Patents

Literature

120 results about "Milk flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

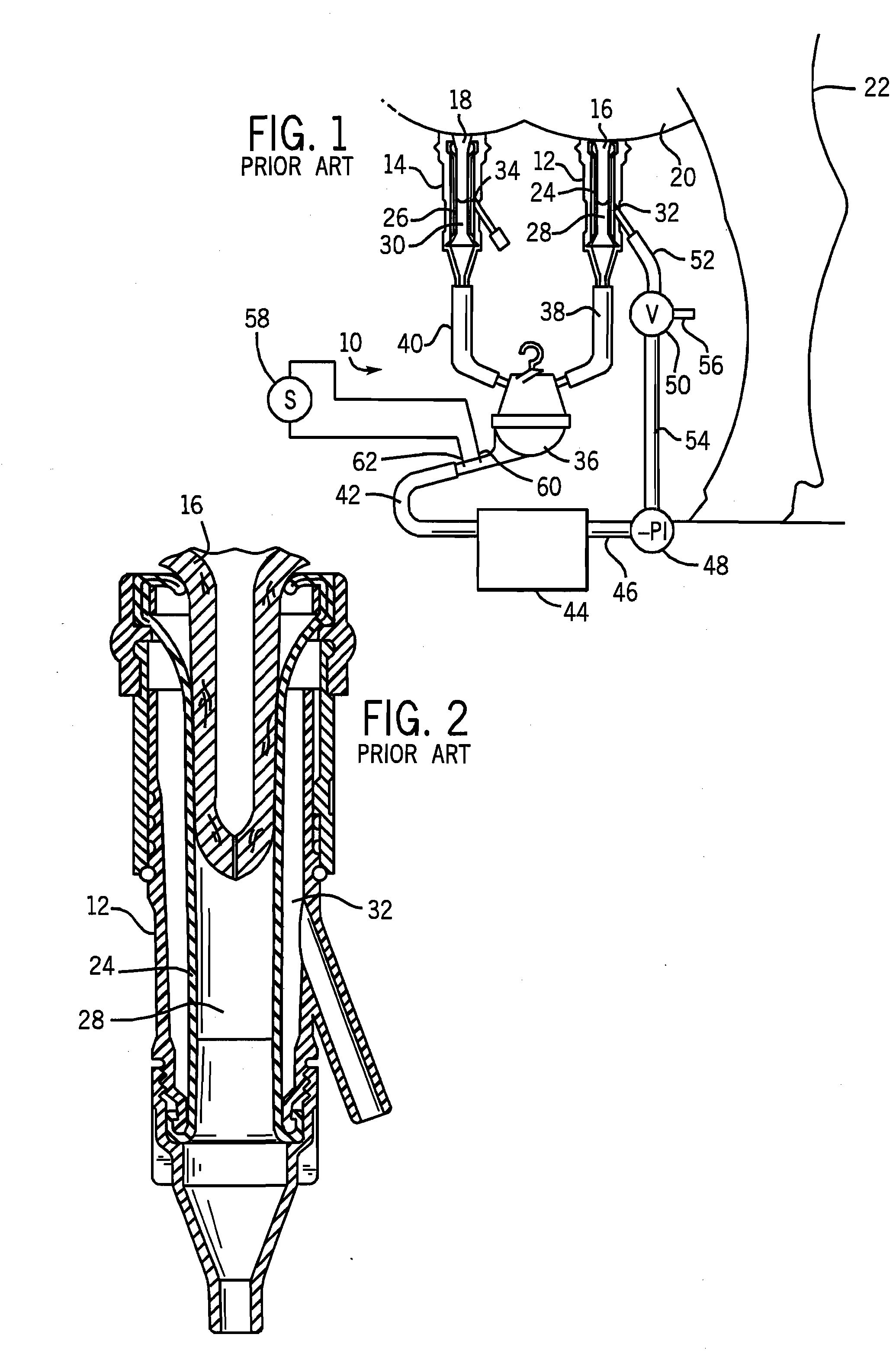

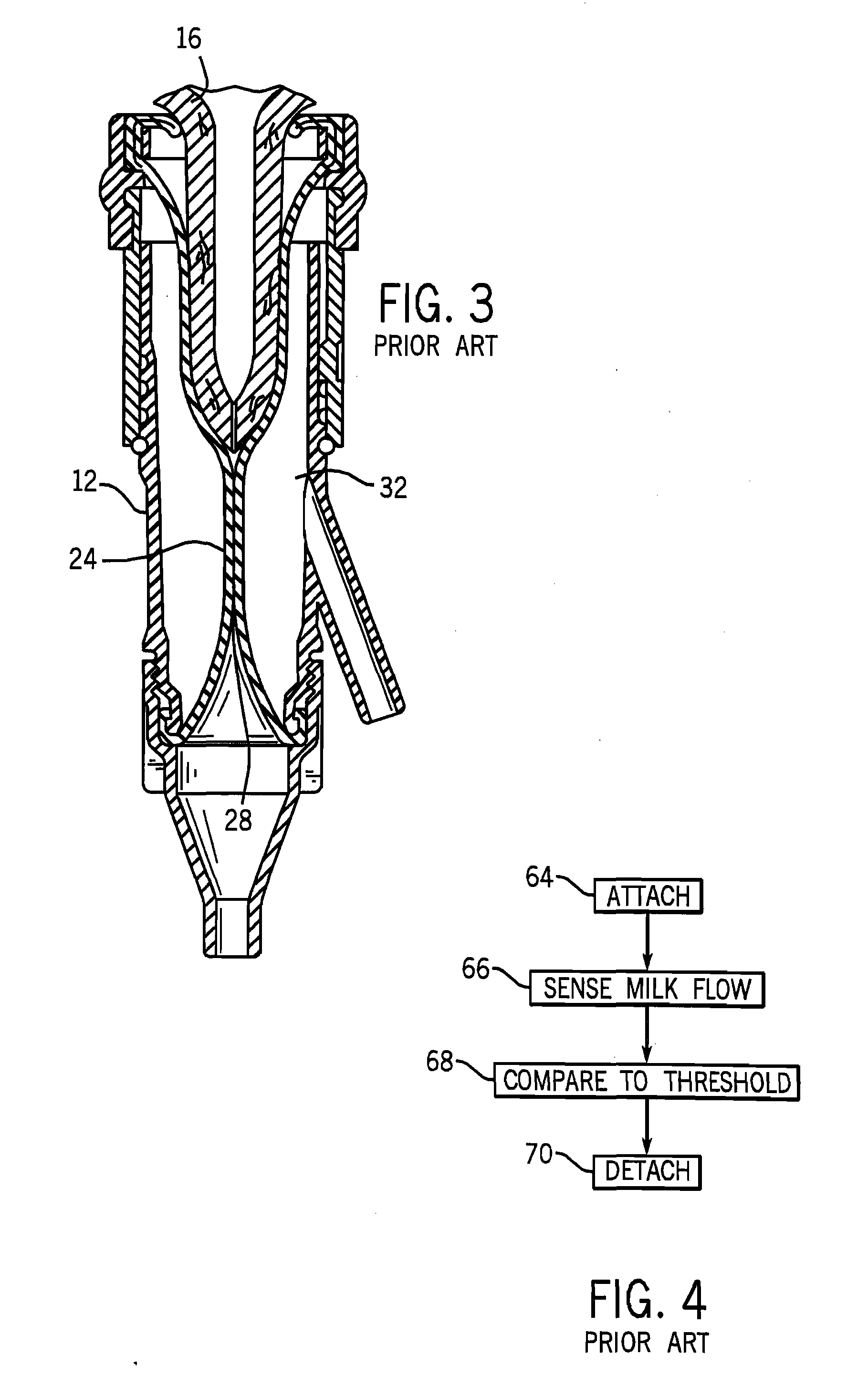

Milk flow monitor and milker unit detacher

A milk monitor with a sensor positioned near the milker unit to monitor milk conditions and adjust a variety of dairy facility operations in response to milk conditions. The milk monitor is programmable to provide flexibility, real-time adjustment of dairy operations, and trend analysis and control to optimize milk production and herd health.

Owner:GOMPPER BRION +2

Optimization of milking

Owner:DELAVAL HLDG AB

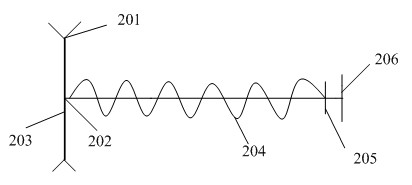

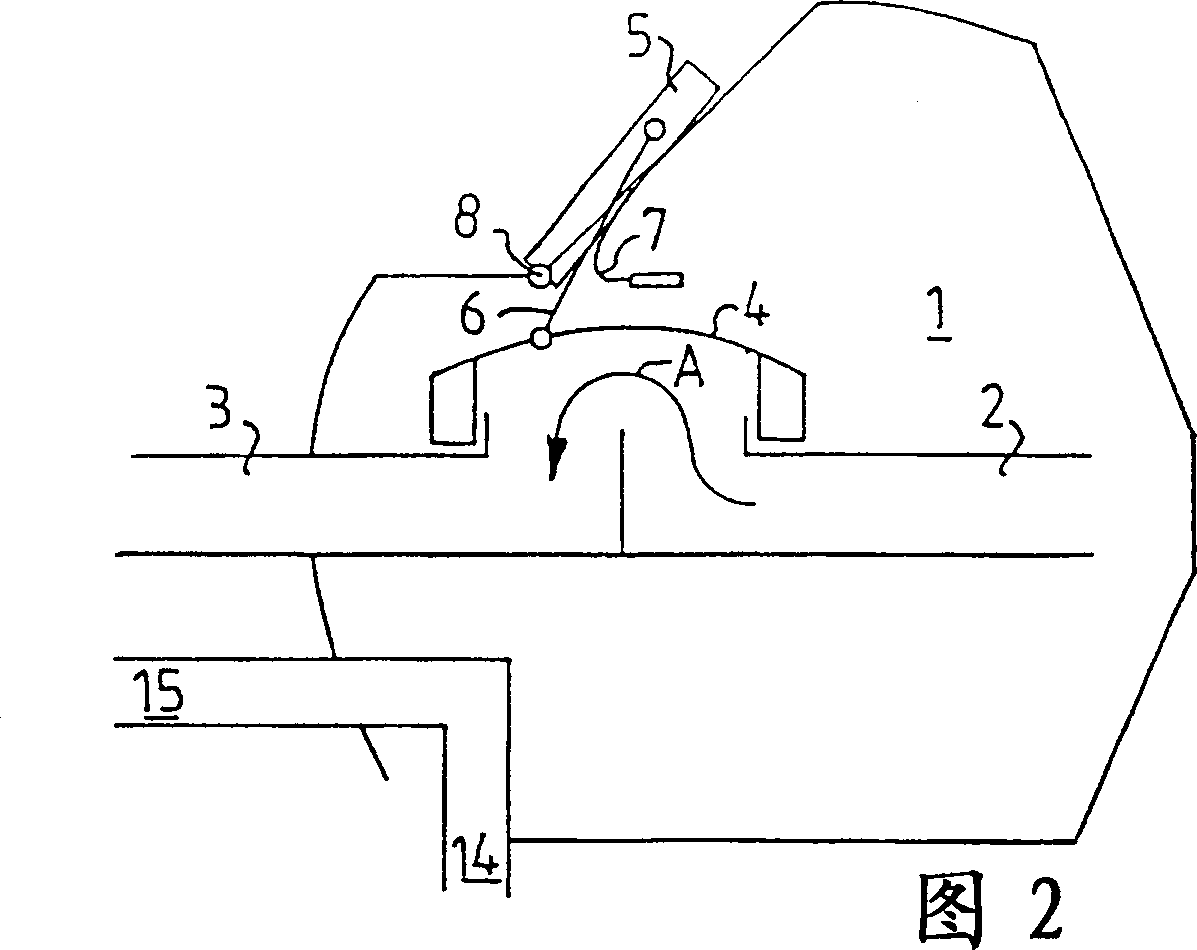

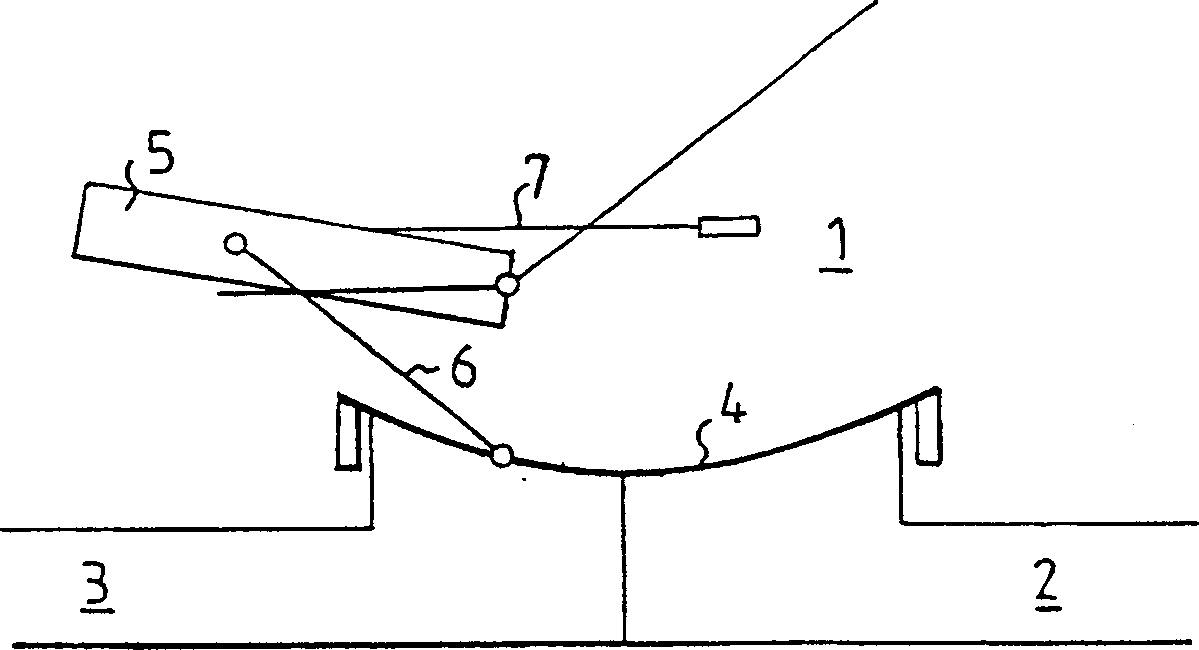

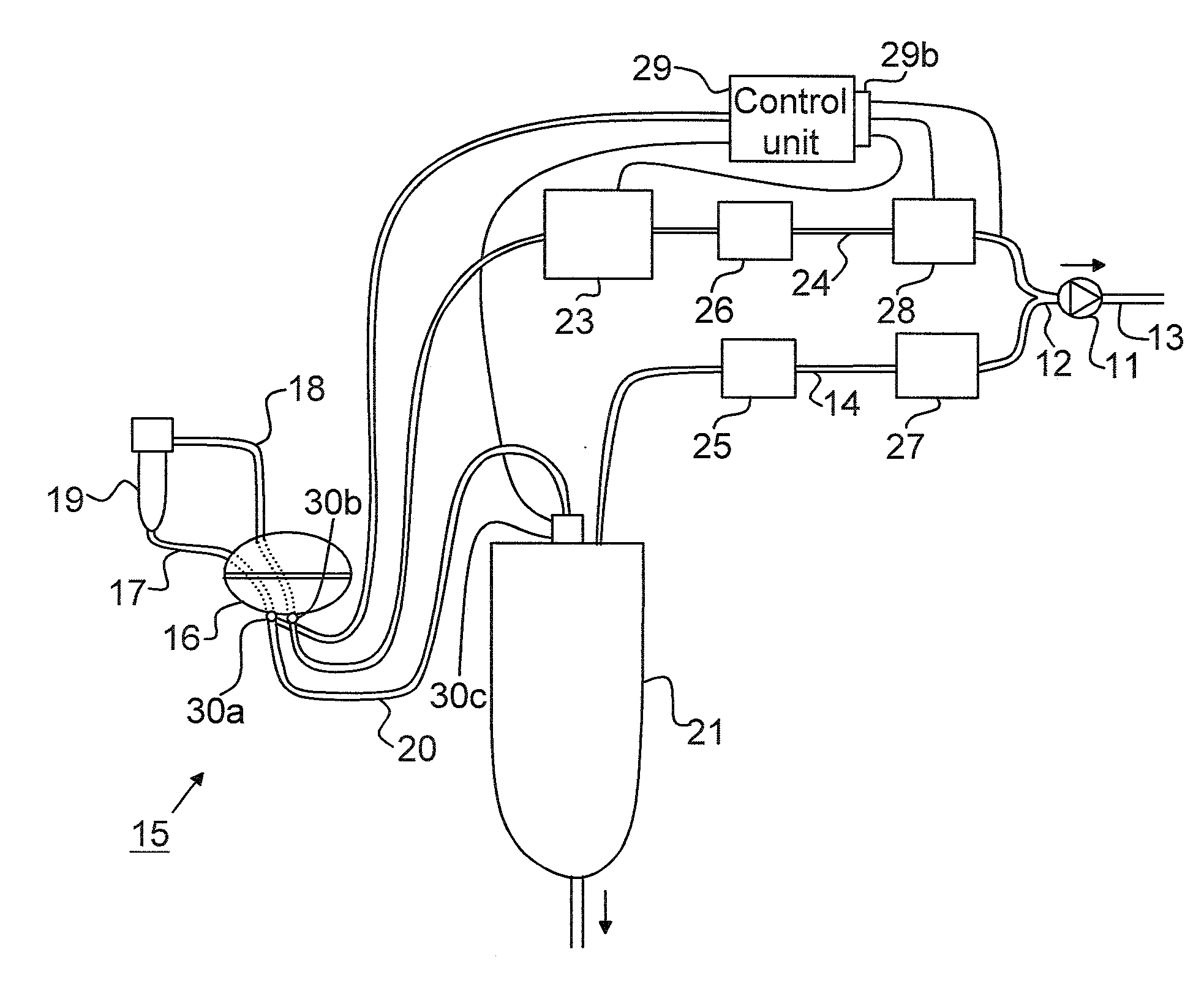

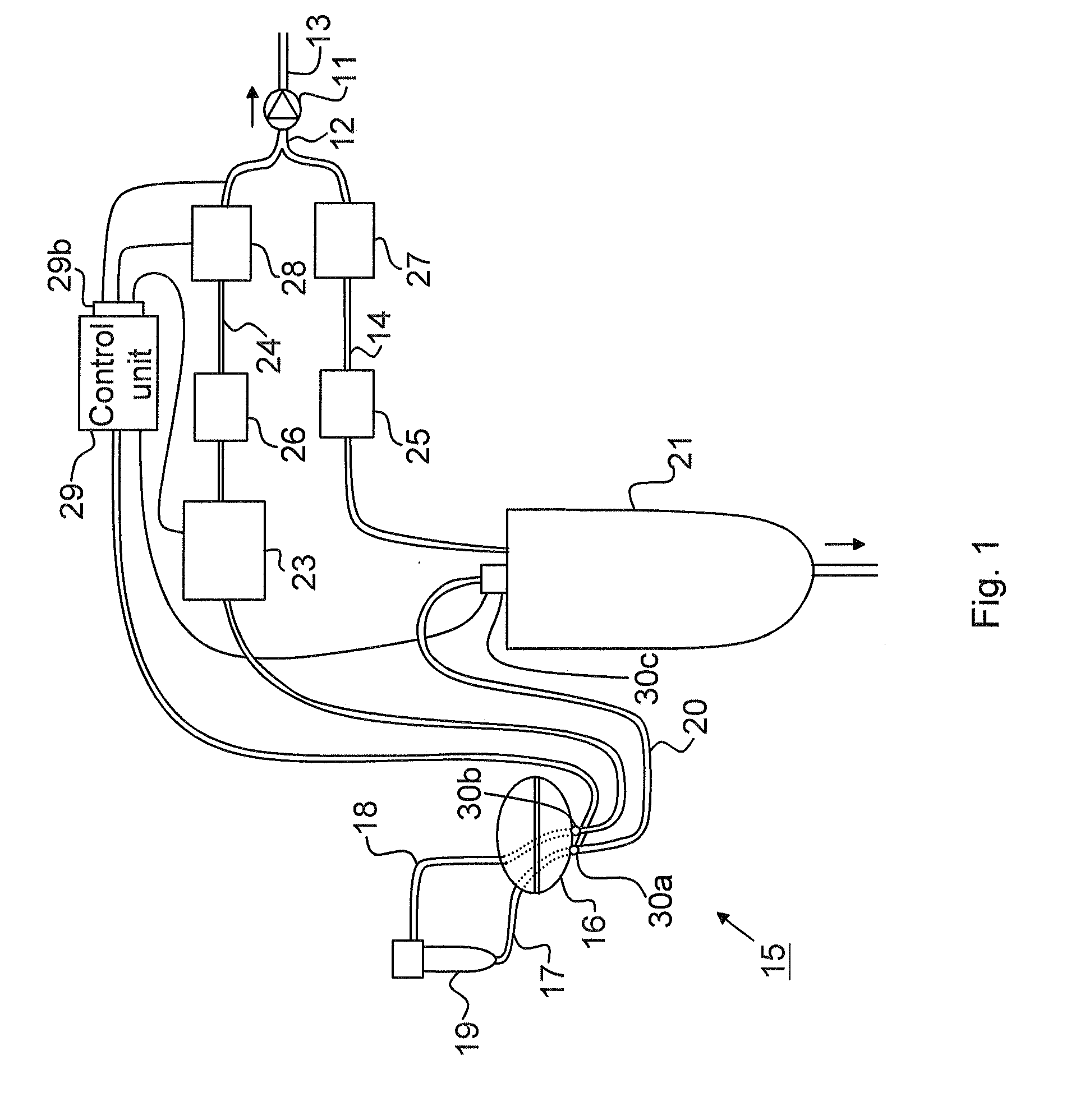

Device and a method for sampling of milk

InactiveUS20050223996A1The method is simple and fastEliminate riskCathetersWithdrawing sample devicesLine tubingMilk sample

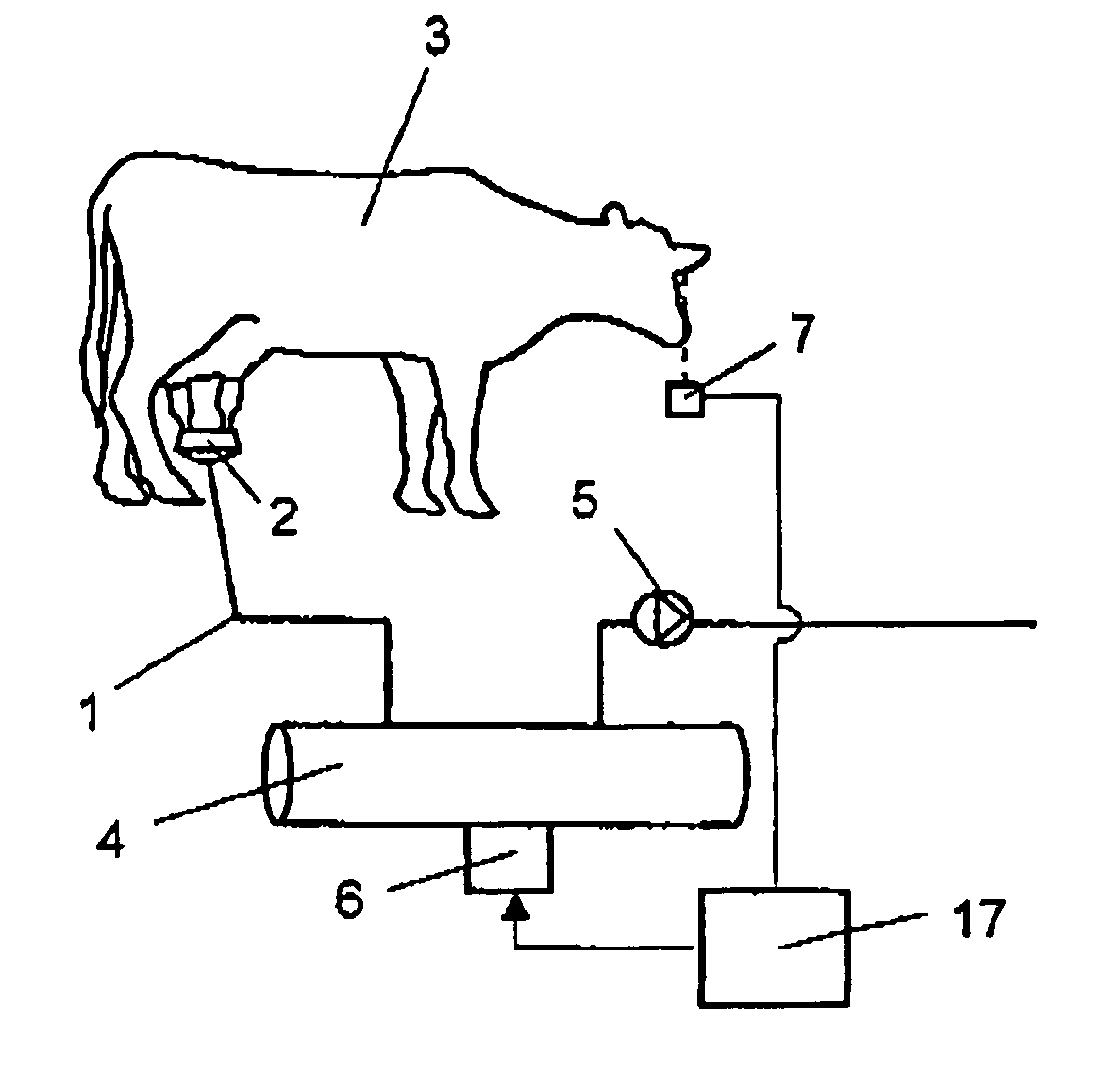

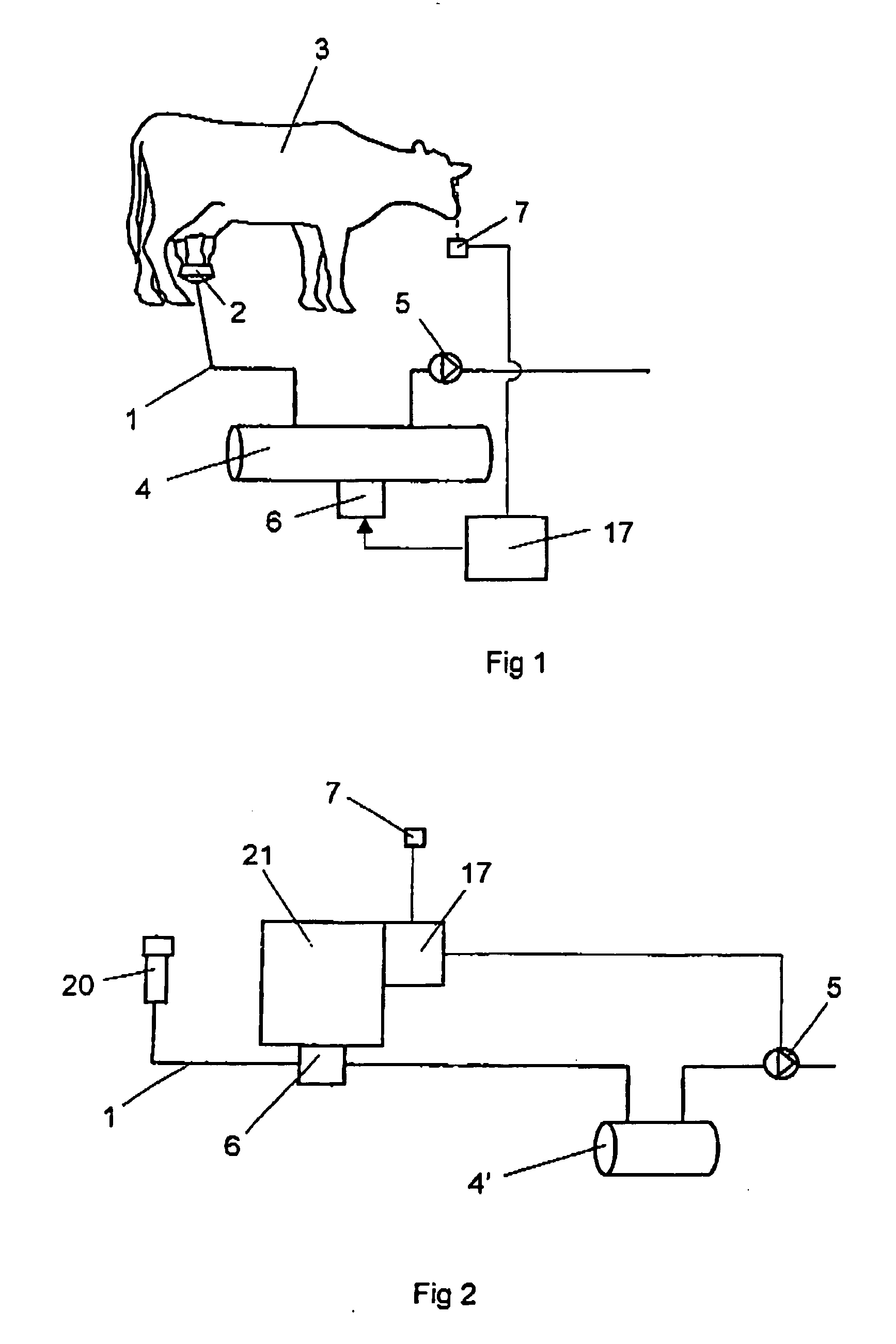

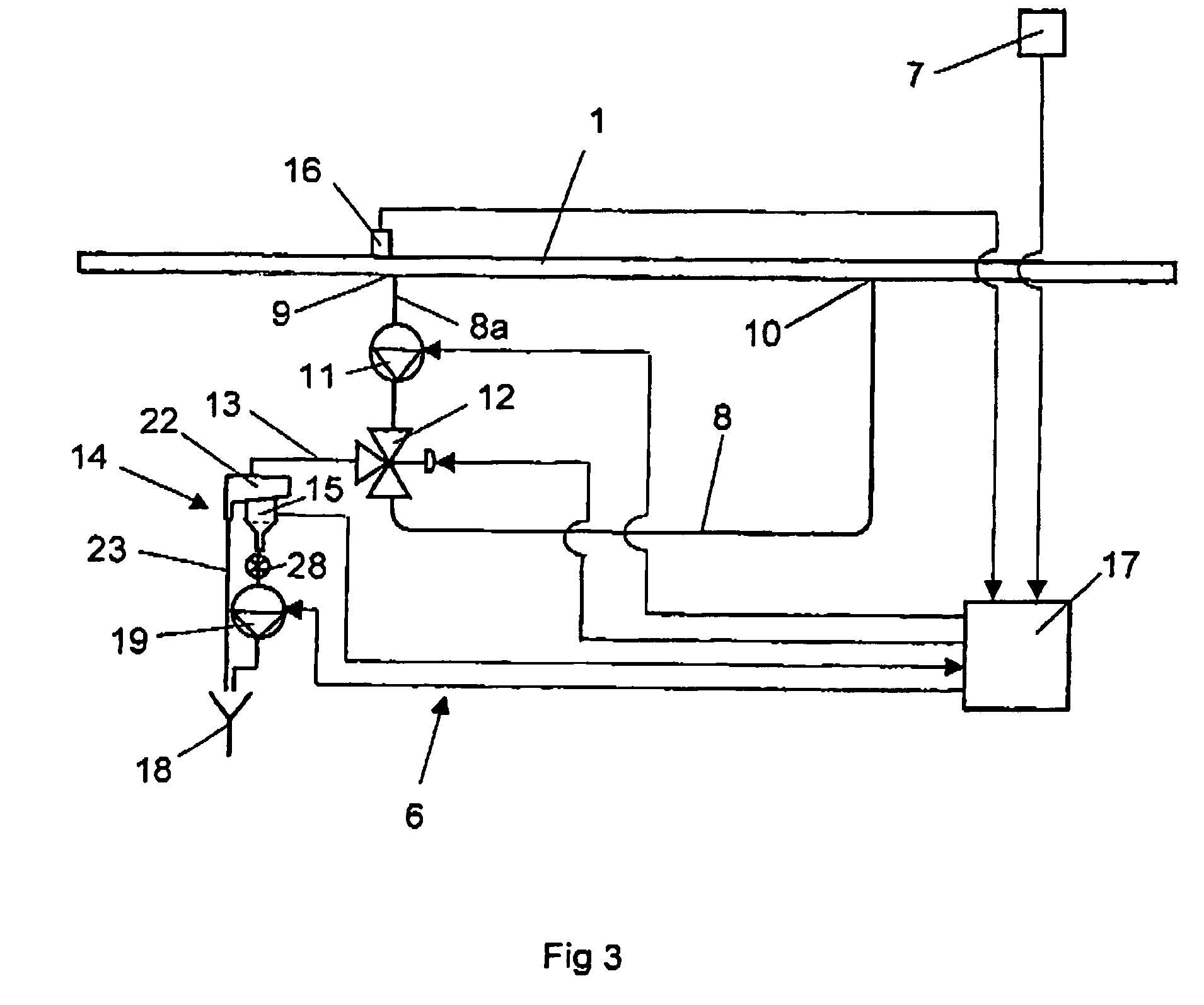

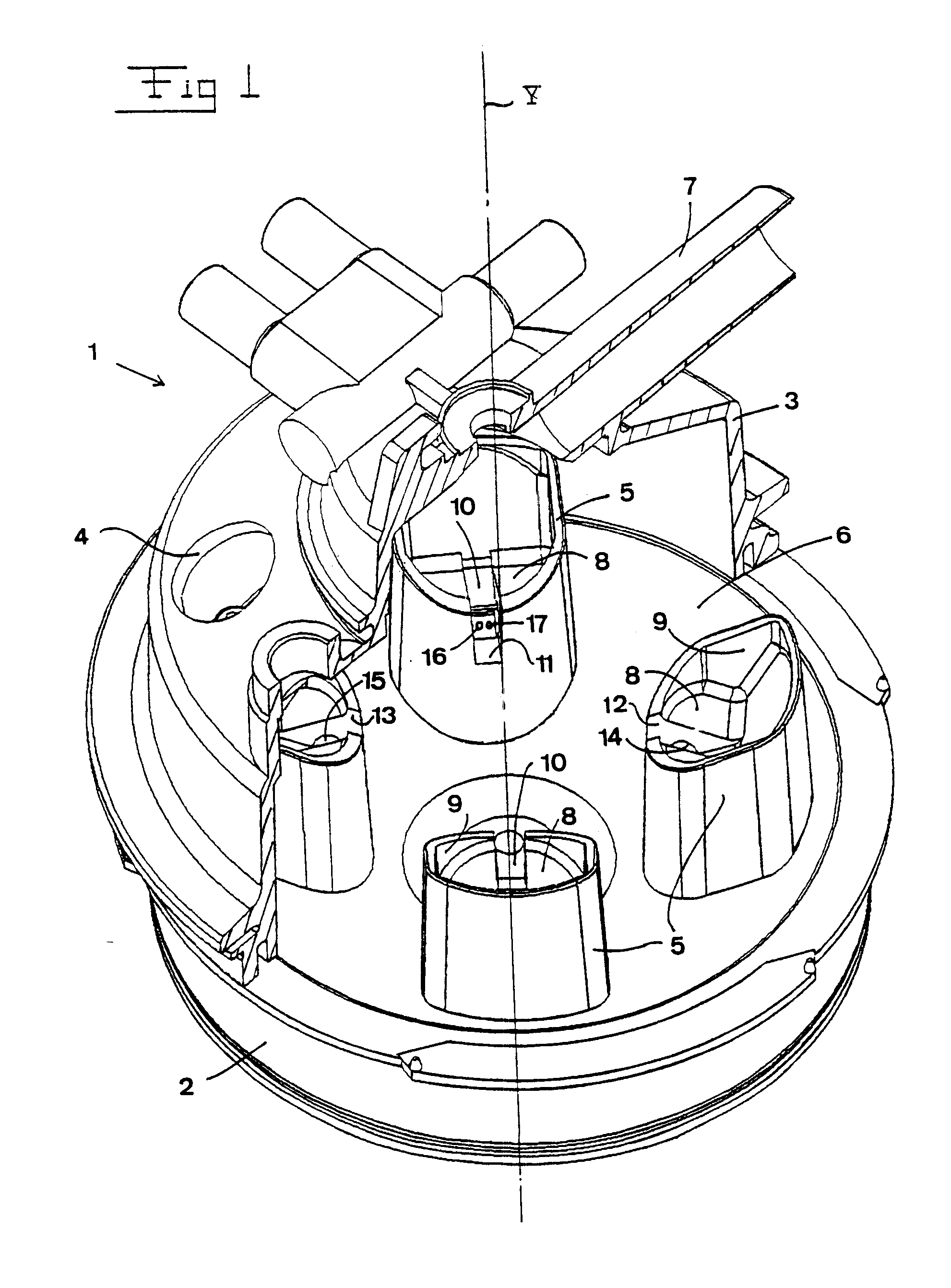

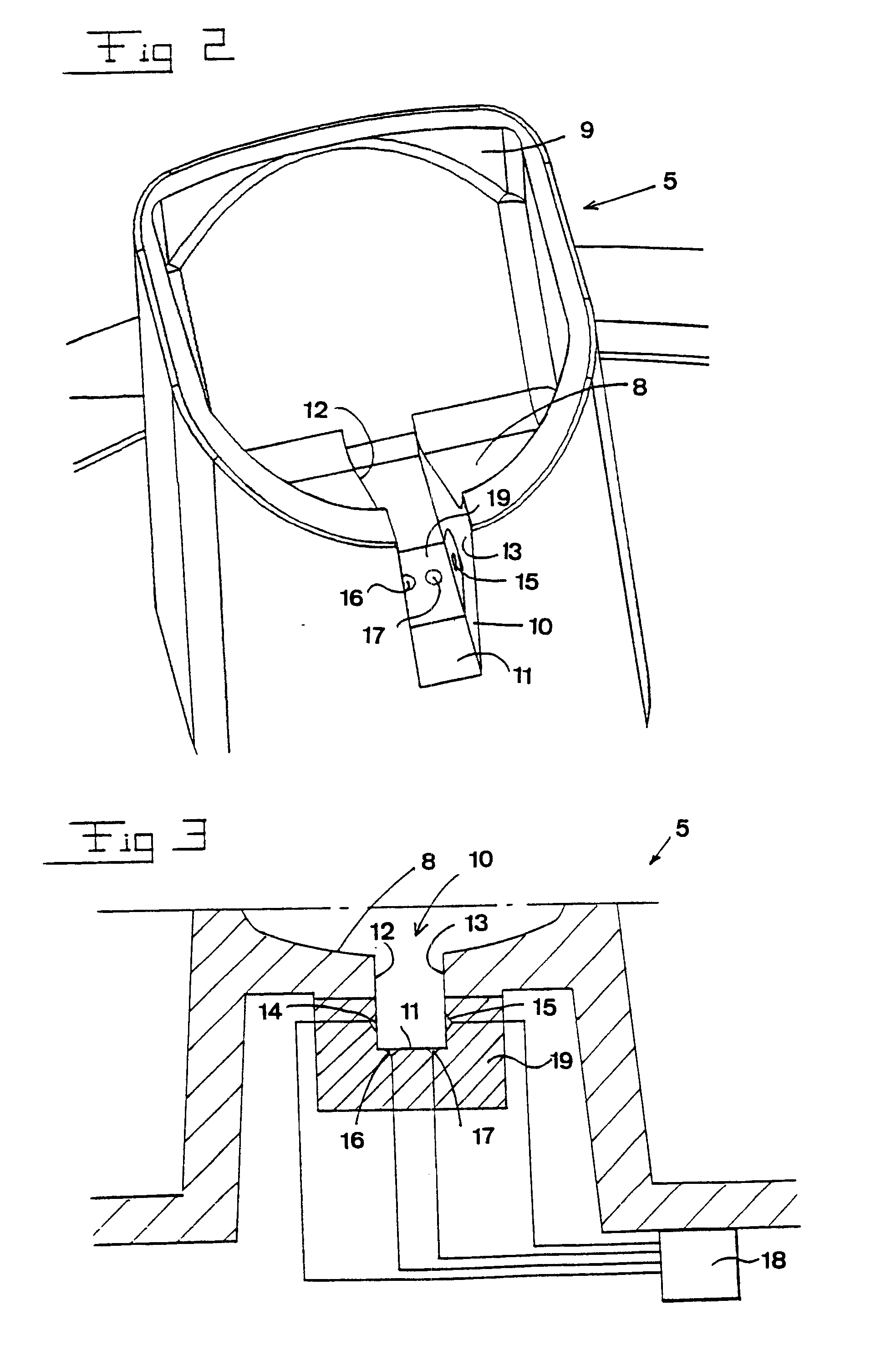

This invention relates to a device and a method for sampling of milk. The device includes a collecting member (15, 15′) arranged to receive milk samples from a milk line (1), which is arranged to transport milk from one animal (3) at a time, and a passage (8a, 12″, 13) arranged to allow a milk flow from the milk line (1) to the collecting member (15, 15′). The device comprises flow means (11, 19) arranged to provide a milk flow, from the animal (3), through at least a part of the passage (8a, 12″, 13) at least a time period before a milk sample is to be taken in order to rinse at least the part of the passage (8a, 12″, 13) from milk residues from a previously milked animal.

