Automatic bean curd maker and soybean milk maker

A tofu machine, automatic technology, applied in milk substitutes, cheese substitutes, beverage preparation devices, etc., can solve the problems of a large number of probes, difficult maintenance, and high cost, and achieve the effect of simple valve structure, improved quality and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

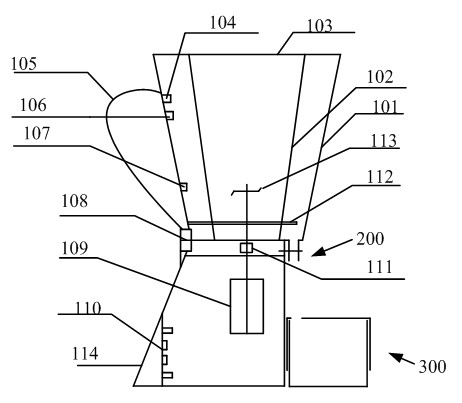

[0035] Such as figure 1 As shown, a specific embodiment of the tofu machine includes a soybean milk cup 101, a soybean milk cup cover 103, a handle 105, a power socket 108, a filter screen 102, an overflow sensor 104, a water level sensor 106, a temperature sensor 107, an agitator 113, Heater 112, transmission coupling 111, motor 109, controller 110, pulp valve 200, base 114 and bean curd box 300.

[0036]Wherein, the soy milk cup 101 is on the base 114, the soy milk cup cover 103 is used to cover the top of the soy milk cup 101, the handle 105 is on the soy milk cup 101, the power socket 108 is on the side of the bottom 101 of the soy milk cup, and the milk release valve 200 is on the soy milk cup 101 At the bottom, the bean curd box 300 is used to hold the soybean milk flowing out from the milk release valve 200, the filter screen 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com