Preparation method of instant bird's nest

A bird's nest and stewing technology, which is applied in the field of preparation of instant bird's nest, can solve the problems of broken bottle sterilization, improper sterilization operation, low filling temperature, etc., and achieve the effect of ensuring integrity and avoiding water stain residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

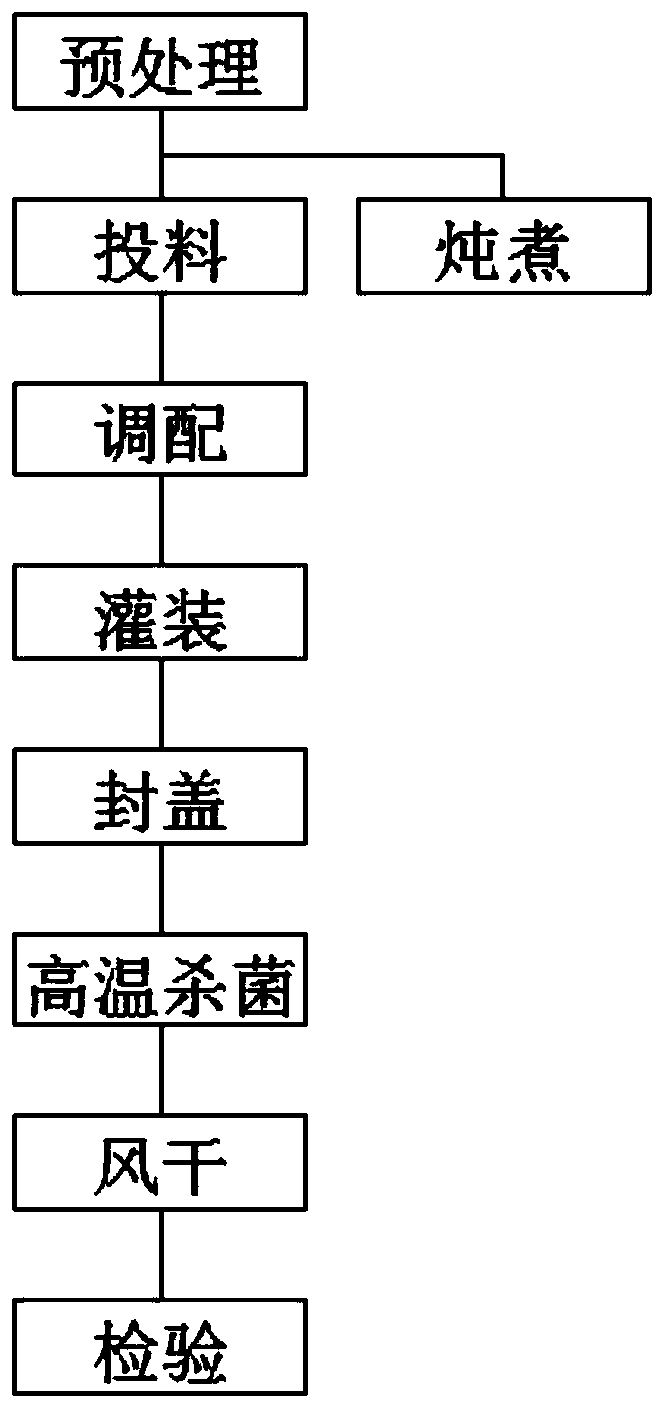

[0025] A preparation method of instant bird's nest, comprising pretreatment, feeding, blending, filling, capping, high-temperature sterilization, air-drying and inspection steps, to complete the preparation of instant bird's nest; the specific steps are as follows:

[0026] (1) Pretreatment: Soak the dried bird’s nest that has been removed of impurities with pure water, remove the soaked bird’s nest, remove impurities, and then use ultrasonic cleaning to remove the nitrite attached to the bird’s nest, so that the content of nitrite Less than 30mg / kg; the soaking time is 10h, the soaking temperature is 10°C; the ultrasonic power of ultrasonic cleaning is 550W, and the ultrasonic frequency is 30Hz.

[0027] (2) Feeding: weigh the processed bird's nest by electronic balance, and control the error of each bottle between ±0.03g;

[0028] (3) Blending: Then add the blending ingredients to the bird’s nest after feeding, filter through a 100-mesh filter, extract the filtrate, heat up ...

Embodiment 2

[0035] A preparation method of instant bird's nest, comprising pretreatment, feeding, blending, filling, capping, high-temperature sterilization, air-drying and inspection steps, to complete the preparation of instant bird's nest; the specific steps are as follows:

[0036] (1) Pretreatment: Soak the dried bird’s nest that has been removed of impurities with pure water, remove the soaked bird’s nest, remove impurities, and then use ultrasonic cleaning to remove the nitrite attached to the bird’s nest, so that the content of nitrite Less than 30mg / kg; the soaking time is 20h, the soaking temperature is 20°C; the ultrasonic power of ultrasonic cleaning is 1500W, and the ultrasonic frequency is 40Hz.

[0037] (2) Feeding: the processed bird's nest is weighed and fed by an electronic balance, and the error of each bottle is controlled at ±0.03g;

[0038] (3) Blending: Then add the blending ingredients to the bird’s nest after feeding, filter through a 100-mesh filter, extract the ...

Embodiment 3

[0045] A preparation method of instant bird's nest, comprising pretreatment, feeding, blending, filling, capping, high-temperature sterilization, air-drying and inspection steps, to complete the preparation of instant bird's nest; the specific steps are as follows:

[0046] (1) Pretreatment: Soak the dried bird’s nest that has been removed of impurities with pure water, remove the soaked bird’s nest, remove impurities, and then use ultrasonic cleaning to remove the nitrite attached to the bird’s nest, so that the content of nitrite Less than 30mg / kg; the soaking time is 15h, the soaking temperature is 15°C; the ultrasonic power of ultrasonic cleaning is 1075W, and the ultrasonic frequency is 35Hz.

[0047] (2) Feeding: the processed bird's nest is weighed and fed by an electronic balance, and the error of each bottle is controlled at ±0.03g;

[0048] (3) Blending: Then add the blending ingredients to the bird’s nest after feeding, filter through a 100-mesh filter, extract the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com