Owner:DELAVAL HLDG AB

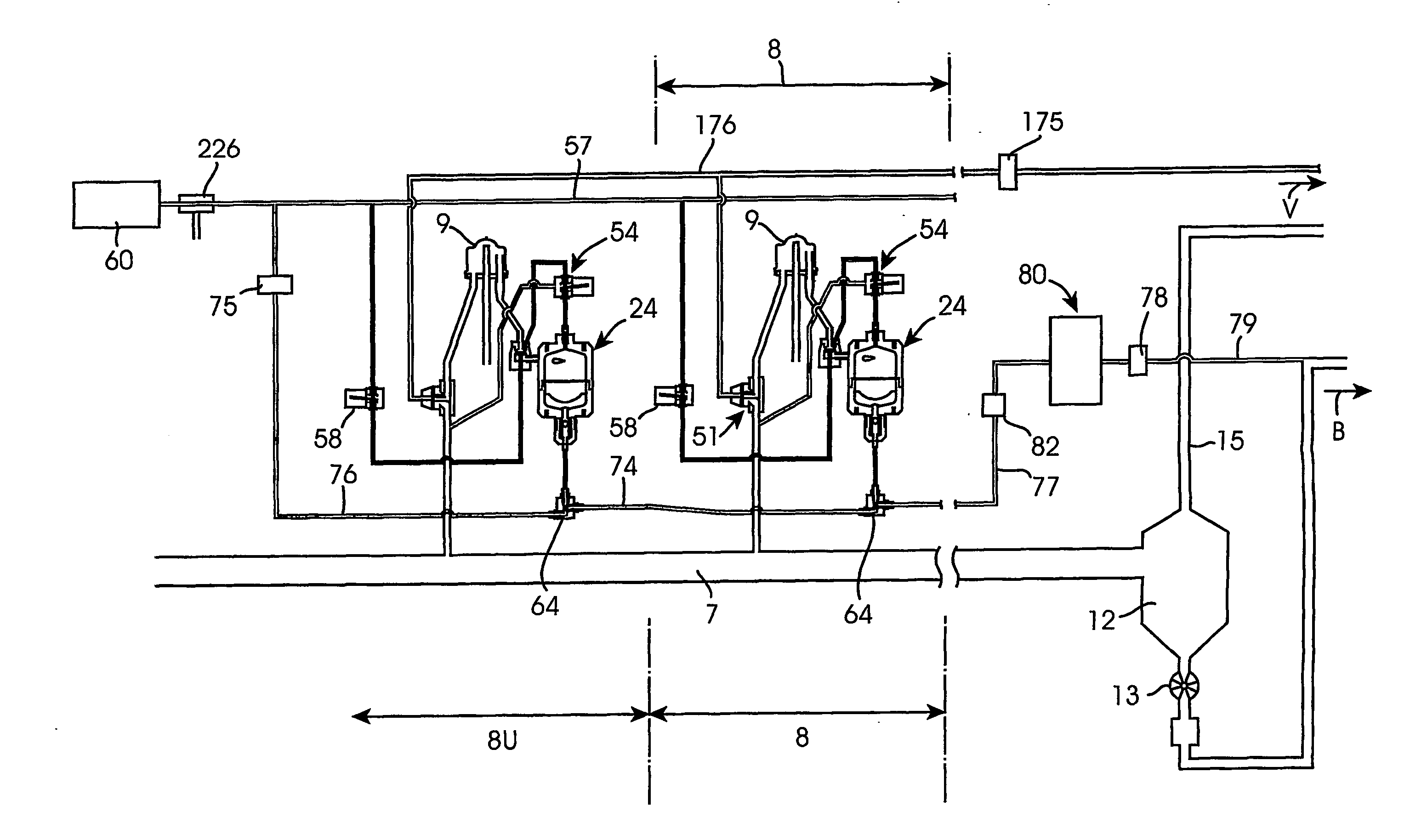

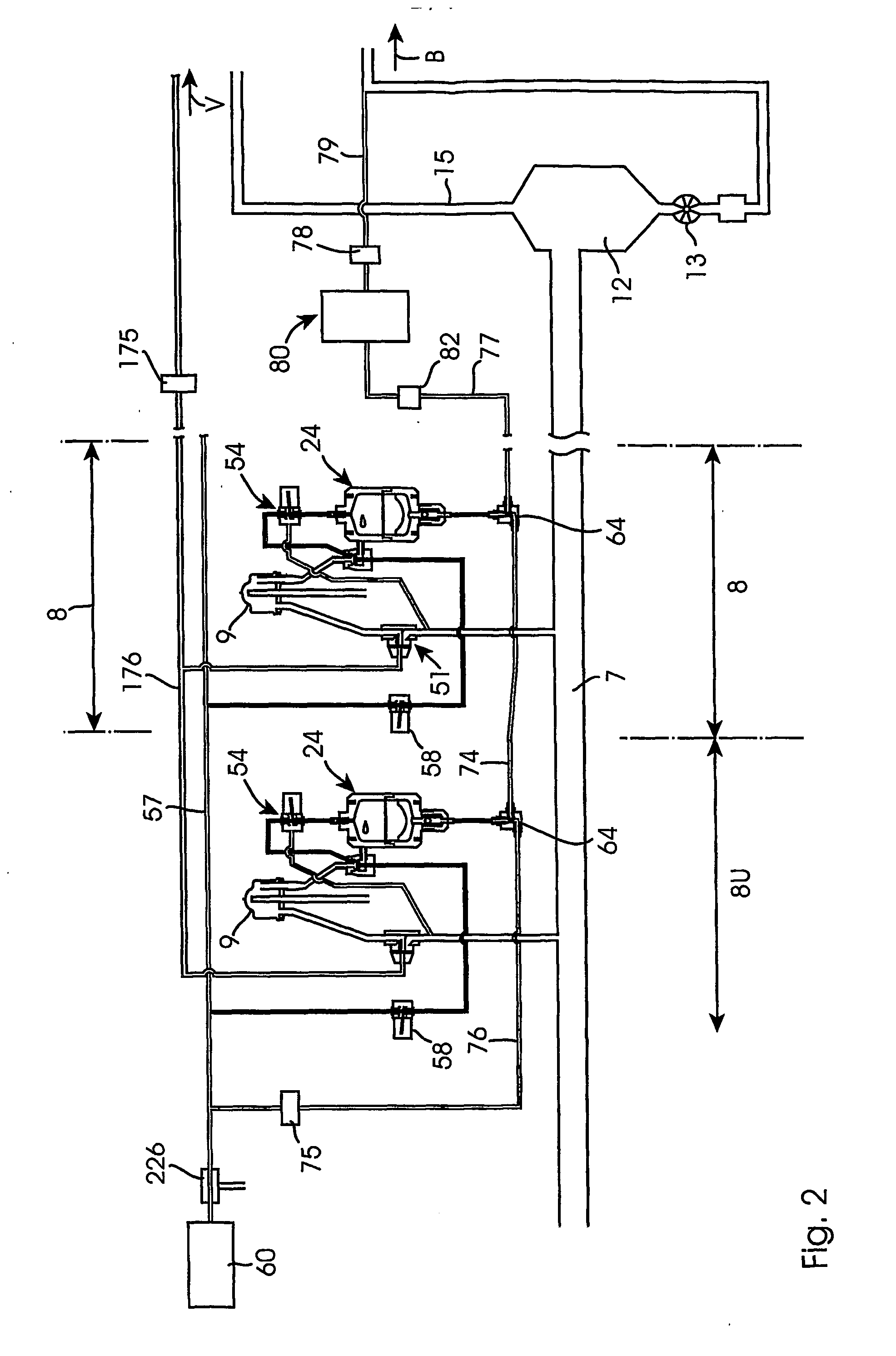

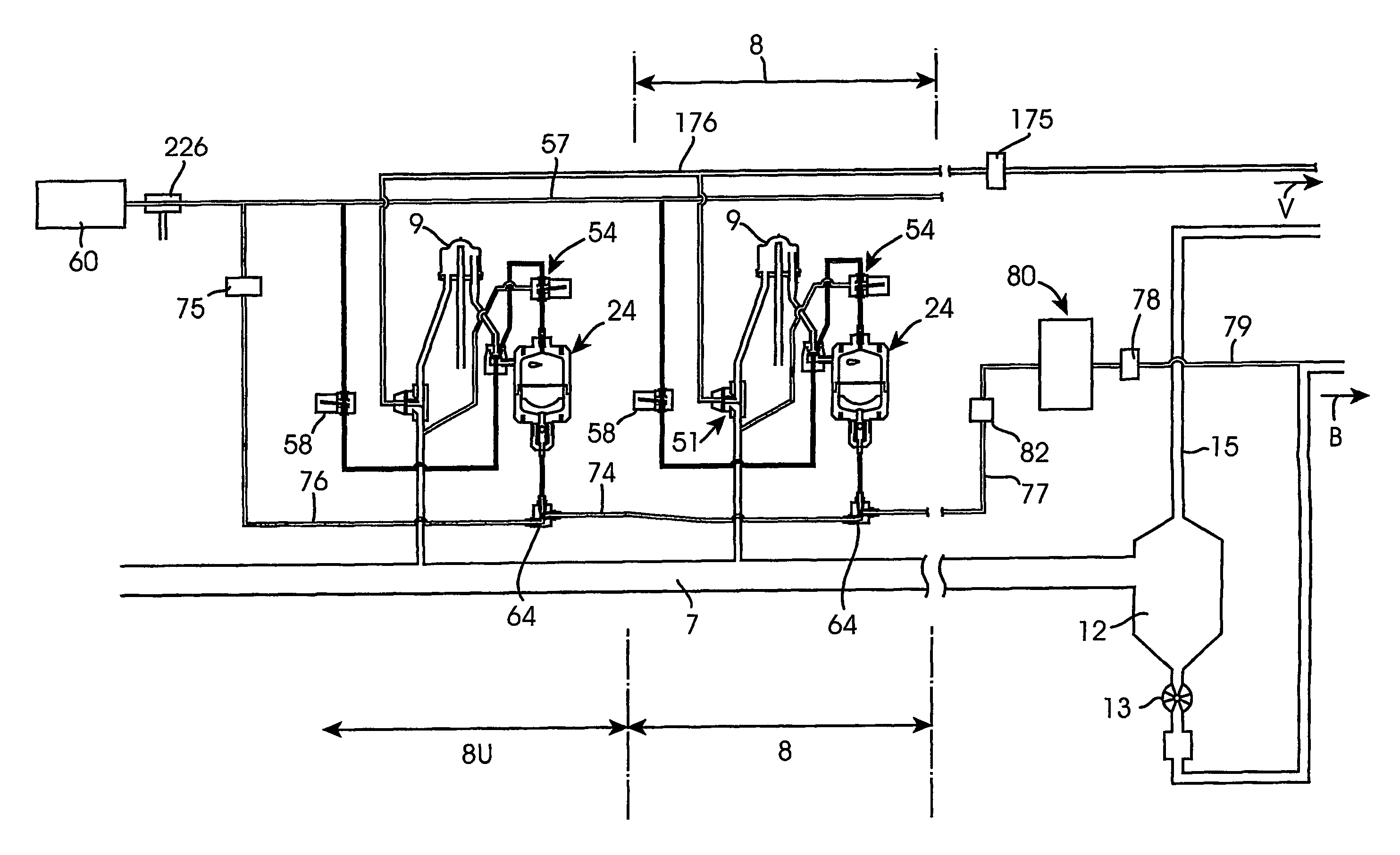

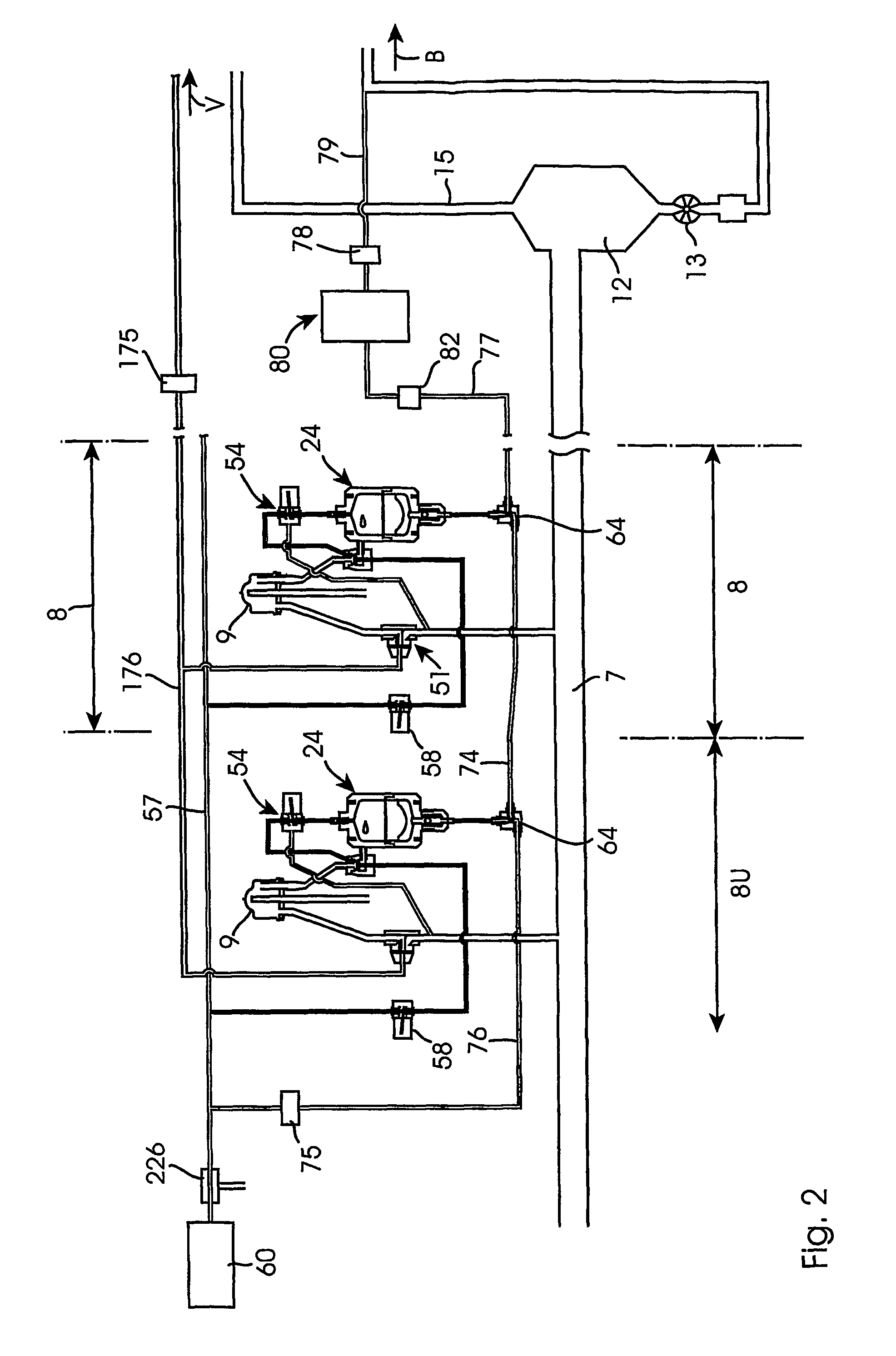

Milk sampling and testing

A method of collecting a sample of milk while milking a succession of animals comprises diverting a portion of milk from an animal into a flowpath (74, 77) leading to an extraction point (80). The flowpath (74, 77) is dimensioned such that milk flows along the flowpath as a plug occupying the whole of its cross-section and allows some of the milk from the animal to pass the extraction point (80). Thereafter the milk is transferred into a container or other receiver and at least some of the remaining milk of that animal reaching the extraction point.

Owner:AKERMAN DAVID ERIC

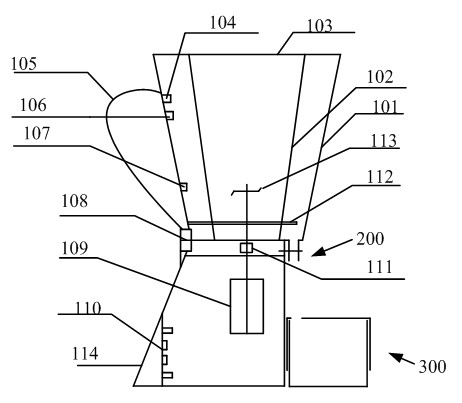

Heating method and heating device of soy milk and its application on soy milk machine

InactiveCN1426723AHigh degree of thermal expansionReduce temperature shrinkageBeverage vesselsEngineeringHigh pressure

A method and its device for heating soybean milk are disclosed, and can be used for domestic soybean milk maker. Its heater is composed of external cylinder and its cover and internal cylinder whose top is fastened to the inner surface of the said cover and whose side wall is perforated. When soybean milk is boiling, a slightly higher pressure is formed at upper part of internal cylinder to make the hot milk flow into the external cylinder through the holes. It is circulated between internal and external cylinders at 100-105 deg.C for 4-10 min for emulsifying it well.

Owner:JOYOUNG CO LTD

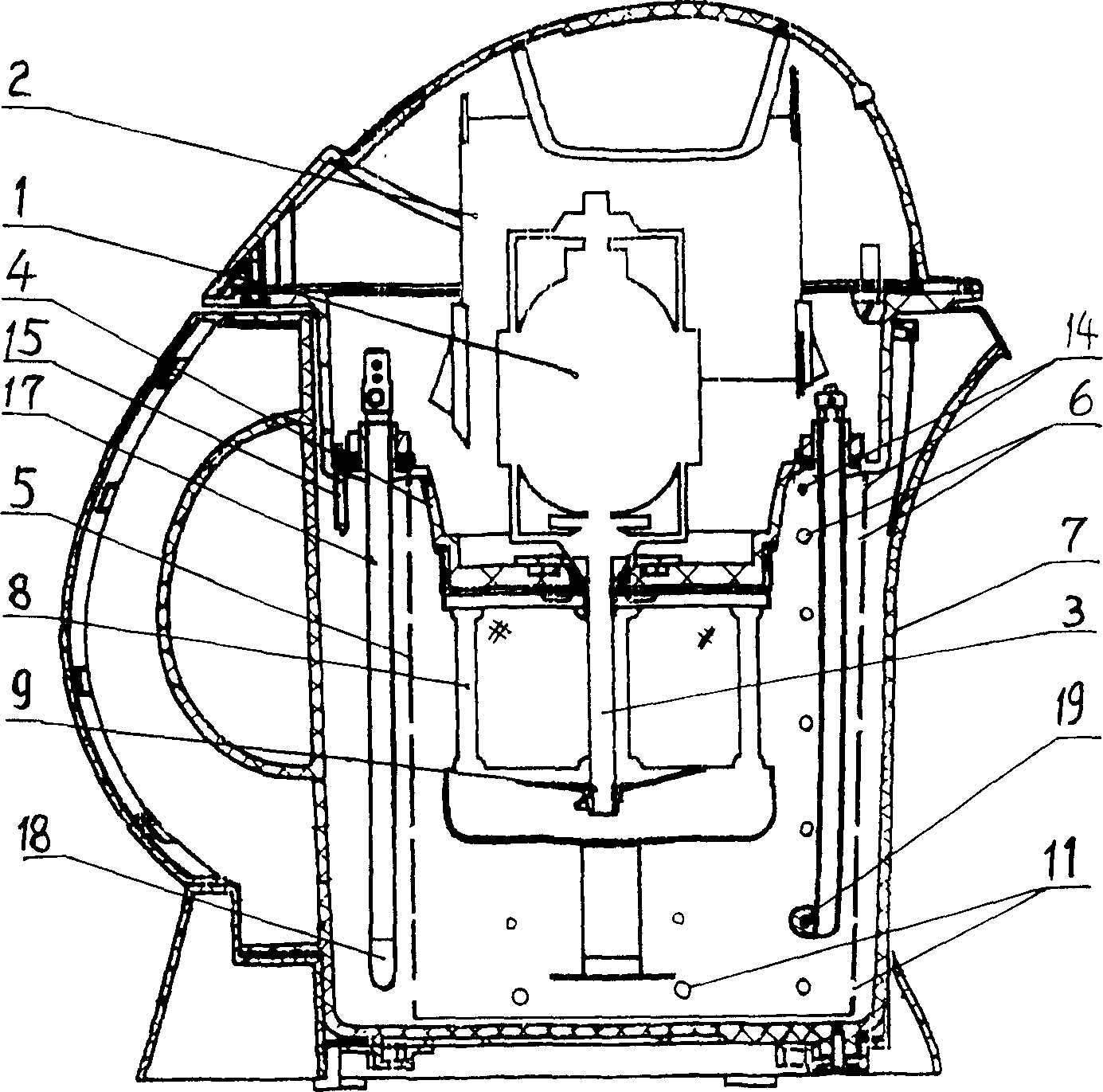

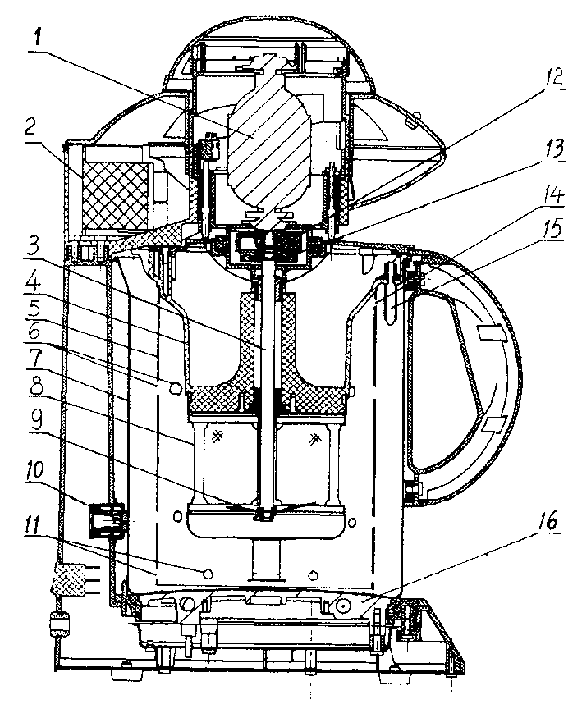

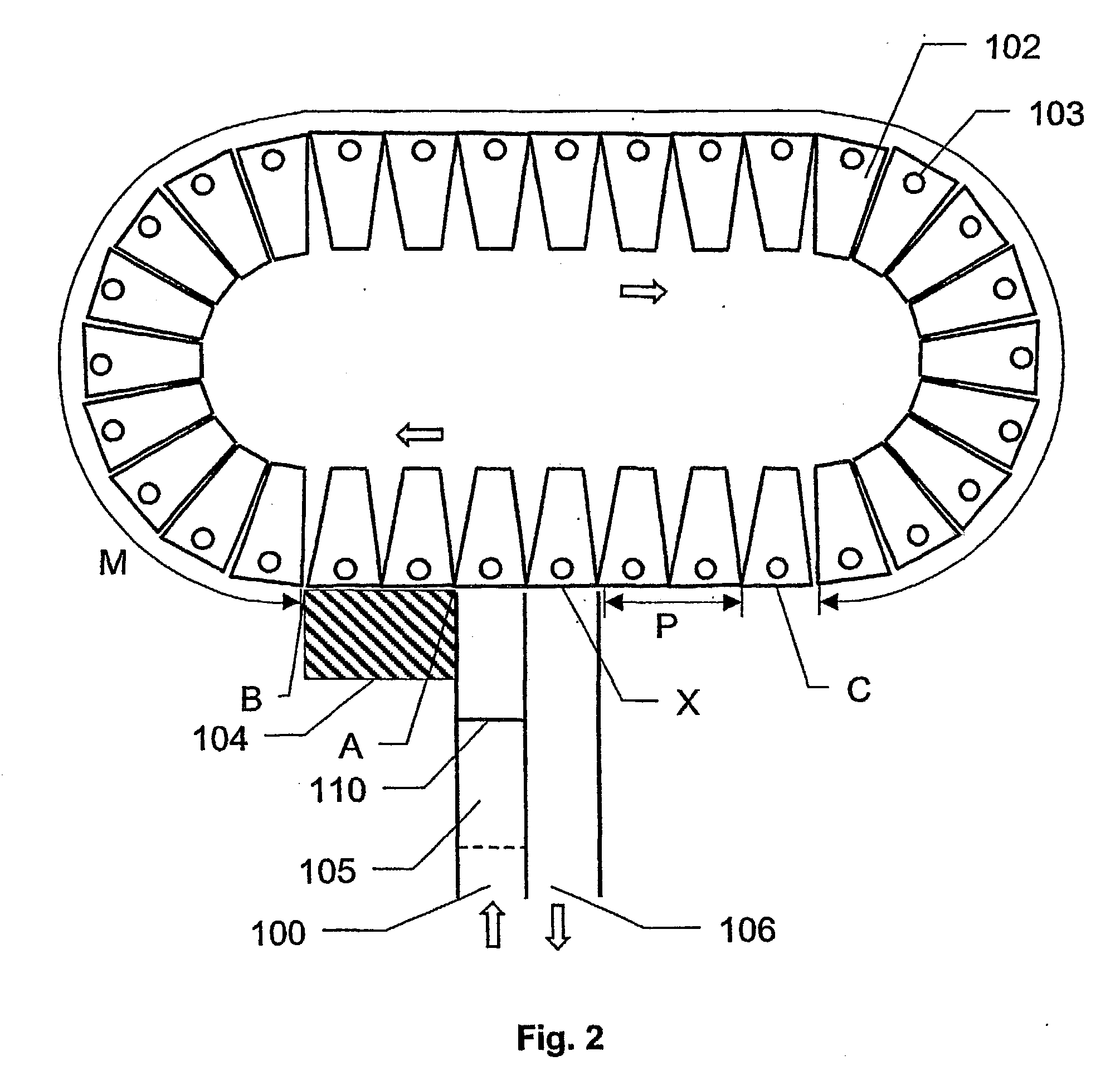

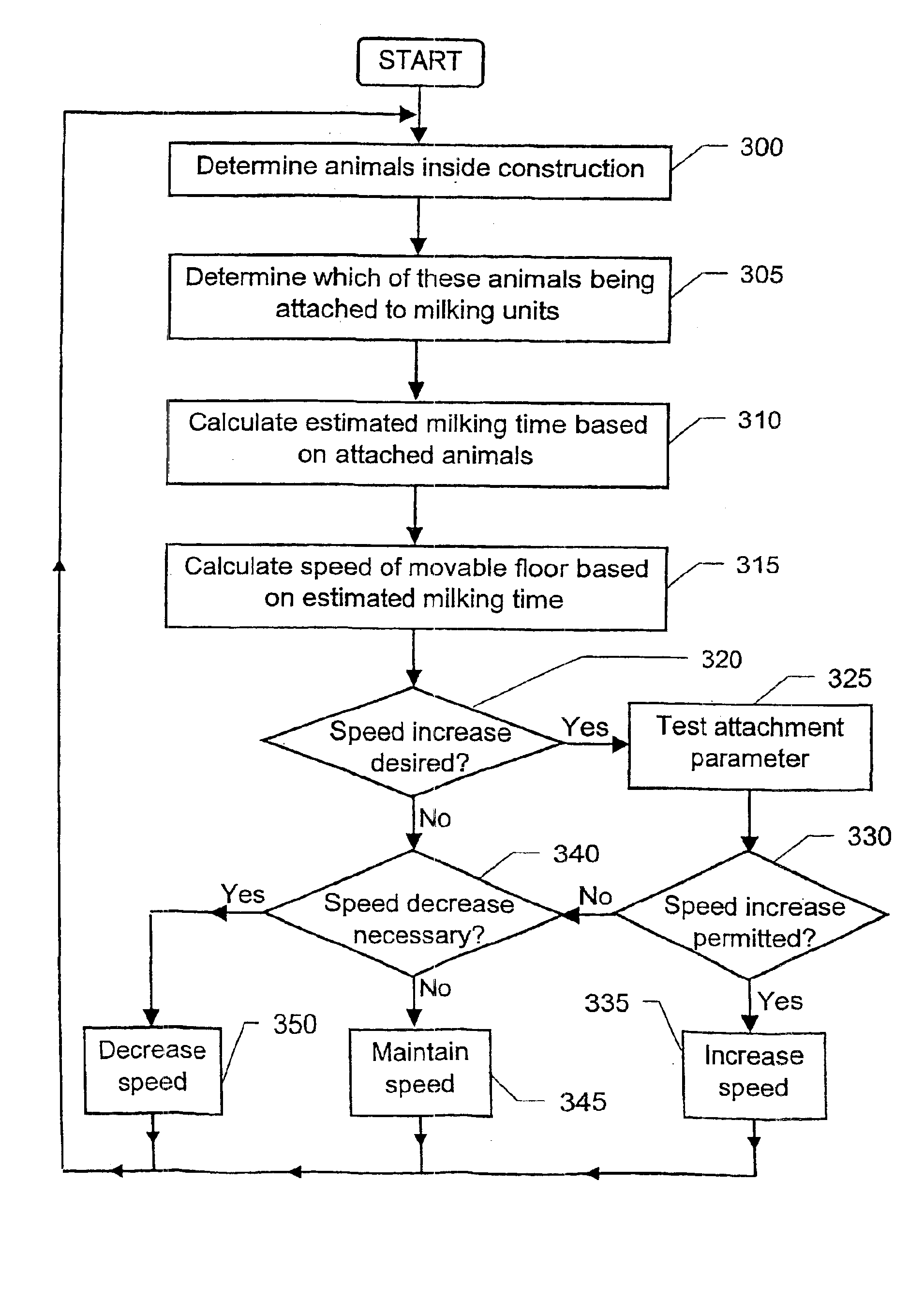

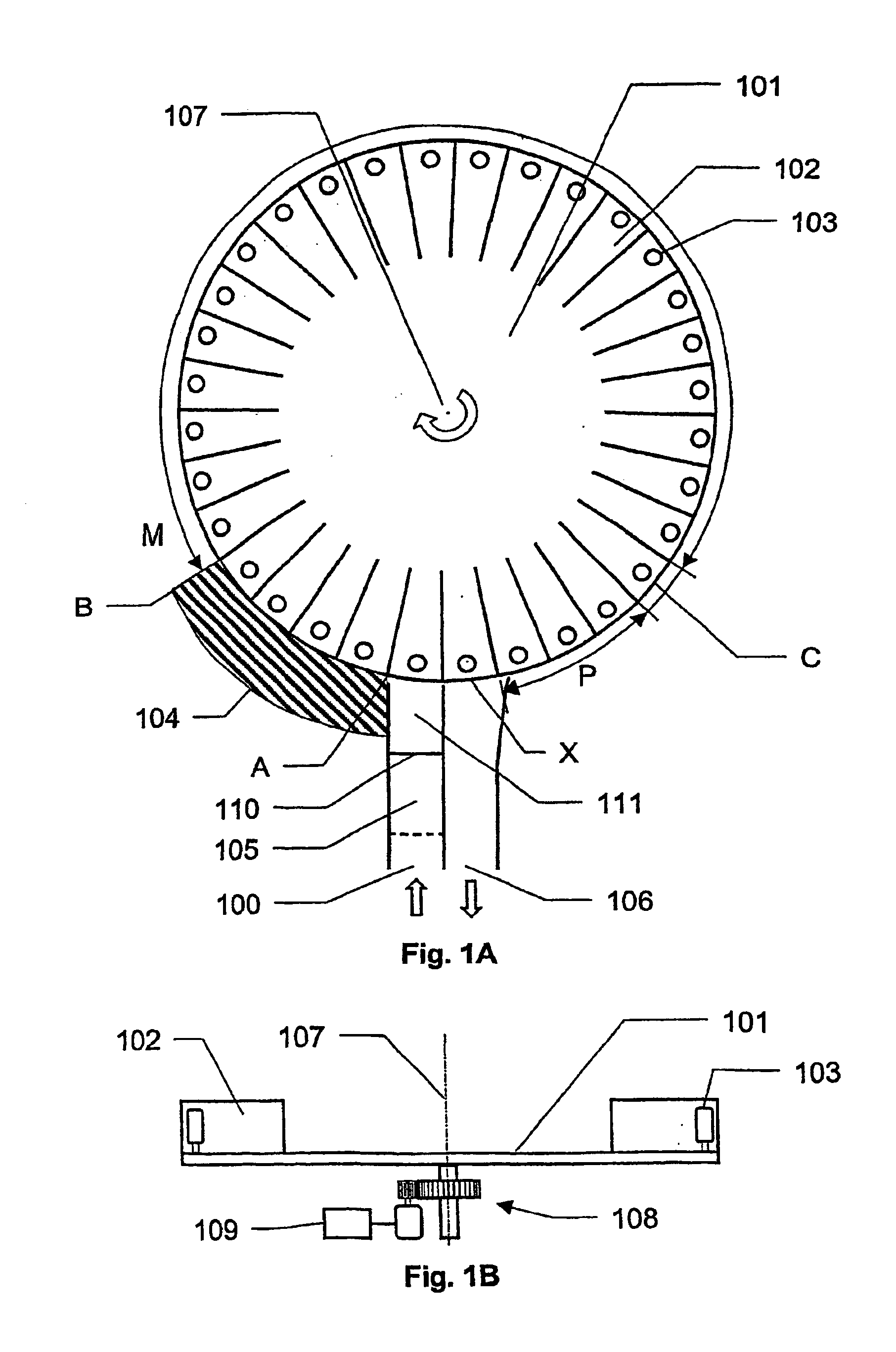

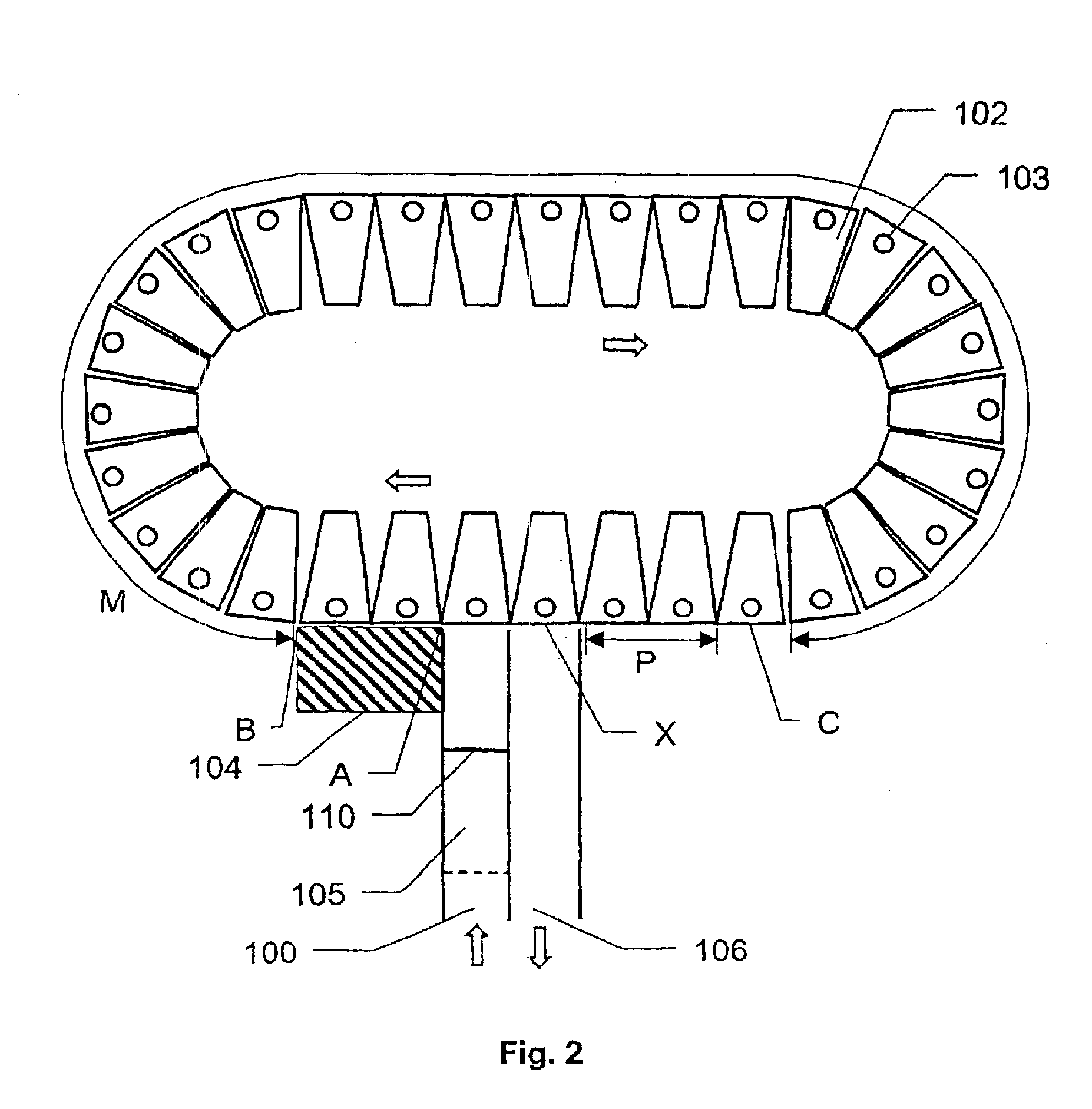

Construction for milking of animals

InactiveUS20030150389A1Introduces elasticityReduce mechanical stressCathetersAnimal housingOccupancy rateEngineering

The invention relates to a method of milking animals which uses an implement having a moveable floor on which the animals are milked in milking spaces. The animals enter and exit the floor via automatic gates. The invention involves automatic adjustment of the speed to the moveable floor first, on an estimated milking time of the animals presently in a milk flow mode, i.e. attached to a milking unit and second whether milking units have been attached to the animals before leaving an attachment zone, where the milking units are attached to the animals, either manually or automatically by a robot. The speed of the movable floor is primarily adjusted with the aim at optimizing the occupancy rate of the implement for milking animals with respect to the first condition. The second condition places constraint on when a speed increase is permitted.

