Patents

Literature

35results about How to "Avoid Burnt Situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

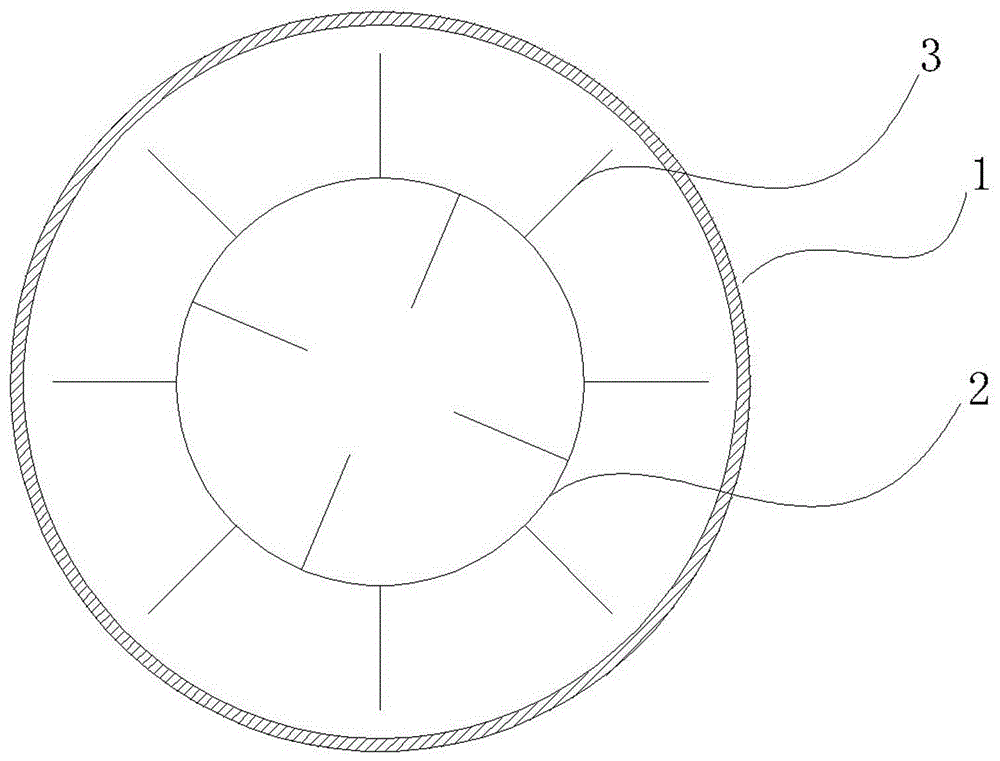

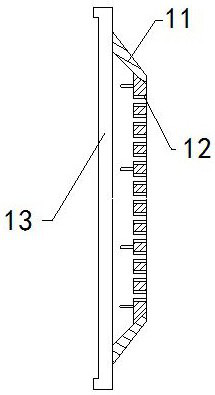

Making technology of tea cakes

InactiveCN106070741ASimplify processing stepsAvoid Burnt SituationsPre-extraction tea treatmentFood shapingTea leafChemistry

The invention discloses a making technology of tea cakes in the field of processing of tea leaves. The making technology comprises the following steps of: step I, performing resurgence: spraying water to tea leaves so that the tea leaves are in resurgence; step II, steaming tea: steaming the tea leaves after the resurgence with steam for 4-6 seconds; step III, loading the cooked tea leaves into a mold: paving a liner cloth in a circular mold in advance, then placing an annular snap ring on the liner cloth, wherein the snap ring and the mold are concentric circles, the height of the snap ring is less than that of the mold, and a plurality of dividing strips are arranged on the outer edge and the inner edge of the snap ring, and then putting the steamed tea leaves of which the placing thickness is greater than the height of the snap ring, in the mold,; step IV, performing pressing to obtain cakes: putting the mold loaded with the tea leaves in a tea cake briquetting machine for briquetting so as to obtain the tea cakes; step V, performing drying: taking out pressed tea cakes, and putting the tea cakes in a drying room for drying; and step VI, performing packaging: packaging the dried tea cakes so that the packaged tea cakes can be sold. The tea cakes made by the technology disclosed by the invention can be divided into tea leaf blocks by the snap ring and the dividing strips, so that the tea cakes are convenient to eat, and waste of the tea leaves is avoided.

