Valve, milking claw and milking system

A technology of milking machine and valve body, which is applied in the field of milking claws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

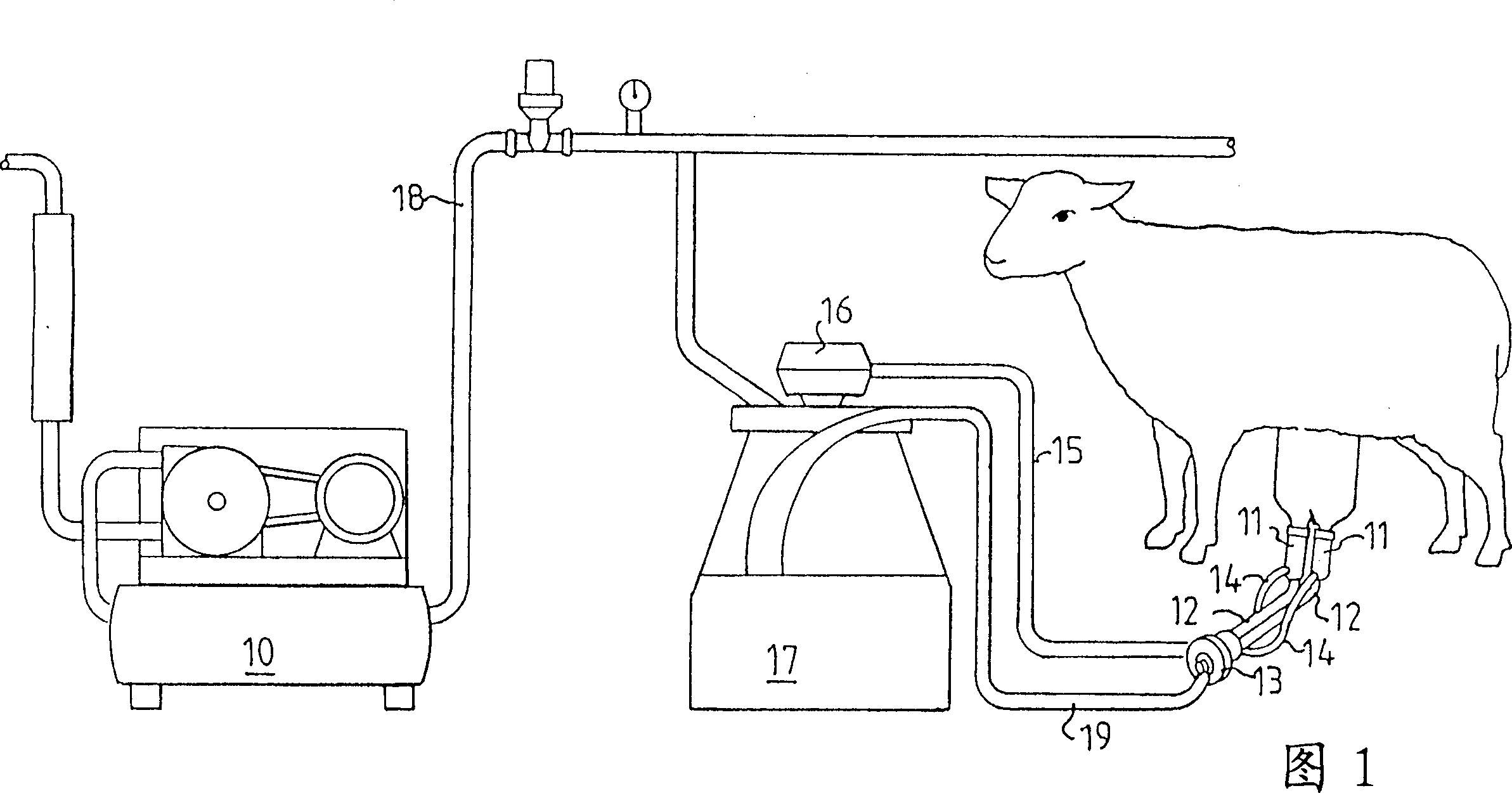

[0016] Figure 1 schematically shows an example of a milking system according to the invention, in this case a system for milking sheep. Only one milking station out of many milking stations driven by a common vacuum pump 10 is shown here. Two milking cups 11 are secured to the teats of the sheep which are milked in a known manner by a pulsating vacuum supplied through short and long pulsating tubes 14 and 15 respectively. A short milk tube 12 leads from the teat cup 11 to a valve according to the invention contained in the jaw 13 from which the milk flows out of the jaw via a long milk tube 19 into a receiving tank 17 .