Owner:DELAVAL HLDG AB

Construction for milking of animals

InactiveUS6883461B2Reducing any accurateness in the estimated milking timeImprove throughputCathetersAnimal feeding devicesOccupancy rateEngineering

Owner:DELAVAL HLDG AB

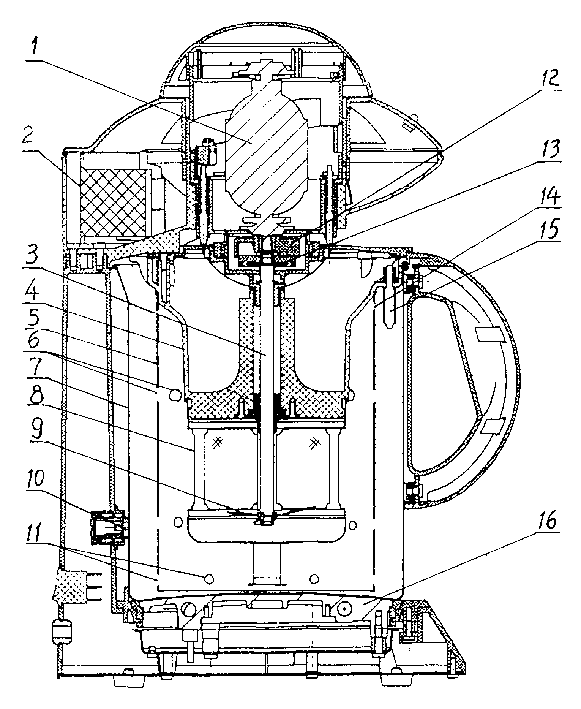

Automatic bean curd maker and soybean milk maker

InactiveCN102113572AAvoid Burnt SituationsImprove qualityBeverage vesselsCheese manufactureEngineeringMechanical engineering

The invention discloses an automatic bean curd maker and an automatic soybean milk machine. The automatic bean curd maker comprises a soybean milk cup, a filter screen, a heater, a motor, a stirrer and a controller, wherein the filter screen is arranged in the soybean milk cup, and the stirrer is connected with the motor and arranged in the filter screen; and the automatic bean curd maker furthercomprises a discharging valve and a bean curd box, wherein the discharging valve is arranged on the soybean milk cup, the bean curd box is used for holding the soybean milk flowing out from the discharging valve, and the controller is used for controlling a heater to heat water contained in the soybean milk cup to a set temperature and then controlling the motor to drive the stirrer to rotate; and the discharging valve comprises a valve motor, a hose, a press lever, a check block, a spring and a spring retaining wall, wherein the press lever and the check block are arranged on two sides of the hose, one side of the press lever is connected with the valve motor through a transmission lever, the opposite other side of the press lever is connected with one end of the spring, the other end ofthe spring is connected with the spring retaining wall, and the valve motor is use for driving the press lever to act.

Owner:SHENZHEN ROTA INTELLIGENT LIFE APPLIANCE

Heating method of soy milk and its application on soy milk machine

InactiveCN1160013CHigh degree of thermal expansionReduce temperature shrinkageBeverage vesselsEngineeringHigh pressure

A method and its device for heating soybean milk are disclosed, and can be used for domestic soybean milk maker. Its heater is composed of external cylinder and its cover and internal cylinder whose top is fastened to the inner surface of the said cover and whose side wall is perforated. When soybean milk is boiling, a slightly higher pressure is formed at upper part of internal cylinder to make the hot milk flow into the external cylinder through the holes. It is circulated between internal and external cylinders at 100-105 deg.C for 4-10 min for emulsifying it well.

Owner:JOYOUNG CO LTD

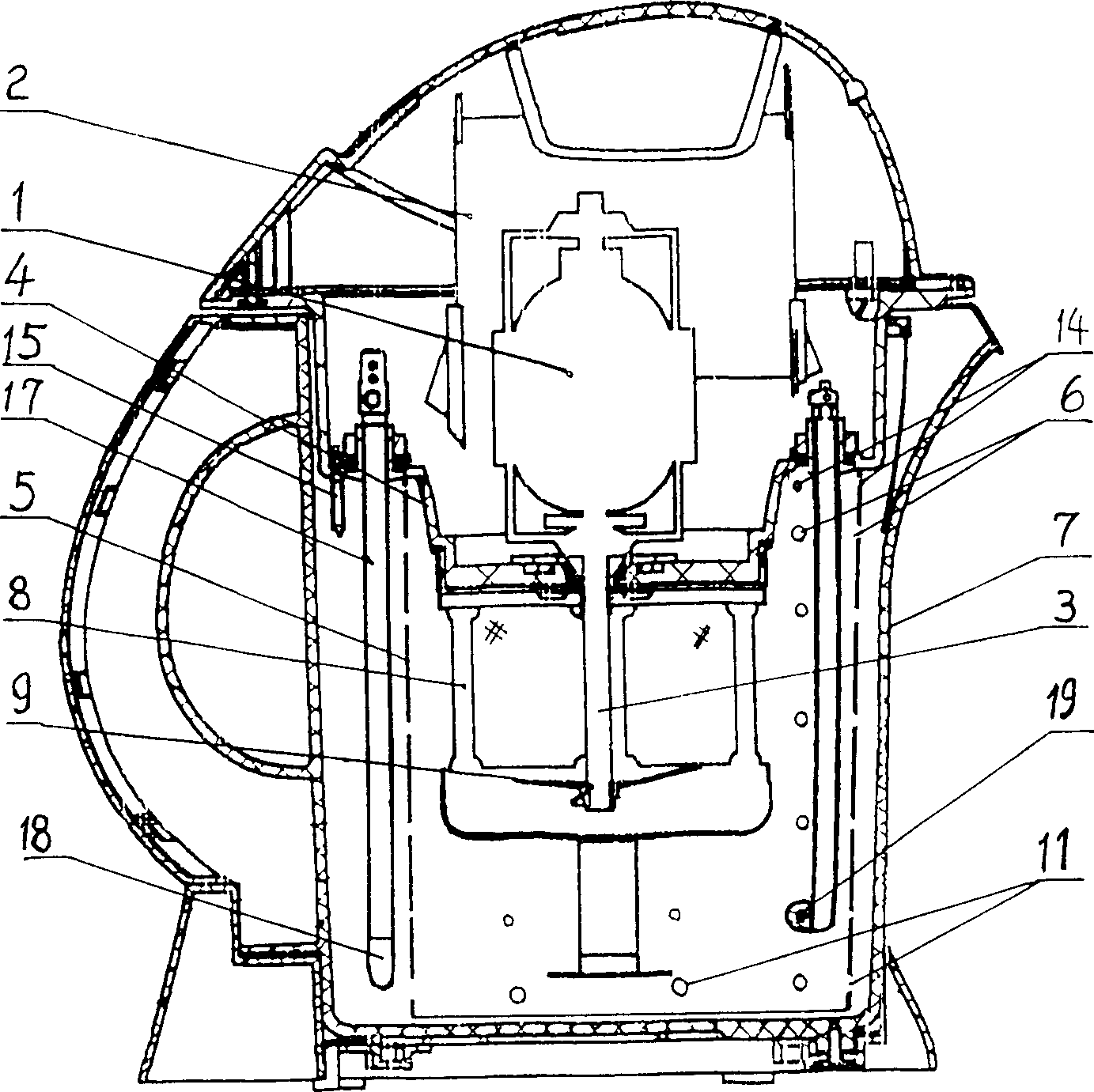

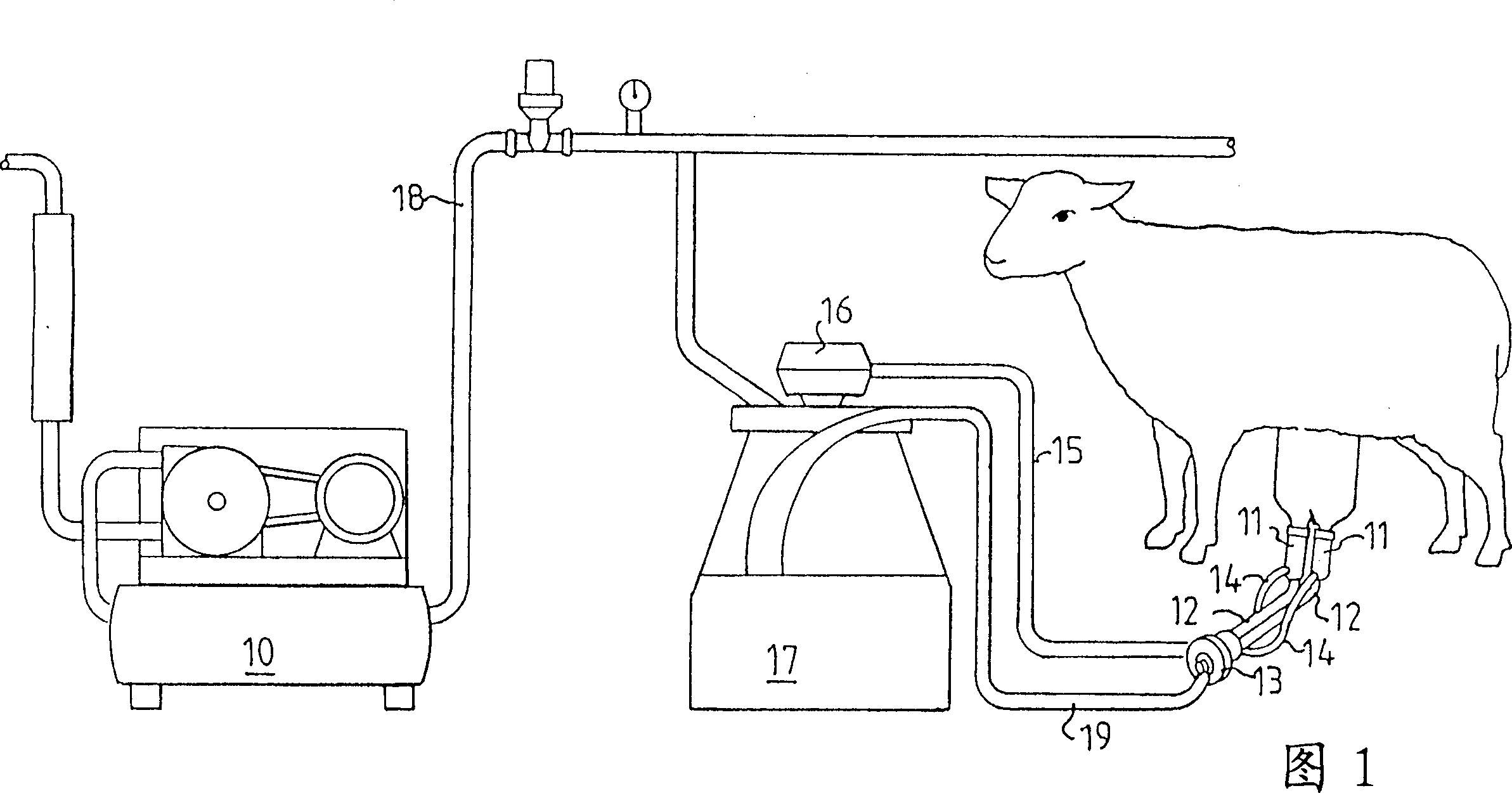

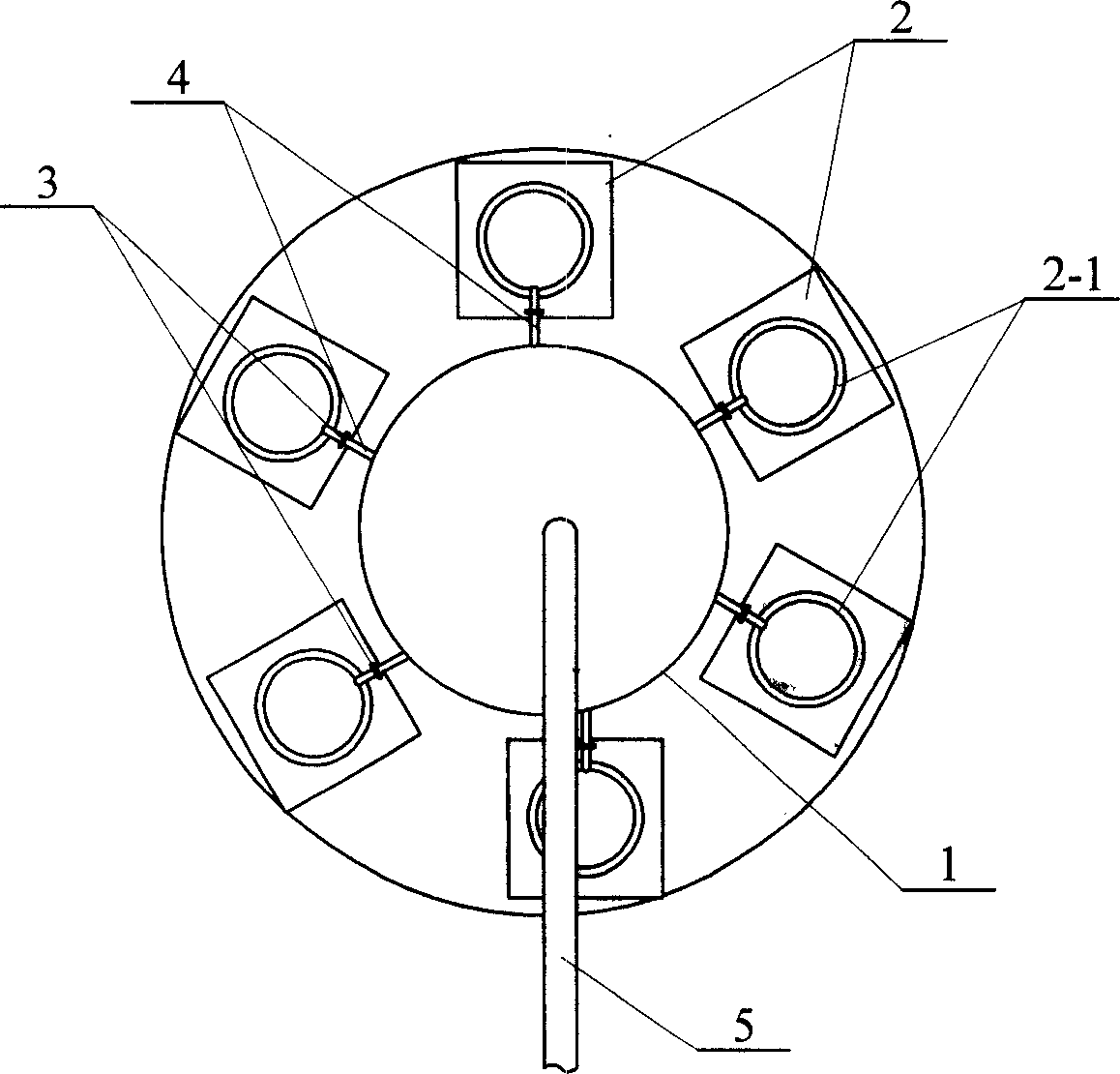

Milking system for mammals, preferably cattle, that differentiates when the milk is over, comprising a collector, teat cups and hoses

A system that attached to mechanized milking equipment allows its automation that solves the subclinical mastitis by “differentiating” among each individual mammary quarter the time when teat cups must be removed after the milk is over, in an asynchronous and independent manner from other teat cups. Minimize the negative consequences of over-milking as a results of not removing teat cups on time after the milk flow has stopped; reduces economic, financial and productivity problems arisen as a result of subclinical mastitis mainly caused by over-milking; thus improving the product quality and amount. Mastitis produces somatic cells in milk, the greater the amount of these cells the lower the price received by the producer. Damage to the mammary gland may be permanent resulting in the loss of the gland and may be contagious.The system includes teat cups, tubes, collector, discrete flow sensor, vacuum sensor, command control, software comprising as a part thereof the mammary quarters with physiological and anatomical characteristics thereof.

Owner:USLAR VALENZUELA WILLIAM RONNIE

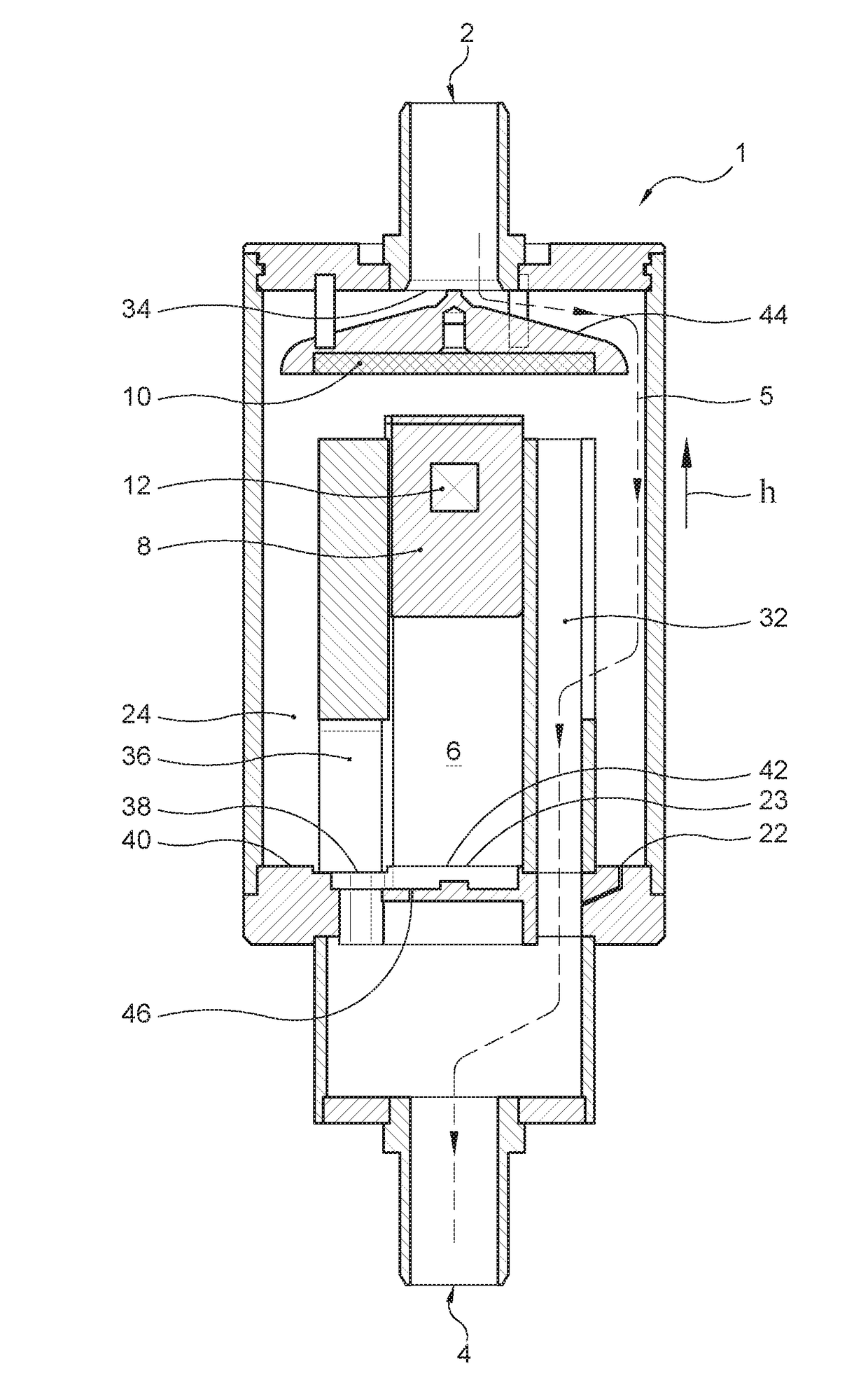

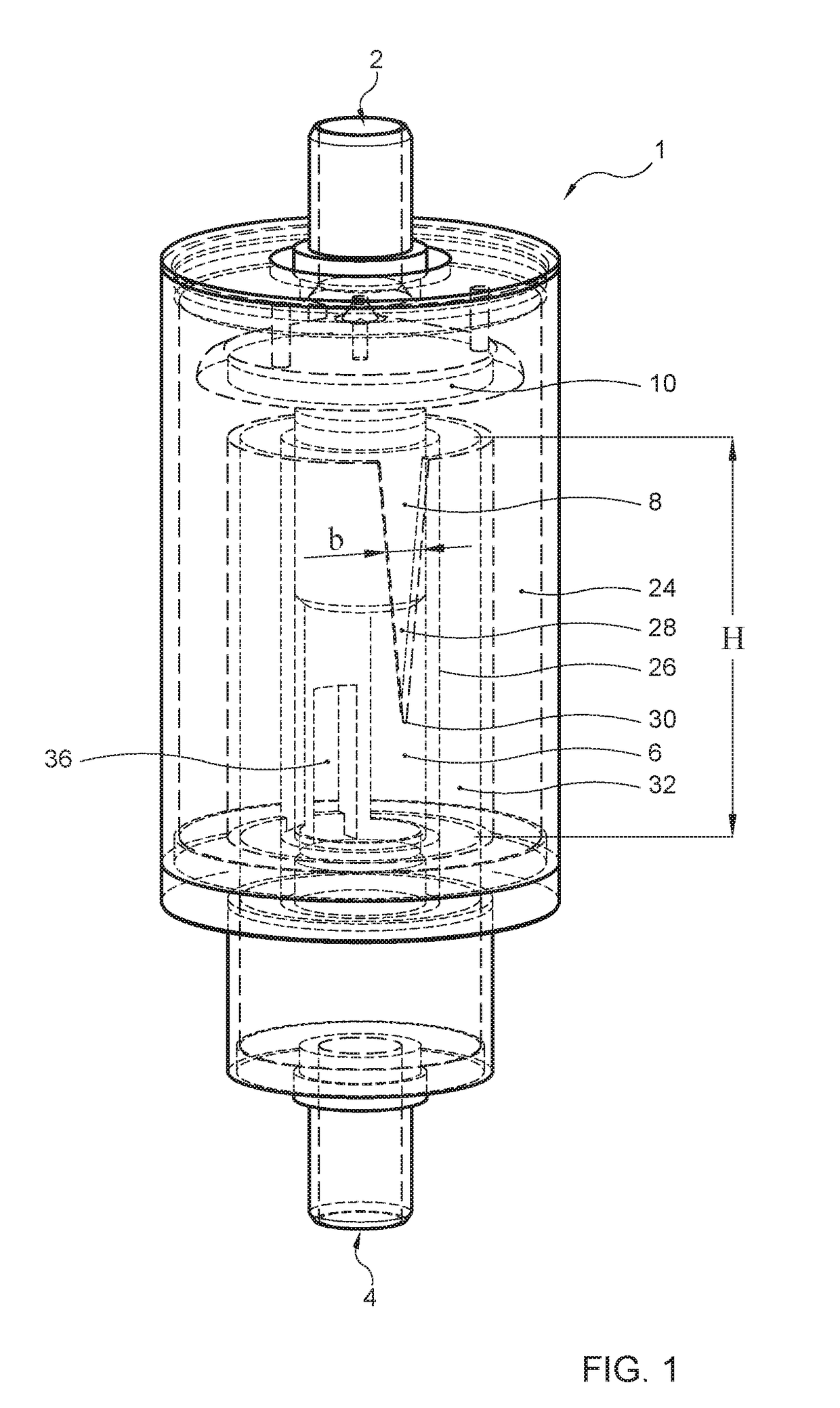

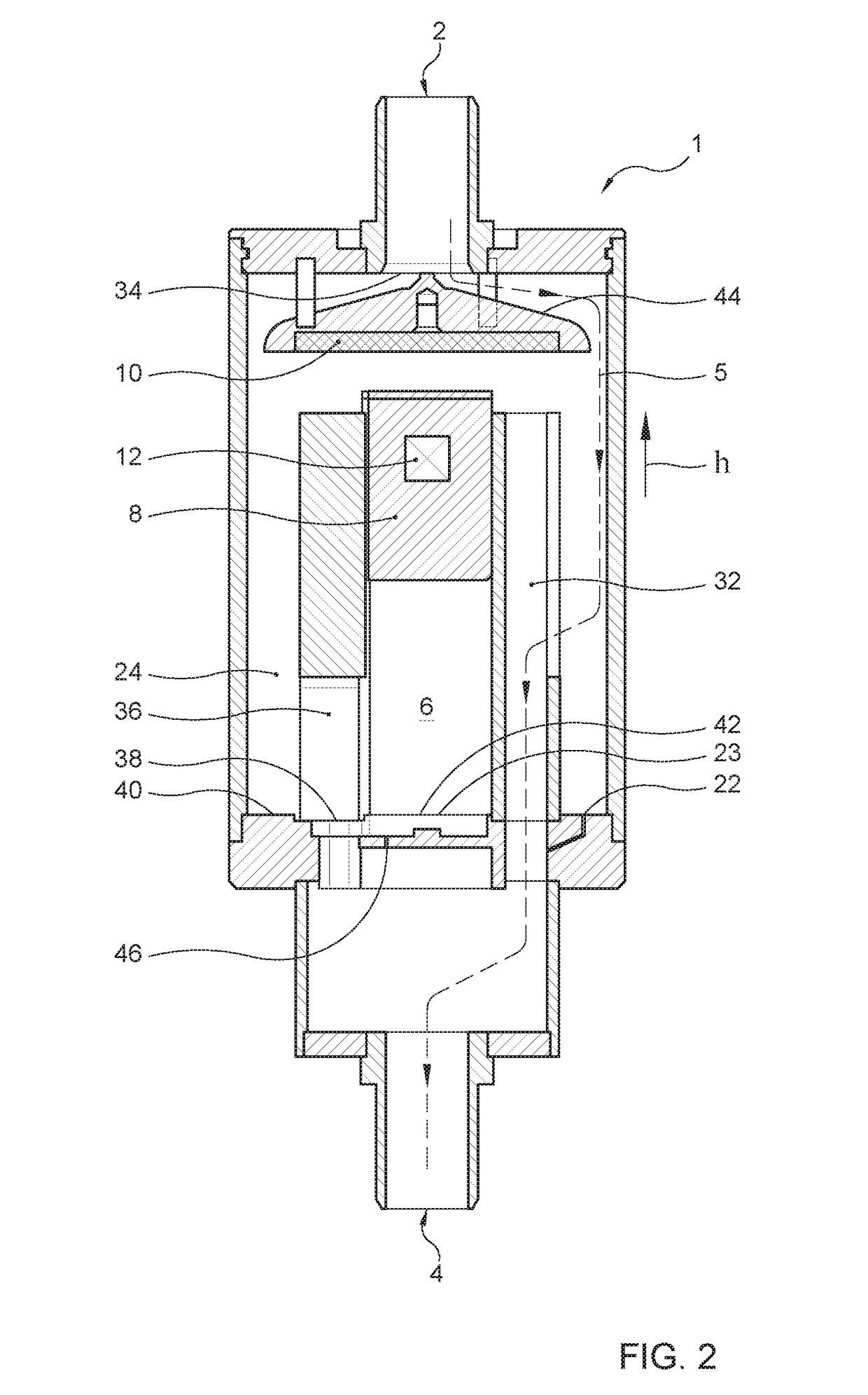

Milk meter

ActiveUS20170115145A1Lot of cable can be savedWell contaminationVolume/mass flow by mechanical effectsMilking devicesStreamflowMagnetic field

Milk meter for measuring a flow rate of a milk flow, provided with an inlet, an outlet, and a liquid flow path from the inlet to the outlet. The milk meter has a measuring chamber and a float in the measuring chamber configured to float on milk. The milk meter determines the flow rate from the level of milk and the milk meter is provided with a magnetic unit for generating a magnetic field and the magnetic field varies in height direction of the measuring chamber, and the float has an electronic measuring unit for measuring the strength of the magnetic field. The measured strength of the magnetic field is a measure of the height at which the float is floating on the milk and the measured strength of the magnetic field is a measure of the flow rate of the milk flow.

Owner:N V NETHERLANDSCHE APPNFAB NEDAP

Milk sampling and testing

A method of collecting a sample of milk while milking a succession of animals comprises diverting a portion of milk from an animal into a flowpath (74, 77) leading to an extraction point (80). The flowpath (74, 77) is dimensioned such that milk flows along the flowpath as a plug occupying the whole of its cross-section and allows some of the milk from the animal to pass the extraction point (80). Thereafter the milk is transferred into a container or other receiver and at least some of the remaining milk of that animal reaching the extraction point.

Owner:AKERMAN DAVID ERIC

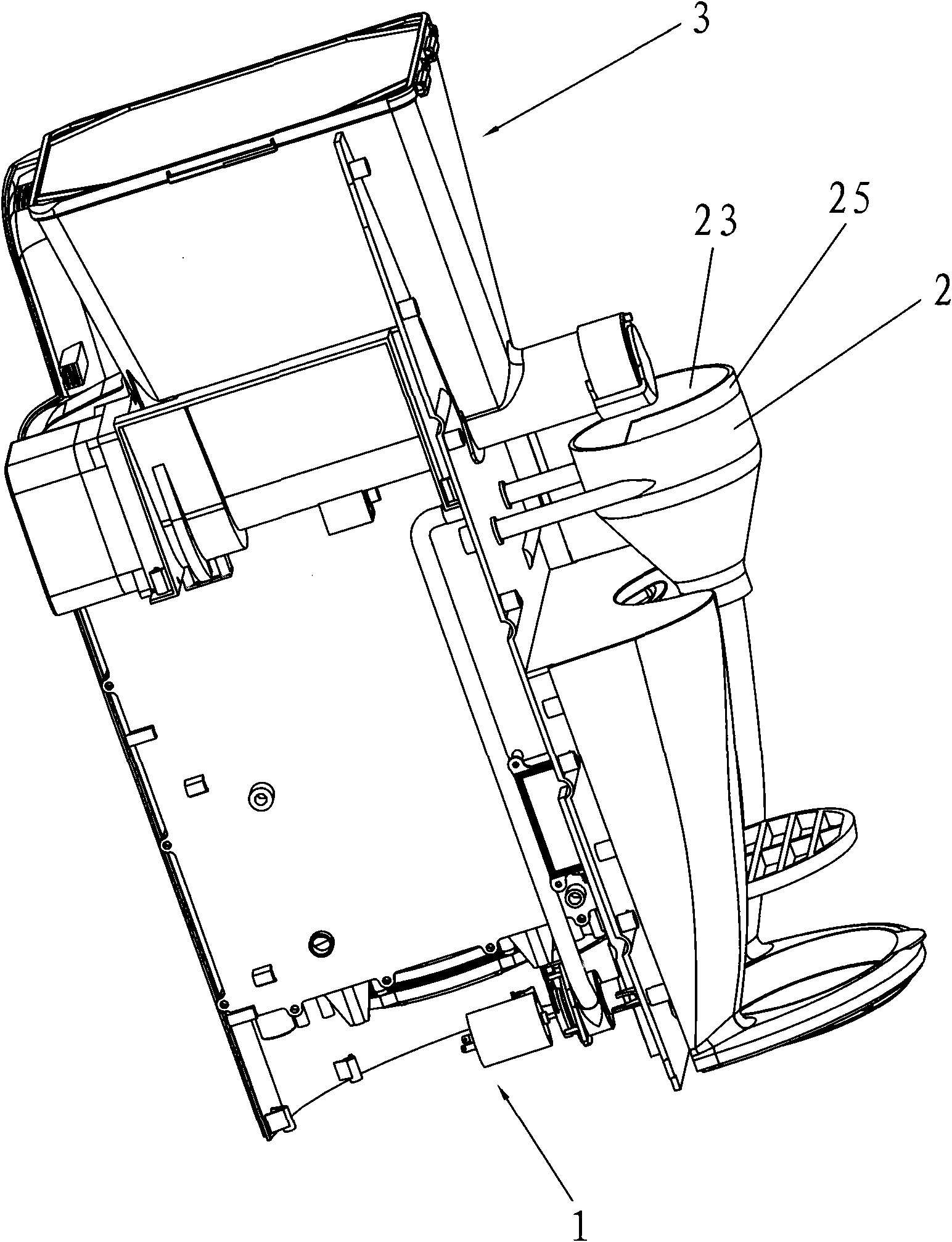

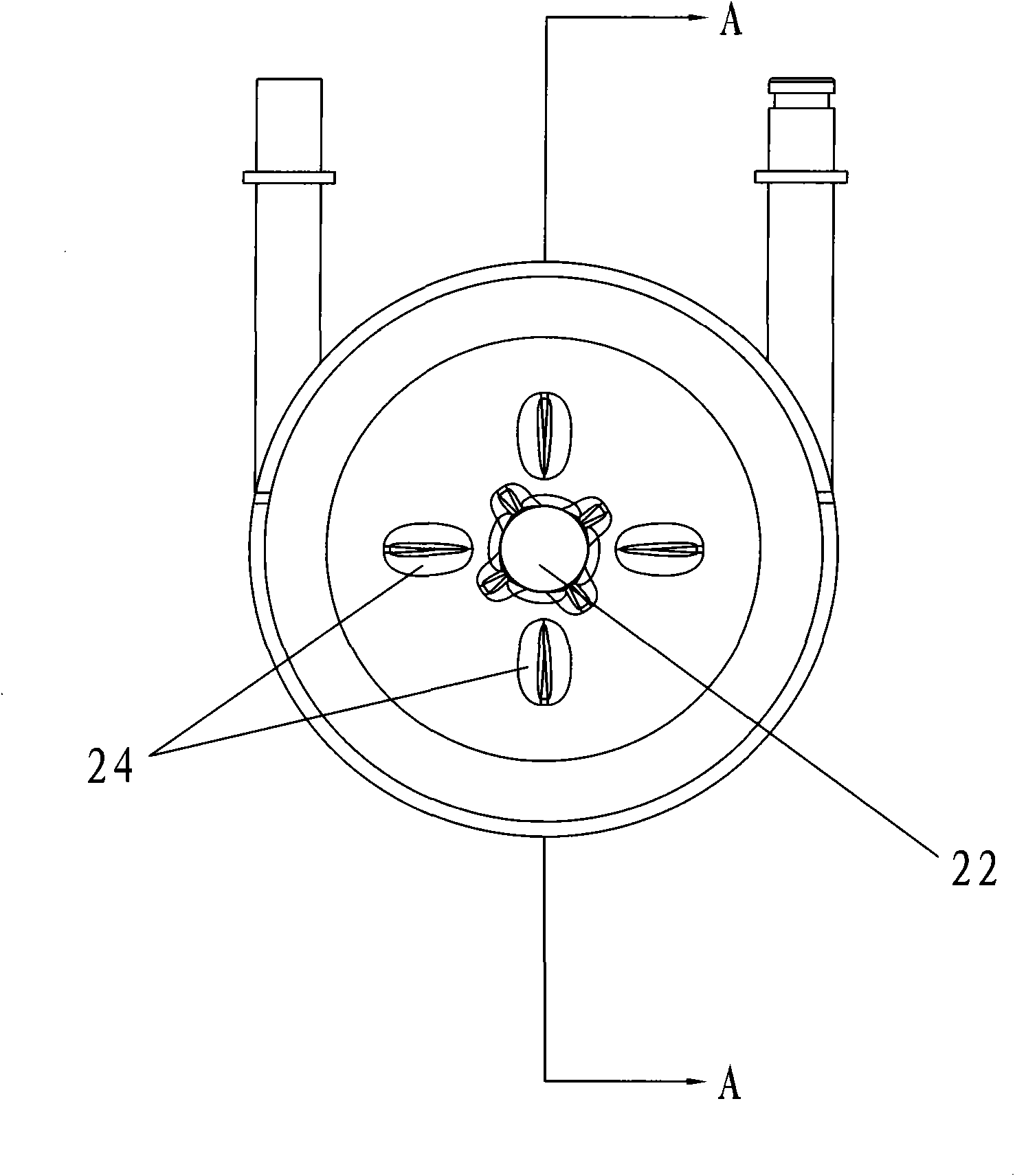

Valve, milking claw and milking system

A diaphragm valve for shutting off the milk flow through the claws of a vacuum-driven milking machine, the valve in a preferred embodiment having a lever (5) connected to the outside of the milk flow with a link (6) on the diaphragm (4), thus avoiding any easily leaking sleeves. The lever (5) can be swung by hand to a position that holds the diaphragm off its seat allowing milk to flow. In the self-closing embodiment, the lever is in this case against the bias of the spring (7) and remains at the position when the suction force acting on the diaphragm (4) and connecting rod (6) is sufficient to overcome the bias of the spring (7). In this open position, this is the case where milk flows normally through the valve. When the milking cup is removed from the animal's teat, only air flows through the valve, thereby reducing the suction force on the linkage (6) and allowing the spring (7) to swing the lever away from its valve-opening position to a loose When the diaphragm is in the open position, air suction will pull the diaphragm, sealing it against the valve seat, cutting off the flow of potentially contaminated air through the system. The principles of the invention can also be implemented on a rotating knob (21) which is attached to the diaphragm (4) and interacts with an inclined groove (23) and a spring (24) biasing the knob to Advance to a position where the diaphragm is released when flow is insufficient. This system is especially useful on sheep or goat dairy farms where milking cup assemblies are frequently installed and removed.