Owner:务川自治县雾青茶业有限公司

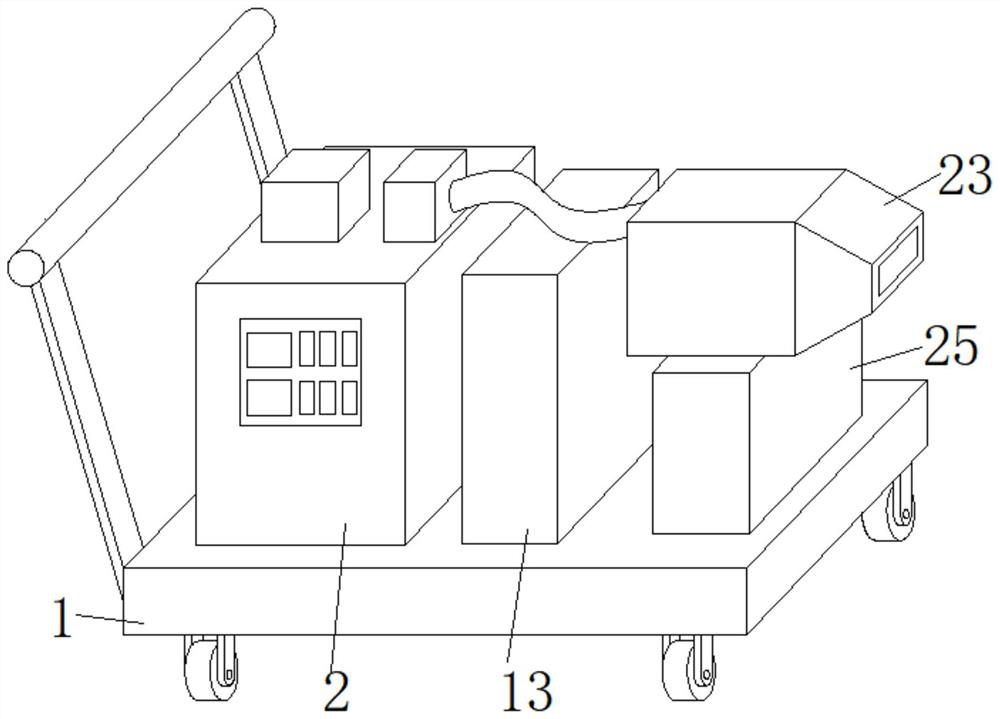

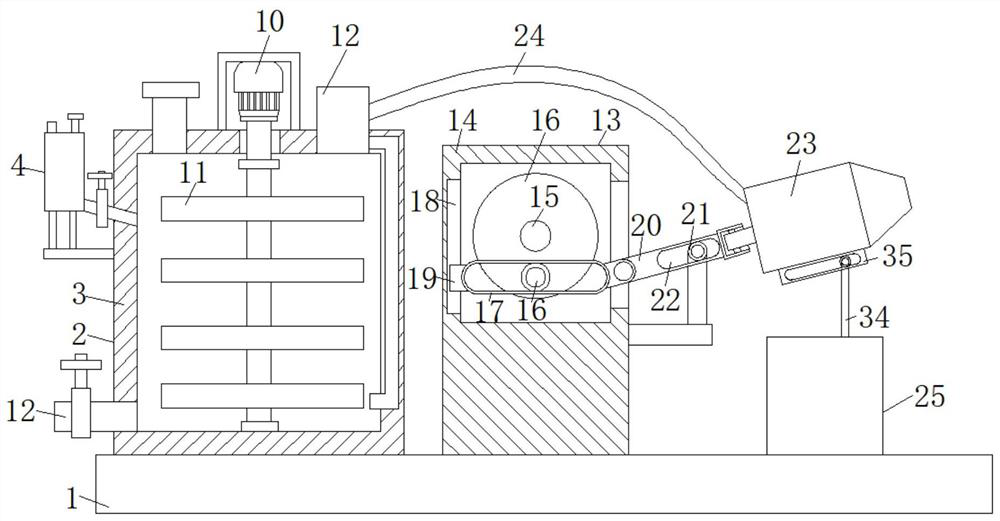

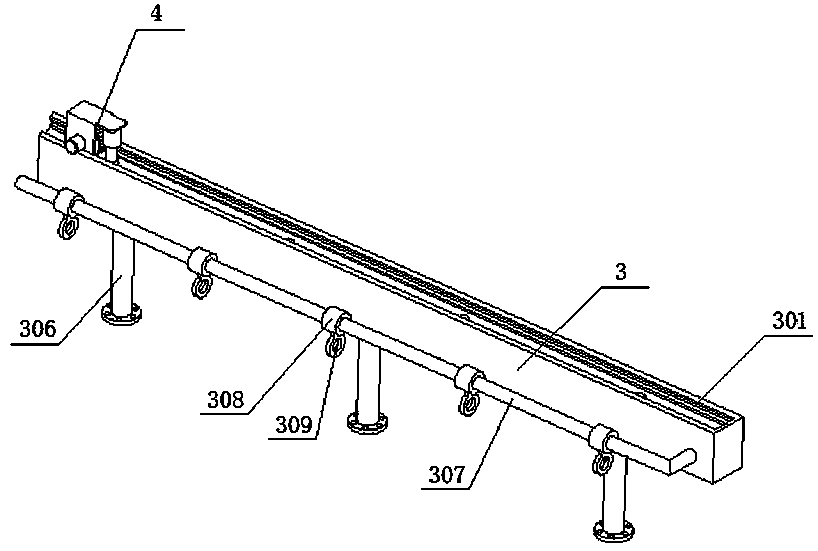

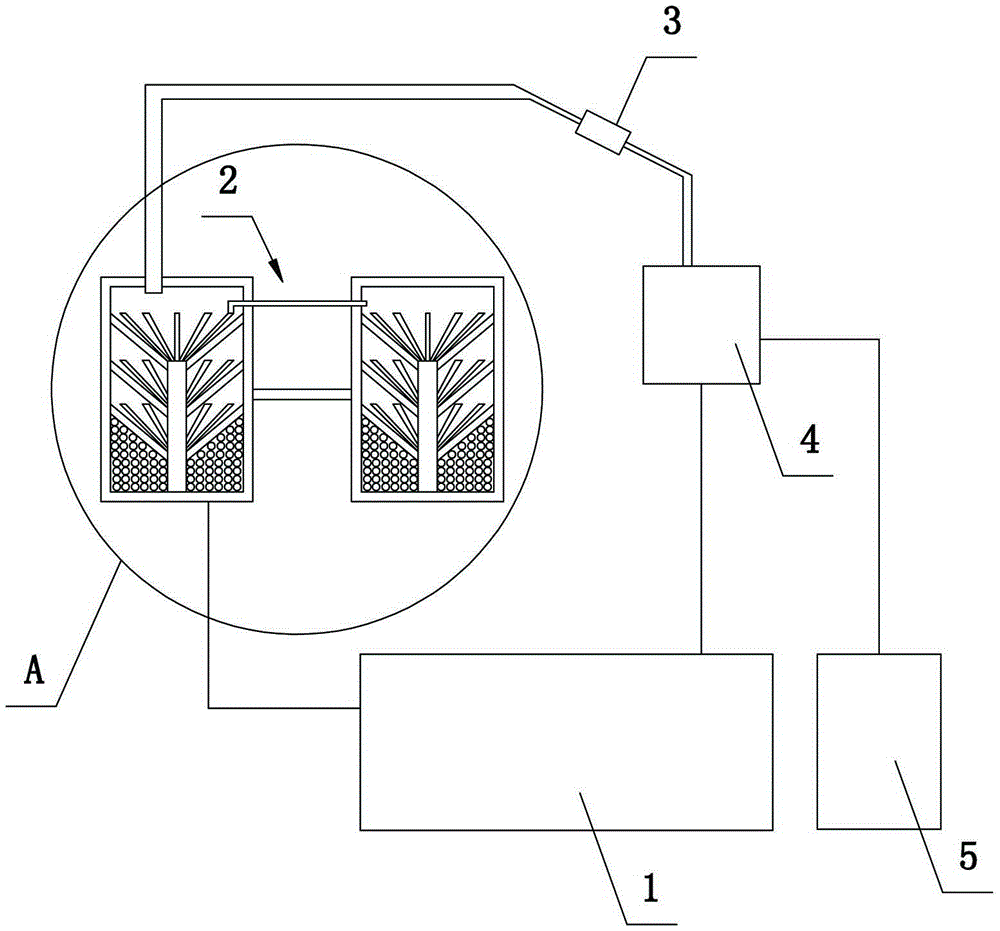

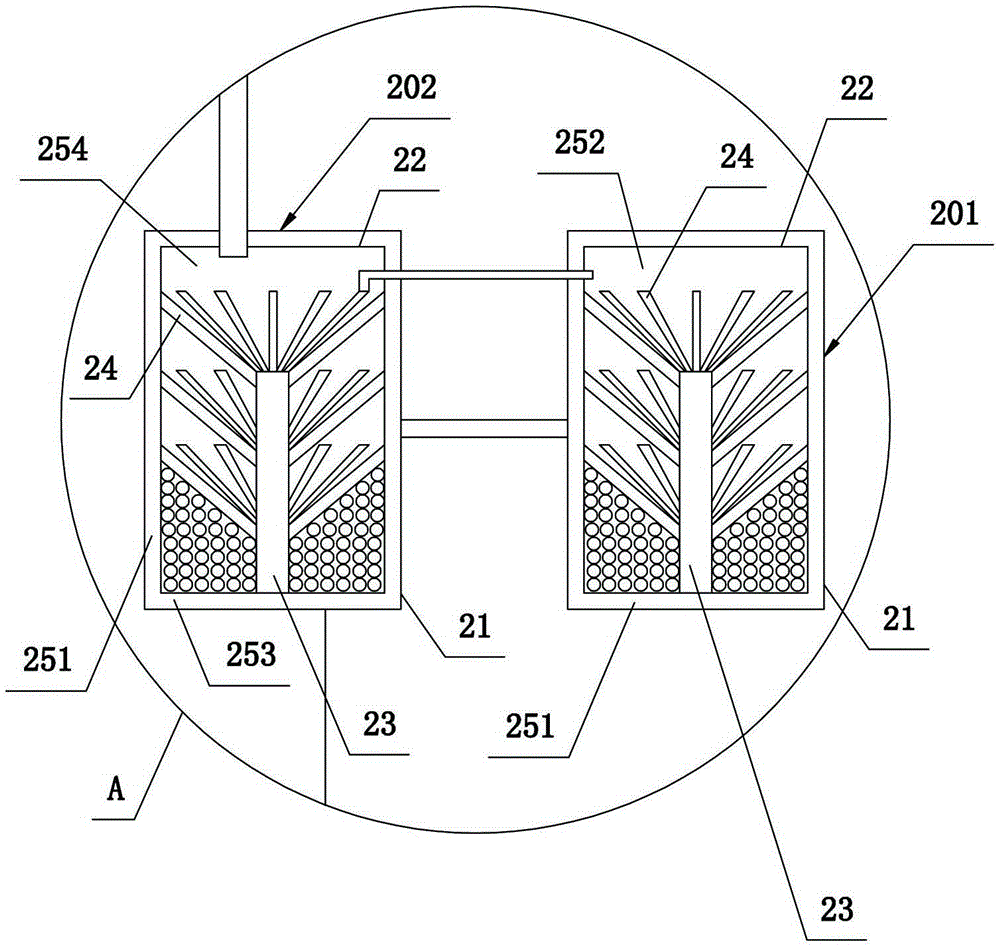

Adjustable miniature irrigation device for agricultural planting

ActiveCN111955324AAvoid Burnt SituationsImprove absorption rateClimate change adaptationWatering devicesAgricultural scienceAgricultural engineering