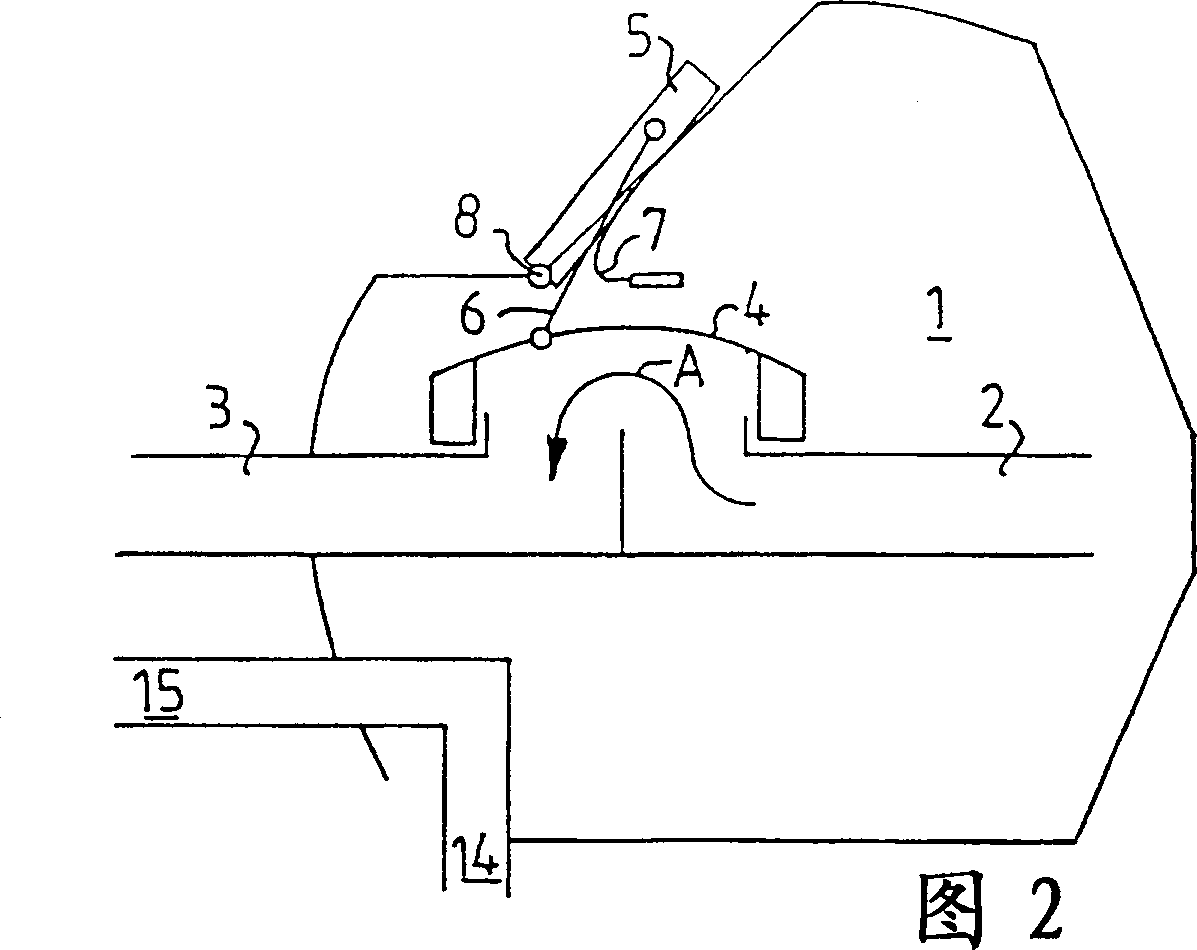

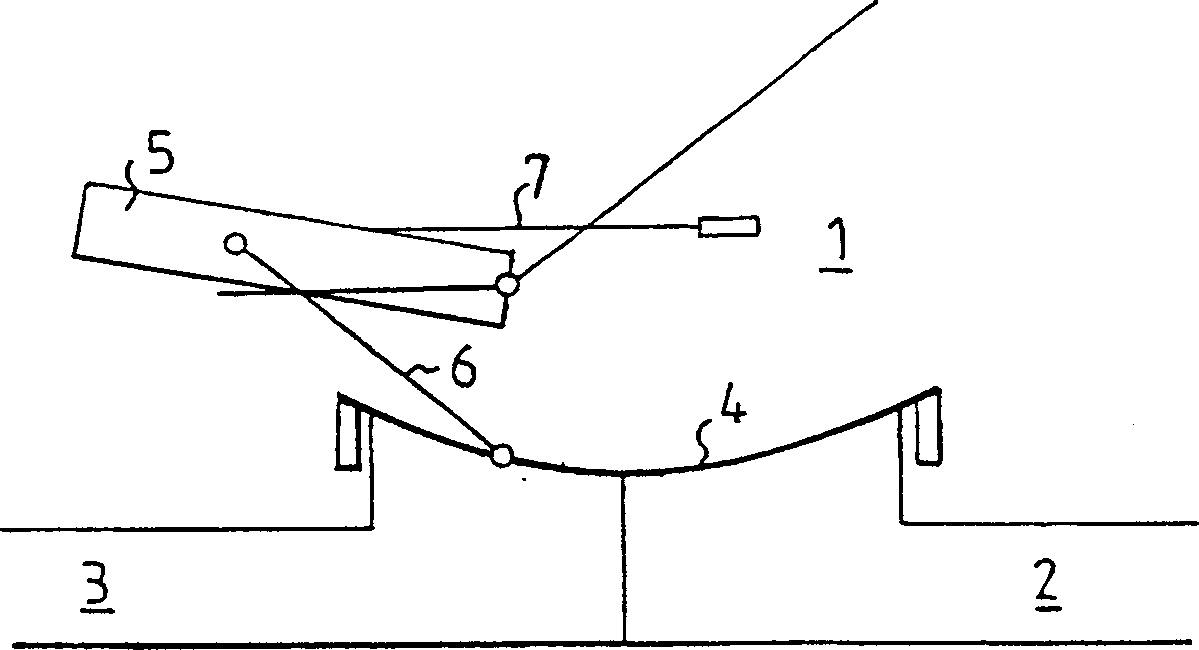

[0017] FIG. 2 shows very schematically a first embodiment of a valve 1 according to the invention which can be accommodated in the jaw 13 shown in FIG. 1 . The inlet 2 of the valve directs milk flow from tube 12 into the valve and, when the valve is in the open position shown in FIG. A diaphragm 4 of elastic material is arranged in its open position shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com