Heat dissipation protection device for electromechanical equipment

A technology for protection devices and electromechanical equipment, which is applied to structural components of electrical equipment, electrical equipment shells/cabinets/drawers, electrical components, etc., and can solve the problems of shortening the service life of electromechanical equipment, damage to internal components of electromechanical equipment, and contact between moisture and electromechanical equipment Excessive and other problems, to avoid moisture damage, easy to operate, simple and labor-saving installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

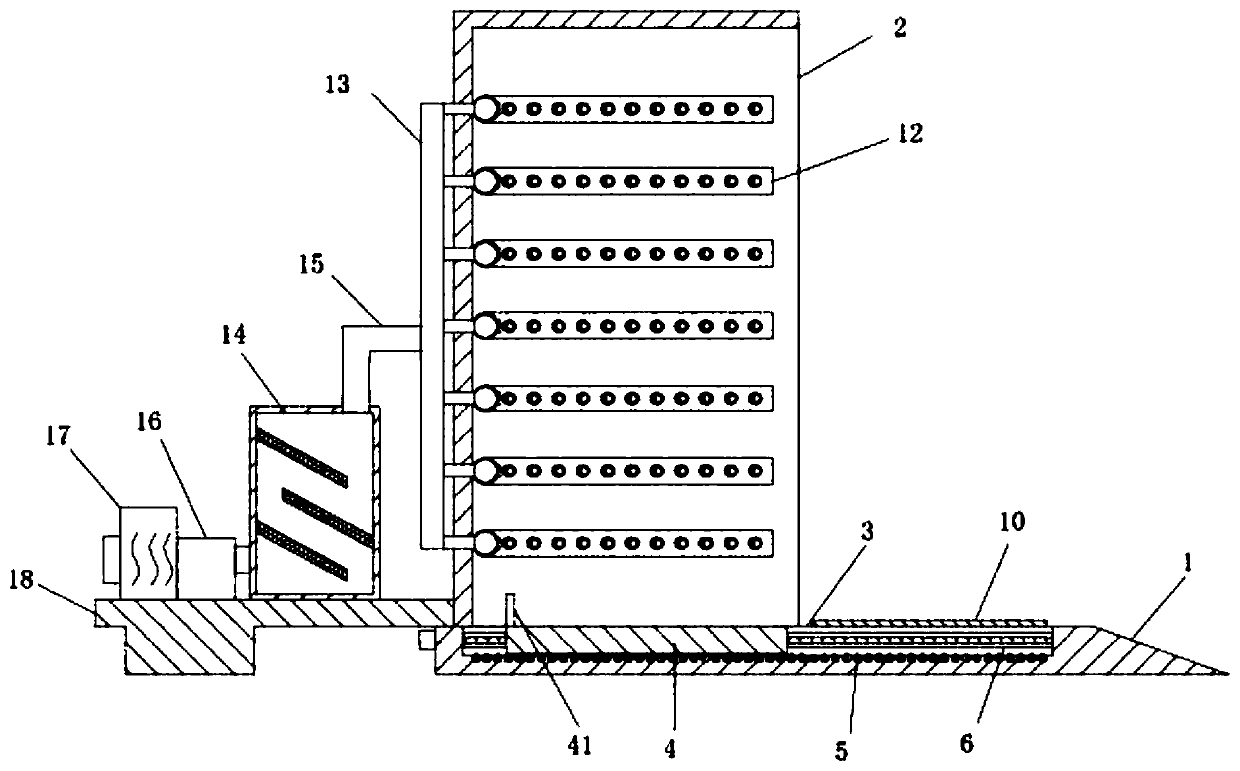

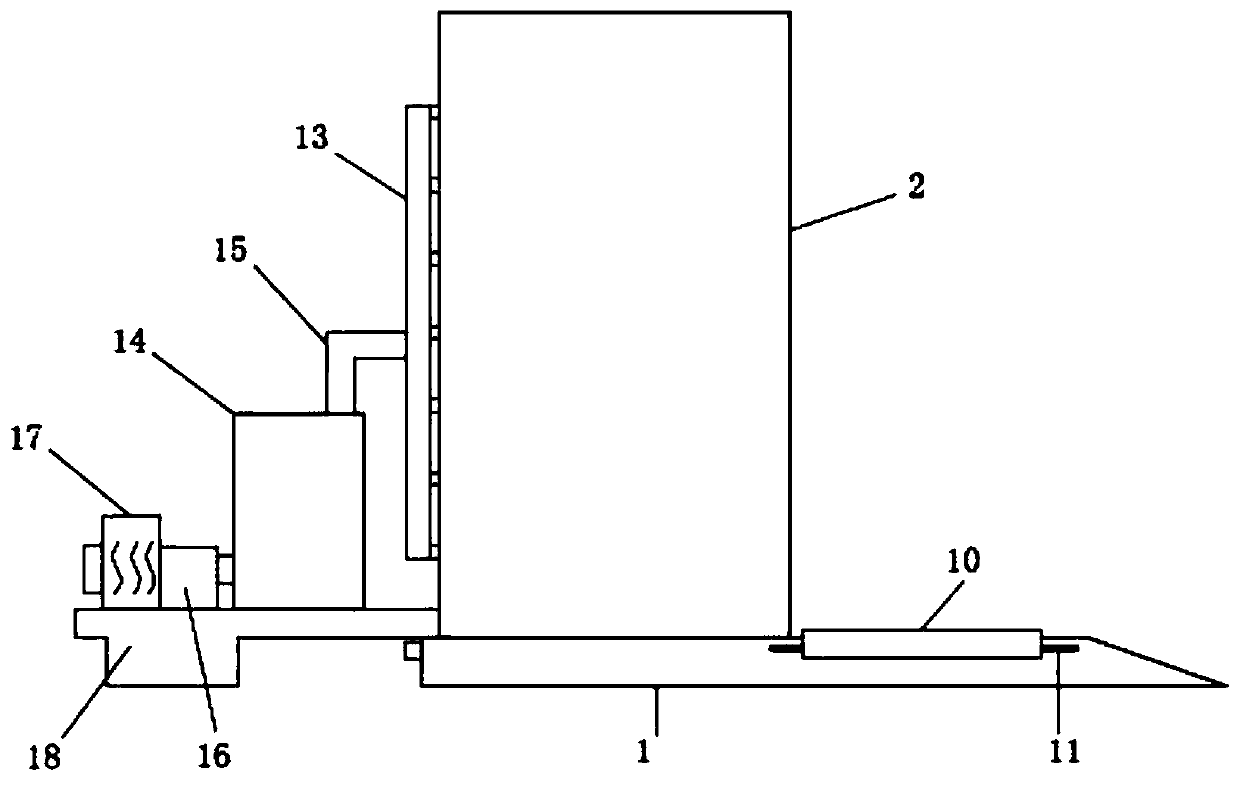

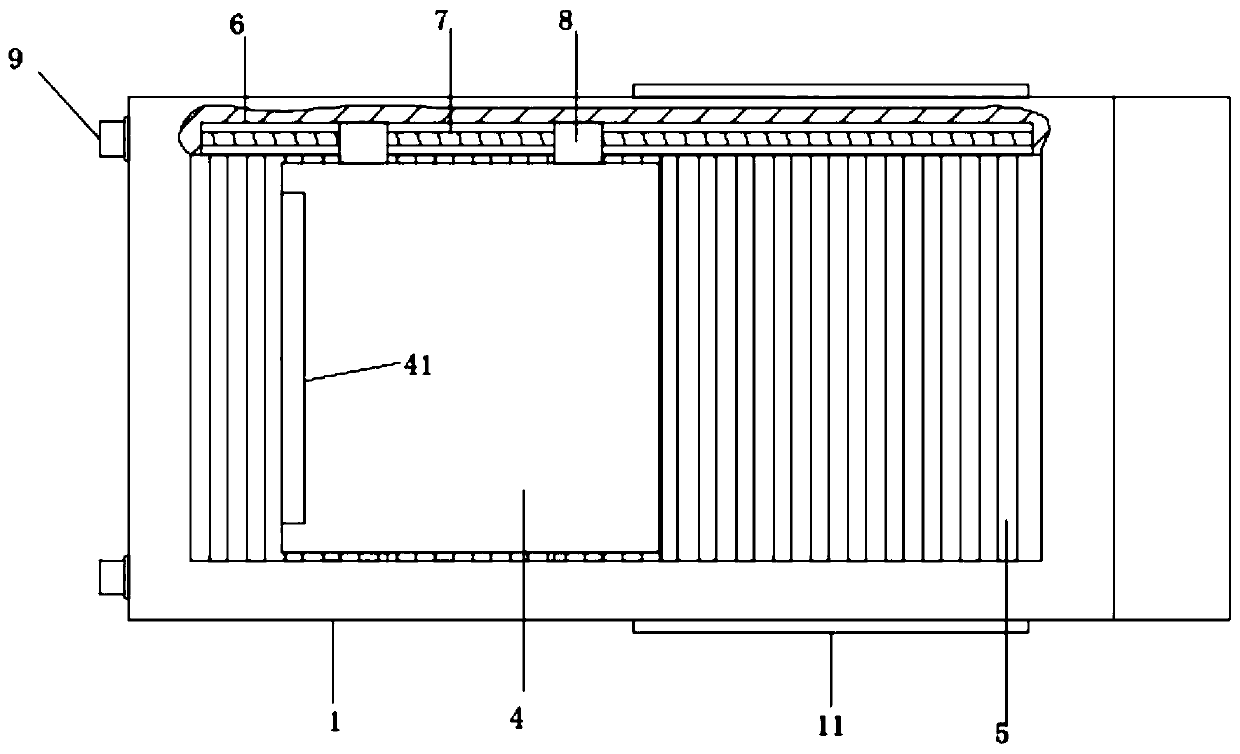

[0028] The invention provides a technical solution: a heat dissipation protection device for electromechanical equipment, including a base 1, a protective cover 