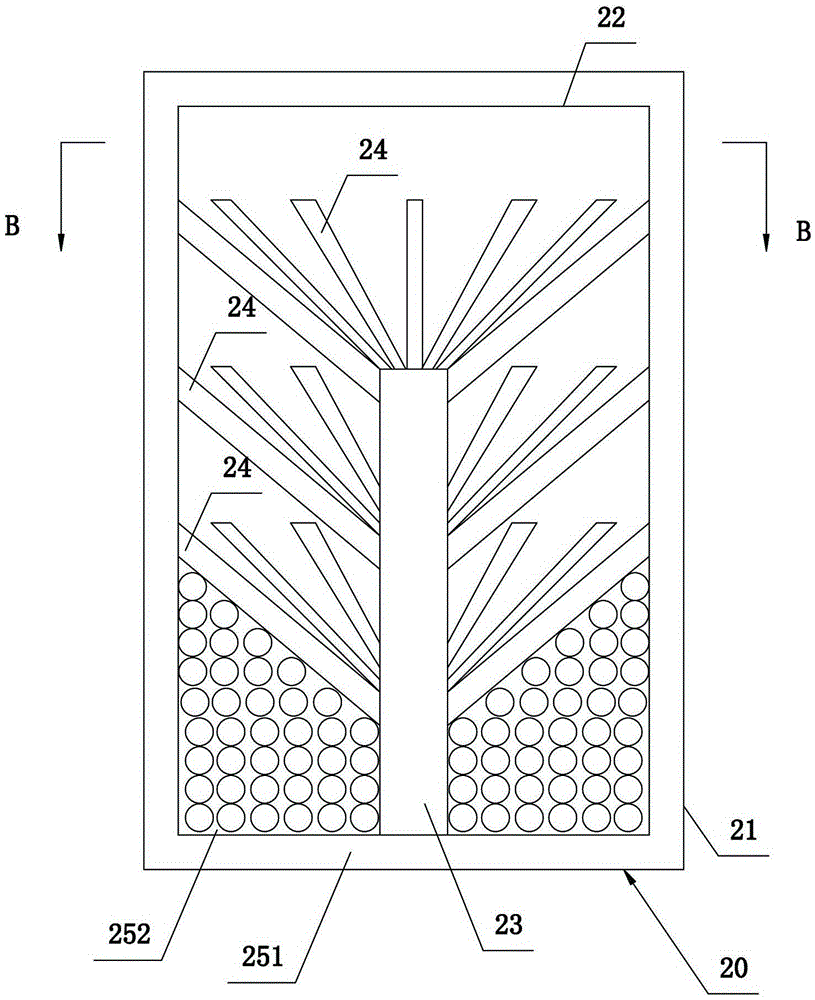

The invention discloses an adjustable miniature irrigation device for agricultural planting and relates to the technical field of irrigation devices. The miniature irrigation device comprises a bottomplate, an agitation mechanism, a spray adjustment mechanism, a circuitous spray mechanism and an atomizer, wherein the agitation mechanism, the spray mechanism and the circuitous spray mechanism arefixedly arranged on the upper surface of the bottom plate; a water outlet end of the agitation mechanism communicates with the atomizer through a water outlet pipe; and output ends of the spray adjustment mechanism and circuitous spray mechanism are movably connected with the surface of the atomizer. By utilizing the length of a size stick extending to an outer side of a dosing tank, the volume ofa fertilizer solution inside the current dosing tank can be determined, and an agitation rod is driven by a first motor to sufficiently mix the fertilizer solution and clear water, so that the mixingproportion precision of the fertilizer solution and the clear water can be accurate, the situation that crops are burnt by the fertilizer solution due to high proportion of the fertilizer solution can be avoided, the absorption rate of the crops on the fertilizer solution can be improved, and normal growth of the crops can be guaranteed.

