An easy-to-clean reaction kettle for lubricating oil production

A lubricating oil and reactor technology, which is applied in the field of lubricating oil production reactors, can solve the problems that the processing efficiency needs to be improved, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

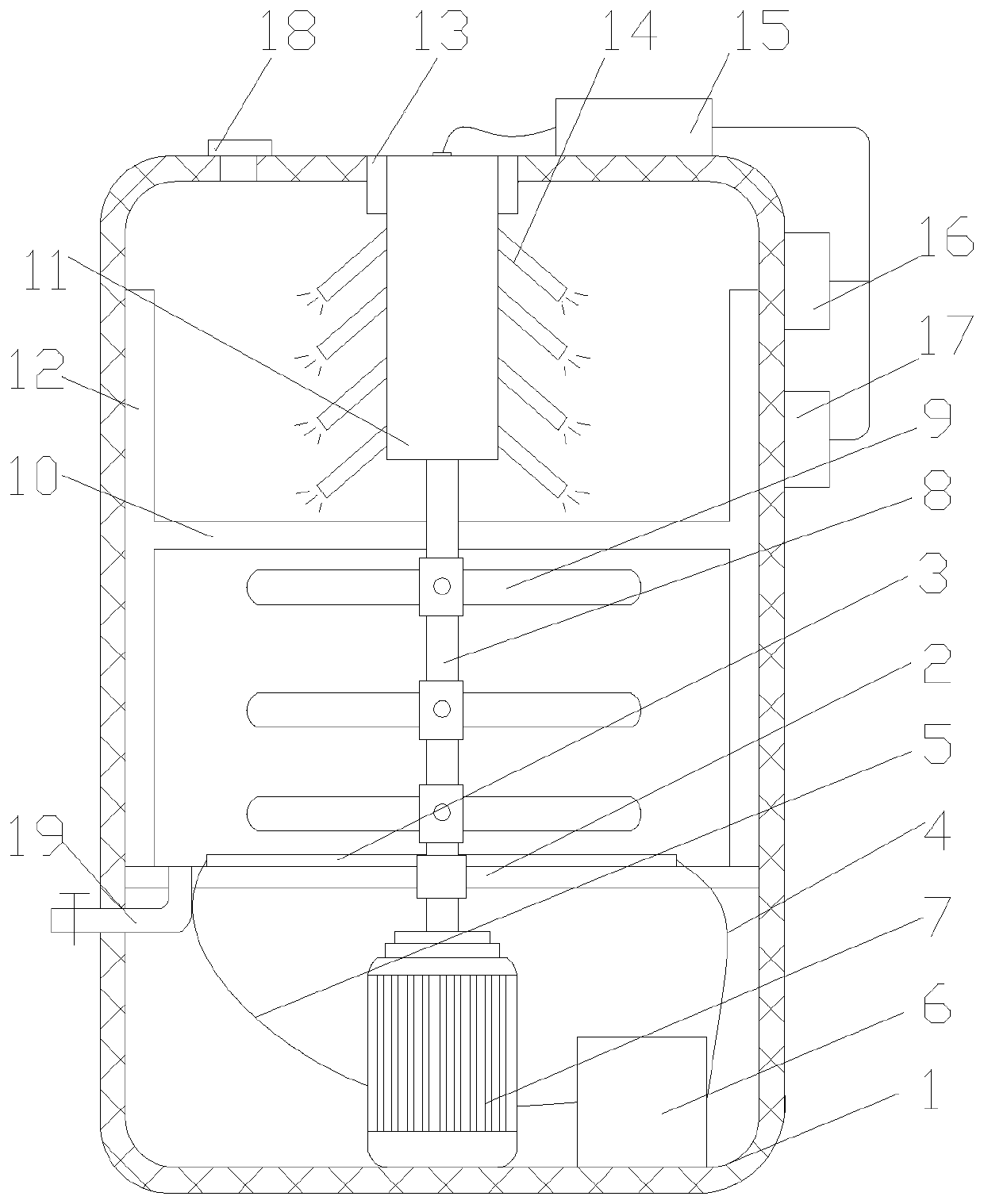

[0017] like figure 1 shown, figure 1 It is a schematic structural diagram of a reaction kettle for lubricating oil production which is convenient for cleaning proposed by the present invention.

[0018] refer to figure 1 , a kind of reaction kettle for lubricating oil production that is easy to clean proposed by the present invention, includes a kettle body 1, a cooling coil 3, a steam generator 6, a motor 7, a mixer 15, a high-pressure pump 16 and a heating box 17;

[0019] The kettle body 1 is provided with a partition plate 2, and the partition plate 2 divides the kettle body 1 into a lower electrical cavity and an upper reaction cavity. The heat dissipation coil 3 is connected to the partition plate 2. The pipe 3 is connected to the steam generator 6 through the steam inlet pipe 4 and the steam outlet pipe 5. The steam generator 6 and the motor 7 are both located in the electrical cavity, and the output shaft of the motor 7 is driven to connect one end of the stirring sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com