Peanut frying device with built-in rotary container

A technology of peanut oil and oil tank, which is applied in application, food preparation, food science, etc. It can solve the problems of large and small peanuts, affecting the taste of peanuts, uneven mixing of peanuts and edible oil, etc., and achieve the effect of improving the quality and flavor of frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

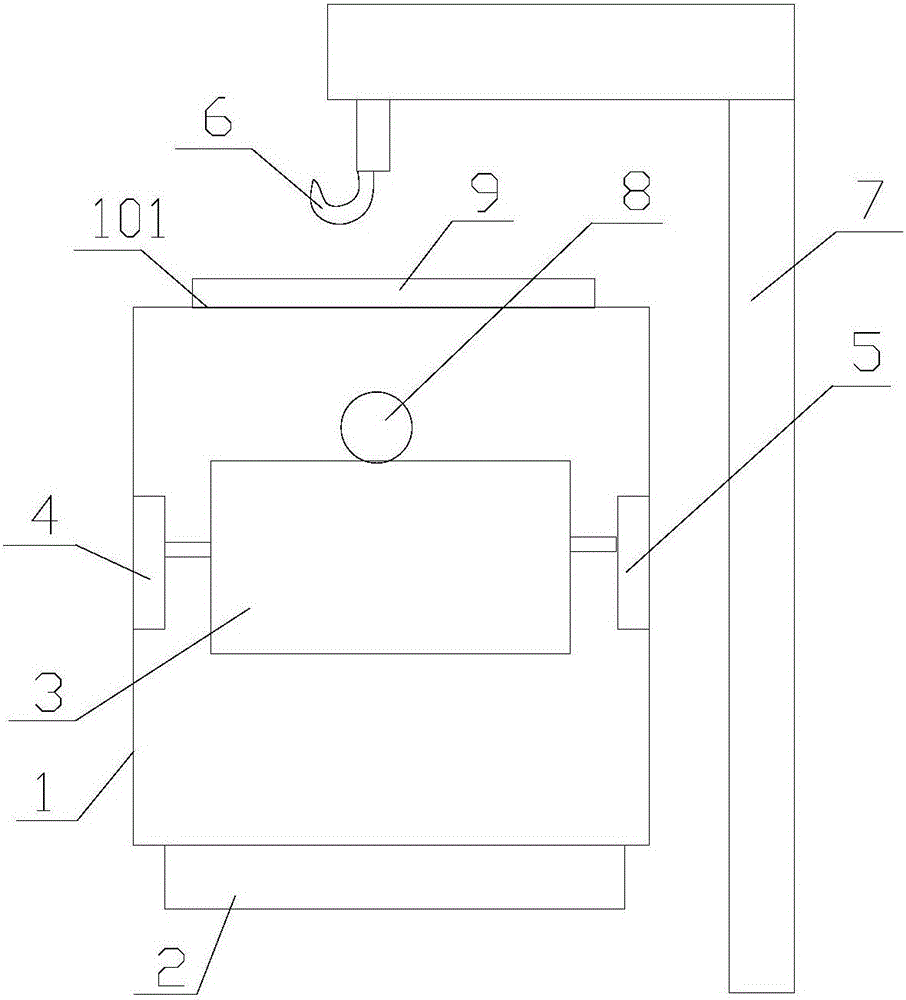

[0015] refer to figure 1 , a peanut frying device with a built-in rotating tank proposed by the present invention, comprising: an oil tank 1, a heating mechanism 2, a rotating tank 3, a first clamping part 4, a second clamping part 5, a hook 6 and a support frame 7 .

[0016] An outlet 101 is arranged on the top of the fuel tank 1, and a lock gate 9 is installed at the outlet 101. When the lock gate 9 is closed, the fuel tank 1 is sealed. The heating mechanism 2 is installed at the bottom of the fuel tank 1 to heat the storage in the fuel tank 1 .

[0017] The first clamping part 4 and the second clamping part 5 are co-rotatably installed inside the oil tank 1 and located on opposite sides. The rotating bladder 3 is a hollow structure, which can be installed inside the fuel tank 1 through the first clamping part 4 and the second clamping part 5. The rotating tank 3 is provided with a plurality of through holes and a discharge gate.

[0018] Both the first clamping part 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com