Owner:DELAVAL HLDG AB

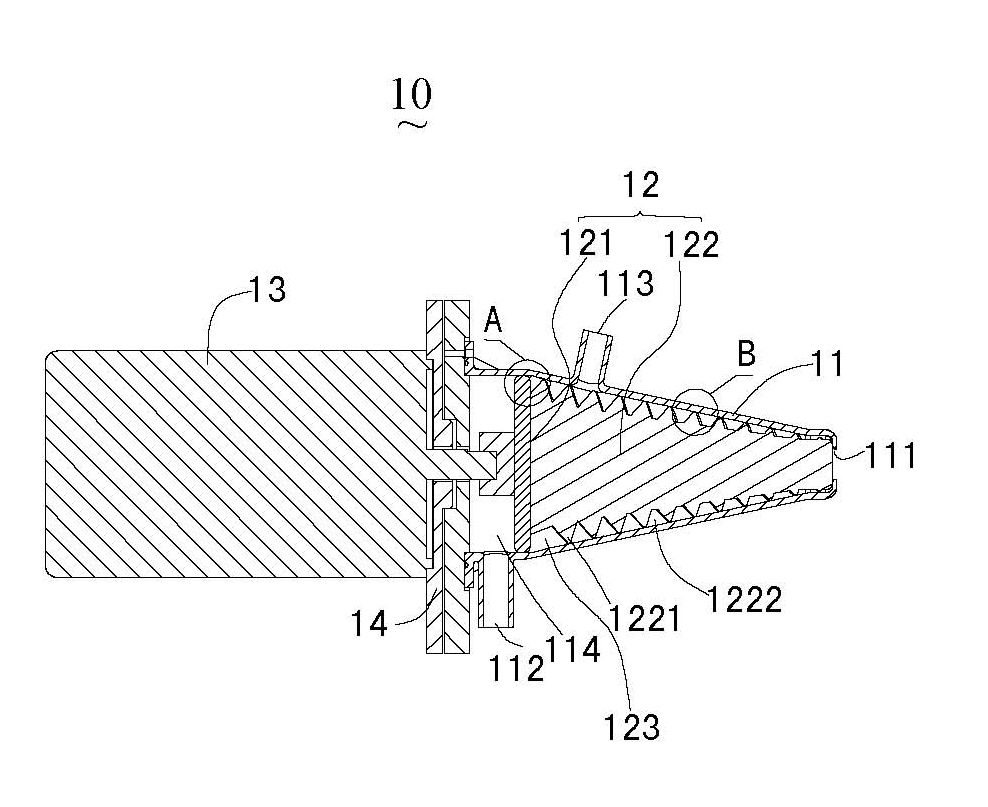

Method for quickly dissolving powdered milk

The invention discloses a method for quickly dissolving powdered milk. According to the method, firstly, water is sprayed into a water guide seat by virtue of a water discharge mechanism to form eddying current which rotatably flows clockwise or counterclockwise in the water guide seat; secondly, powdered milk is uniformly fed into the water guide seat by virtue of a powdered milk discharge mechanism, and the powdered milk falls down on the edge of the eddying current; thirdly, the powdered milk and the eddying current are mixed completely to form milk, and the milk flows out from a flow restricting port of the water guide seat, meanwhile, the powdered milk which is not completely dissolved is pressurized and dissolved by the flow restricting port; and finally, when the milk dissolving process is completed, the powdered milk discharge mechanism is firstly turned off for stopping feeding the powdered milk, and then the water discharge mechanism is turned off for stopping spraying water. In the method, after the eddying current is formed, the powdered milk is added, so that the powdered milk can be sufficiently mixed with the eddying current, milk residue is prevented, and the milk quality is guaranteed.

Owner:东莞市华钦塑胶模具有限公司

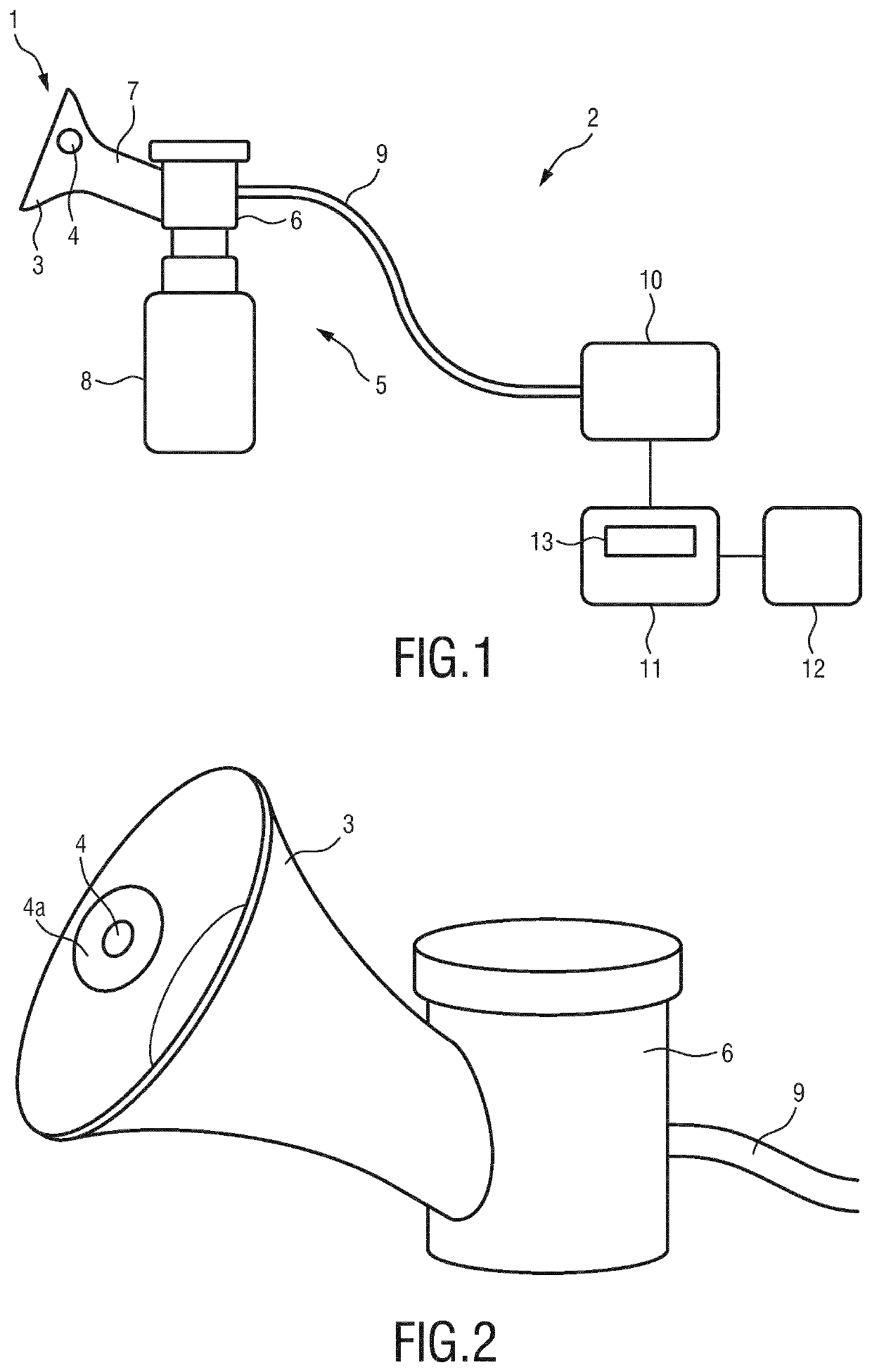

Breast shield arrangement for breast pump, breast pump and method of operation

ActiveUS10729830B2High precisionComfortable to useElectrocardiographyMilking pumpMechanical engineeringMammary fluid

The present invention relates to a breast shield arrangement (1) for a breast pump (2) comprising: a breast shield (3) for receiving a user's breast therein, and a sensor (4) for transmitting an input signal into the breast and receiving a corresponding reception signal in response, said reception signal indicating changes in milk flow in the breast.

Owner:KONINKLJIJKE PHILIPS NV

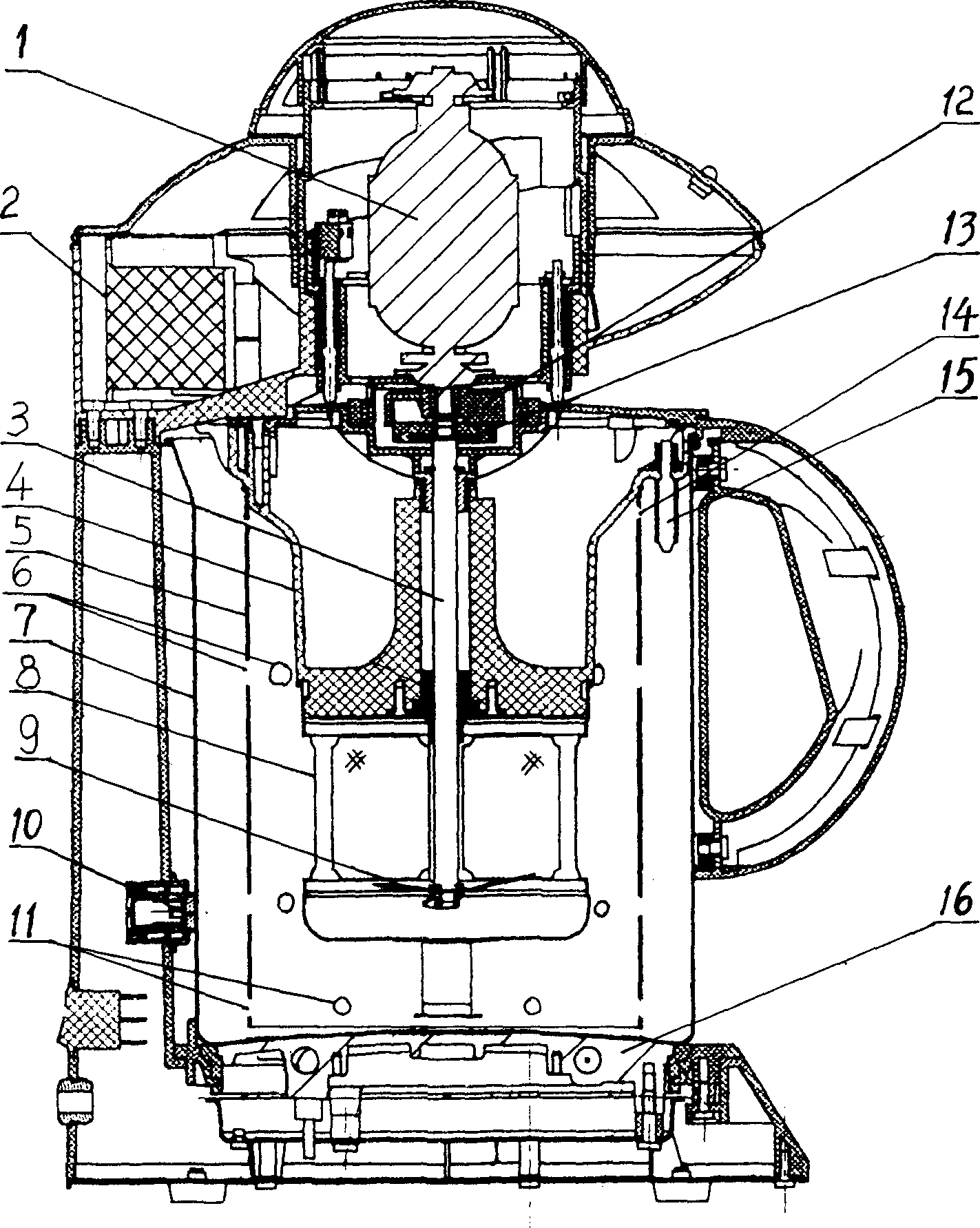

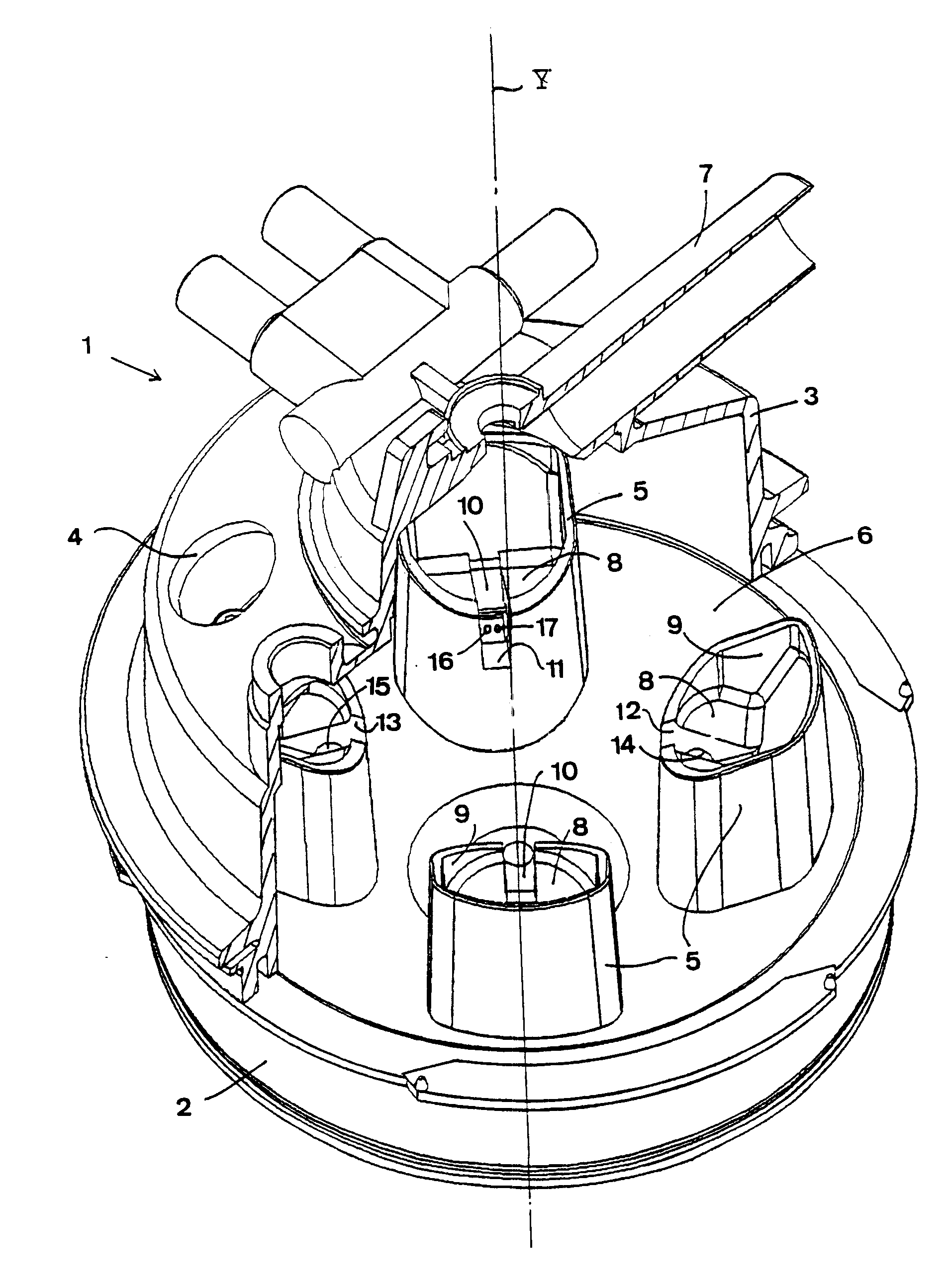

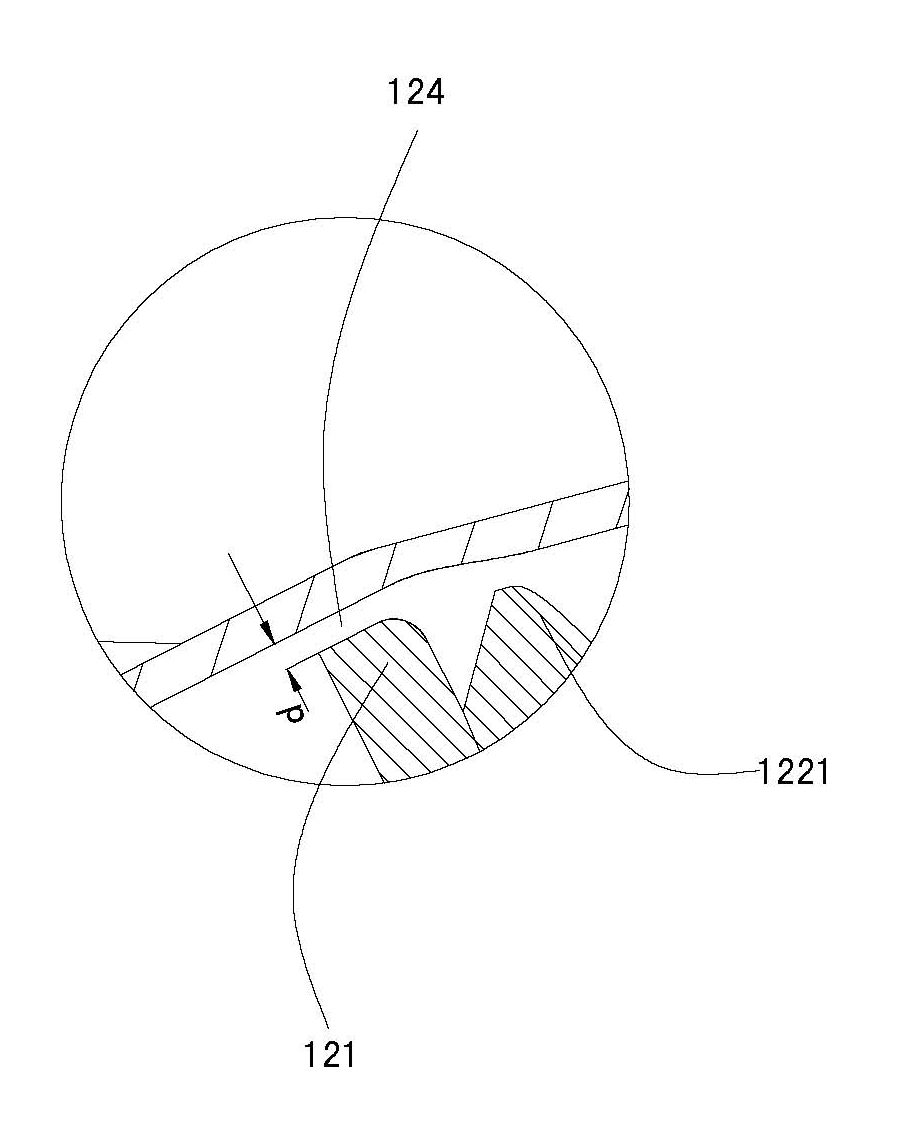

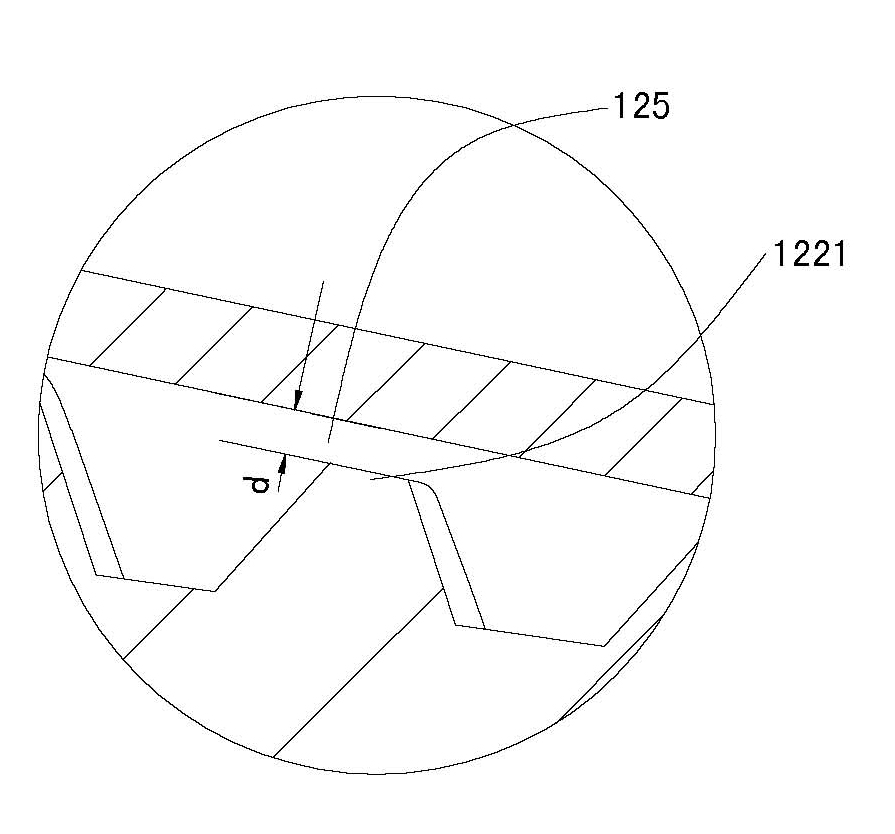

Device for measuring an electrical parameter in the milk

A device for the measurement of an electrical parameter in the milk during the milking of an animal comprises a transportation member (1), arranged to transport the milk from a teat of said animal to a milk collecting member of a milking machine and forming a passage for the milk to be transported, and at least two electrodes (14-17) provided to be in contact with the milk flowing through the passage, and connected to an evaluation unit (18). The transportation member (1) comprises a wall member (5) provided in the passage and forming a groove (10) being open towards the passage, said electrodes (14-17) being provided on the wall member (5) in the groove (10). The wall member (5) is provided to receive a part of the milk flowing through the passage, said groove (10) being shaped in such a manner that at least a part of said received part quantity of the milk flows through the groove while contacting said electrodes (14-17).

Owner:DELAVAL HLDG AB

Automatic coagulating agent adding method in soybean curd production process and used automatic coagulating agent adding device

InactiveCN1823619AIncrease productivityUniform product qualityFood preparationEngineeringStorage tank

An automatic coagulating machine for producing bean curd is composed of a bean milk storage tank with milk inlet tube, a bean milk coagulating tank and a pipeline with valve for communicating both tanks with each other. Its method features that the procedure of making the bean milk flow in the coagulating tank is controlled.

Owner:HARBIN UNIV OF COMMERCE

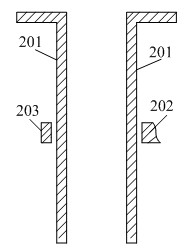

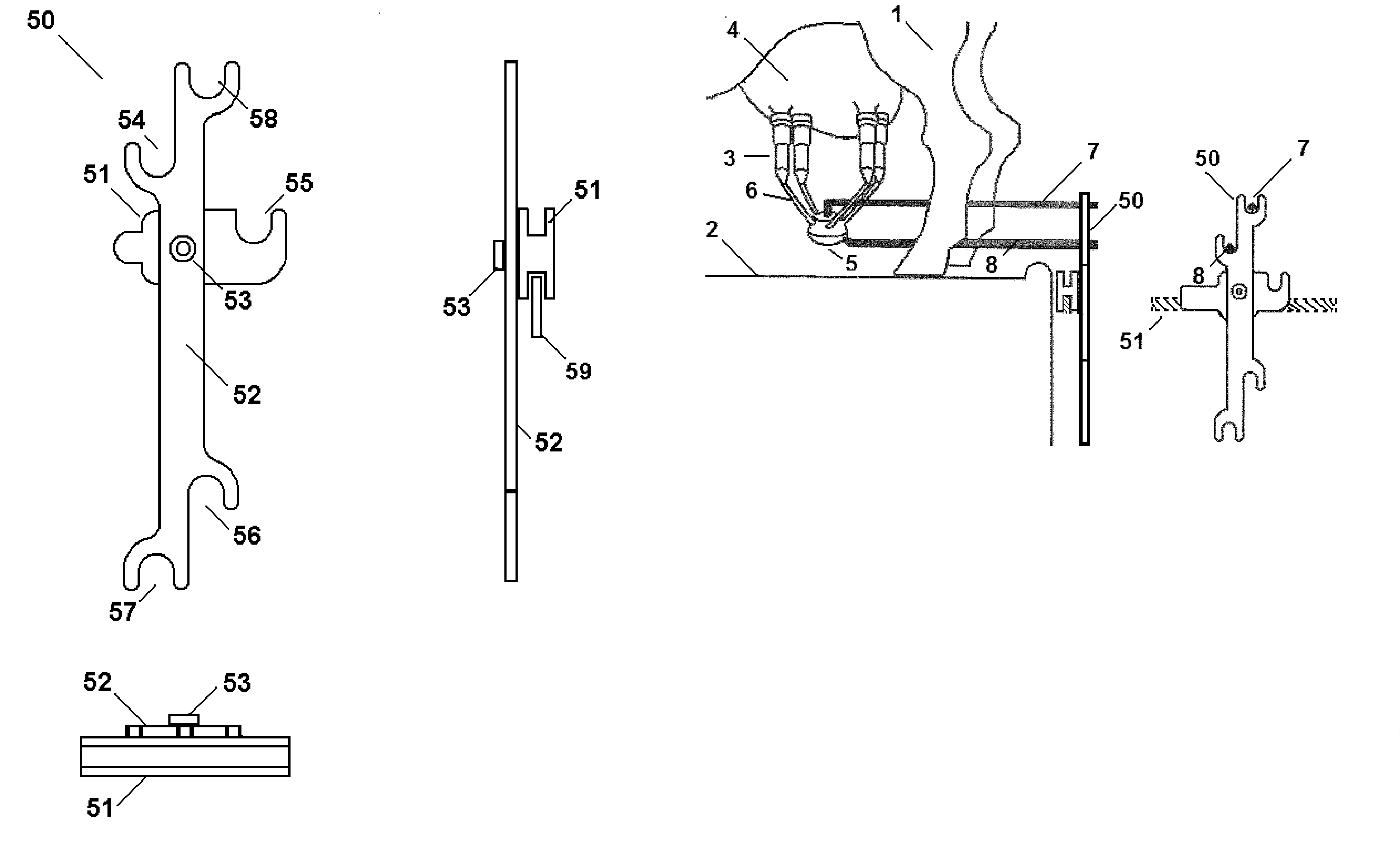

Slender milking hose support tree

InactiveUS20100024734A1Reduce usageIncrease milk efficiencyCathetersAnimal housingTraffic capacityCollection system

A device and method of use of a hose support device for supporting hoses that extend from an animal attached milking machine to a central milk collection system is disclosed. Adaptation to animal size and position in the stall is provided with a coarse adjustment of the hose support tree. Finer adjustment for optimizing milk flow and preserving animal health is accomplished by providing a selection of hose positions that also hold the hose in position. Further adaptations include attachment to milking stalls of differing configurations including rotary milking parlors.

Owner:GINGRICH GLENN SIMON +1

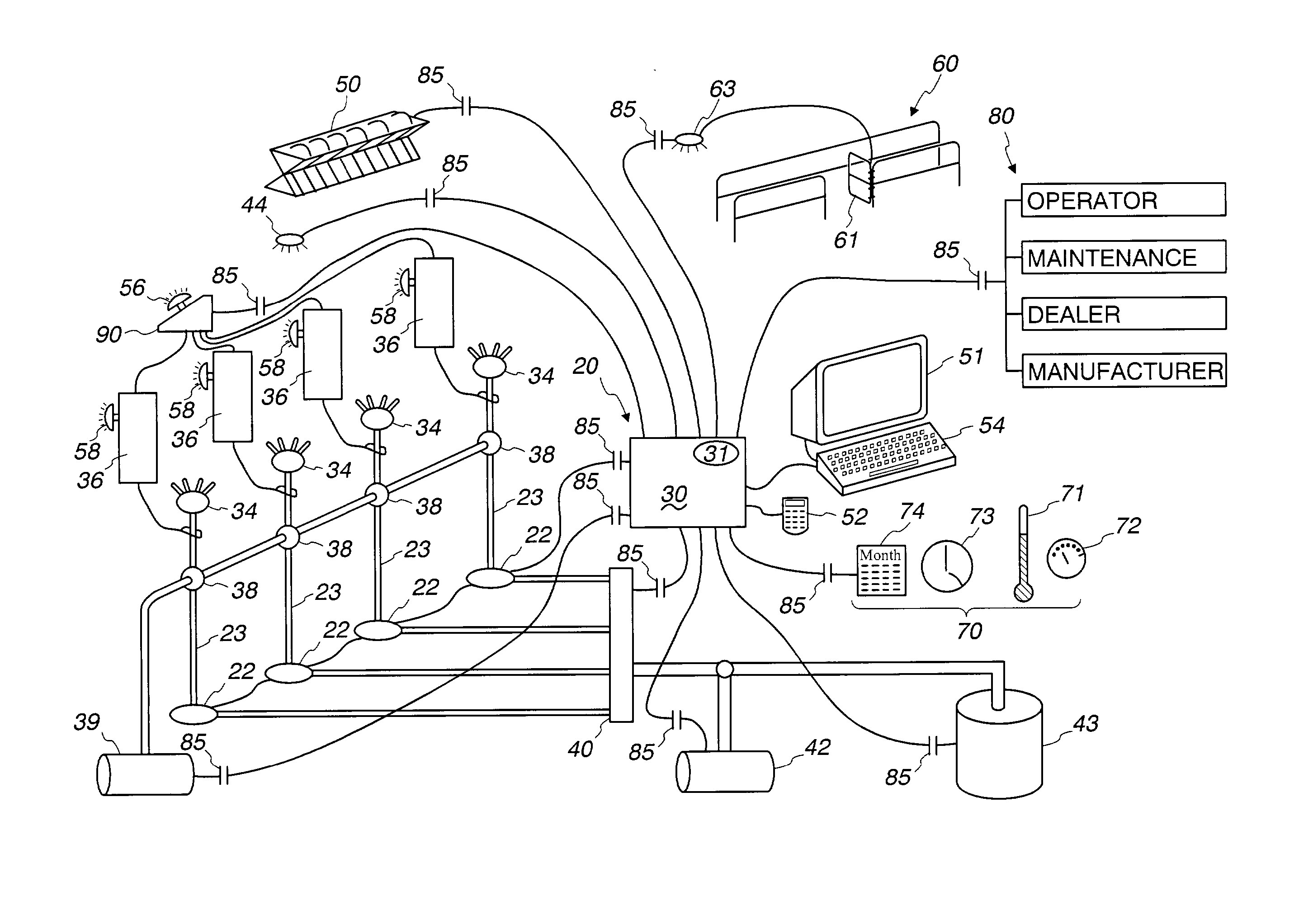

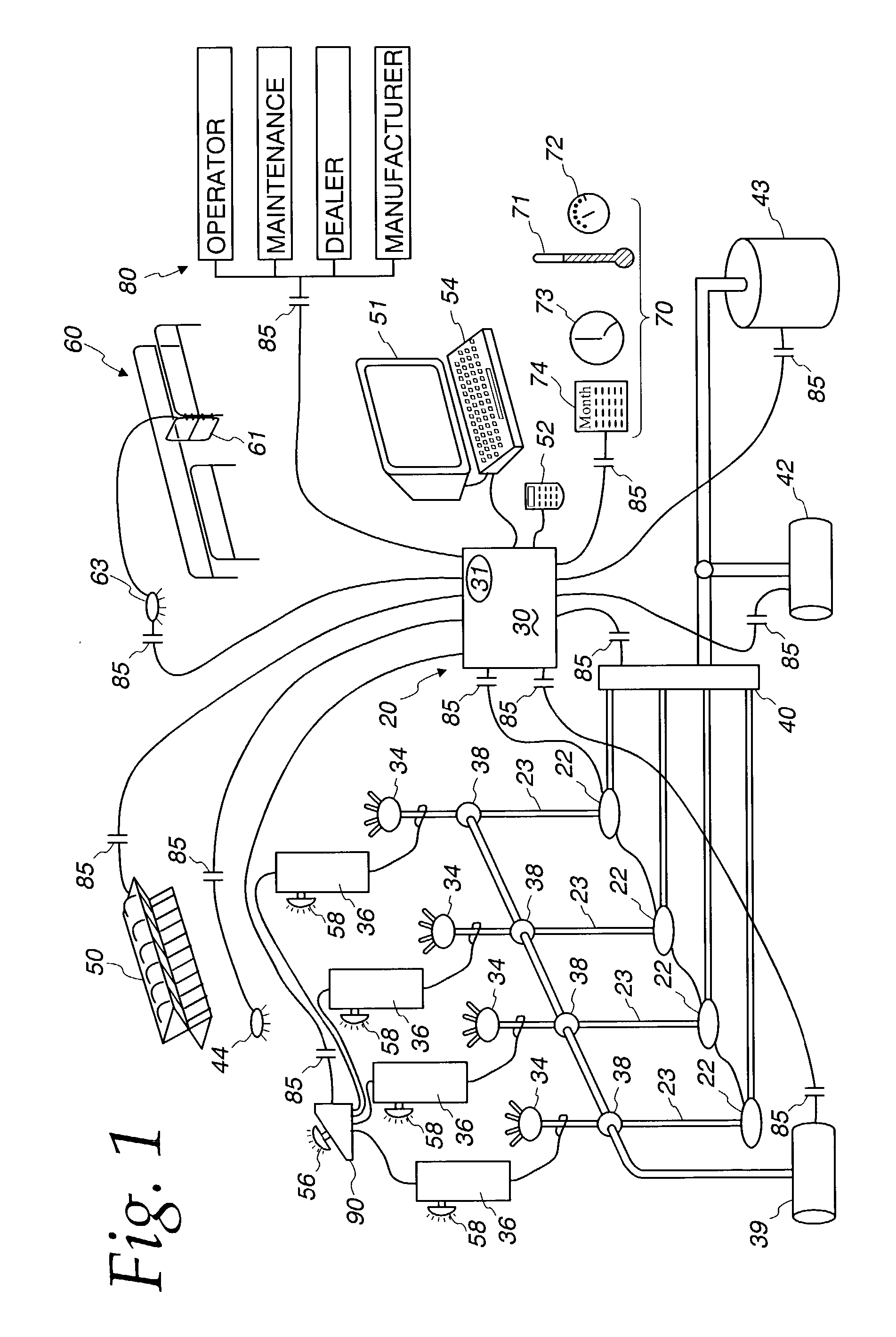

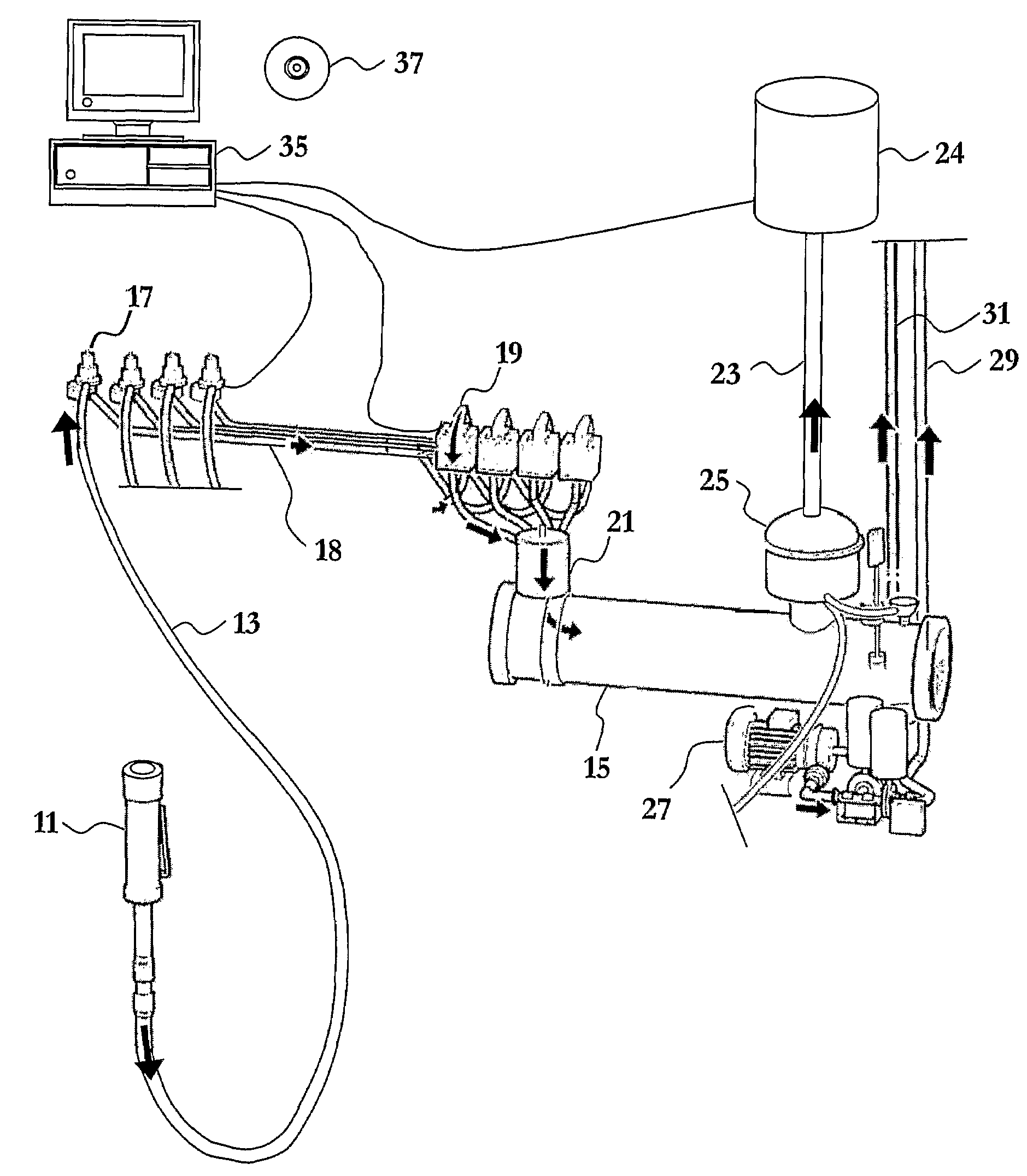

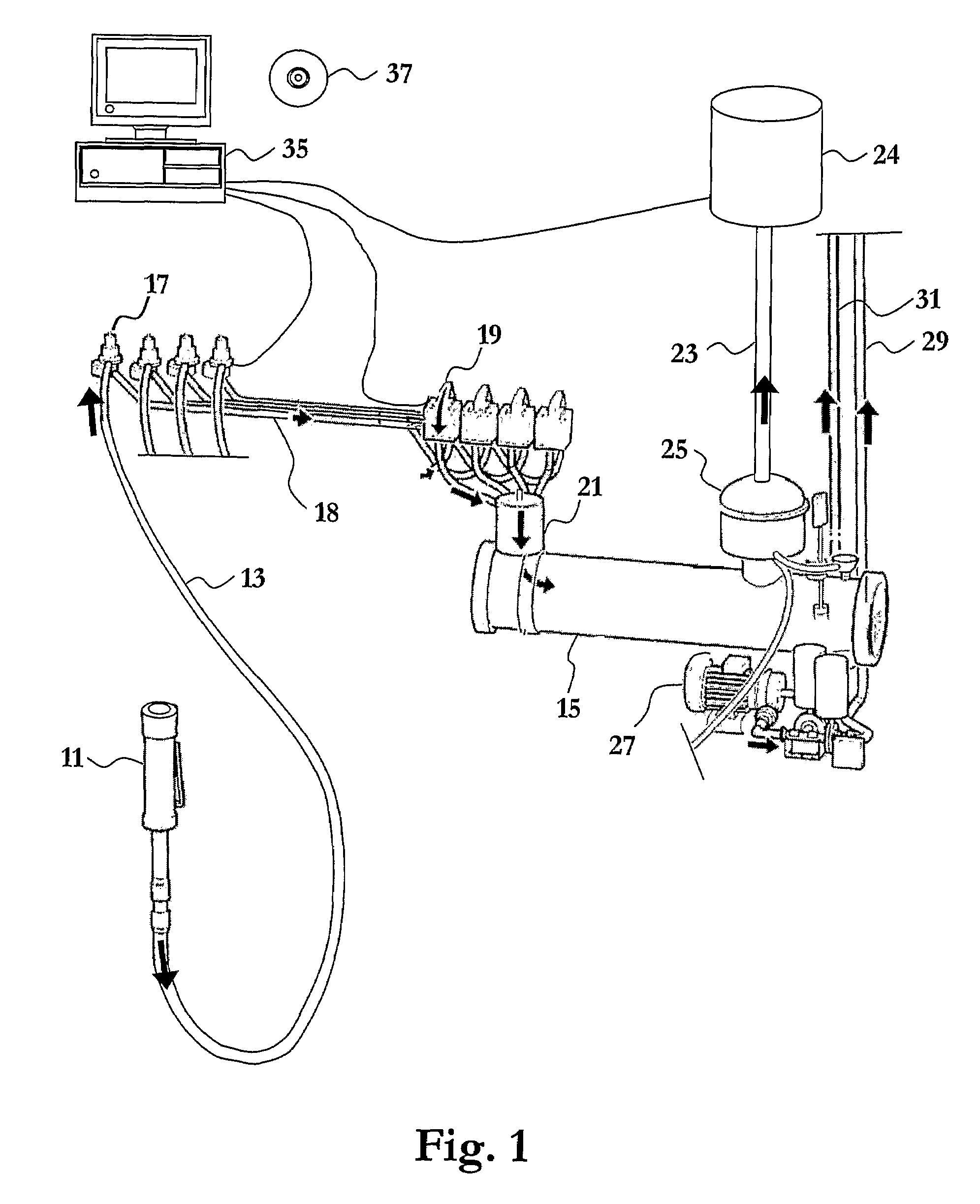

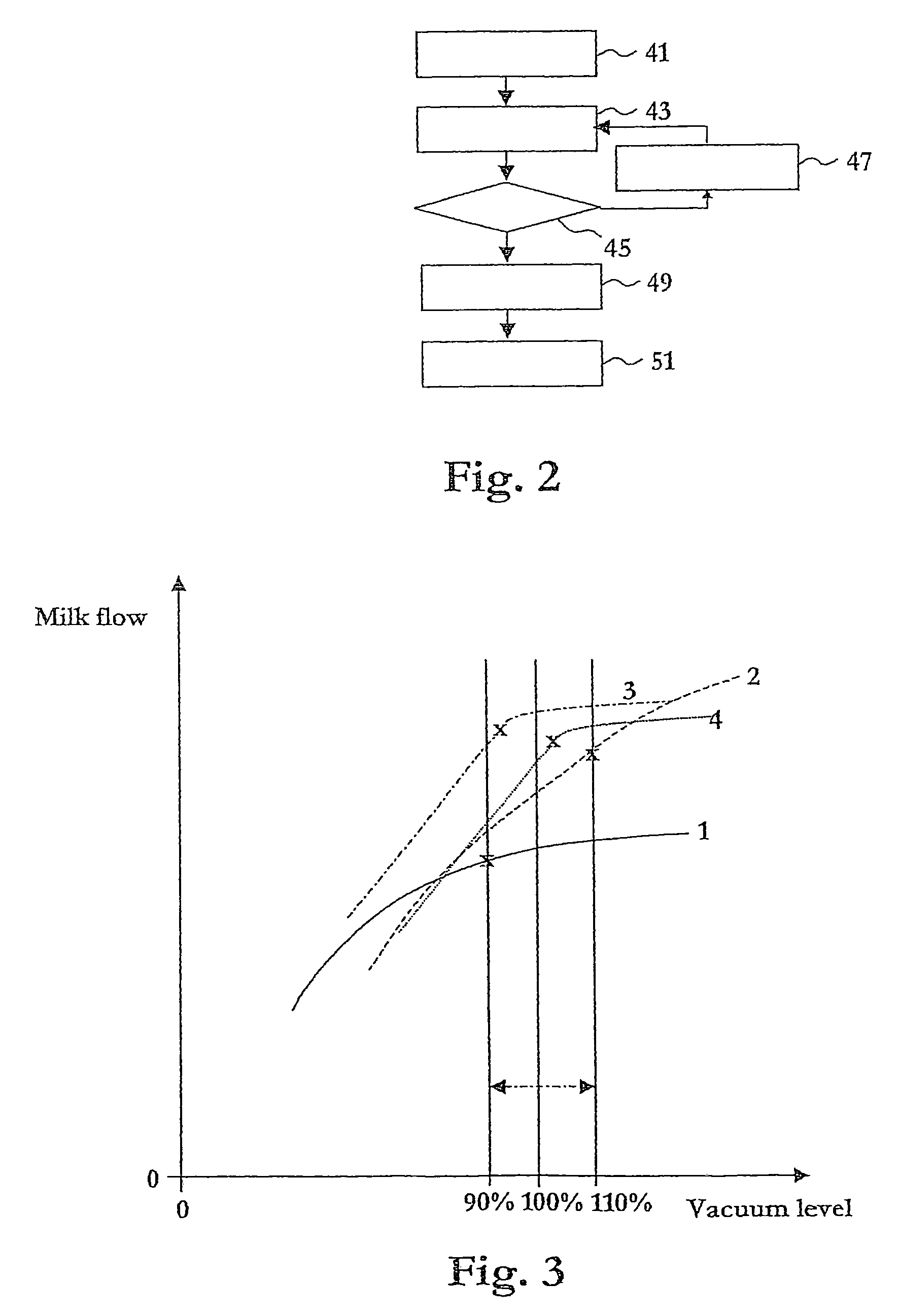

Method, computer program product and arrangement for controlling the milking by a milking machine

