Dicyclopentadiene type unsaturated polyester modified by tung oil, and preparation method and application thereof

A dicyclopentadiene and unsaturated technology, which is applied in the field of preparation of new polymer materials, can solve the problems of unsaturated polyester coatings that cannot meet the requirements of use, poor air drying, poor toughness, etc., and achieve easy industrial The effect of expanding production, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

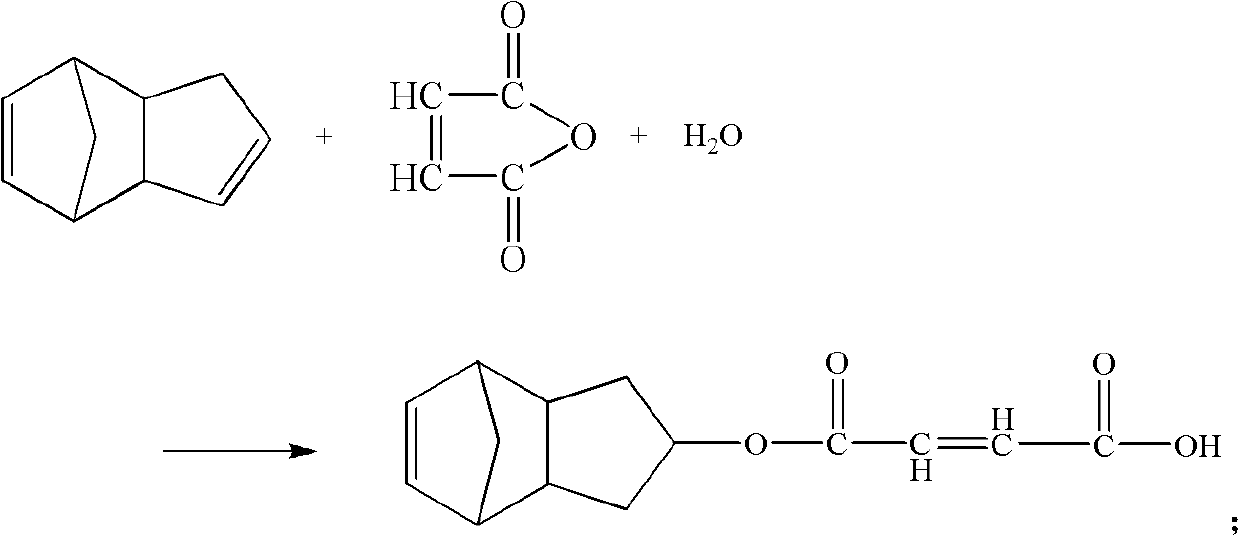

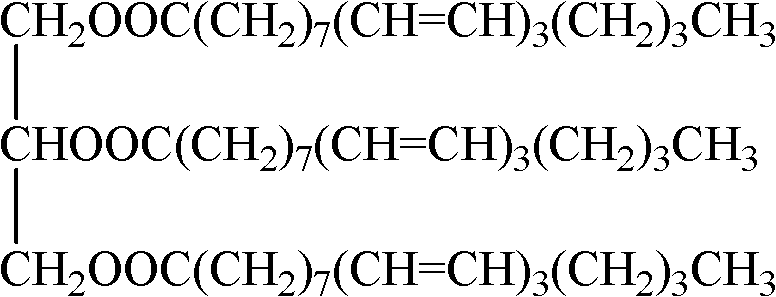

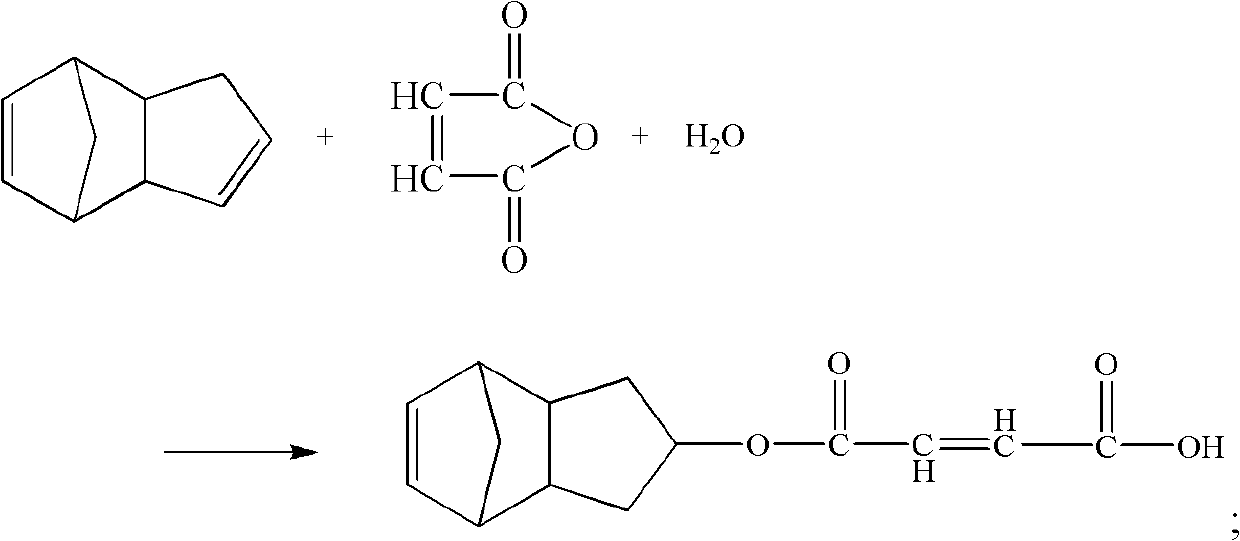

[0047] Put 30g (0.3mol) of maleic anhydride, 40g (0.3mol) of dicyclopentadiene and 0.7g of phosphoric acid into a four-necked flask device with a reflux condenser, raise the temperature to 80-100°C with a protective gas, and add 5.4 g (0.3mol) of water, the temperature of the control system is lower than 140°C; after adding the water, keep it warm for 1.5-2h to obtain dicyclopentadiene maleic acid half ester. Then add 22.8g (0.3mol) propylene glycol, 21.2g (0.2mol) diethylene glycol, 7.4g (0.05mol) phthalic anhydride, 29g (0.25mol) fumaric acid and 0.09g terephthalic acid Diphenol, install a fractionation column and a water separator on a four-neck flask, raise the temperature to 150°C, heat up to 190-210°C for dehydration and esterification after 0.5-1h of heat preservation, and control the temperature of the fractionation column to ≤105°C to reduce the low boiling point loss of diols. When the acid value reaches about 70mgKOH / g, cool down to 140°C and add 5g of tung oil, th...

Embodiment 2

[0049] The add-on of tung oil is increased to 10g, and other is with embodiment 1 (omitted). The final acid value was 22.4 mgKOH / g, the viscosity was 1328 mPa·s, and the number average molecular weight was 1100.

Embodiment 3

[0051] The add-on of tung oil is increased to 15g, and other is with embodiment 1 (omitted). The final acid value was 29.7 mgKOH / g, the viscosity was 1315 mPa·s, and the number average molecular weight was 1100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com