Dry processed protein and process for producing same

A manufacturing method and protein technology, which can be used in animal protein processing, dry-preserved eggs, food preparation, etc. It can solve the problems of poor hot water recovery, raw material taste, and damaged appearance, and achieve excellent flavor, excellent appearance, and economical efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

[0050]

[0051] As the protein to be imitated, pork (meat raw material) and lard were selected, and the raw material added with meat raw material in the range of 20% to 72% was kneaded as shown in Table 1. Eggs (main protein) and soy protein ( The mixture obtained from main protein), wheat (main protein), corn starch, puffing agent, salt, seasoning, etc., is adjusted to obtain a blank, and the blank is pulverized with a pulverizer to produce indeterminate granules of 10 mm or less. At this time, in Examples 1 to 3, the mode diameter of the pellets was 2.8 mm, and the range of the mode diameter ±20% was 65% or less.

[0052] [Table 1]

[0053] Raw material name

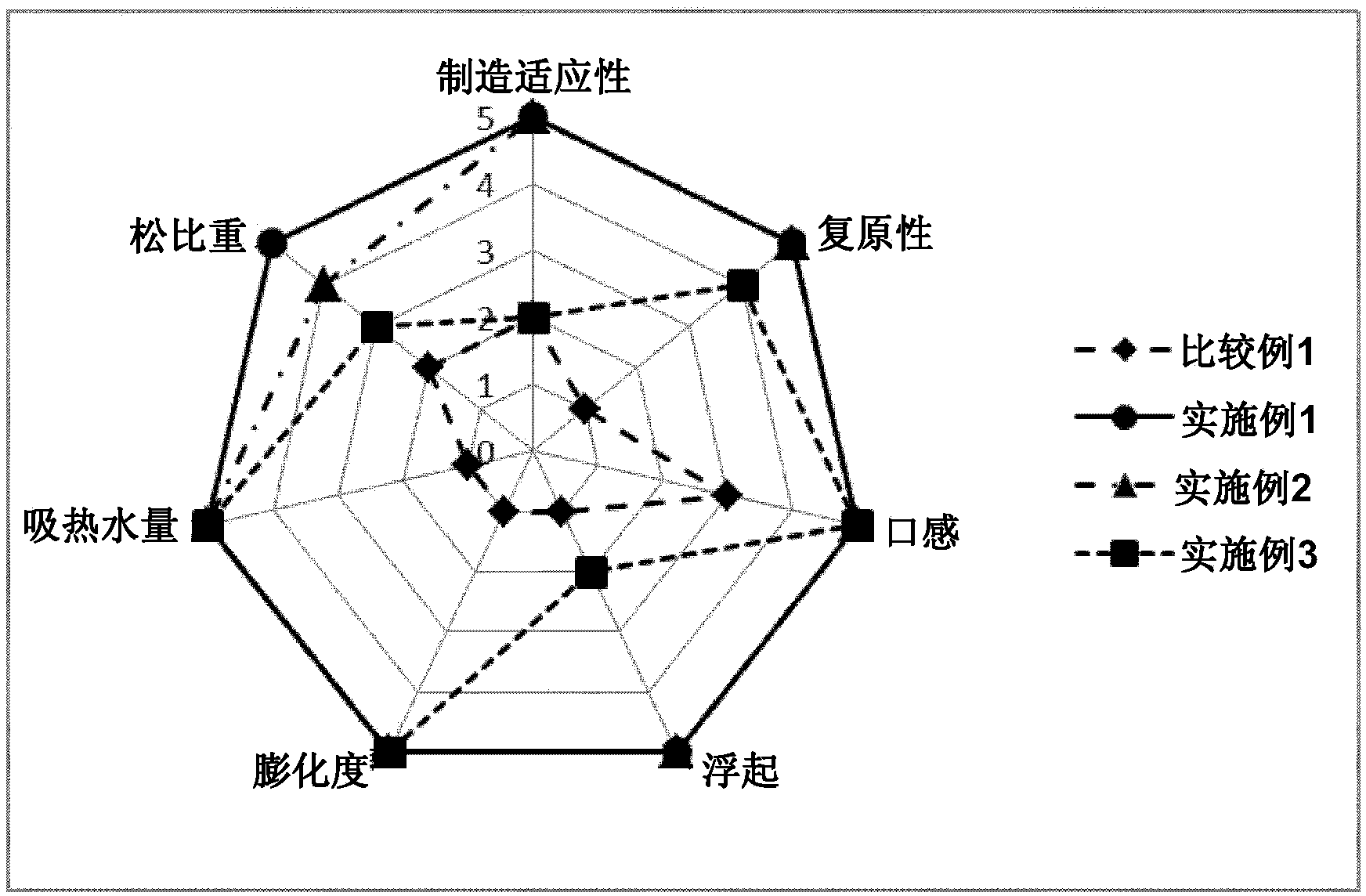

[0054] The small particles obtained by the above treatment are microwave-dried, then crushed with a pulverizer, and subjected to finishing and drying with hot air at a temperature of 80° C. or higher to obtain a pellet-shaped dry food with a diameter of 15 mm or less. At this time, the manufacturing suitability regardin...