Owner:福州市长乐区巧通工业设计有限公司

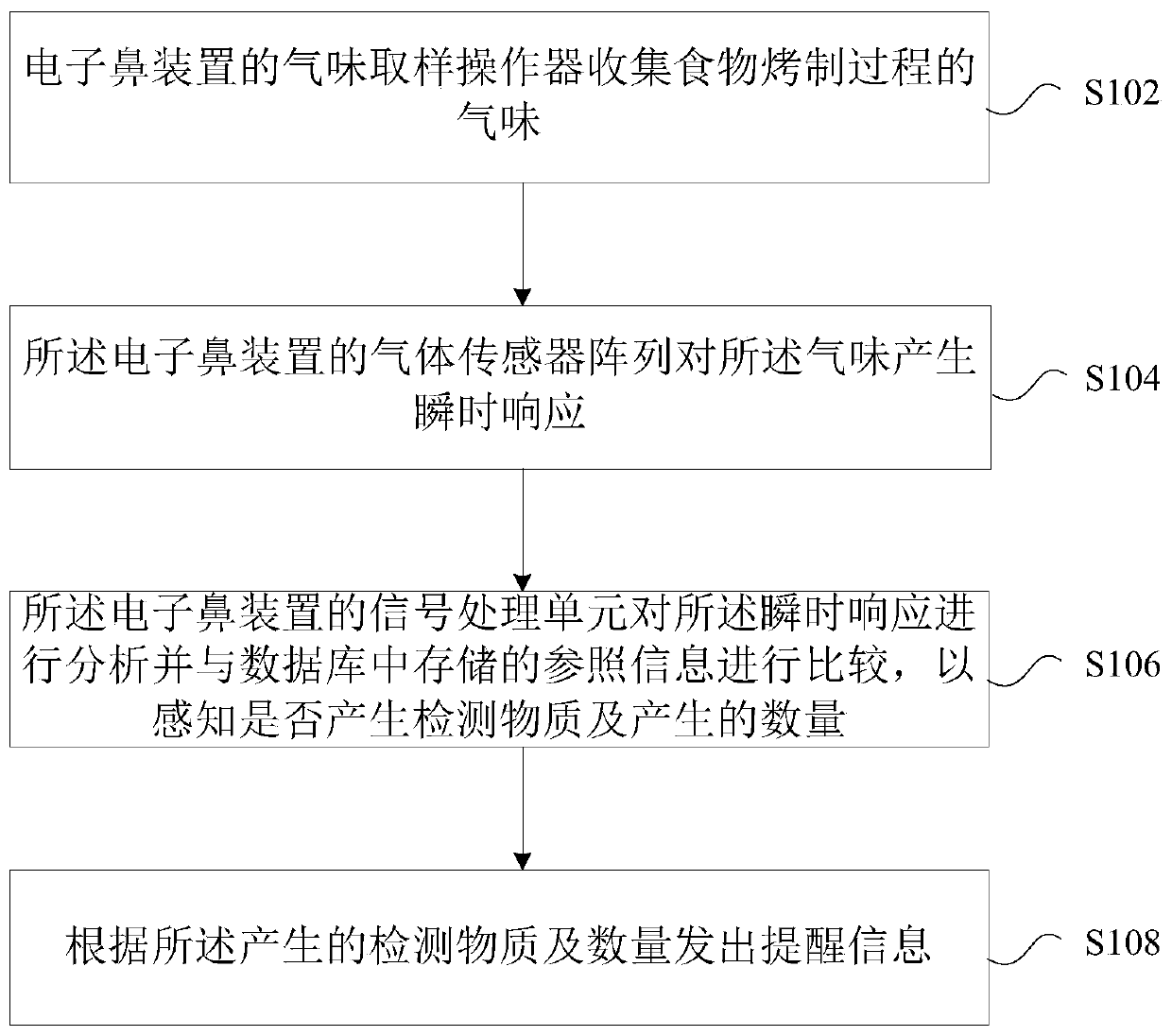

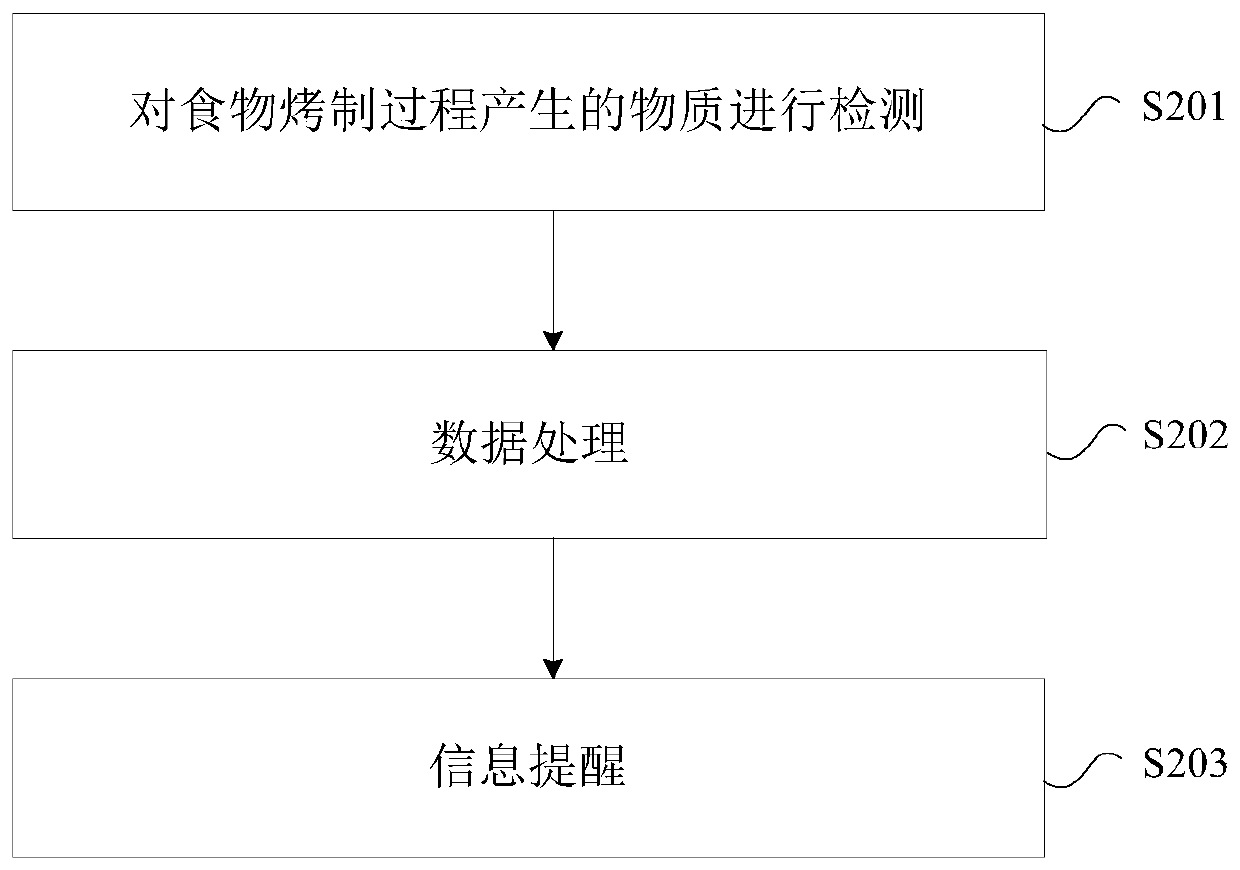

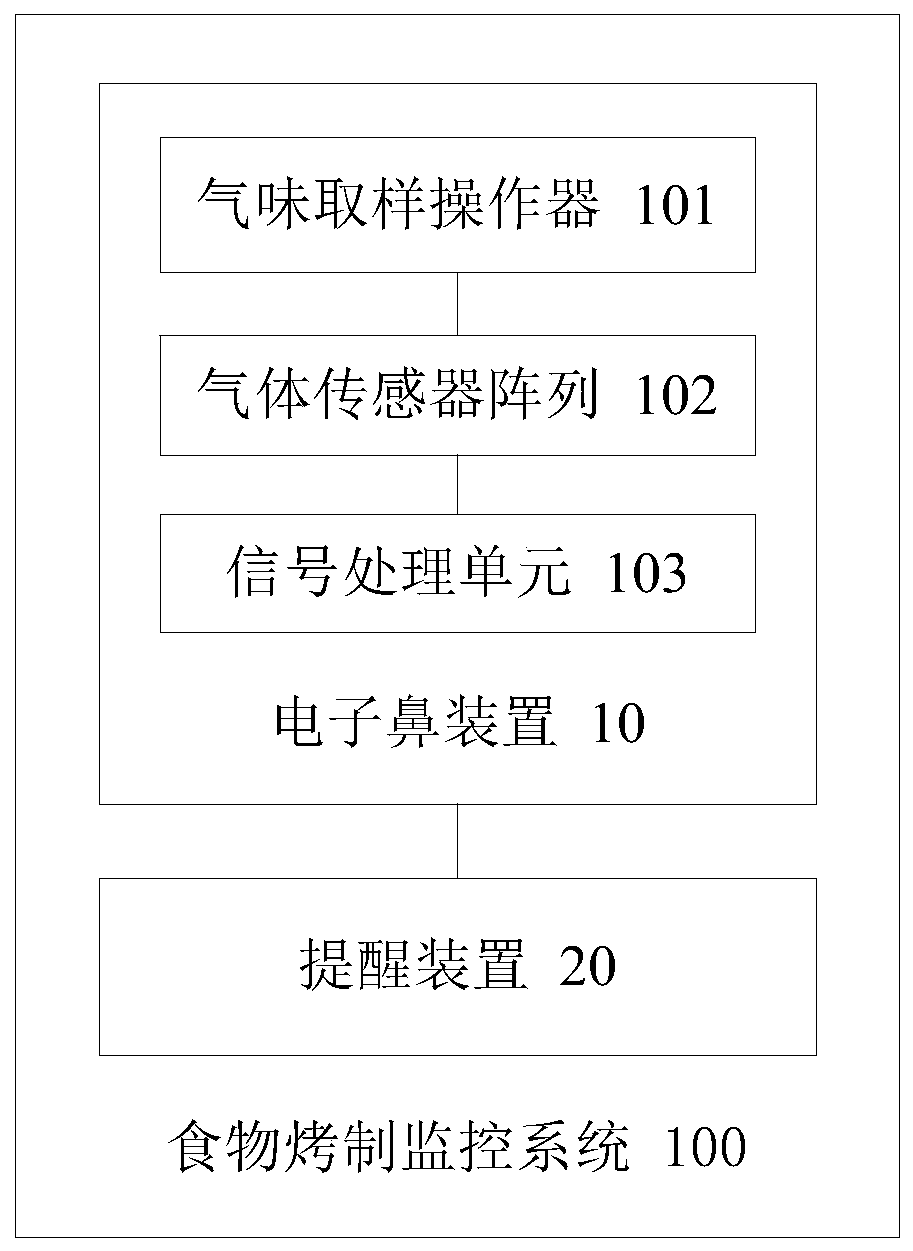

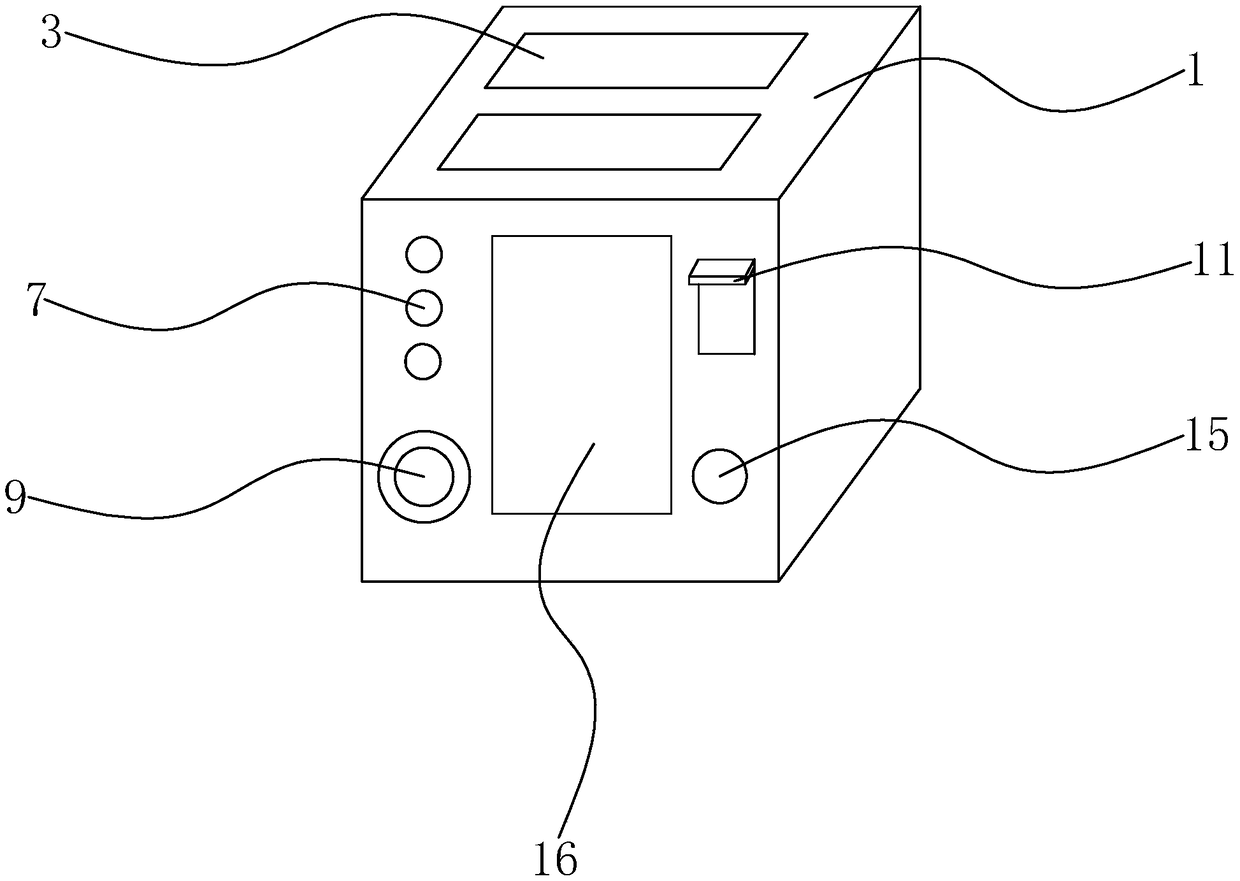

Food baking monitoring method and system

InactiveCN110865150AAvoid Burnt SituationsAnalysing gaseous mixturesThermometer applicationsSensor arrayService personnel