A method for controlling the milking by a milking machine comprises the steps of: (i) controlling (47) a milking vacuum so that the milking vacuum is varied through the vacuum levels of a given range, while a milking animal is milked by the aid of the milking vacuum; (ii) monitoring (43) a milk flow from the milking animal during the variation of the vacuum levels; (iii) setting (49) the milking vacuum to the lowest vacuum level of the given range, for which the milk flow from the milking animal is at least a given fraction of the highest milk flow monitored while the milking vacuum is varied; and (iv) keeping (51) the milking vacuum at the set vacuum level during a following part of the milking of the milking animal.

Owner:DELAVAL HLDG AB

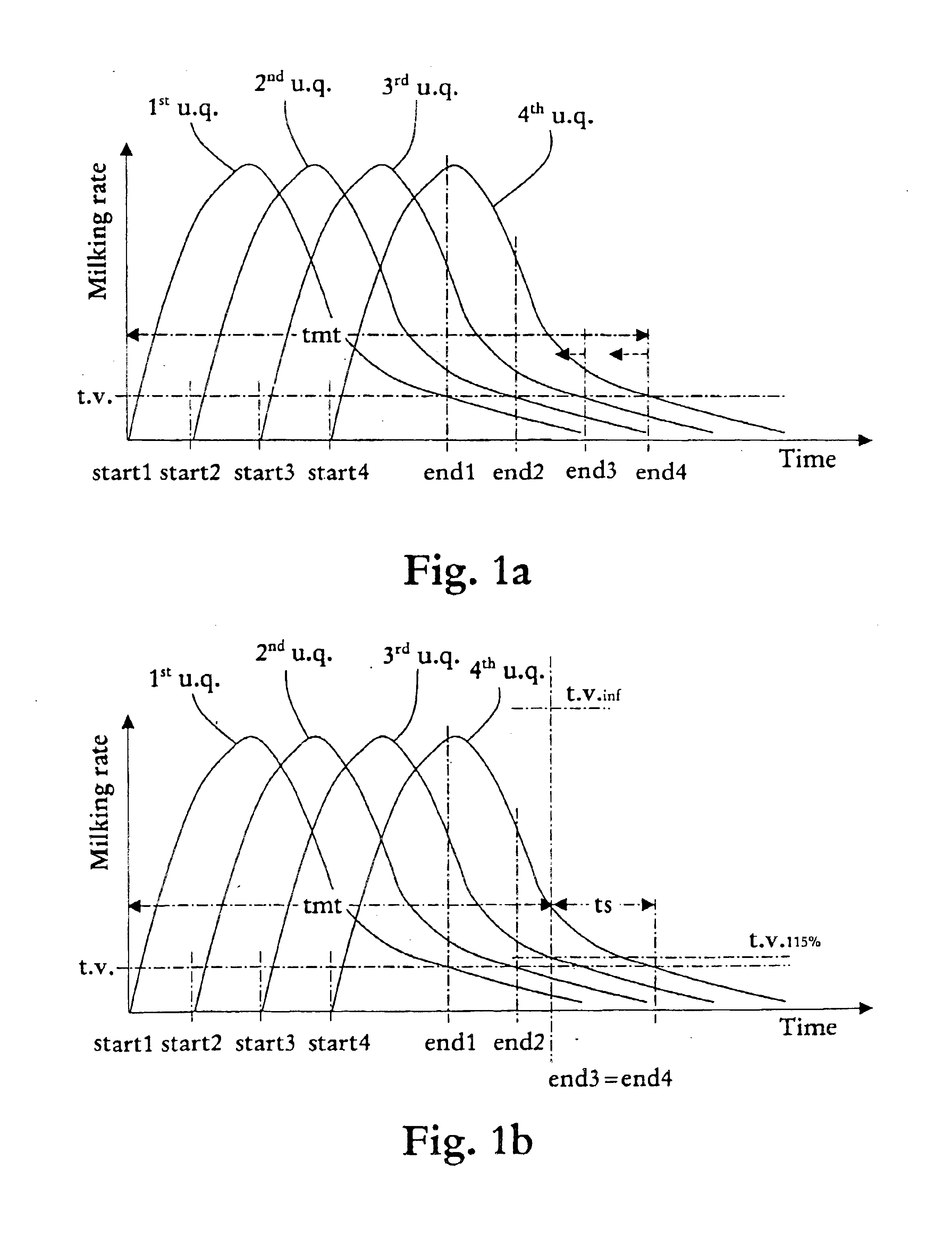

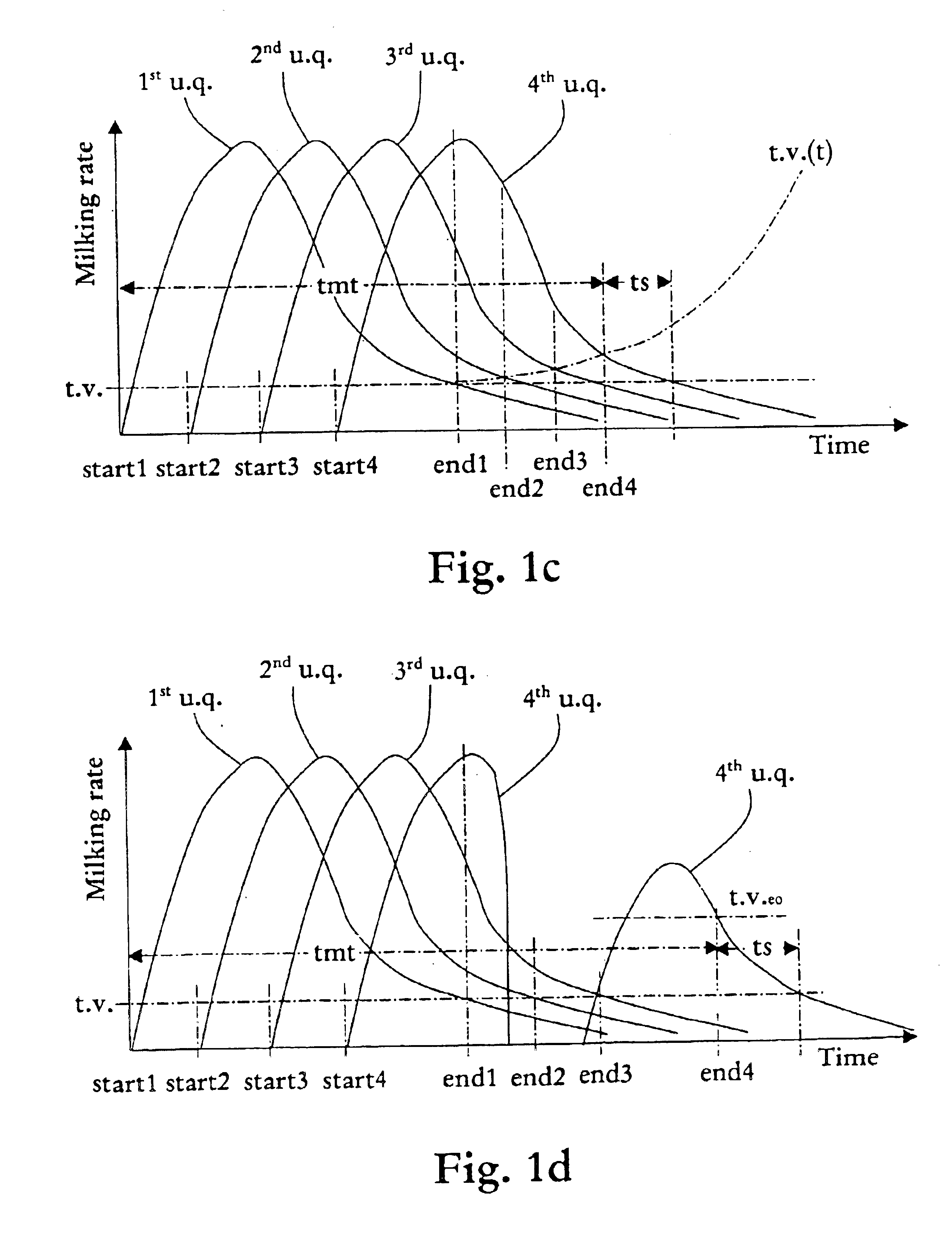

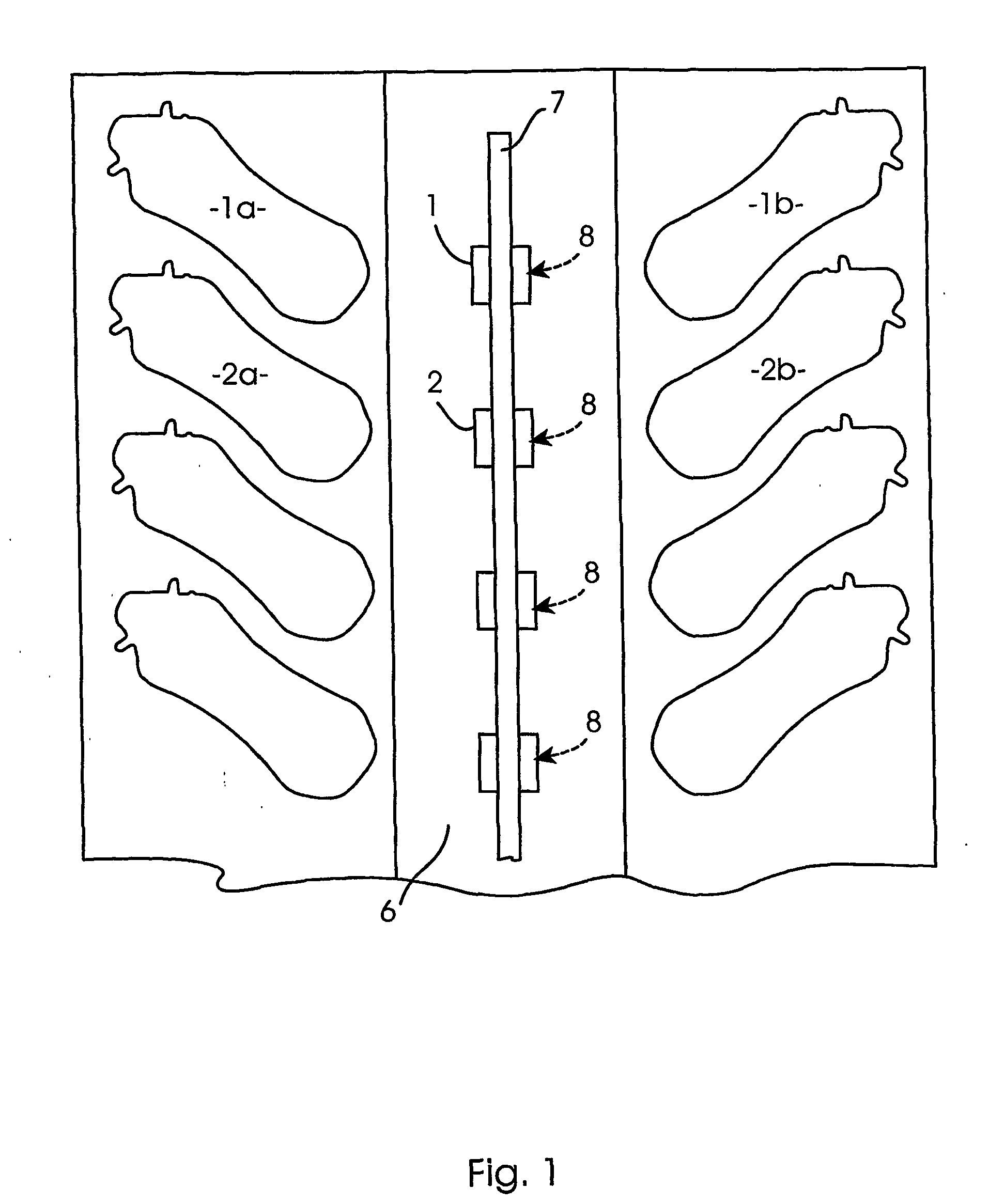

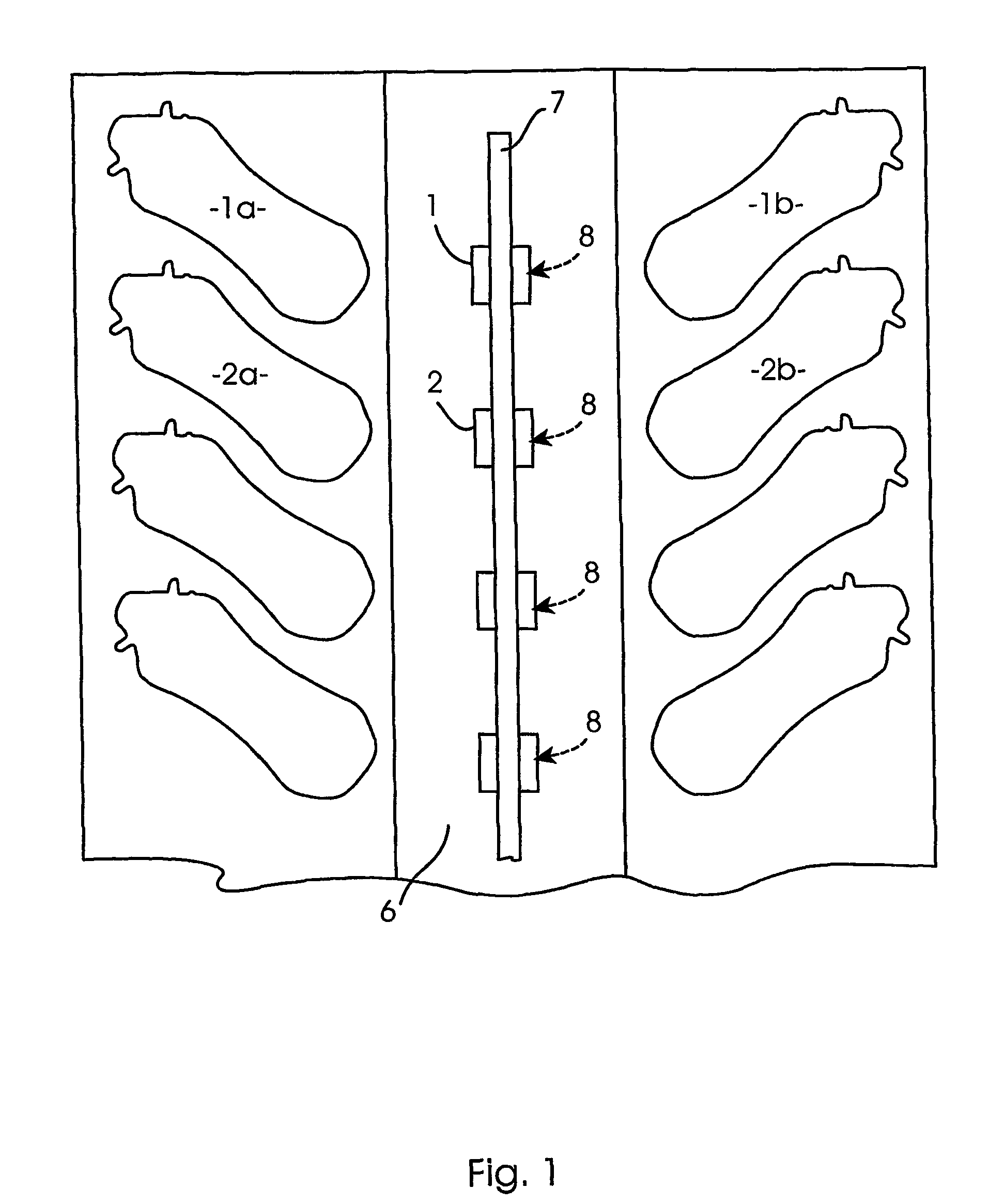

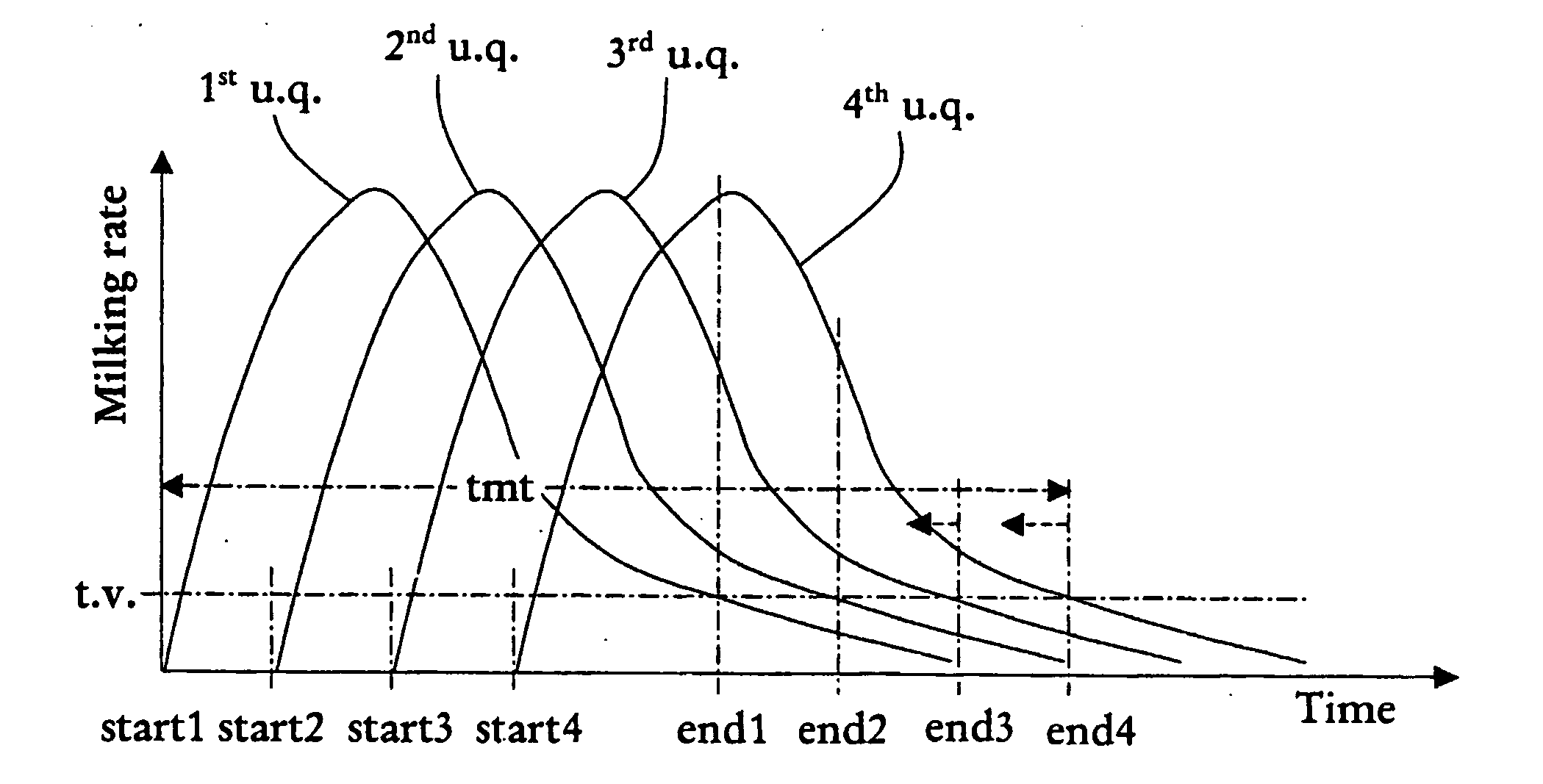

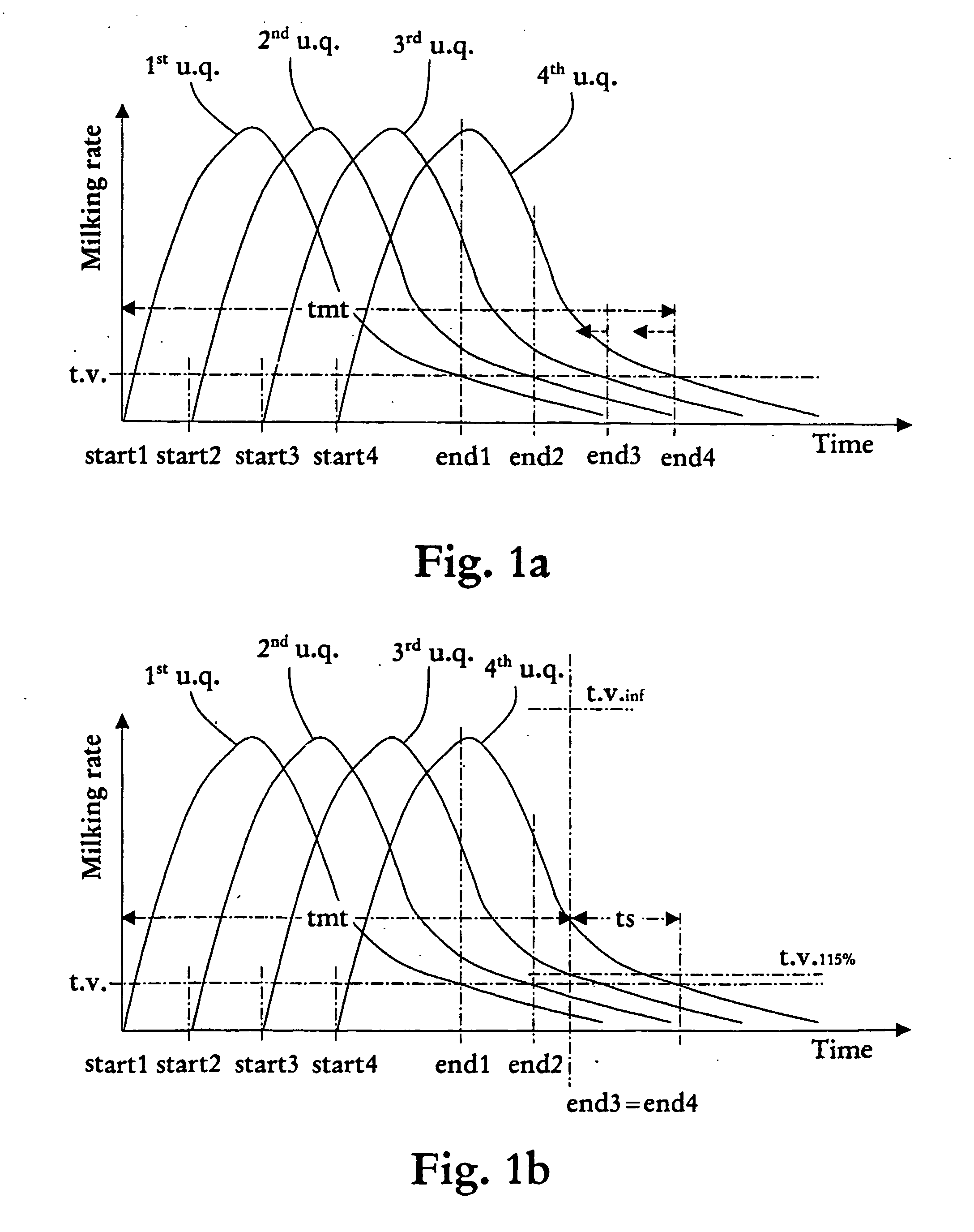

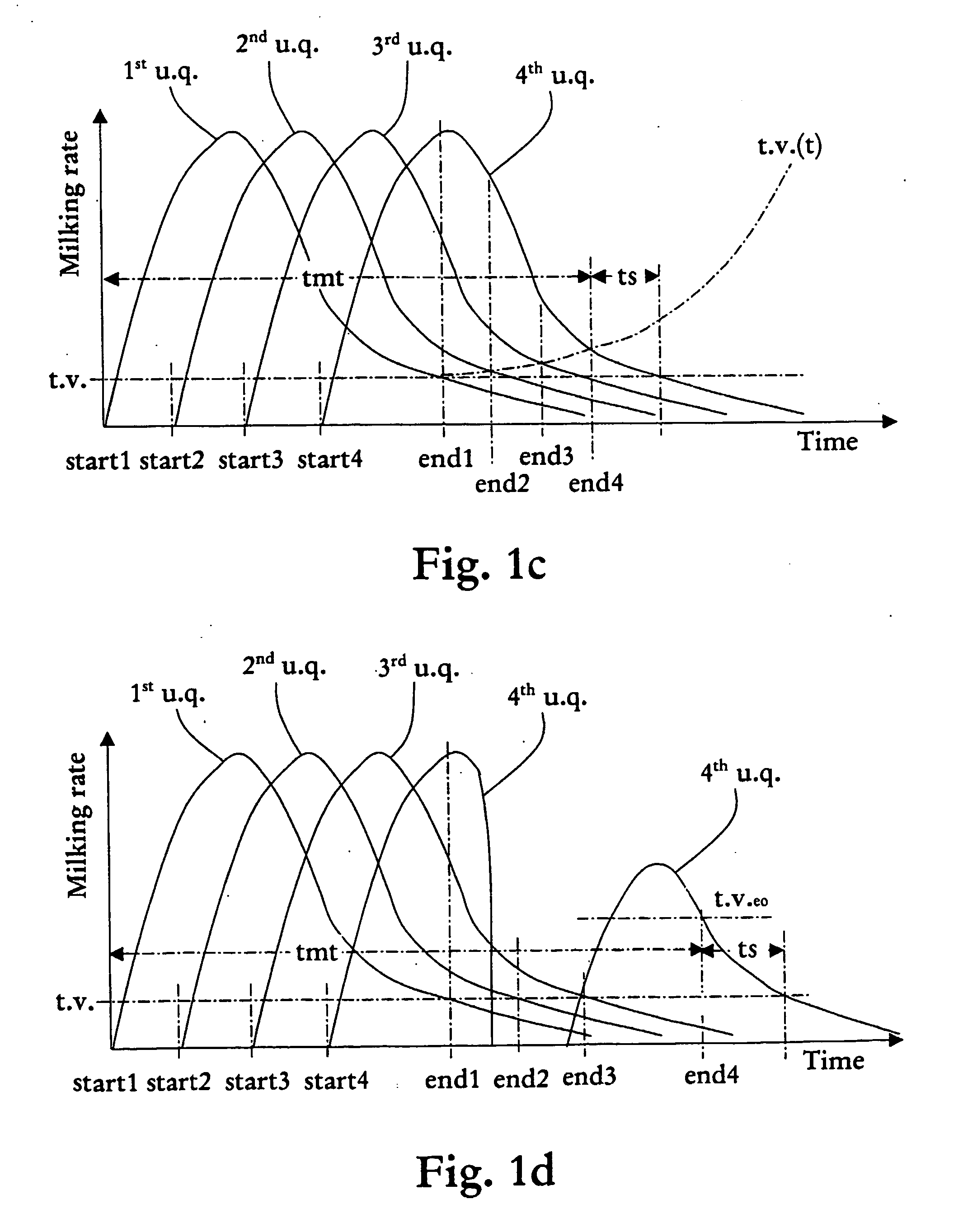

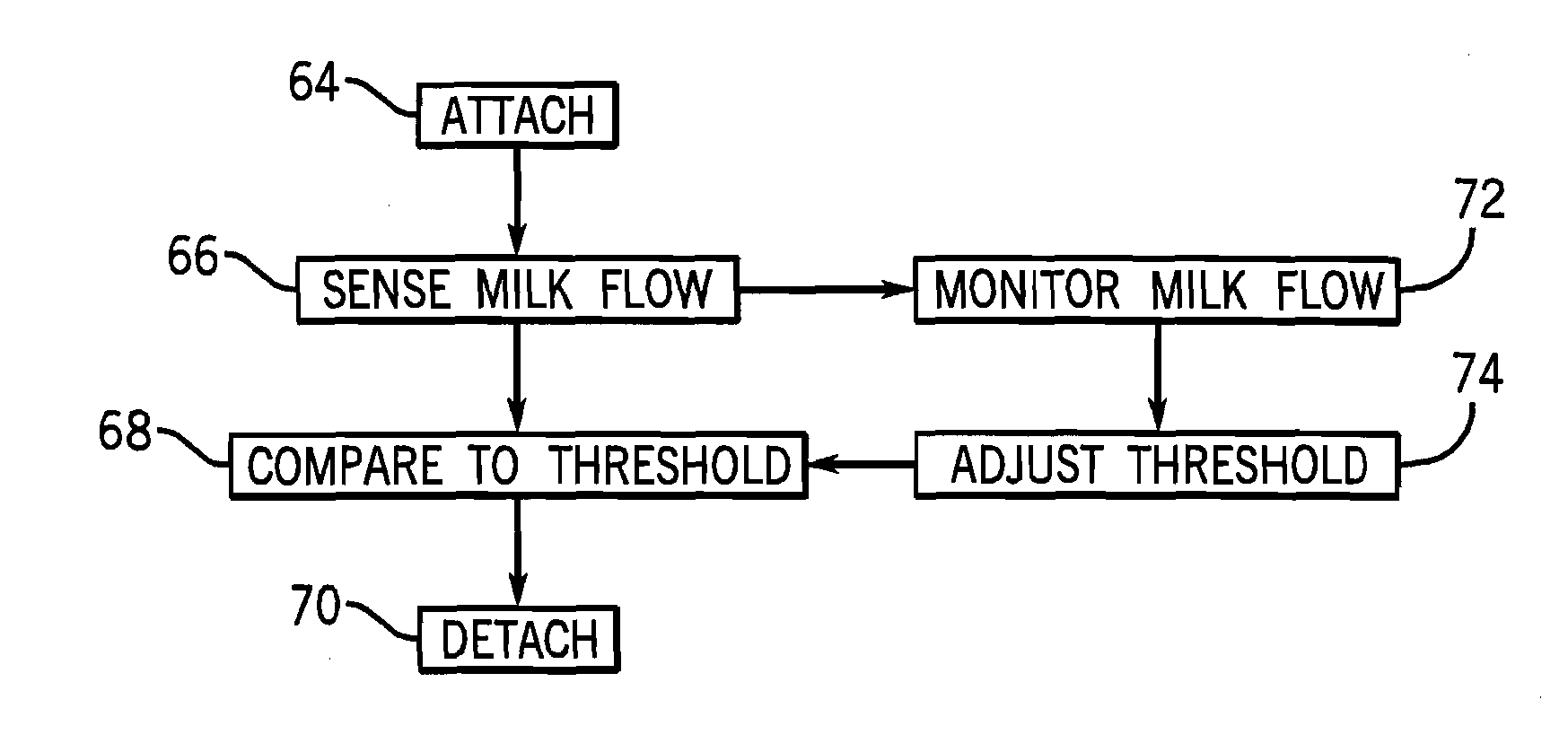

Optimization of milking

A more effective method of automatically milking animals in an automatic milking facility is disclosed. The method includes the steps of (i) assigning a respective threshold value (t.v.) to each of the udder quarters (1<st >u.q.; 2<nd >u.q.; 3<rd >u.q.; 4u.q.) of an animal to be milked indicating when the milking of the corresponding udder quarter is to be ended; (ii) measuring the milk flow from each udder quarter of said animal during milking; and (iv) ending the milking of an udder quarter of the animal (end1; end2; end3; end4) in dependence on the measured milk flow from that udder quarter reaches the corresponding threshold value. According to the invention at least the threshold value for the udder quarter (4u.q.) of said animal, for which the ending of milking very last remains, is raised (t.v.115%; t.v.inf; t.v.(t); t.v.eo) subsequently to the very first ending of milking of an udder quarter of said animal, to thereby shorten the total milking time (tmt) of the animal, and thus more rapidly freeing milking capacity of the milking facility to be used for the milking of a further animal.