Embodiment 1 and comparative example 2~3

[0063]

[0064] Except that the raw material moisture was blended as shown in Table 4, the dried meat processed foods of Comparative Examples 2 to 3 were produced by the same procedure as in Example 1 described above. At this time, in Example 1, the most frequent diameter of the pellets of the dried meat processed food was 2.8 mm, and the range of the most frequent diameter ±20% was 65% or less.

[0065] [Table 4]

[0066] Raw material name

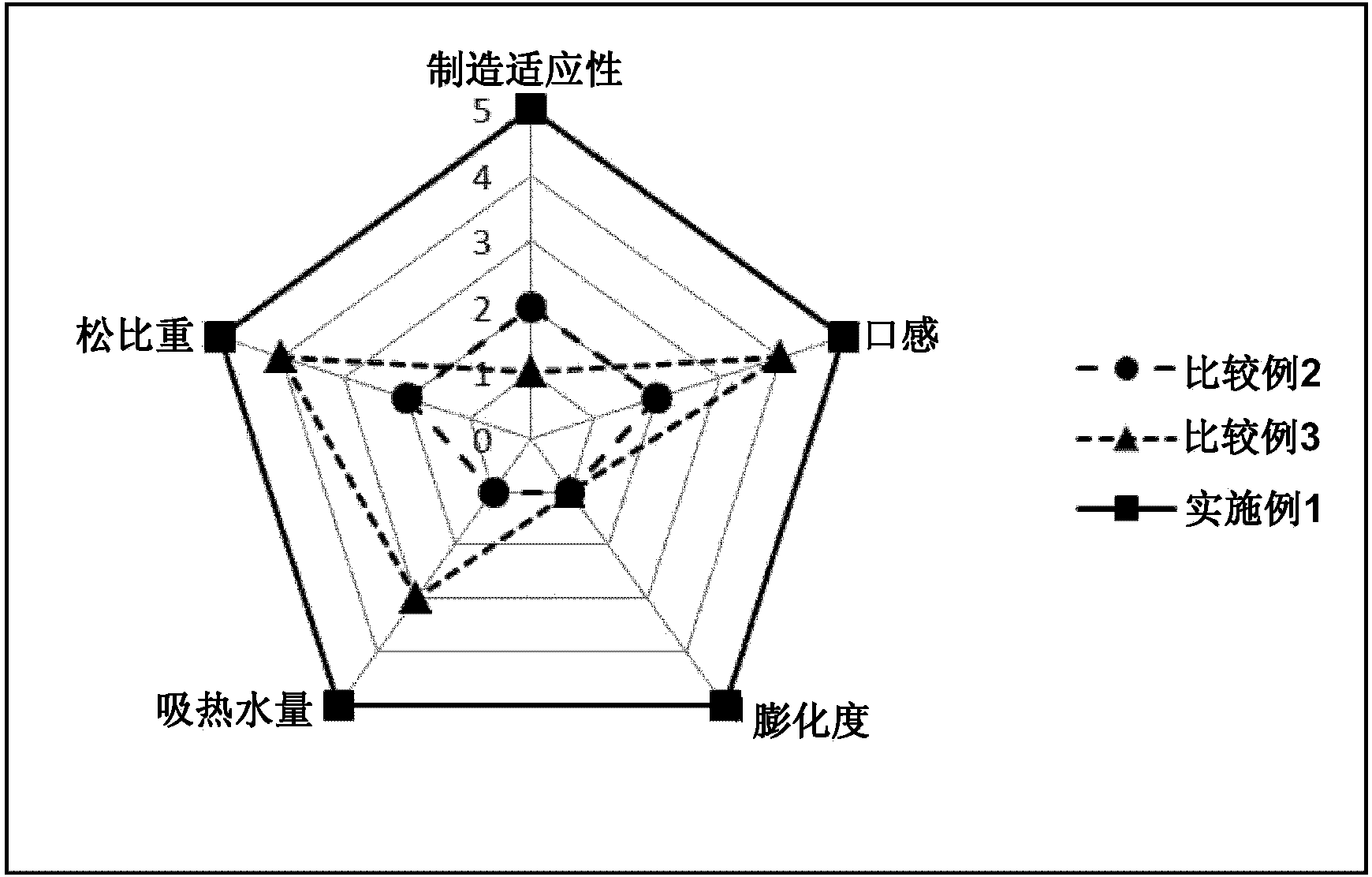

[0067] To evaluate their manufacturing suitability, they were restored with hot water of 85°C or higher for 3 minutes, and then sensory evaluation was performed by 5 specialists. The manufacturing adaptability and taste are set to "1...poor, 2...slightly poor, 3...normal, 4...relatively good, 5...good", and the degree of expansion, water absorption, and bulk density are set to 5 levels as shown in Table 2. Evaluation. The results are summarized in Table 5 and figure 2 . Among them, in Table 5, the expansion degree, the amount of hot wat...

