Self-adjusted automatic cleaner

An automatic cleaning machine and self-adjusting technology, applied in food science, food preservation, poultry industry, etc., can solve the problems of inability to spoil eggs, adapt to the size and shape of eggs, etc., to improve cleaning output, good market prospects, High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

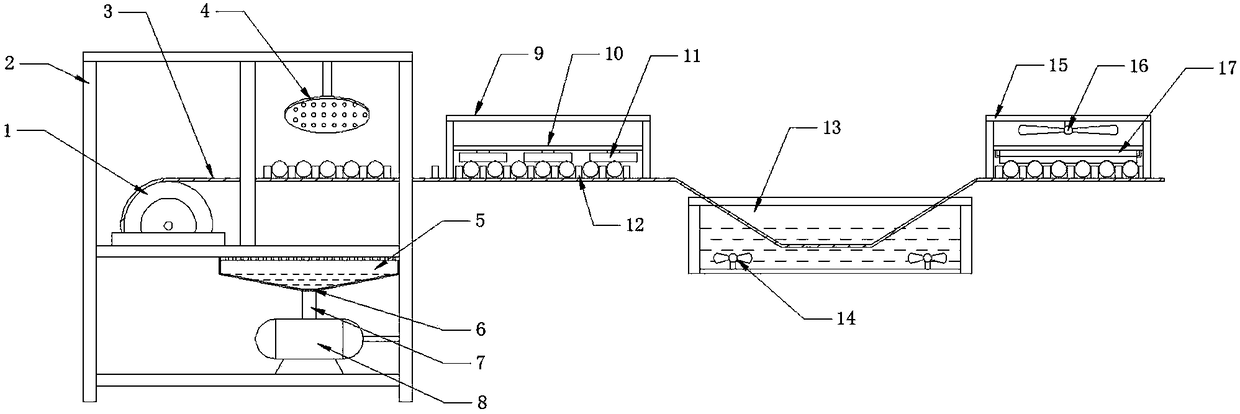

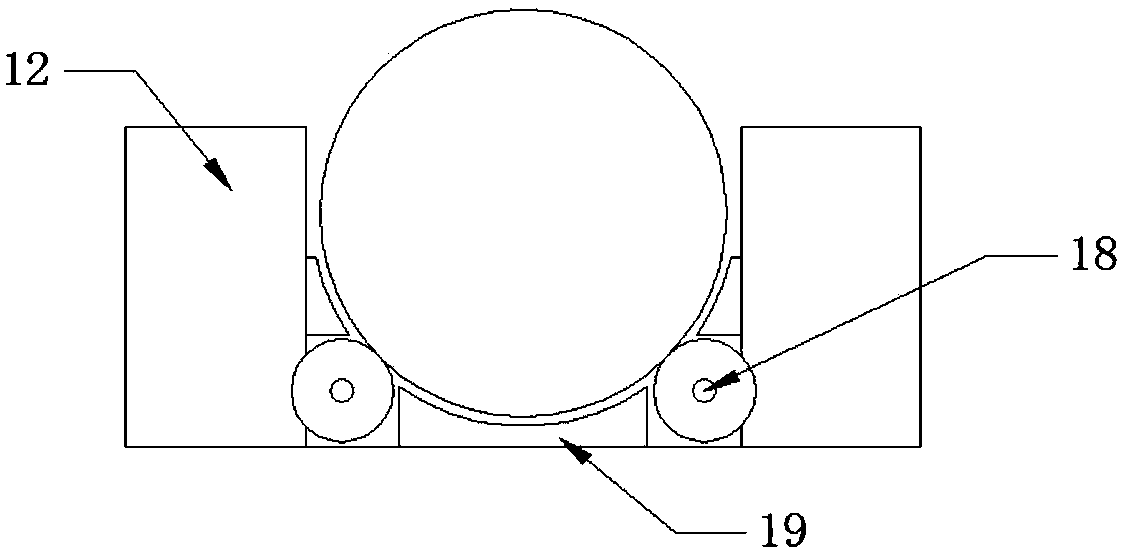

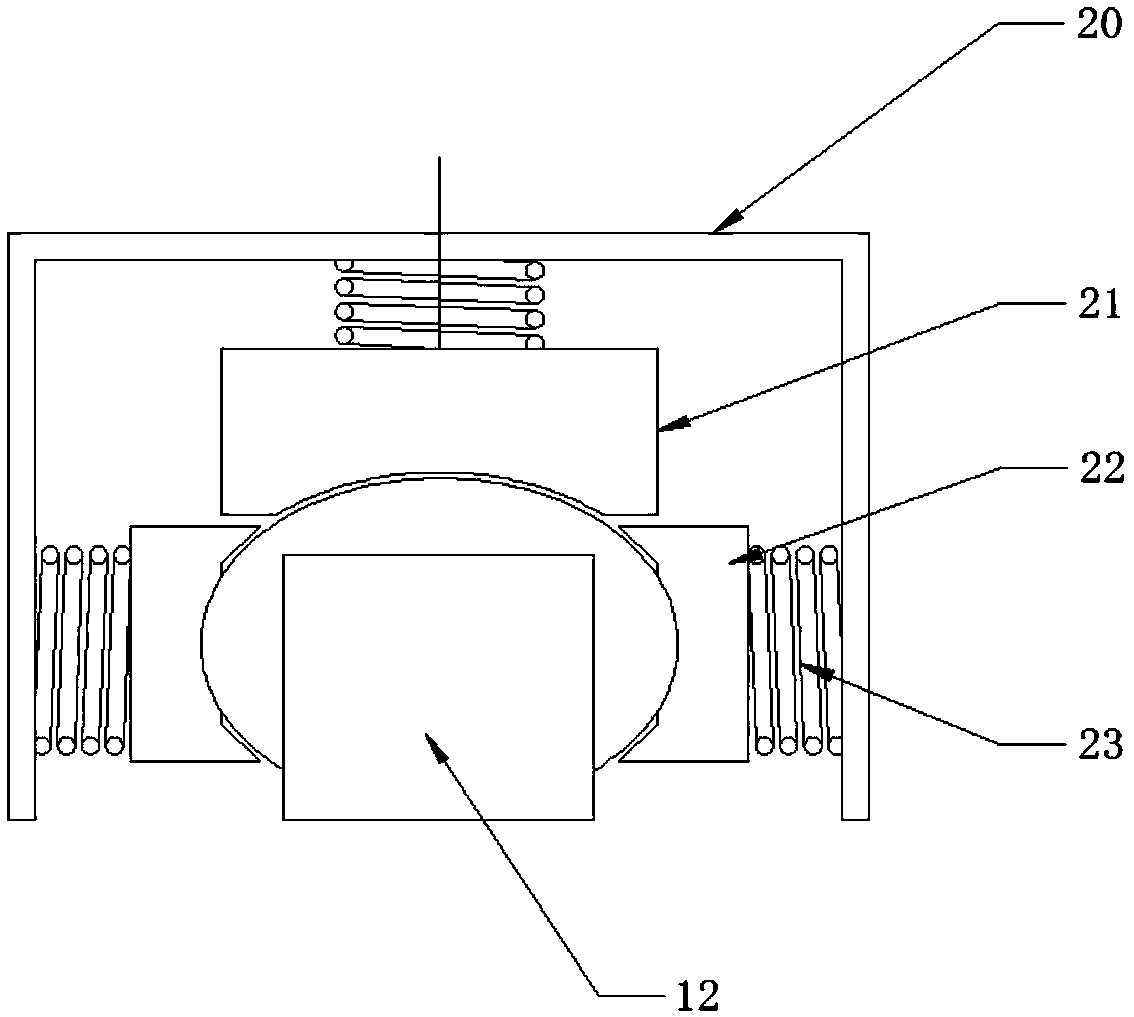

[0034] A self-adjusting automatic cleaning machine, including a shower rack 2, a scrub rack 9, a cleaning box 13 and a drying rack 15 arranged in sequence, a transmission wheel 1 is installed in the shower rack 2, and the transmission wheel 1 is connected with The conveyor belt 3 is characterized in that, the conveyor belt 3 is arranged with a placement frame 12, the sprinkler 4 is installed above the conveyor belt 3 in the shower frame 2, and a crossbeam 10 is installed in the scrubbing frame 9, and the crossbeam The bottom of 10 is connected with hairbrush 11, and fan 16 is installed on the top in drying frame 15, and sponge device 17 is installed on the top of conveyor belt 3 in drying frame 15, and described sponge device 17 comprises the sponge supporting frame that is installed on the outside of placement frame 12 20, the top and both sides of the sponge supporting frame 20 are connected with springs 23, the spring 23 on the top is connected with the first sponge 21, and ...

Embodiment 2

[0039] As a preferred improvement, a sump 5 is installed below the shower frame 2, and a filter screen 6 is installed below the sump 5, and the filter screen 6 is connected to a return pipe 7, and the return flow The pipe 7 is connected with a water storage tank 8, and the water storage tank 8 is connected with the sprinkler 4 to form a circulating water circuit. The water collection tank 5, filter screen 6, water storage tank 8 and shower 4 of this embodiment form a circulating waterway, which can collect, filter and reuse the water after washing, saving water resources and reducing processing costs. More economical and environmentally friendly.

Embodiment 3

[0041] As a preferred improvement, a stirring blade 14 is installed in the cleaning box 13, and a filter cover is installed around the stirring blade 14.

[0042] The cleaning box 13 of the present invention is equipped with stirring blades 14, which can make the water in the cleaning box 13 generate rapid convection to clean the dirt, so that the dirt on the surface of the eggshell can be quickly dropped off, and the cleaning efficiency is improved. A filter cover is installed around the stirring blade 14 of the present invention, which can protect the stirring blade 14 and prevent dirt from damaging the blade, causing the stirring blade 14 to stop working and causing losses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com