2 is provided on the left side of the top of the base 1, the right side of the protective cover 2 is open, and the top of the base 1 There is a groove 3, and the inner cavity of the groove 3 is slidably provided with a support plate 4, and the groove 3 is symmetrically provided with a chute 6 front and rear, and a driving mechanism is arranged in the chute 6, and the support plate 4 and the The driving mechanism is connected, and the inner wall of the protective cover 2 is distributed with air outlet pipes 12. The air outlet pipes 12 have multiple groups, and the multiple groups of air outlet pipes 12 are distributed at equal intervals from top to bottom. On the left side wall of the protective cover 2 A standpipe 13 is provided, and the standpipe 13 communicates with all outlet pipes 12. The left end of the base 1 is p...

Embodiment 2

[0031] The bottom surface of the groove 3 is evenly distributed with rollers 5, and the bottom surface of the support plate 4 slides against the top surface of the rollers 5. This structure can greatly reduce the resistance during the load-bearing movement of the support plate 4 and reduce the energy consumption of the driving mechanism. .

Embodiment 3

[0033] Protruding rails 11 are provided on the right side of the front and rear walls of the base 1 , and cover plates 10 are slidably installed between the protruding rails 11 on both sides.

[0034] The cover plate 10 includes a U-shaped plate body 101, and the inner sides of the vertical plates on both sides of the U-shaped plate body 101 are provided with convex rail slide grooves 102;

[0035] The above structure can cover the groove 3 at the front after the electromechanical equipment moves to the protective cover 2, which is convenient for the staff to operate on the front side of the electromechanical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com