Embodiment 1 and comparative example 4

[0072]

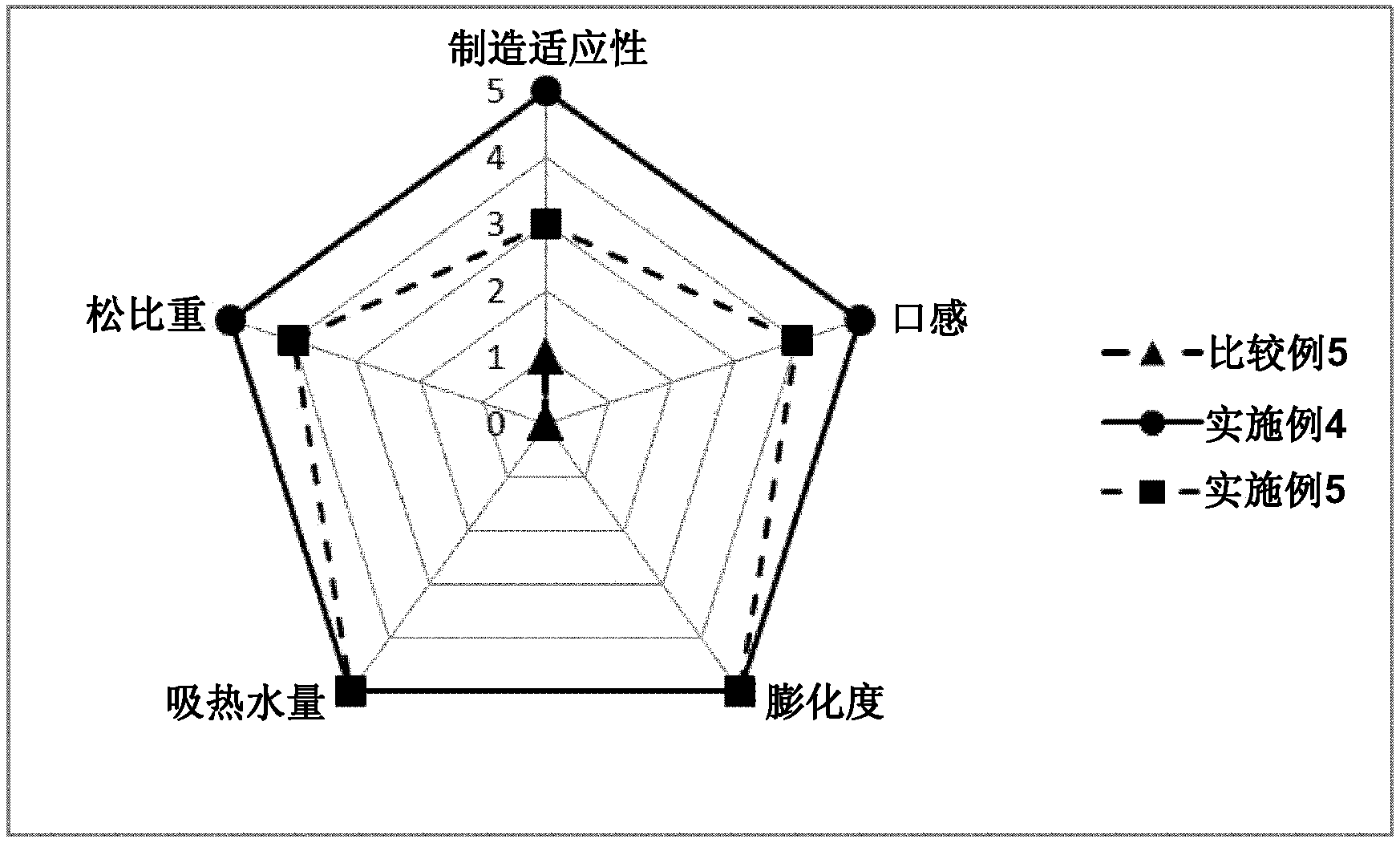

[0073] Example 1 and Comparative Example 4 obtained in accordance with the same procedure as Example 1 except for making 25 mm pellets were restored with hot water at 85°C or higher for 3 minutes, and then sensory evaluation was performed by 5 specialists for restorability and texture.

[0074] The results are summarized in Table 6.

[0075] [Table 6]

[0076] Evaluation item

[0077] As a result, Comparative Example 4 obtained by using 25 mm small grains did not feel a meaty grainy texture, and became a uniform texture. In addition, it is inferior in restorability compared with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com