Owner:DELAVAL HLDG AB

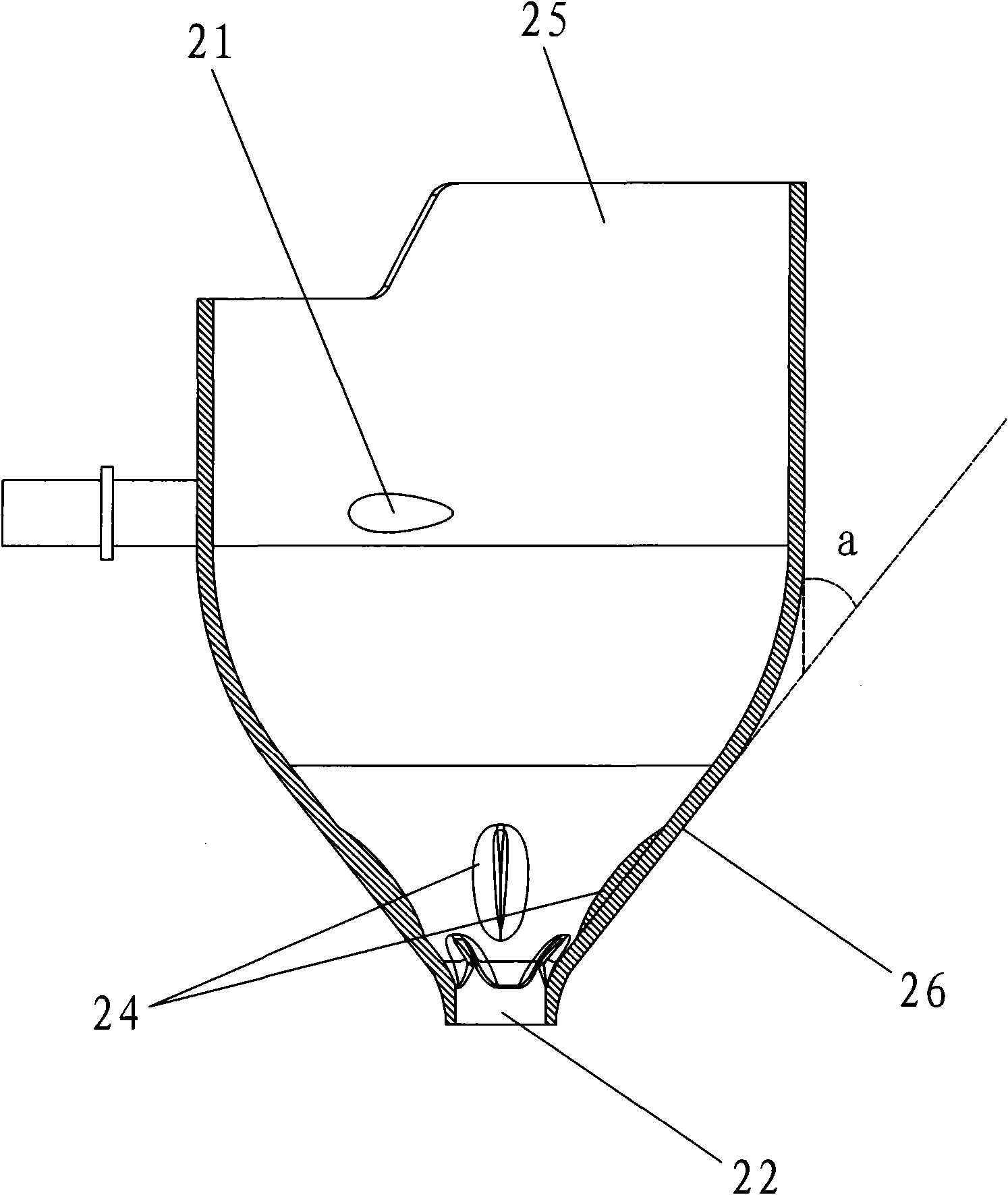

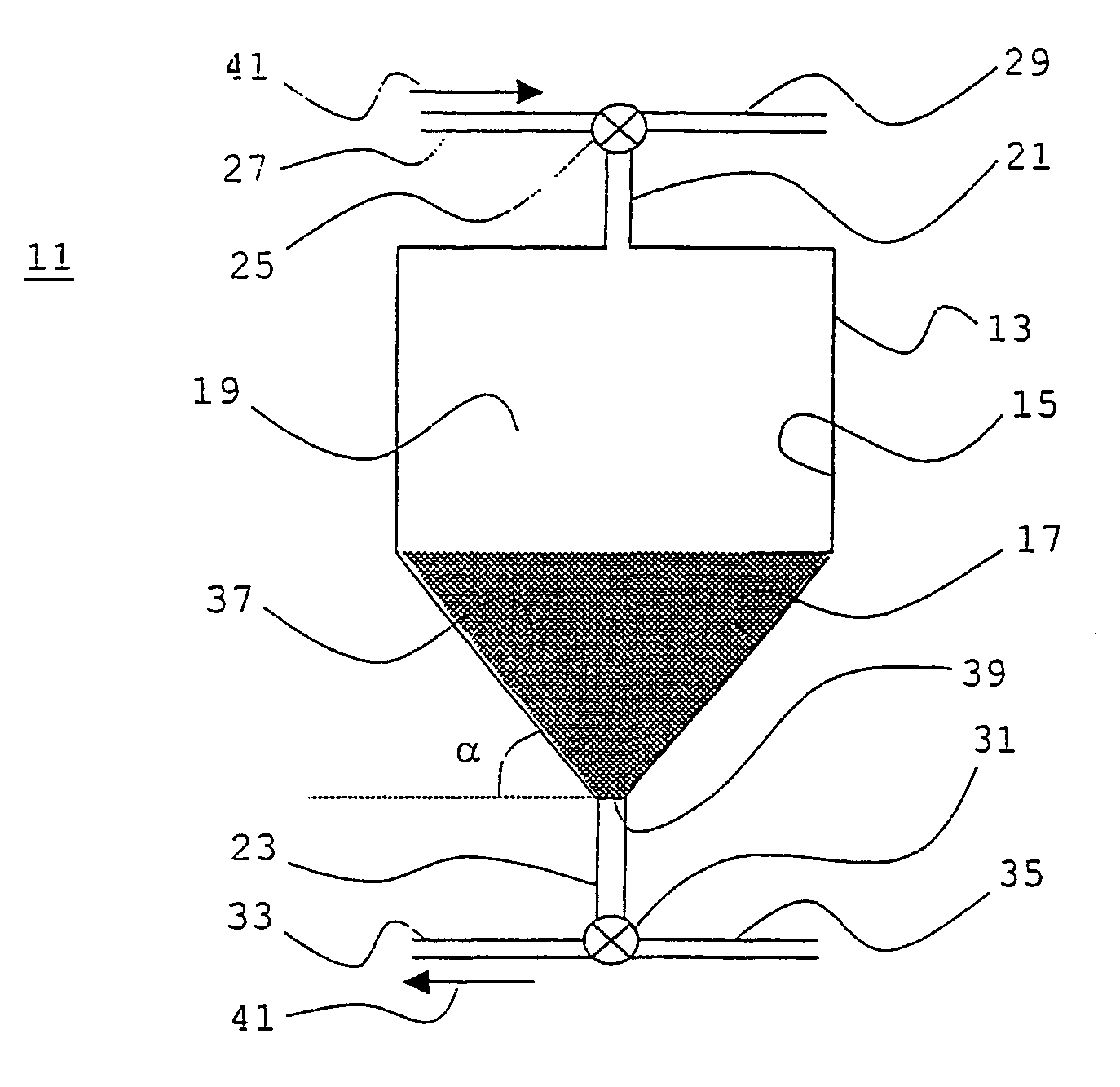

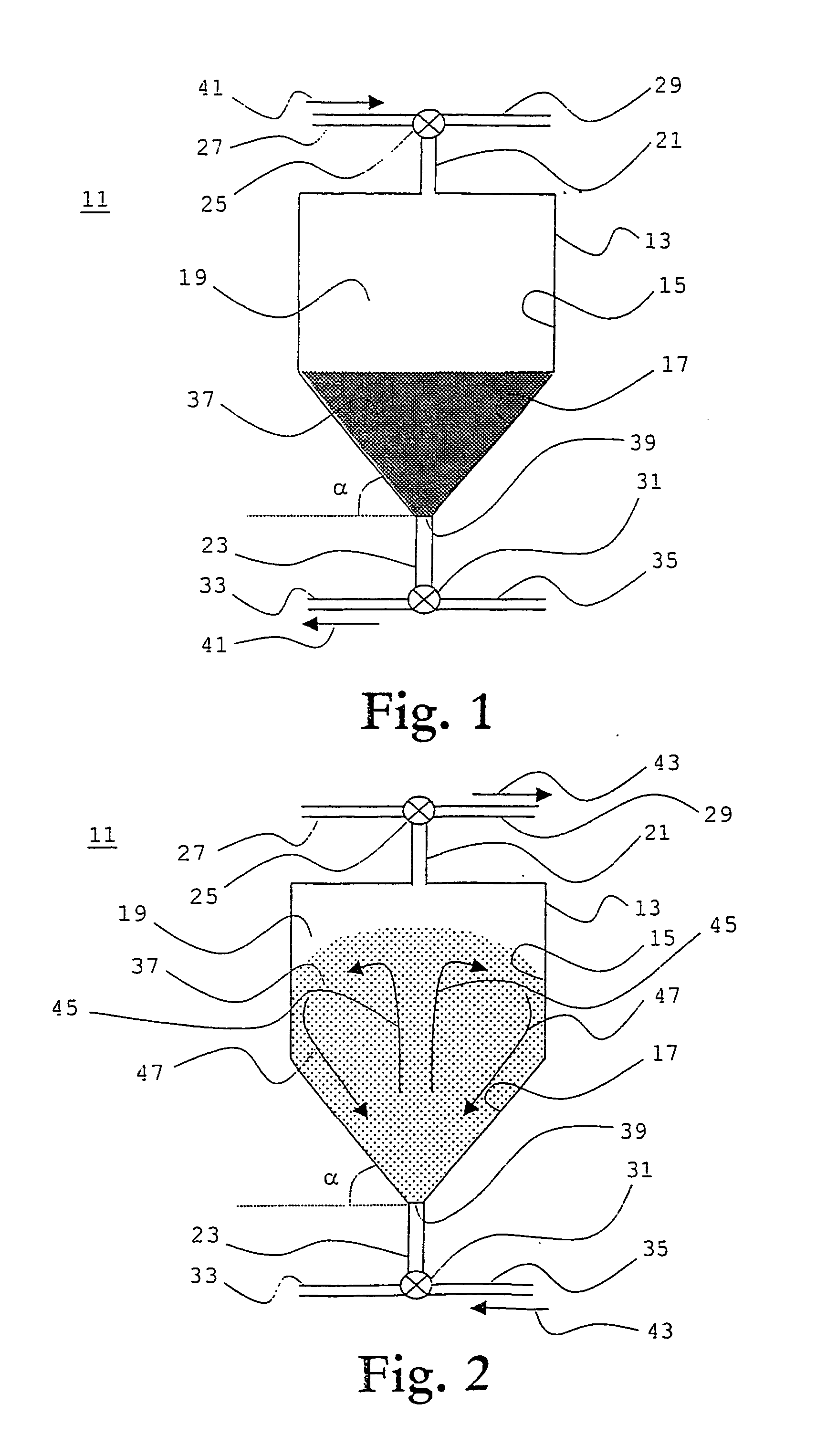

Milk filtration and filter regeneration

InactiveUS20040031765A1Automatically performMilk treatmentWater/sewage treatmentFiltrationEngineering

The present invention refers to an apparatus (11) and a method for milk filtration and filter regeneration. The apparatus comprises a filter vessel (13); a loose filter material (37) housed within the vessel for filtering out contaminants in the milk; and a grid (31) arranged in front of the milk flow outlet to prevent the loose filter material from leaving the vessel. The vessel includes inner walls (15, 17); a milk inlet (21); a milk outlet (23); a cleaning fluid inlet (23) arranged substantially vertically at the lowermost portion of the vessel, through which a cleaning fluid jet can be injected, and a cleaning fluid outlet (21) arranged at the upper portion of the vessel. The lower portions (17) of the inner walls of the vessel form an angle (alpha) with respect to the horizontal plane, the angle being larger than the angle of repose for the filter material in the cleaning fluid. Thus, the filter material, which is flowed vertically upwards (45) by the cleaning fluid jet, moves substantially radially outwards (45) with respect to the jet to descend downwards (47) and slide back (47) towards the jet by aid of the angled inner wall portions.

Owner:DELAVAL HLDG AB

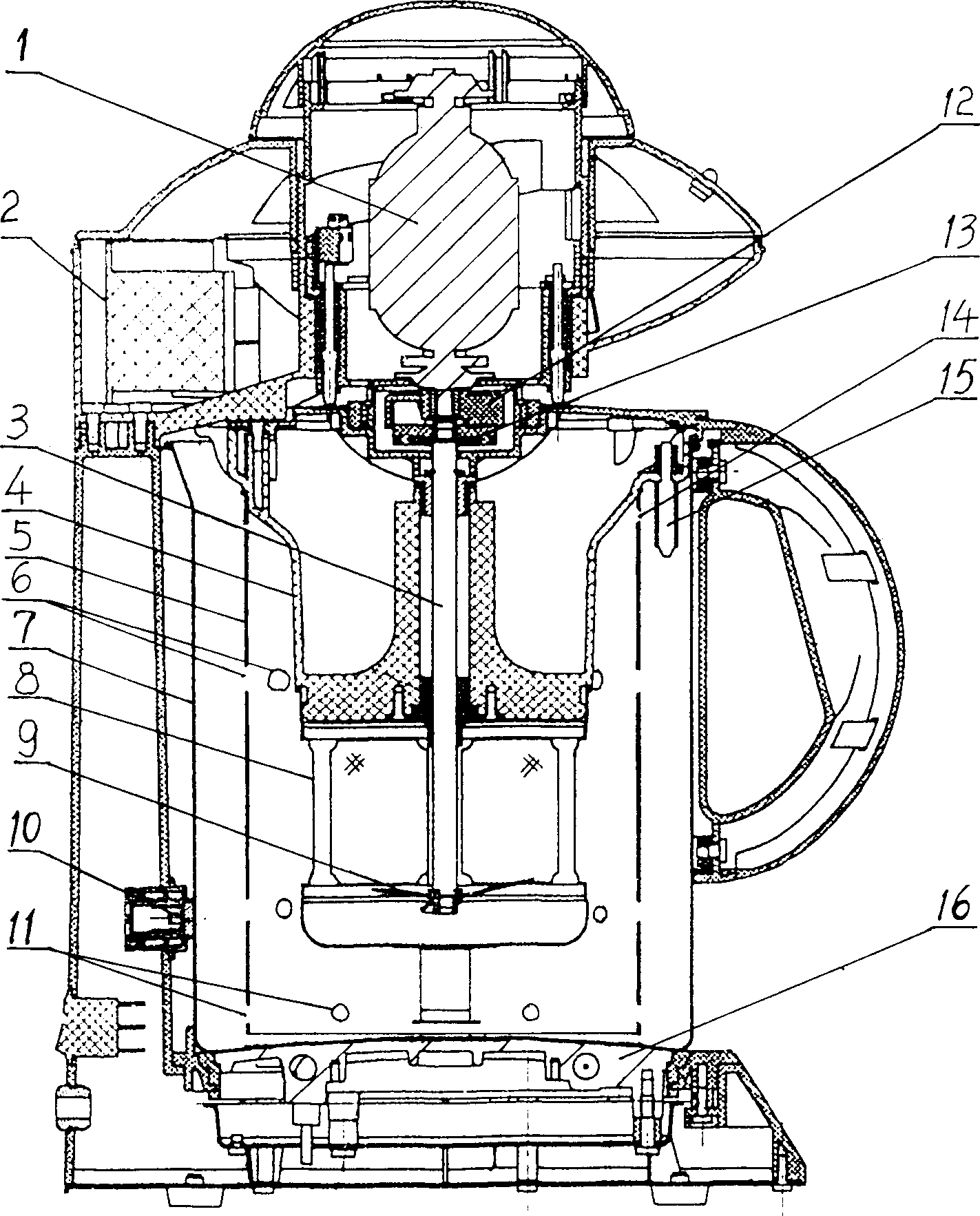

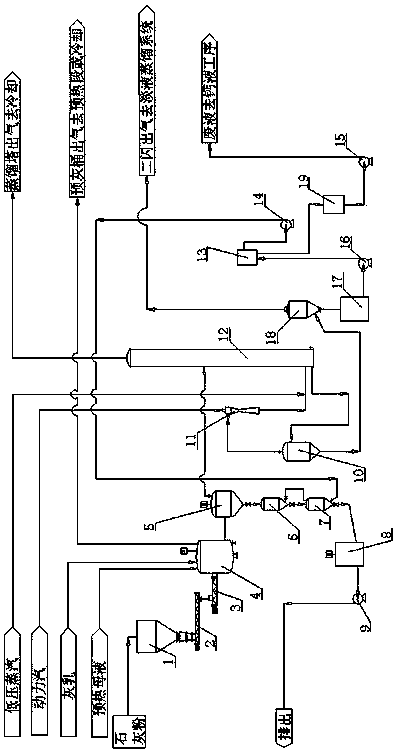

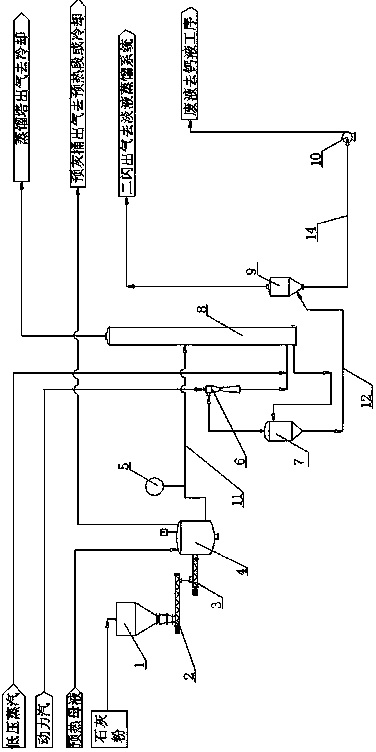

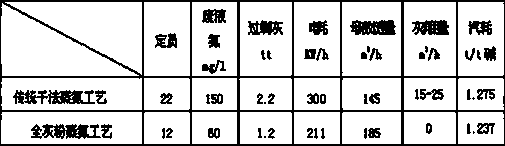

Ammonia distillation device and technology by mother liquor and total ash powder with alkaline method

InactiveCN103693701ADigestive heat is fully utilizedImprove abilitiesWater/sewage treatment by heatingWater/sewage treatment by degassingFluid phaseDistillation

The invention relates to an ammonia distillation device and technology, in particular to an ammonia distillation device and technology by mother liquor and total ash powder with an alkaline method. According to the device and the technology, a bottom end outlet of a second flash tank is connected with a second layout pipeline which is directly connected with a waste liquor charging pump; the preheated mother liquor and lime powder are blended in proportion, sent to a preliming barrel, stirred and mixed and react in the preliming barrel, and ammonia formed by the reaction is sent out from the top end of the preliming barrel and used for other procedures after cooling treatment; and a reaction liquid of the preliming barrel flows into a fixed ammonia distillation column and is in countercurrent contact for heat exchange with steam entering from the lower part, and ammonia in a liquid phase is distilled, output from the top of the distillation column and used for other procedures after cooling treatment. Compared with the prior art, lime milk is not used, total ash powder distillation operation is achieved truly, surplus lime is controlled, lime milk flow is not needed to regulate, besides, heat utilization of quick lime slaking is sufficient, and the capacity of the distillation column is increased.

Owner:TANGSHAN SANYOU CHEM IND

Soybean milk filtering device and soybean milk filtering method thereof

ActiveCN102160576AHigh speedImprove filtration efficiencyBeverage vesselsMilk substitutesEngineeringSoybean oil

The invention relates to a soybean milk filtering device and a soybean milk filtering method thereof. The soybean milk filtering method comprises the steps: in a forward rotation stage of a motor, ribs rotate towards a dreg blocking plate to propel and extrude bean dregs, the soybean milk flows to a soybean milk collecting part through a backflow filtering gap, and the bean dregs are deposited ina dreg storing groove; and in a reverse rotation stage of the motor, the ribs move rotatably to propel the bean dregs to be extruded and discharged towards the direction of a dreg outlet along a spiral groove, and the soybean milk flows to the soybean milk collecting part through the backflow filtering gap. Compared with the prior art, the soybean filtering device and the soybean filtering methodthereof have the advantages that the filtering efficiency is high, the bean dreg content is low, the soybean milk yield is high and the like.

Owner:JOYOUNG CO LTD

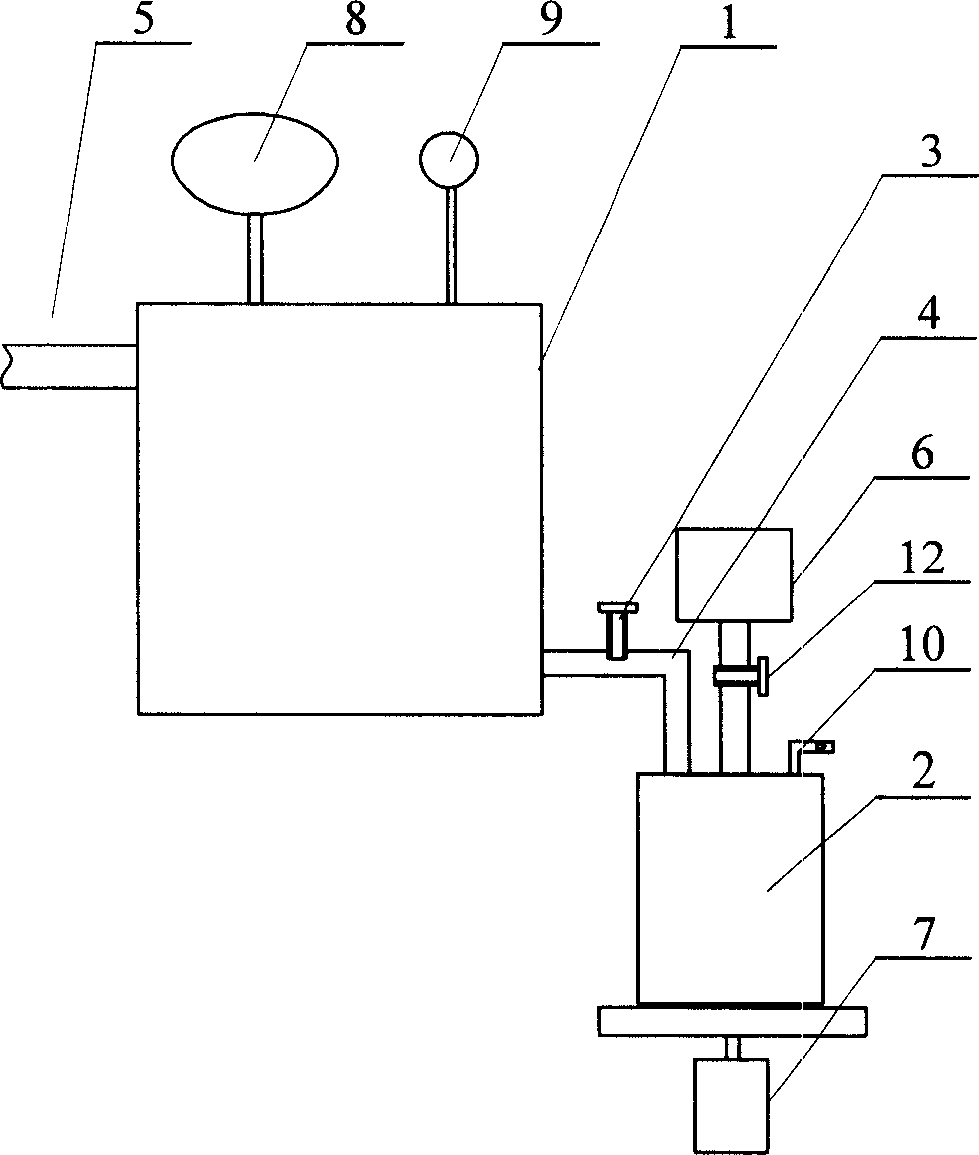

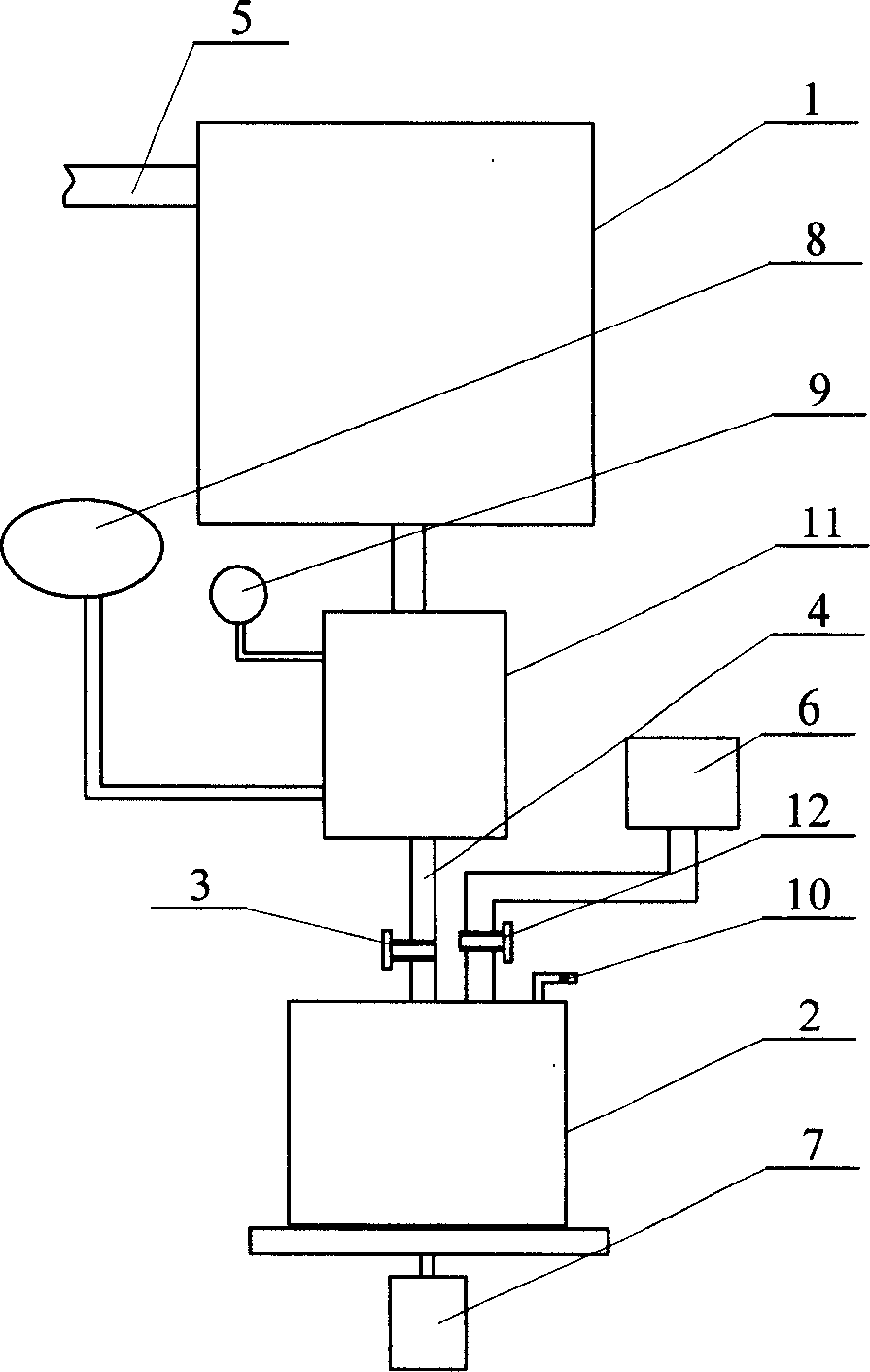

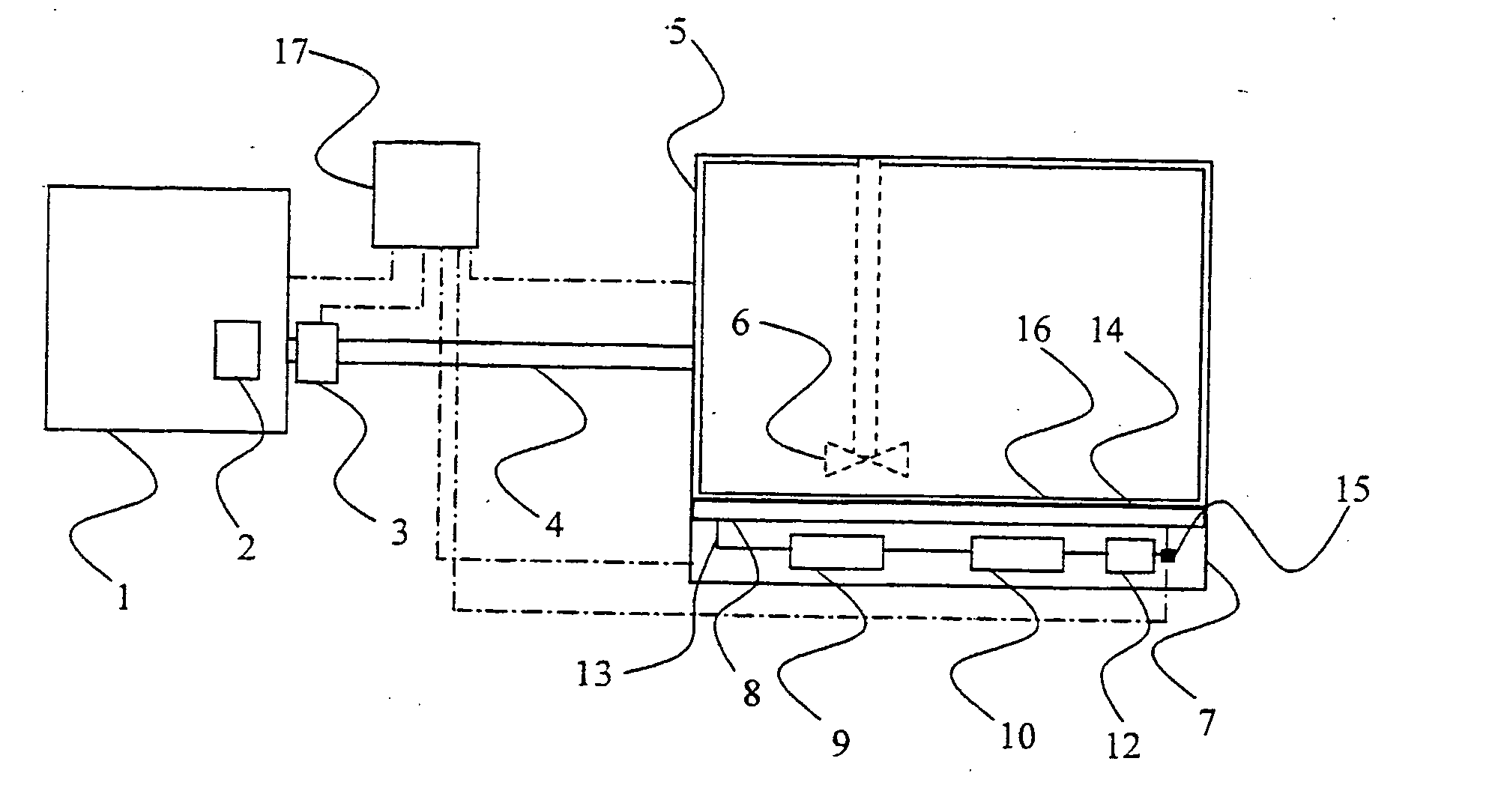

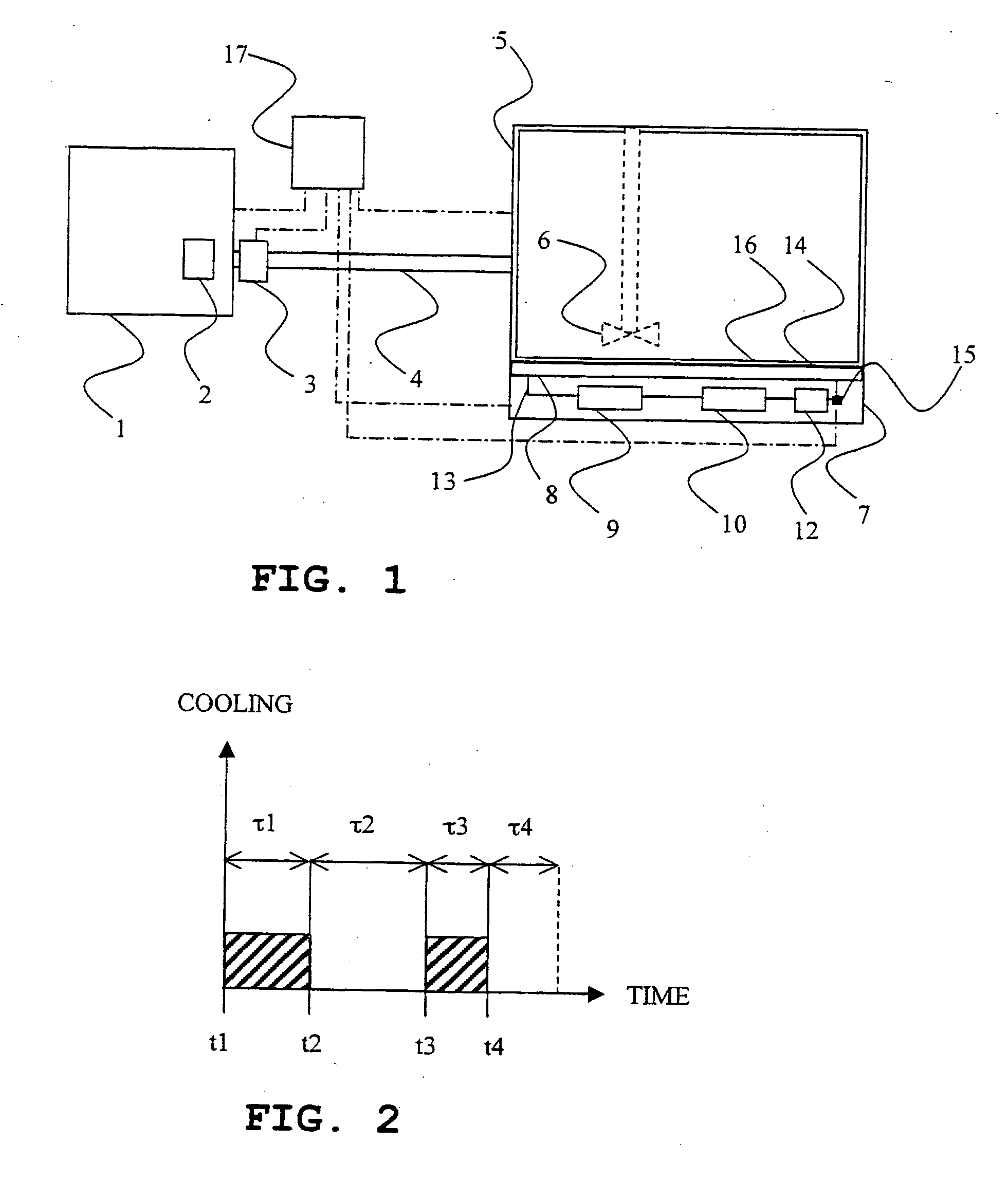

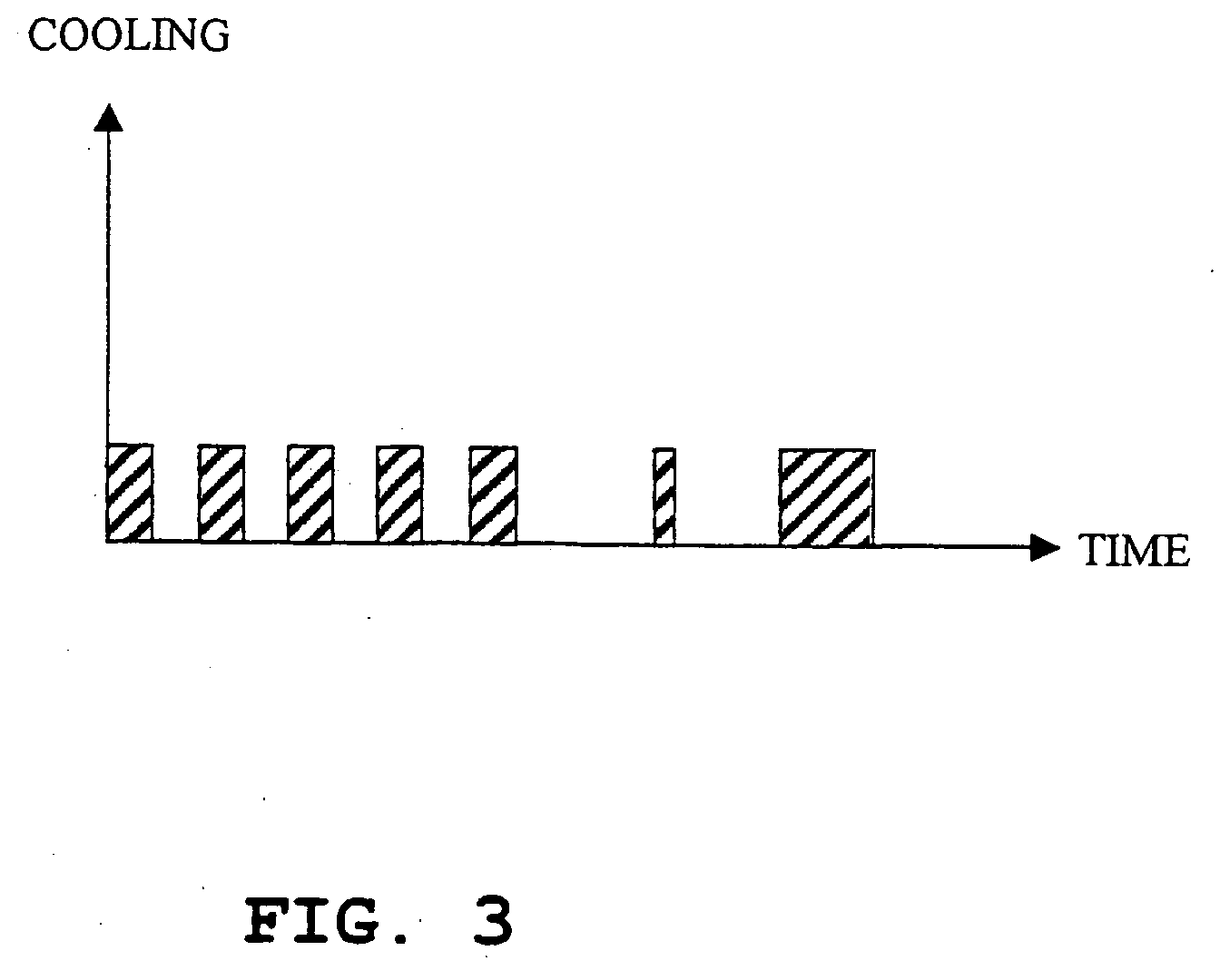

Cooling of milk in an automatic milking system

InactiveUS20060124065A9Without risk of freezingRapid coolingCathetersMilk receptaclesProcess engineeringAutomatic milking

The present invention relates to a method for cooling milk in a milk storage tank of an automatic milling system comprising the steps of (i) measuring an amount of extracted milk by means of a milk flow meter, (ii) determining a cooling need for milk stored or to be stored in said milk storage tank based on said amount of milk; (iii) measuring a quantity indicative of a temperature of an inner surface area of a bottom portion of the milk storage tank; and cooling said bottom portion of said milk storage tank in consecutive periods, such that each period of cooling (τ1, τ3) is followed by a respective period of non-cooling (τ2, τ4), wherein the duration of each period of cooling and / or noncooling is based on said measured quantity indicative of said inner surface area temperature, and said cooling need. The invention also relates to an arrangement for performing the method.

