0028] Example 1 Example 2 Example 3 Raw material name Proportion(%) Proportion(%) Proportion(%) Silicone resin 35 30 33 Glass frit (400±30℃) 10 15 20 Mica iron oxide red 12 15 10 Other fillers 27 20 24 Auxiliary 4 2 3 solvent 12 18 10 total 100 100 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com