Owner:DELAVAL HLDG AB

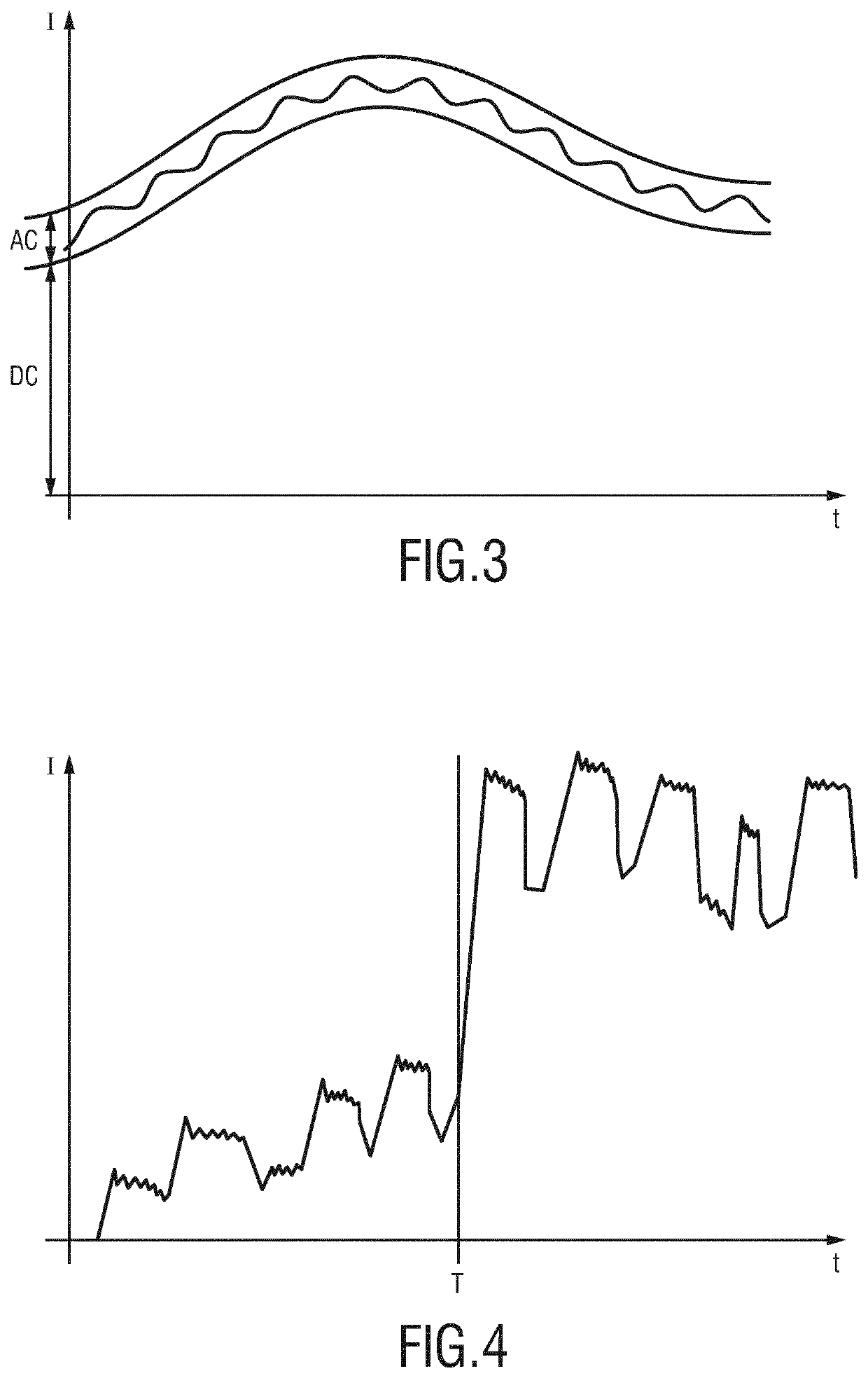

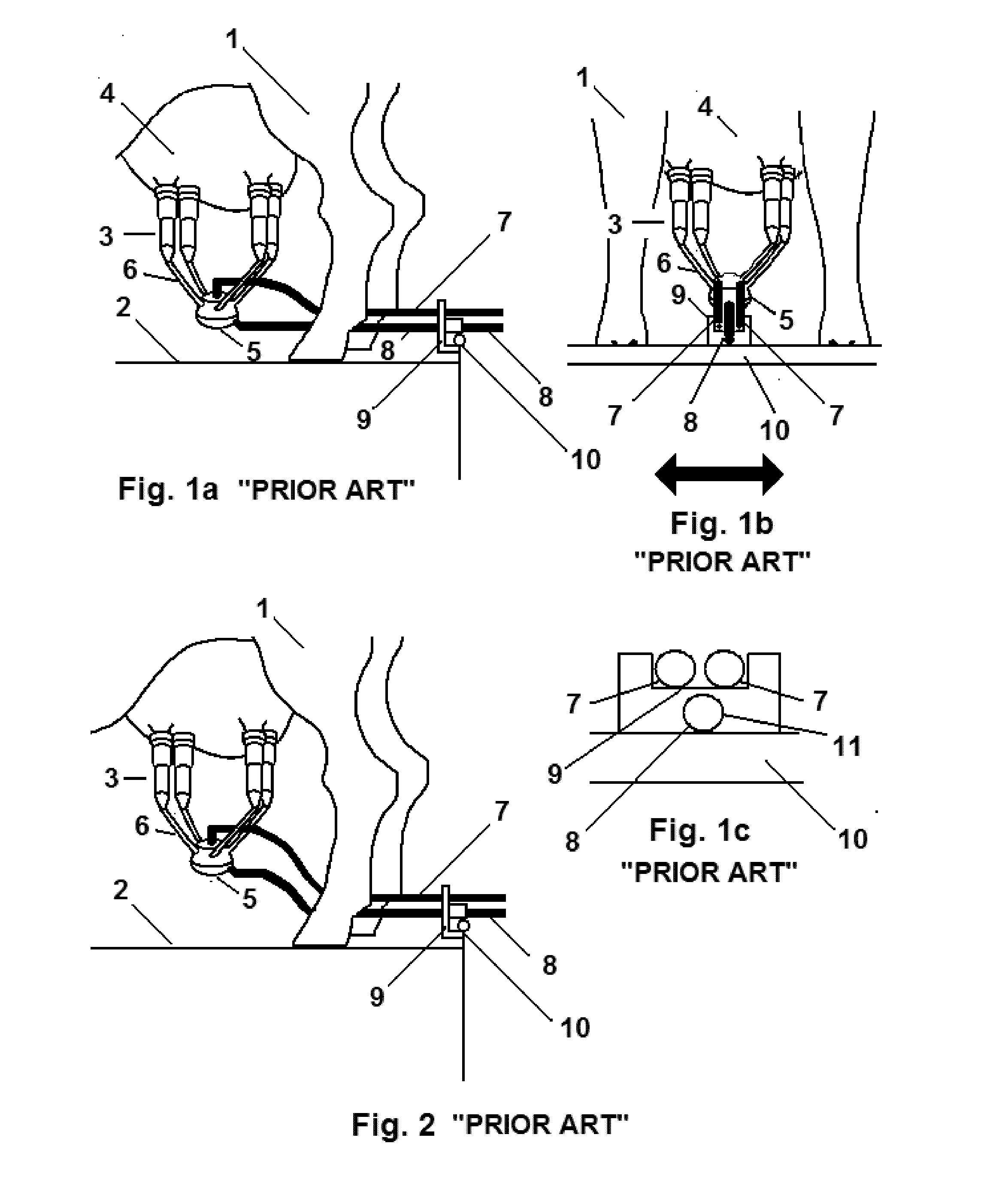

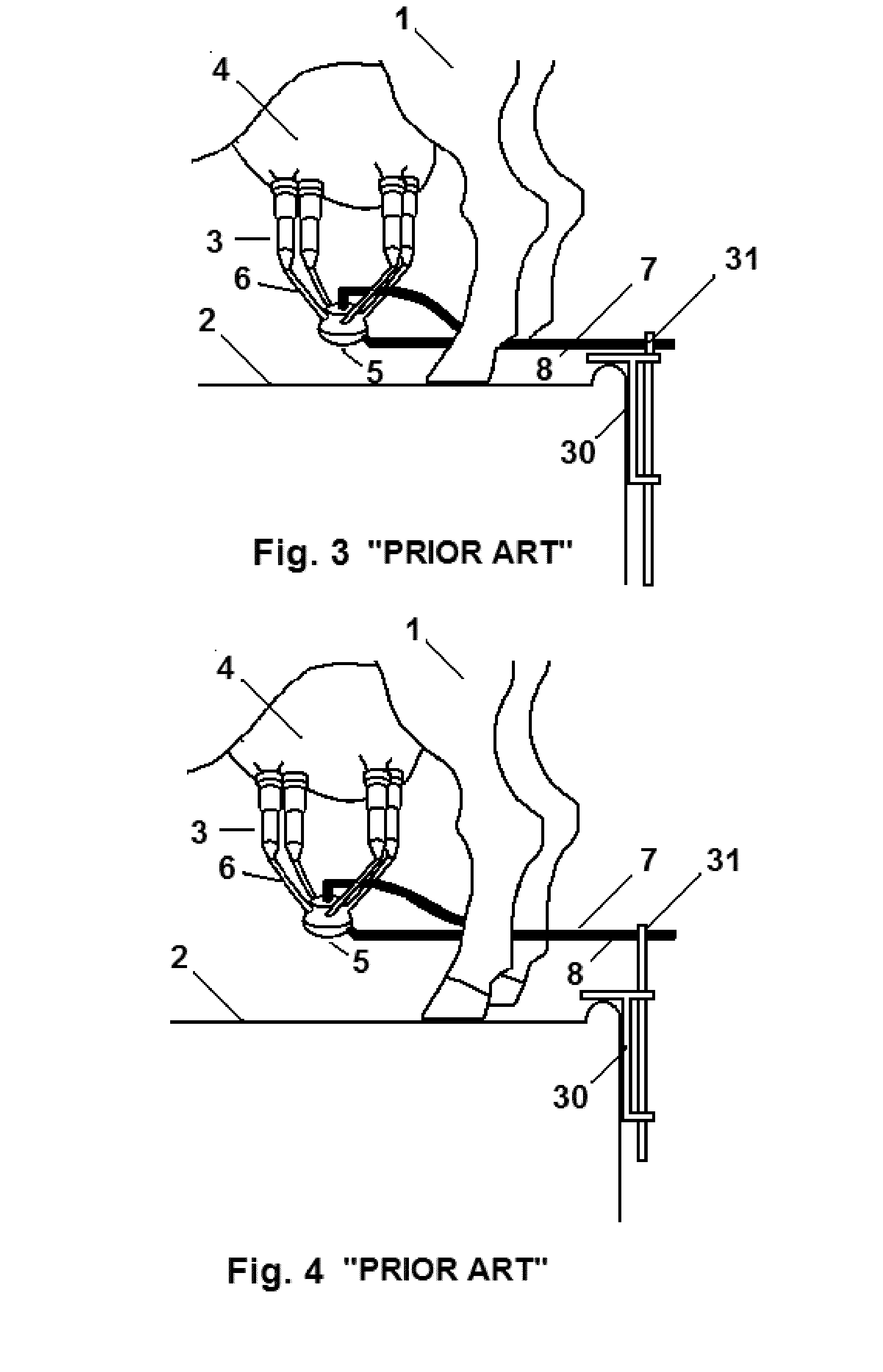

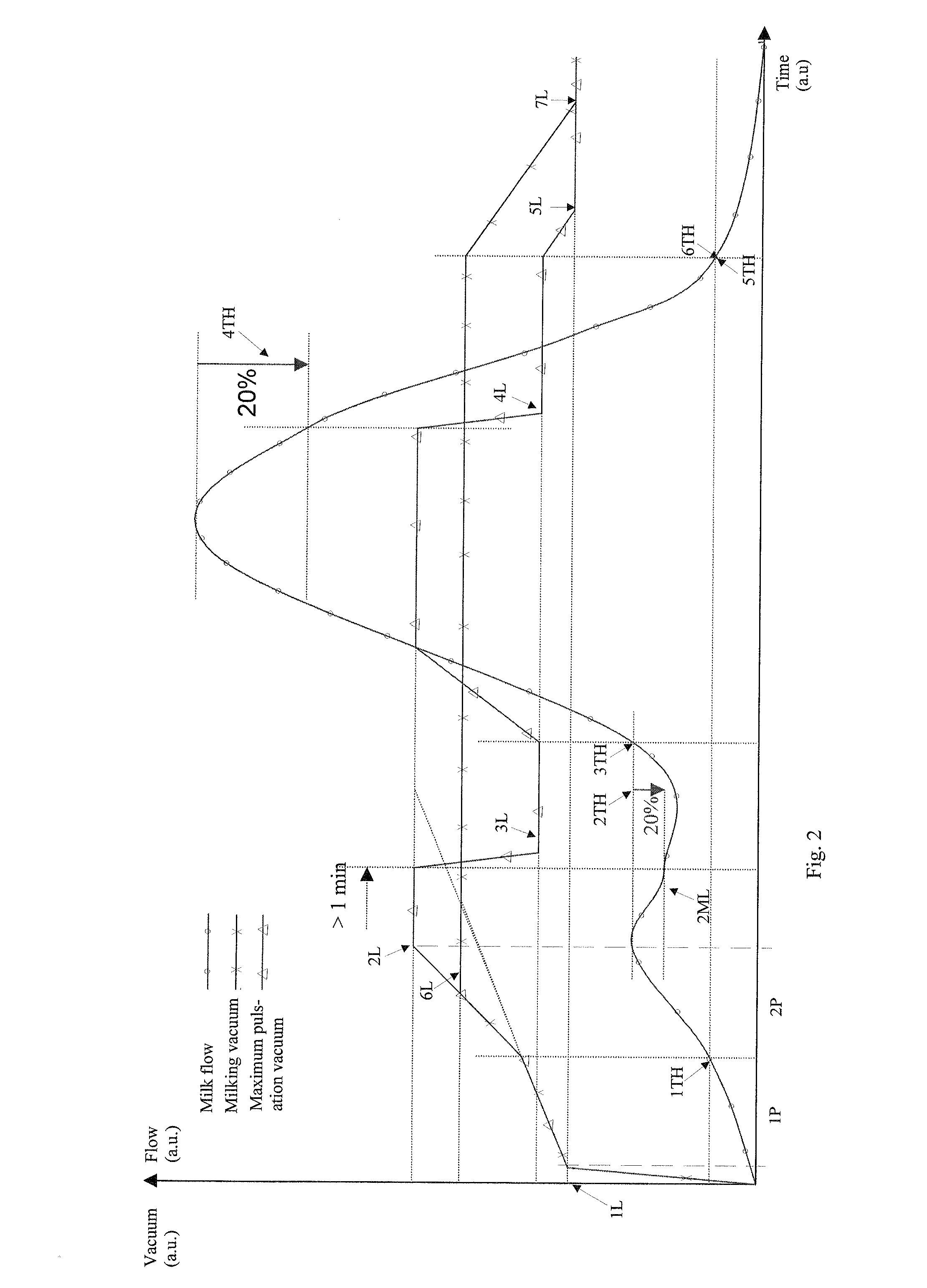

Method and arrangement for controlling the milking by a milking machine

A method for controlling the milking by a milking machine includes, during an initial phase of the milking, increasing a milking vacuum and / or a maximum pulsation vacuum for the milking gradually from a first selected vacuum level (1L) towards a second selected vacuum level (2L) to thereby improve teat stimulation and decreasing the risk of a second milk letdown. When a second milk letdown (2ML) is detected, the maximum pulsation vacuum is preferably immediately lowered to a third selected vacuum level (3L), and is kept at that third selected vacuum level until a certain milk flow has been established, whereupon the pulsation vacuum level is then again increased gradually until the second selected vacuum level is reached.

Owner:DELAVAL HLDG AB

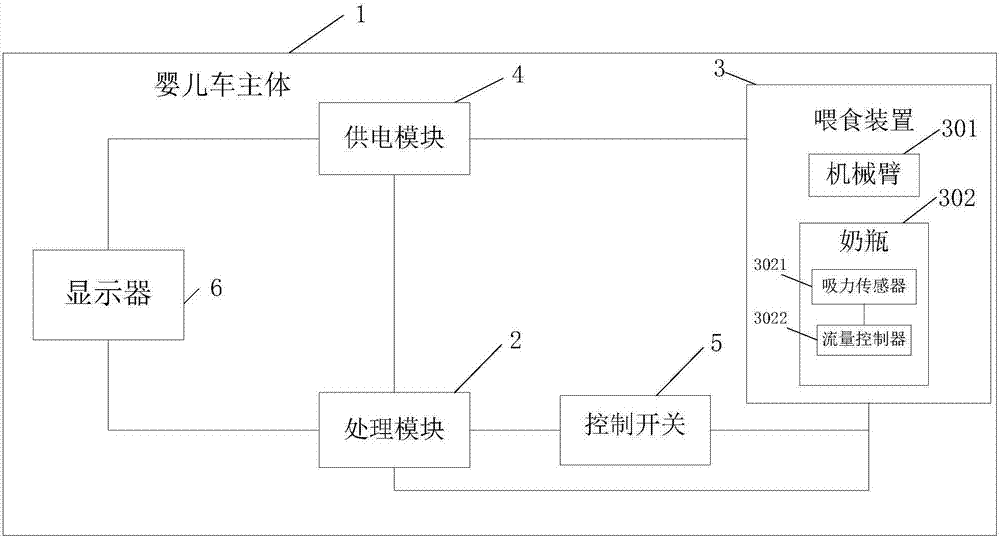

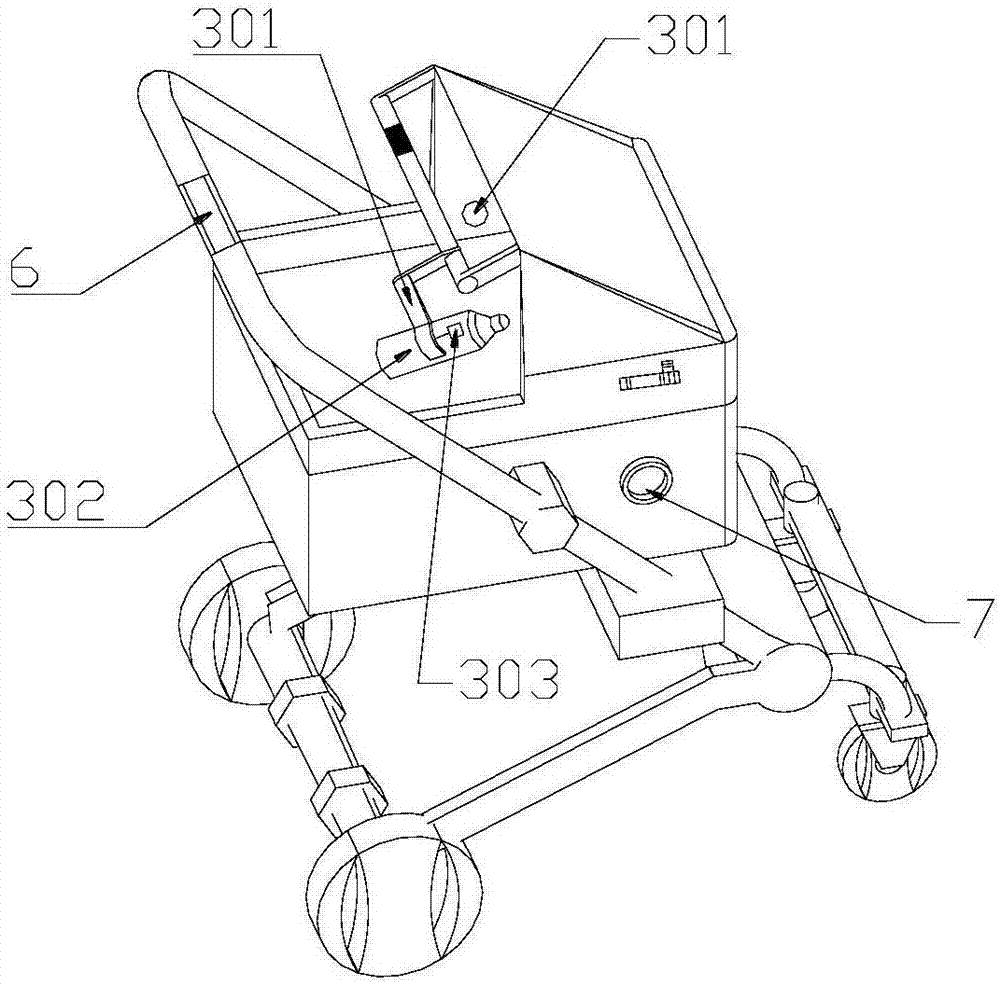

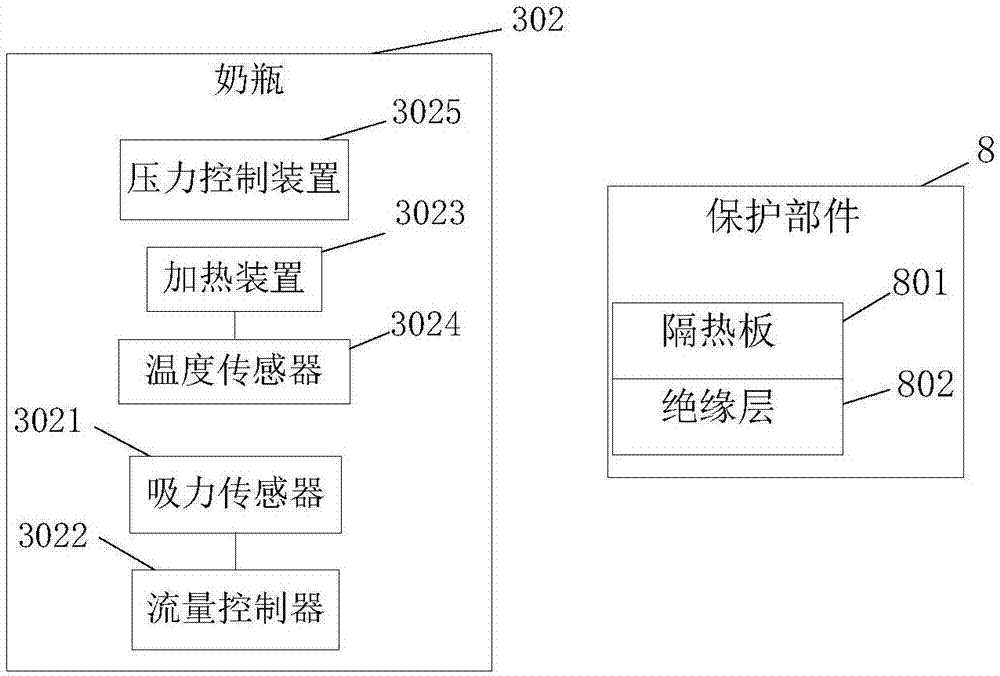

Baby carriage with feeding device

InactiveCN107351903AIntelligently adjust the flow sizeReduce laborCarriage/perambulator accessoriesCharacter and pattern recognitionSuction forceComputer module

The invention discloses a baby carriage with a feeding device. The baby carriage comprises a baby carriage body, a processing module, the feeding device and a power supply module, wherein the feeding device comprises a mechanical arm and a feeding bottle; the mechanical arm is connected with the processing module and the power supply module separately and used for receiving an instruction sent by the processing module for feeding; a suction force sensor and a flow controller are arranged on a nipple of the feeding bottle, and the suction force sensor and the flow controller are connected with the processing module separately and powered on by the power supply module; the processing module is used for analysis after receiving data of the suction force sensor and controlling the flow of the flow controller; a control switch controls the feeding device to be started or stopped through the processing module. According to the baby carriage, a hunger baby can be automatically fed, the milk suction strength of the baby can be sensed, and the flow of milk flowing out of the feeding bottle is intelligently adjusted; meanwhile, it is guaranteed that the temperature of the milk is within a proper range, and the workload for nursing the baby is reduced.

Owner:亚月(武汉)智能科技有限公司

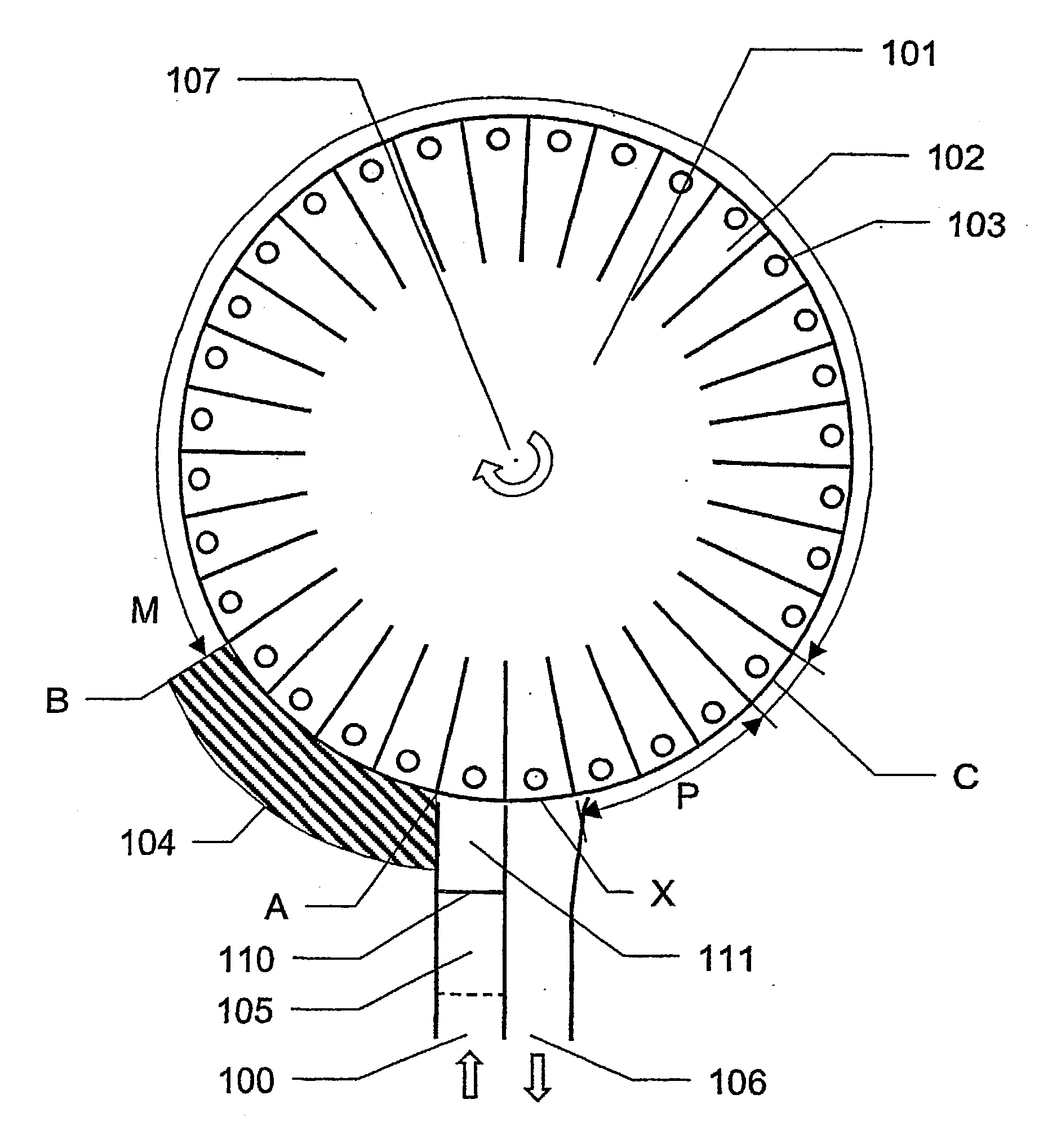

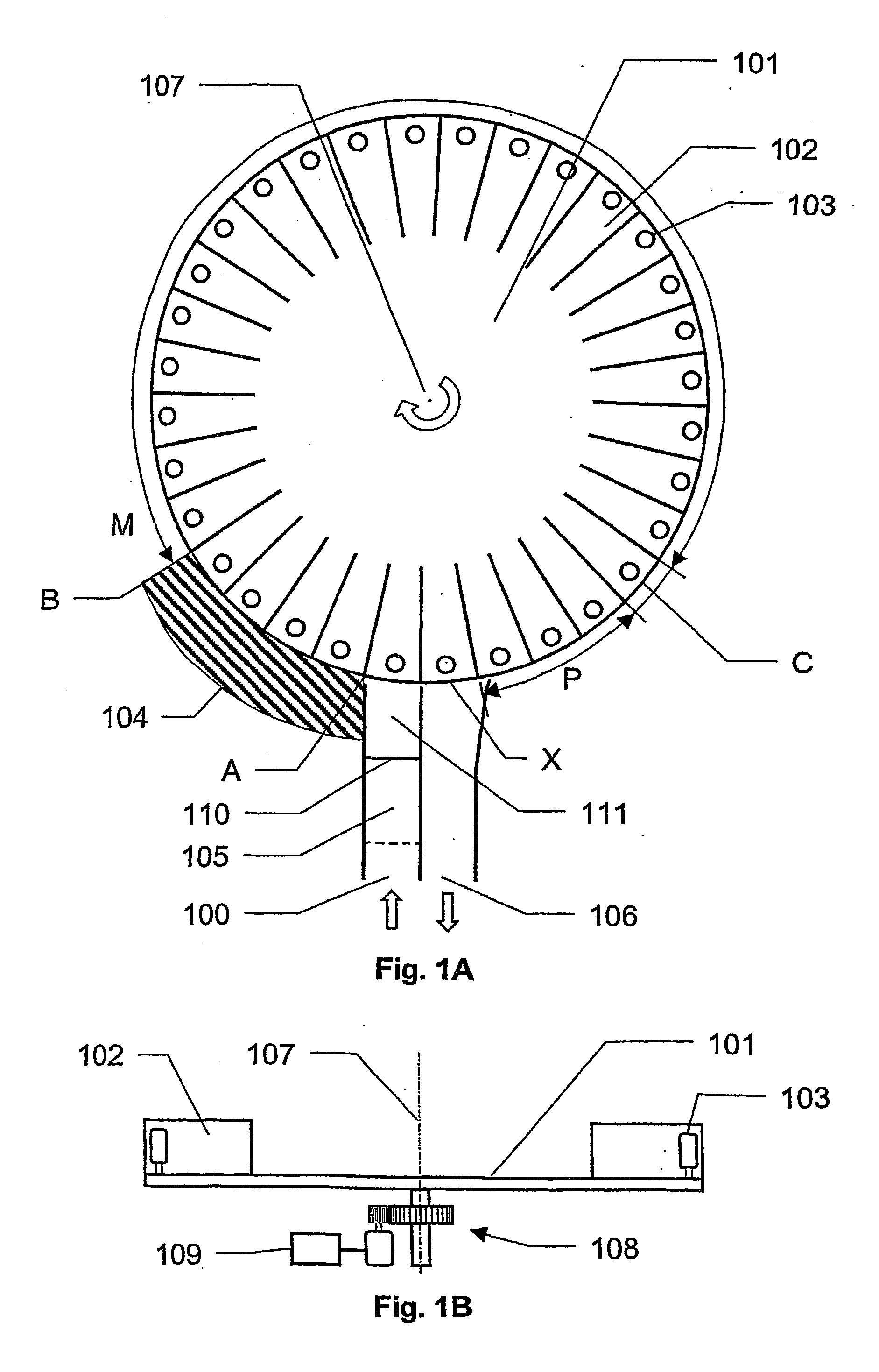

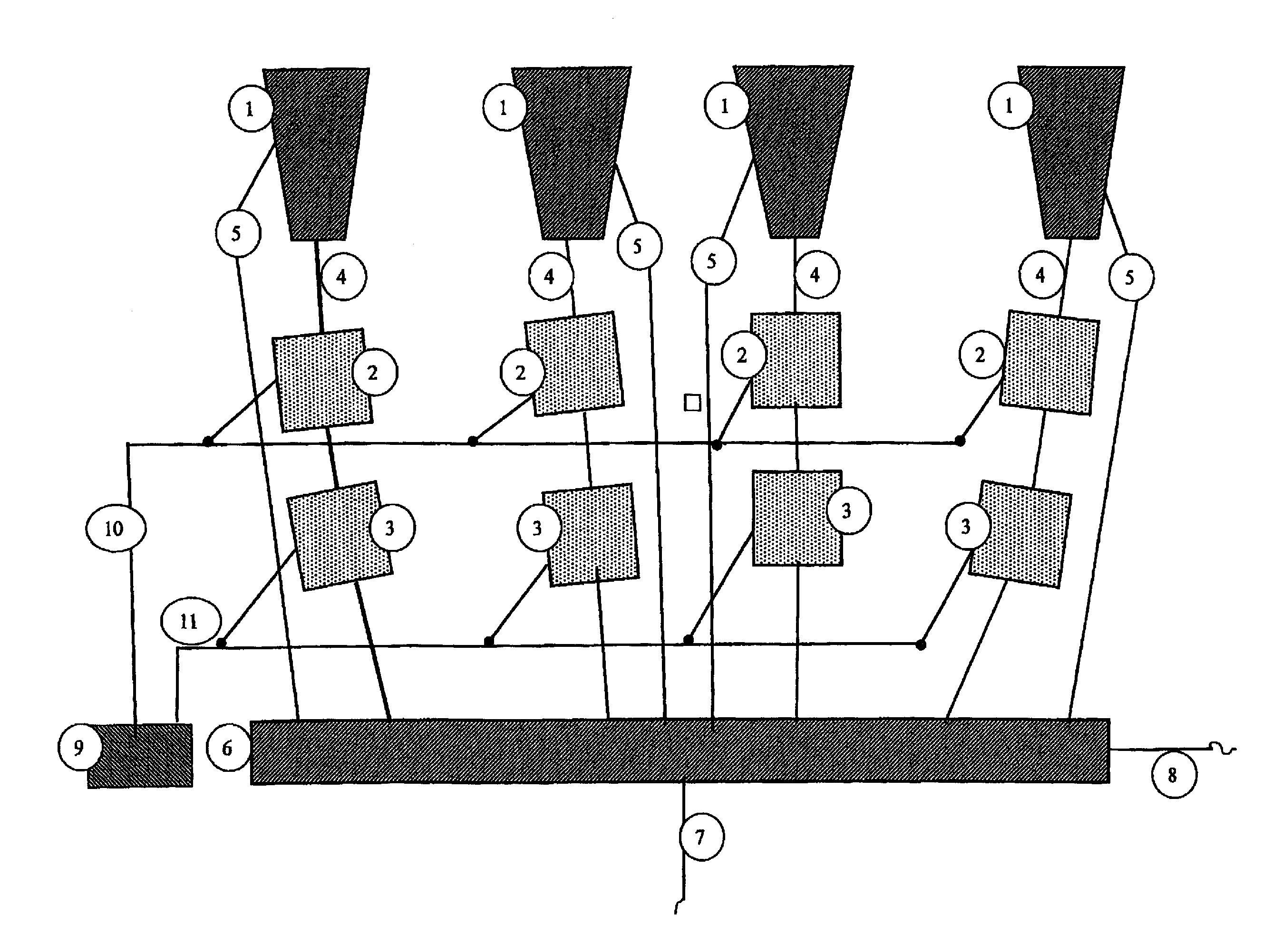

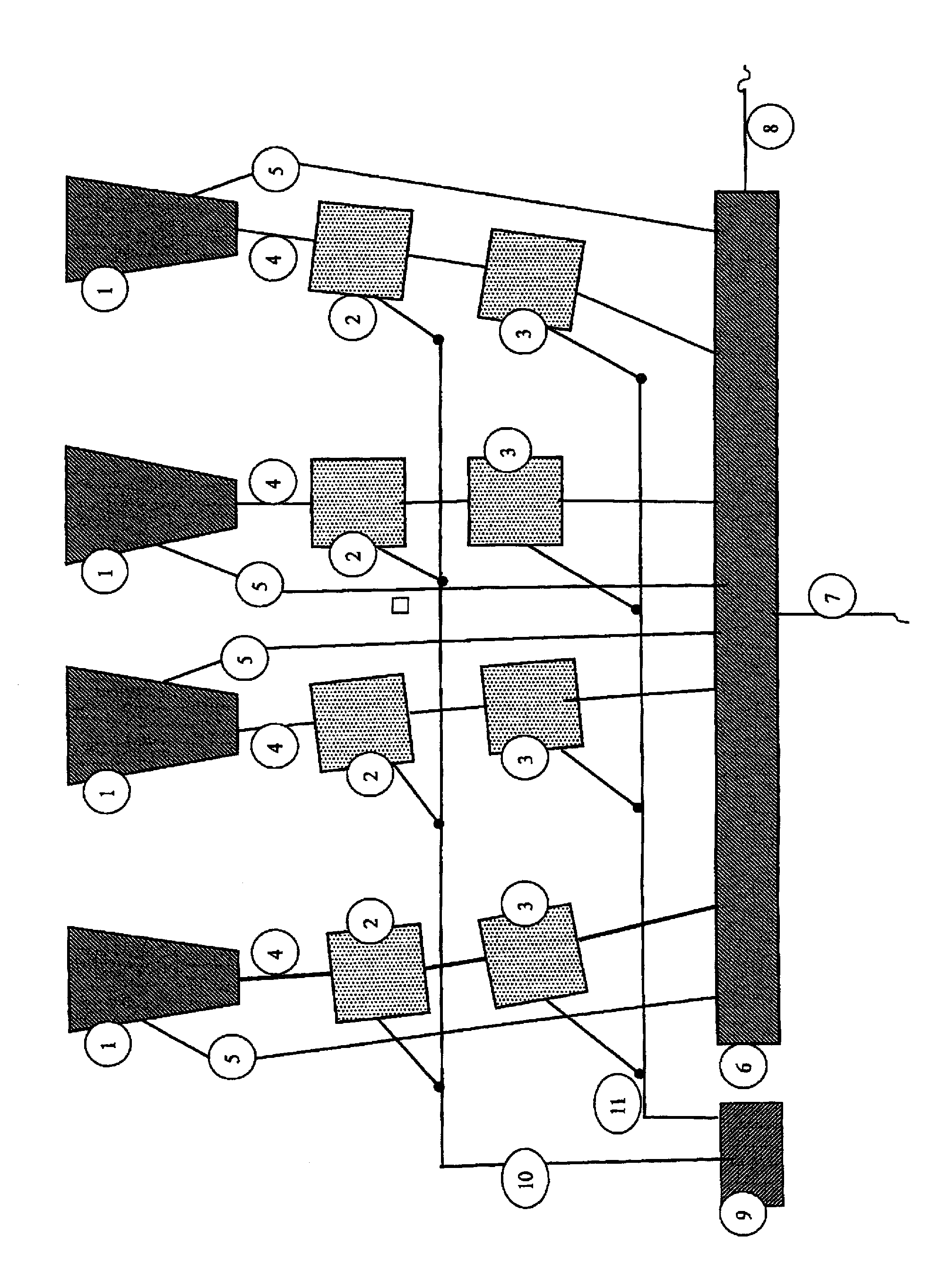

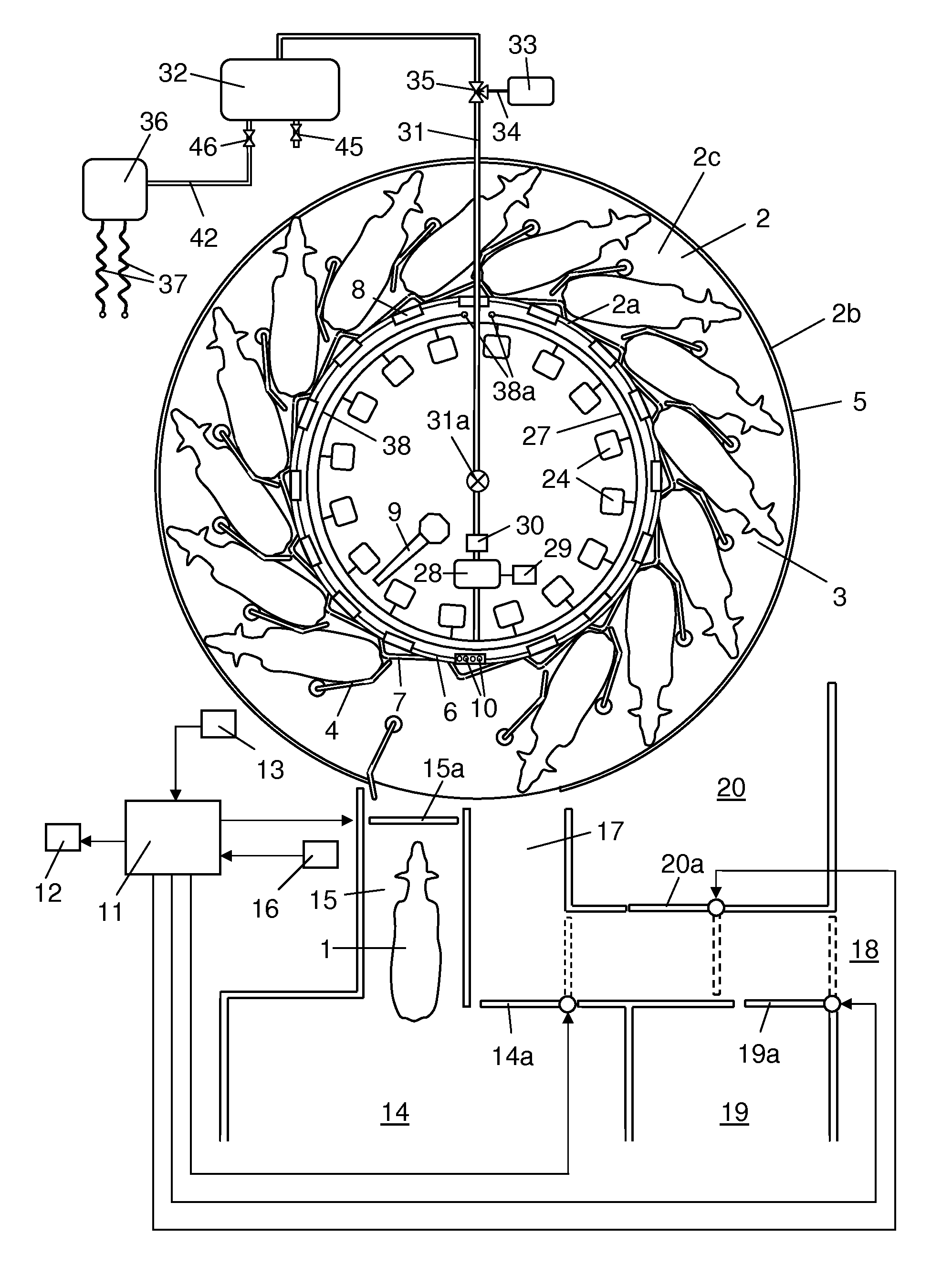

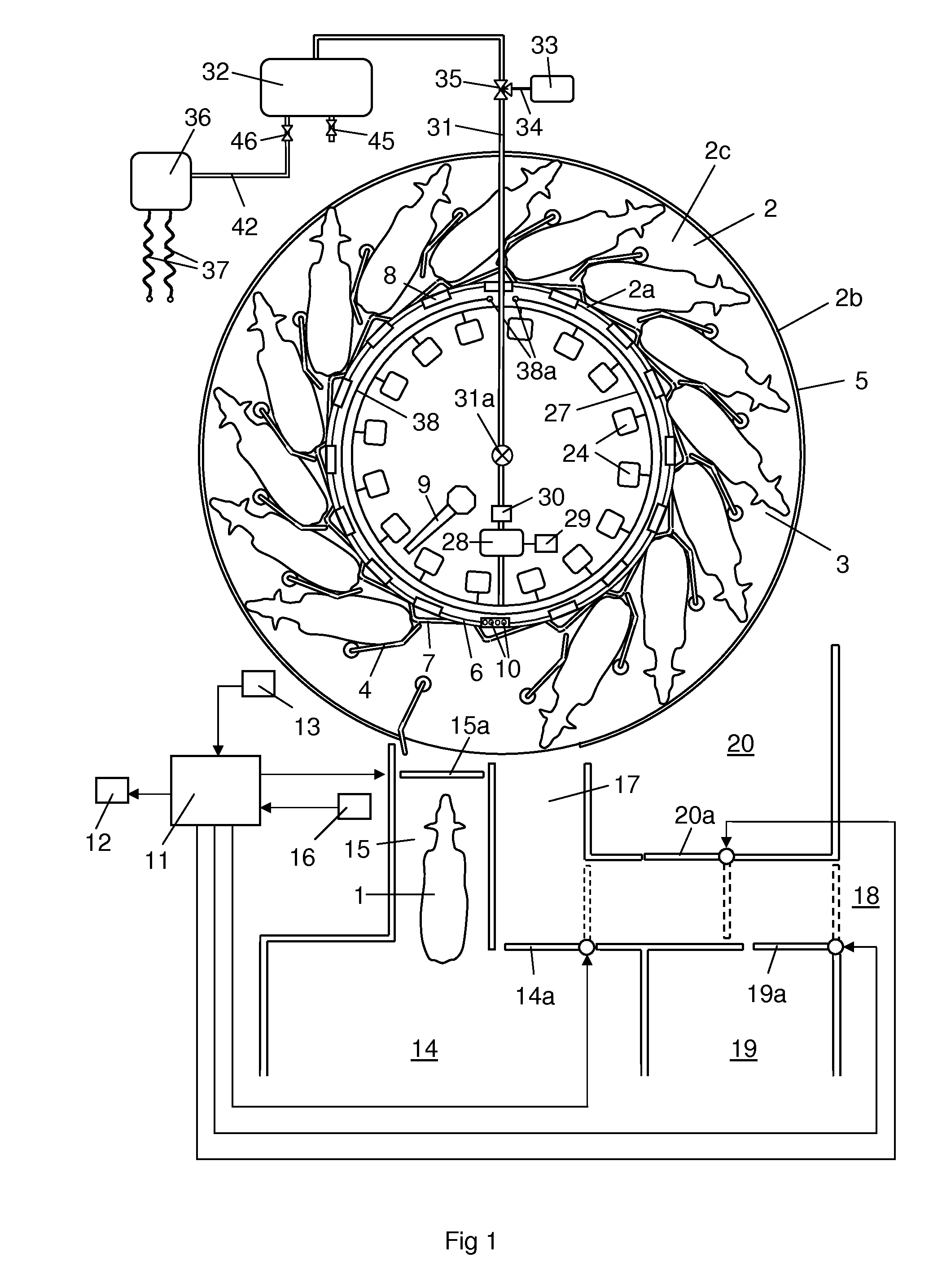

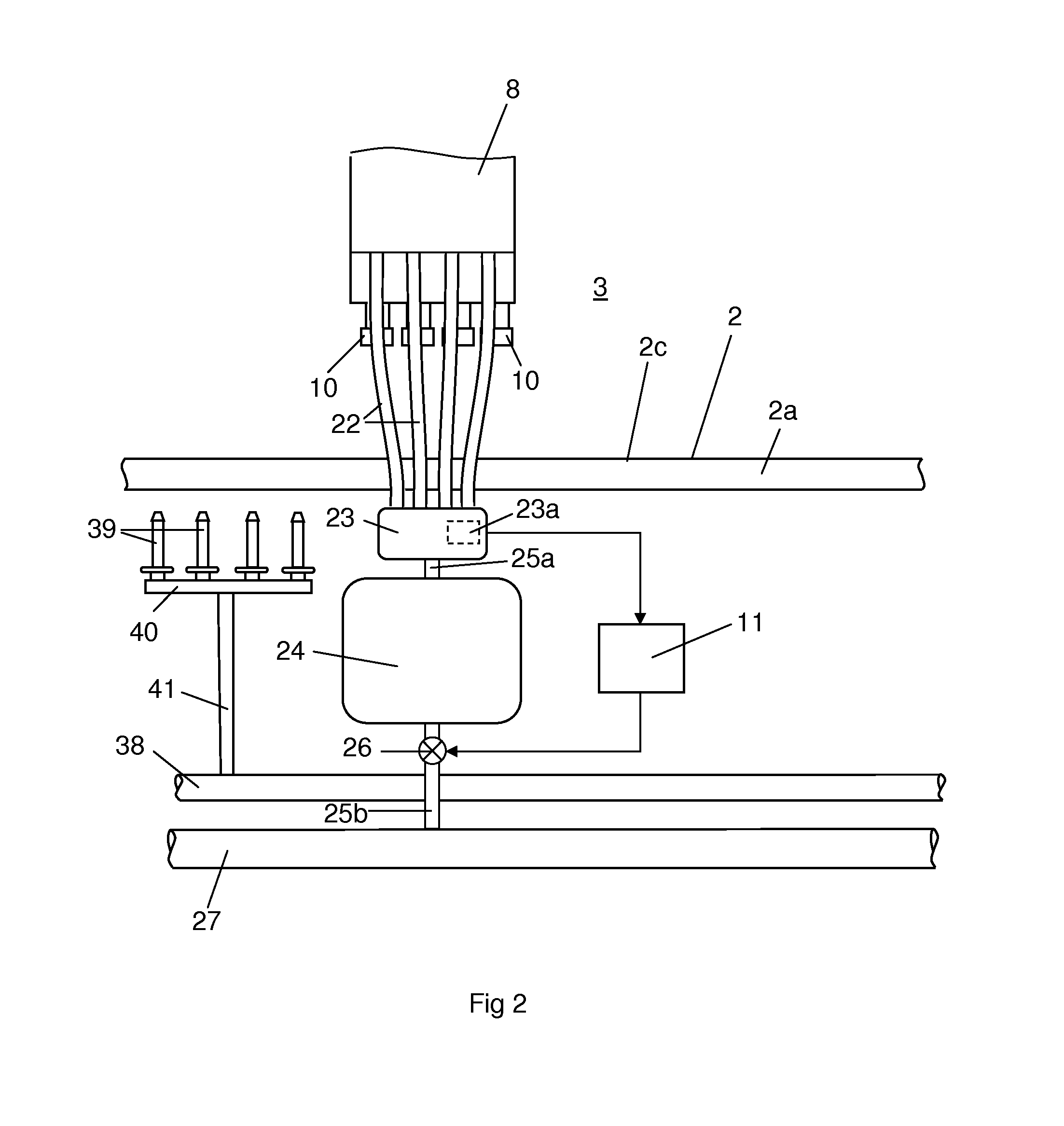

Rotary milking parlour and a method for such a rotary milking parlour

A milking parlour and a method includes a rotary platform, plurality of milking stalls arranged on the rotary platform, a common milk line conducting milk from several milking stalls to a common milk tank, a local milk receiver for each milking stall and a valve member controlling the milk flow from the local milk receiver to the common milk line. The valve members are controlled such that all milk of acceptable quality from the local milk receiver is discharged, via the common milk line, to the common milk tank before milk of unacceptable quality is discharged from the local milk receivers to the common milk line during a milking period in the milking parlour between two following washing processes of the common milk line.

Owner:DELAVAL HLDG AB

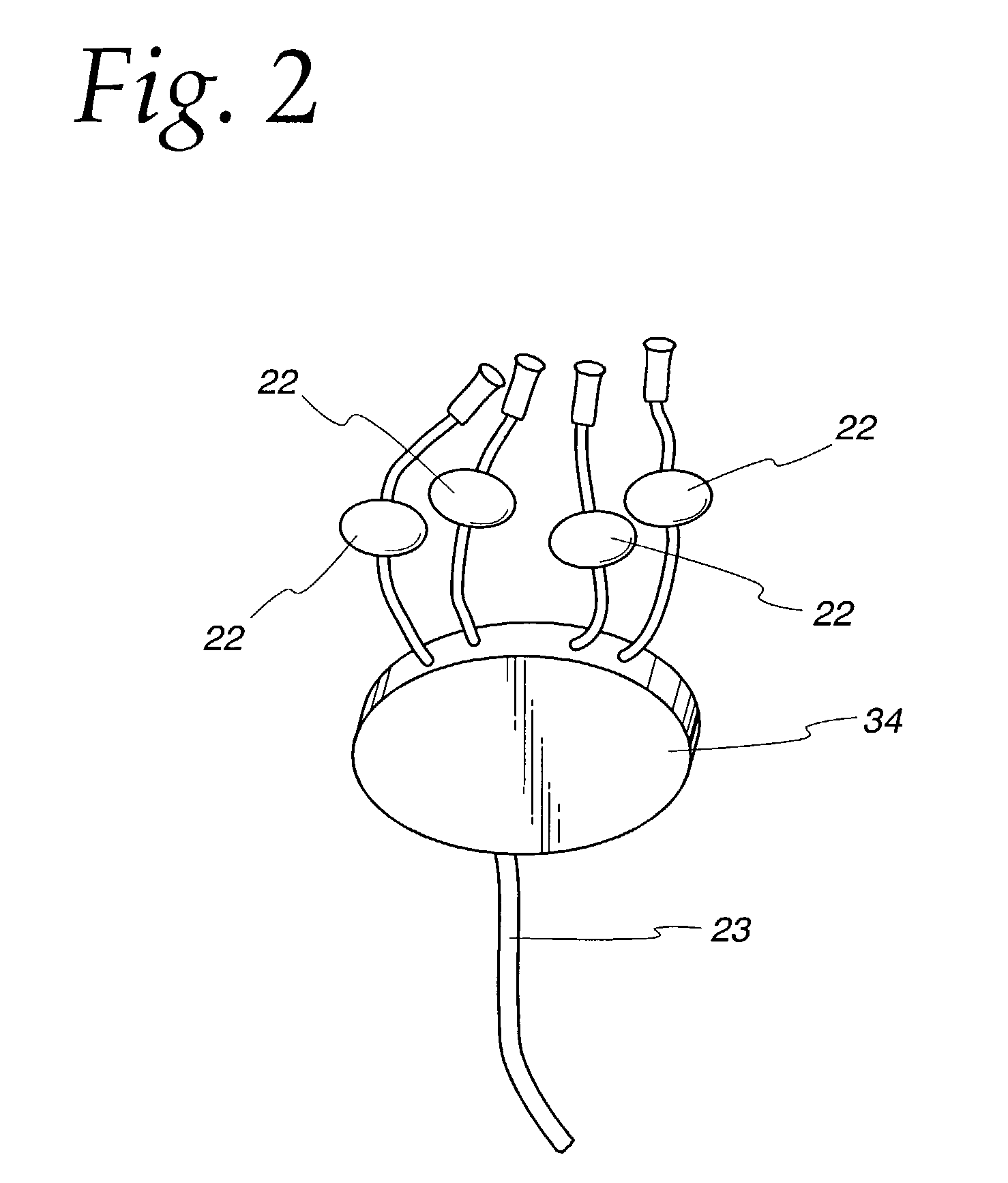

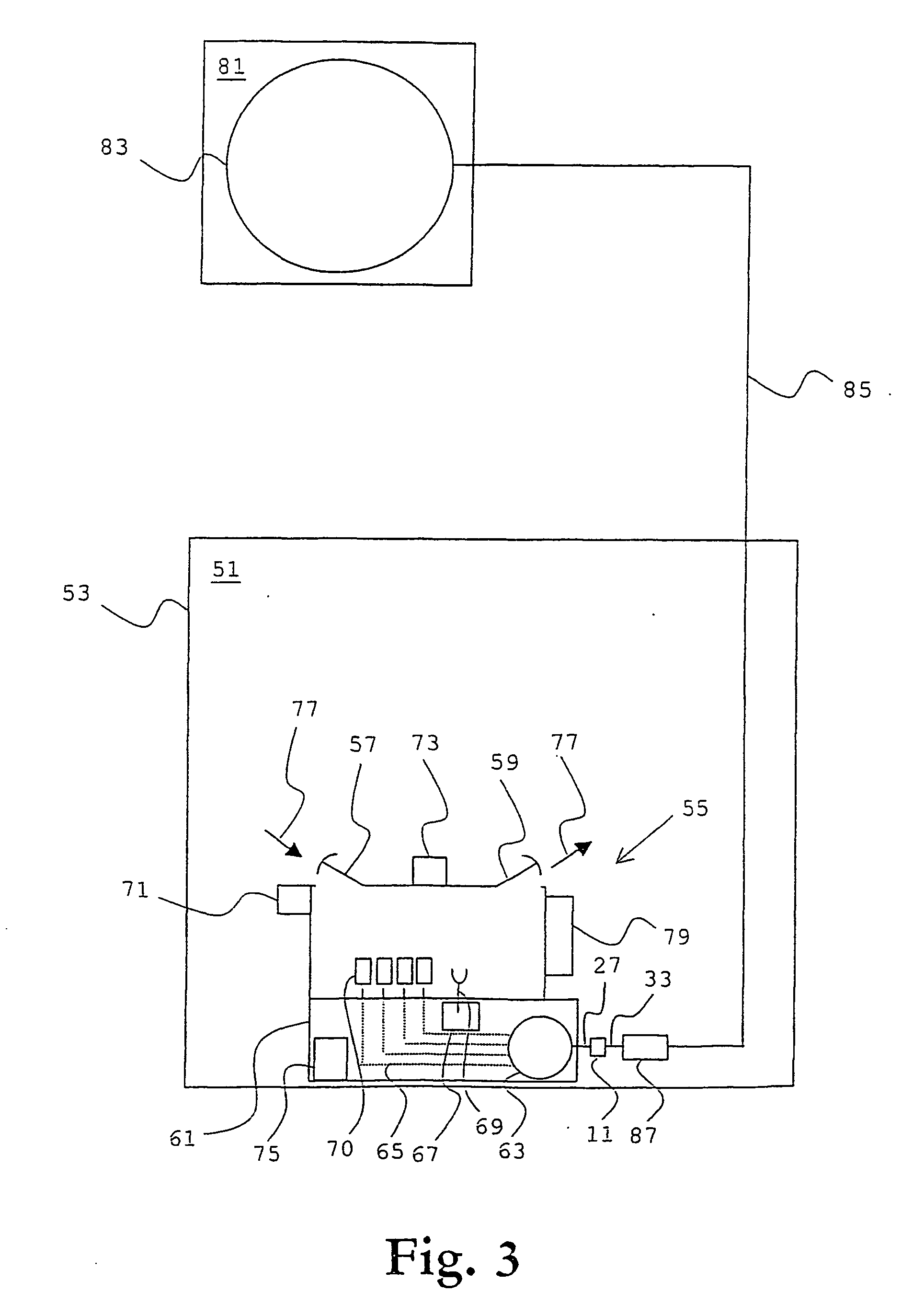

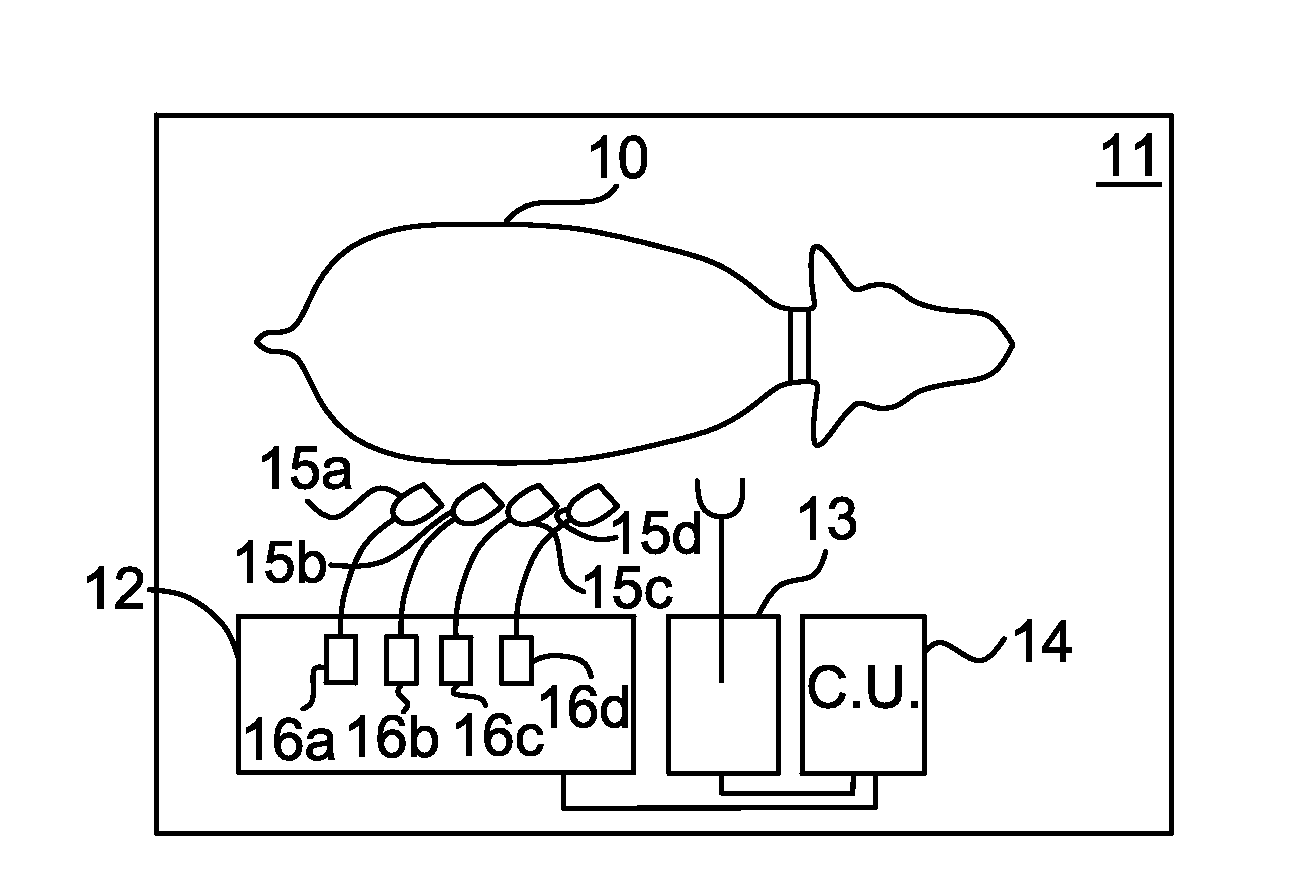

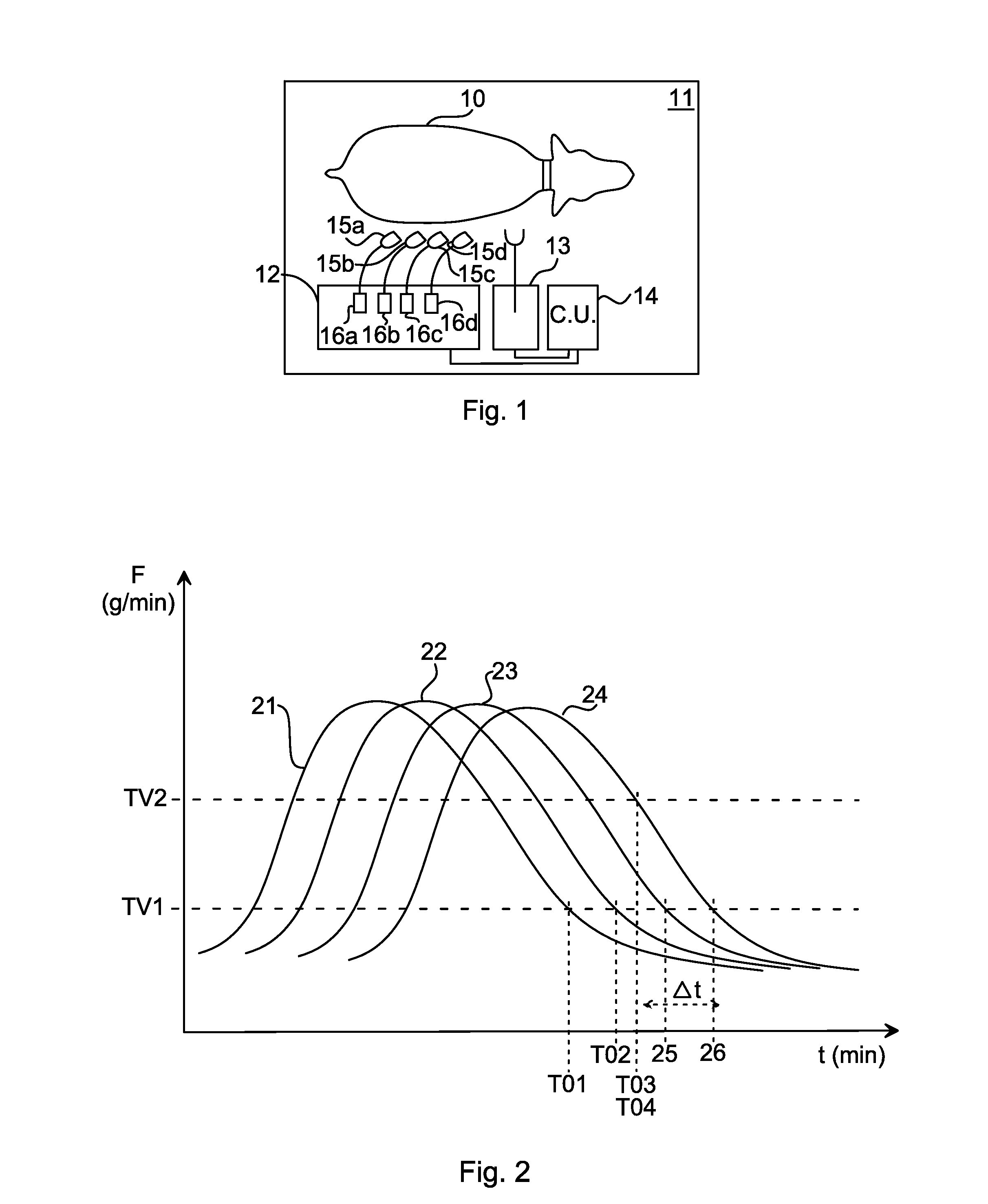

Method of automatically milking animals and automatic milking system

InactiveUS20130036975A1Milk production can be optimizedOverall milk production can be optimizedCathetersAutomatic milkingEngineering

An automatic milking system (11) includes i) a milking apparatus (12) with teat cups (15a-d) and milk flow rate measuring equipment (16a-d) for measuring the individual milk flow from each of the teats of the animal; and ii) a teat-cup device (14) attaching the teat cups to the teats of the animal prior to milking the animal. The milk flow measuring equipment is arranged to measure the individual milk flow rate from each of the teats of the animal continuously during the milking of the animal. The teat-cup device (14) is operatively connected to the flow measuring equipment and is arranged, for each of the teats of the animal, to take off the teat cup from the teat of the animal depending on (i) the measured individual milk flow from the teat of the animal falling below a first threshold value (TV1) and (ii) the measured individual milk flow from each of the teats of the animal being below a second threshold value (TV2), whichever occurs first, wherein the second threshold value is higher than the first threshold value.

Owner:DELAVAL HLDG AB

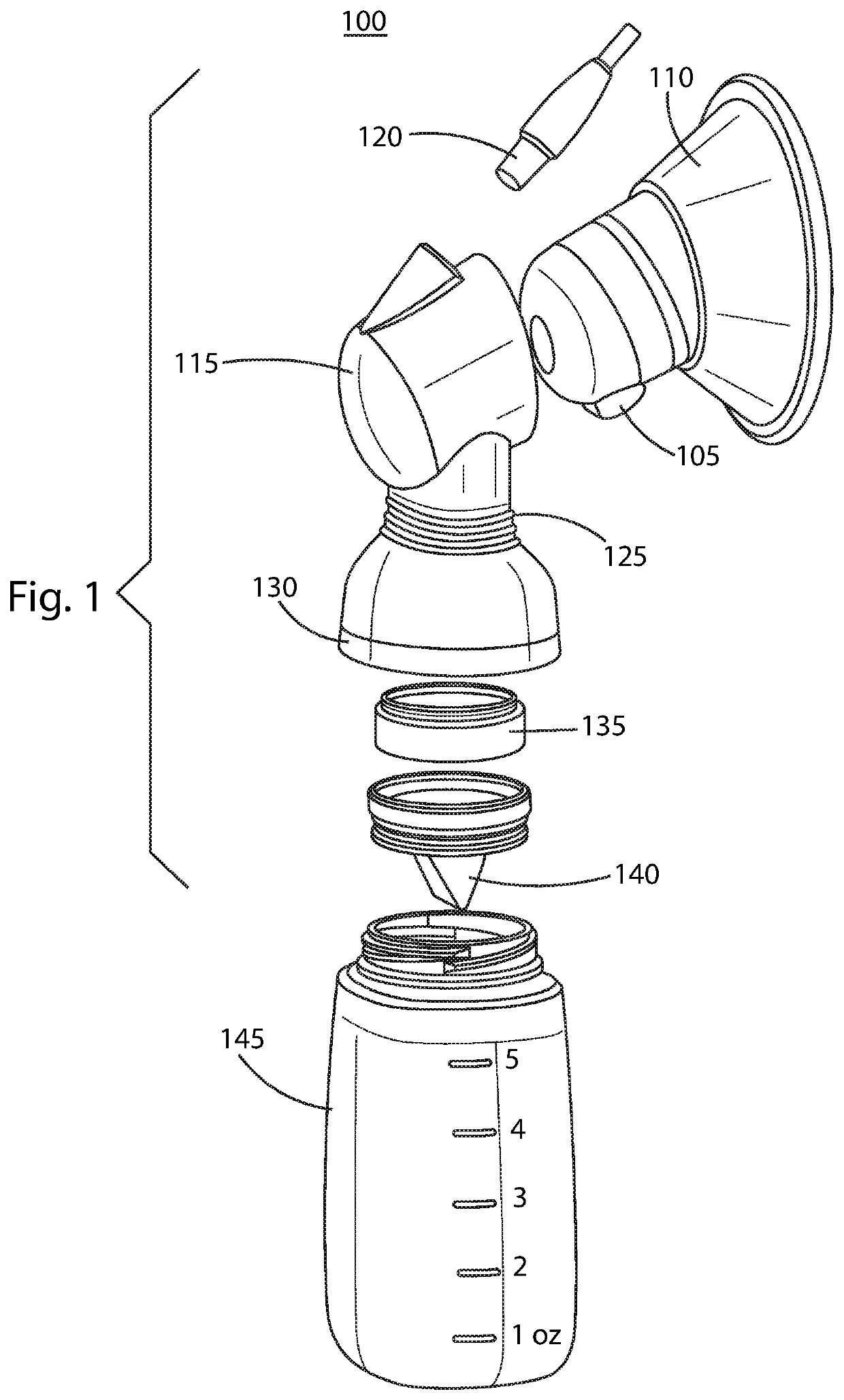

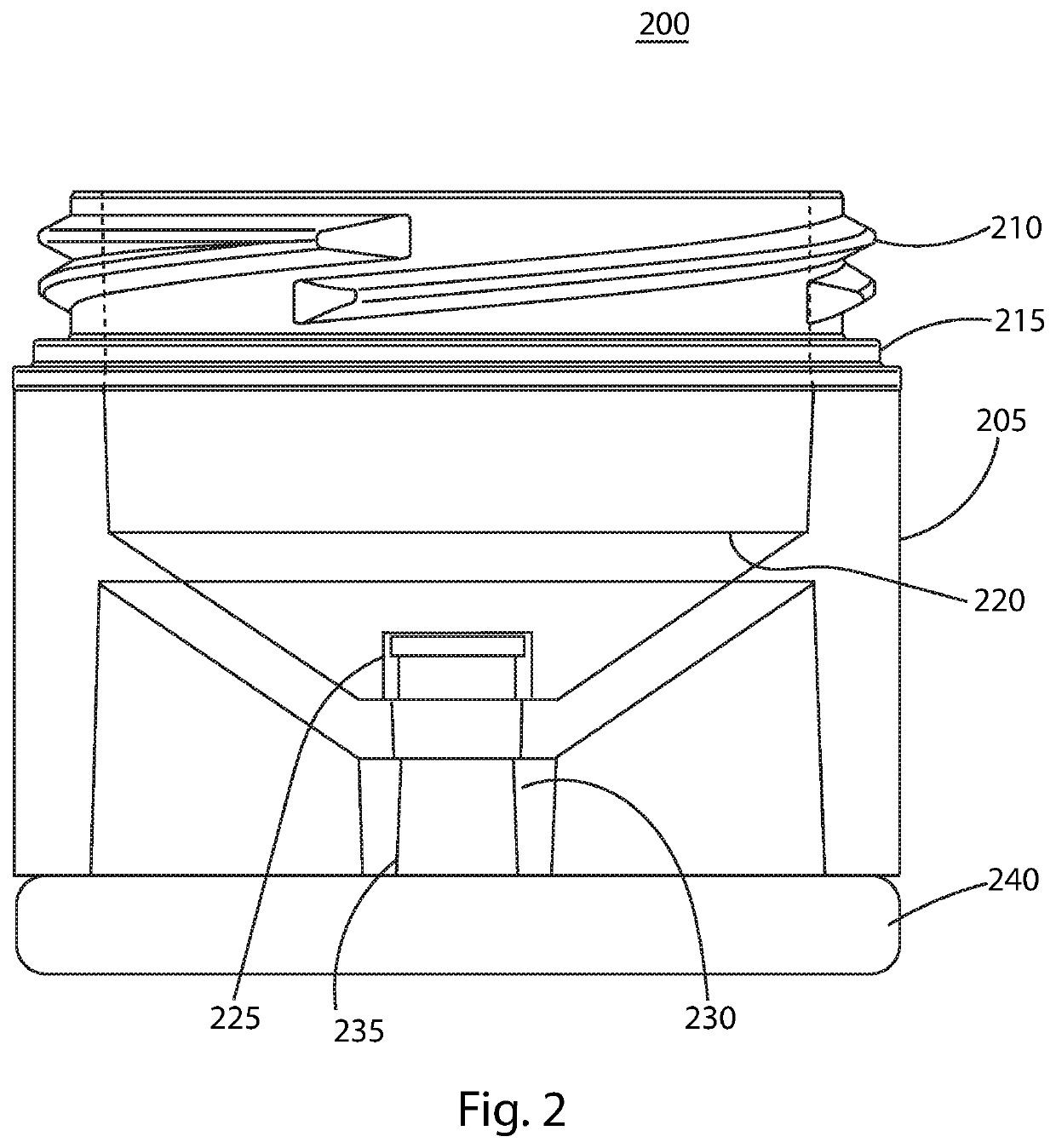

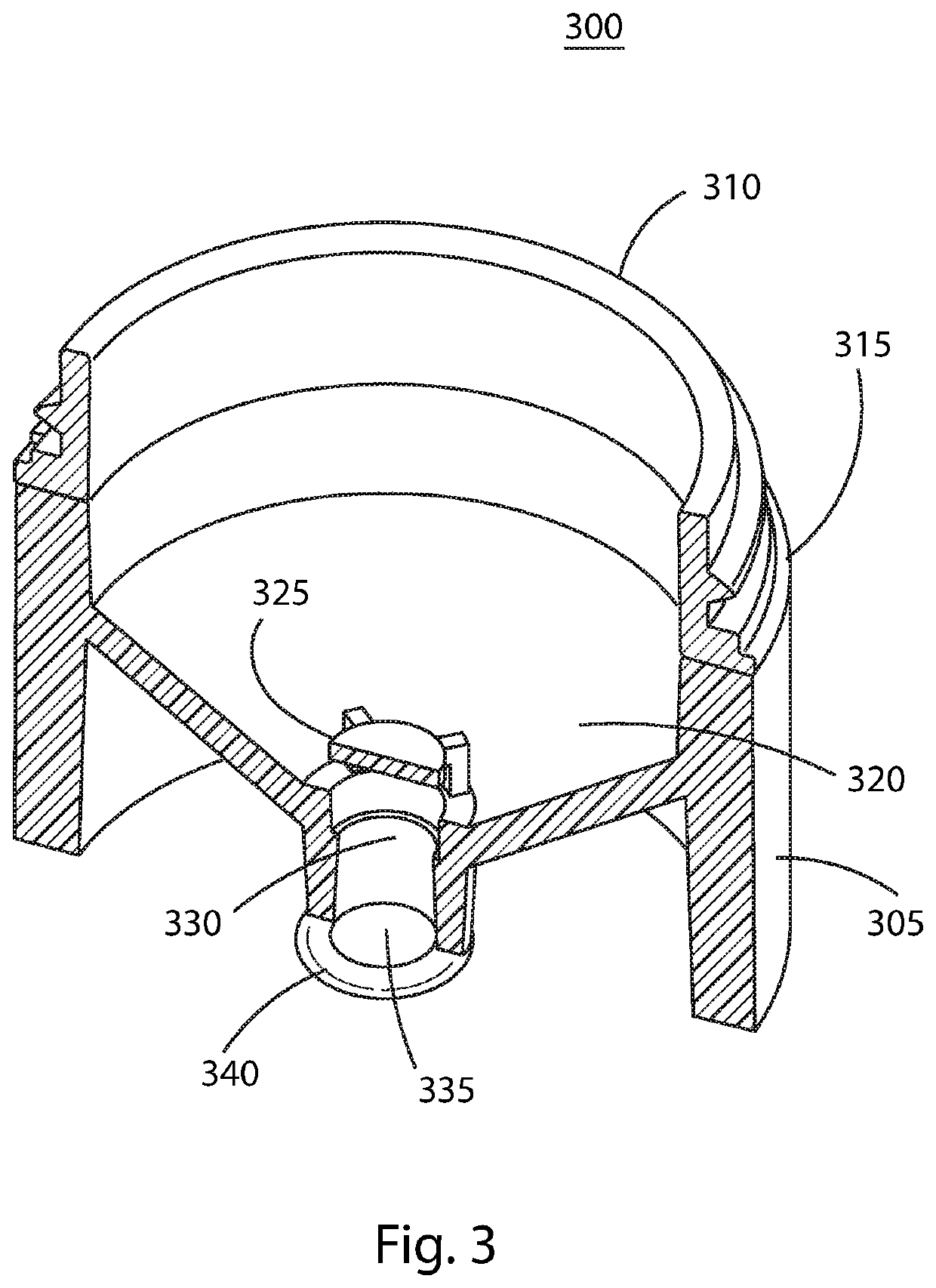

Breast pump milk flow rate sensor system and apparatus

A breast pump milk flow rate sensor system and apparatus for accurately assessing both a flow rate and amount of milk expressed during a pumping session is provided. The breast pump milk flow rate sensor system and apparatus may be contained within a breast pump.

Owner:MOXXLY LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com