The invention provides a food baking monitoring method and system. The method comprises the steps that an odor sampling operator of an electronic nose device collects odor in a food baking process; agas sensor array of the electronic nose device generates an instantaneous response to the odor; a signal processing unit of the electronic nose device analyzes the instantaneous response and comparesthe instantaneous response with reference information stored in a database to sense whether detection substances are generated or not and sense the quantity of the generated detection substances; andreminding information is sent according to the generated detection substances and the quantity of the detection substances. According to the food baking monitoring method and system, the electronic nose device is utilized to detect burnt substances generated in the food baking process, consumers or service personnel can know a food baking degree in time, and therefore the situation food materialsare burnt is avoided.

Owner:上海秒针网络科技有限公司

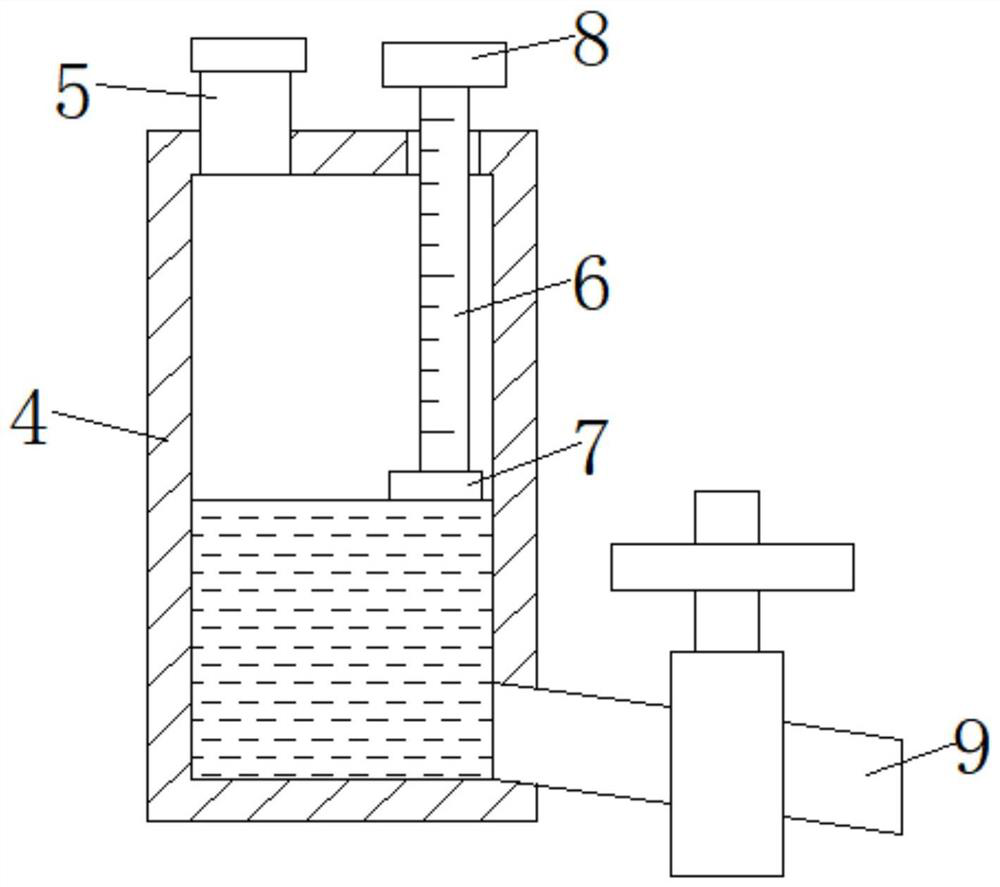

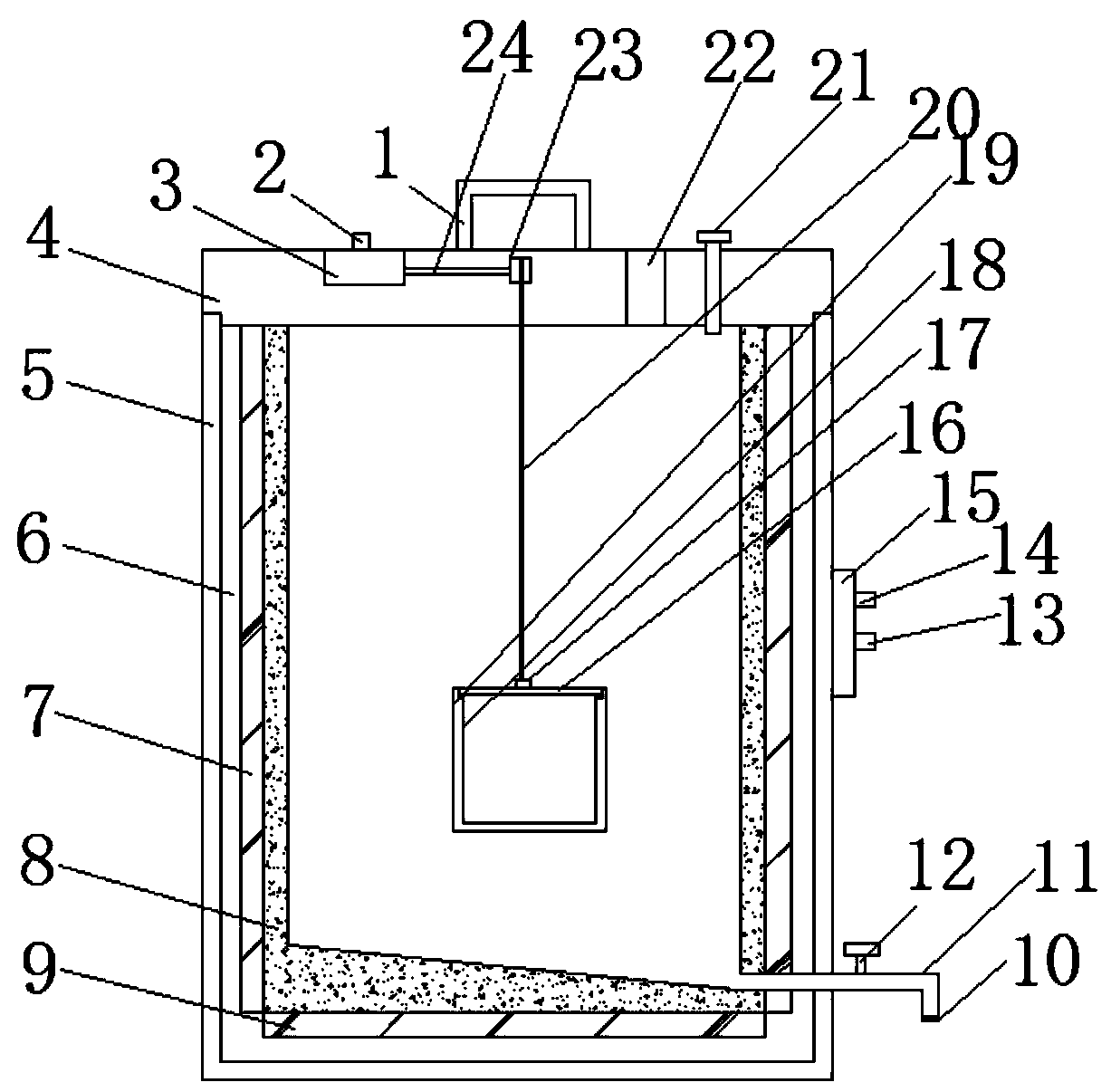

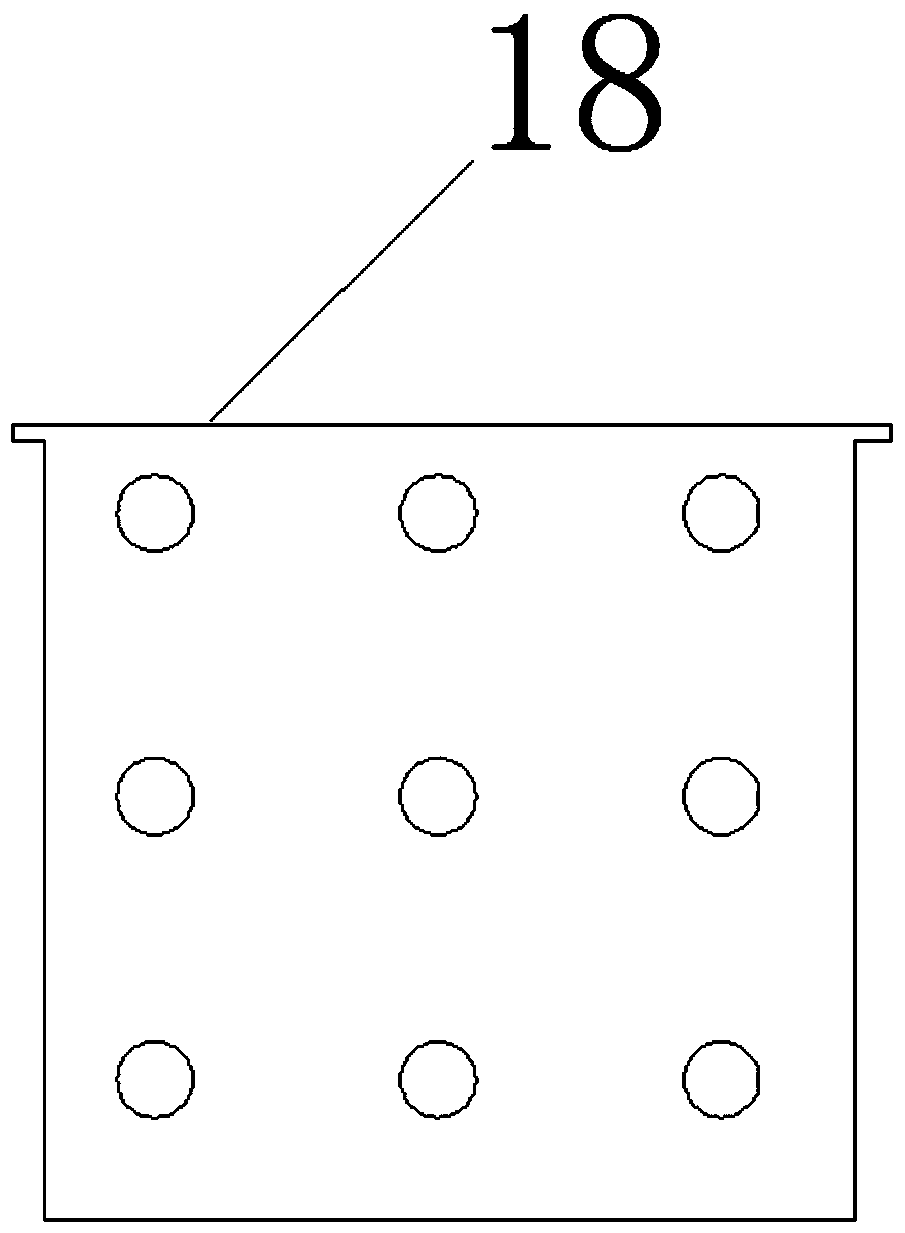

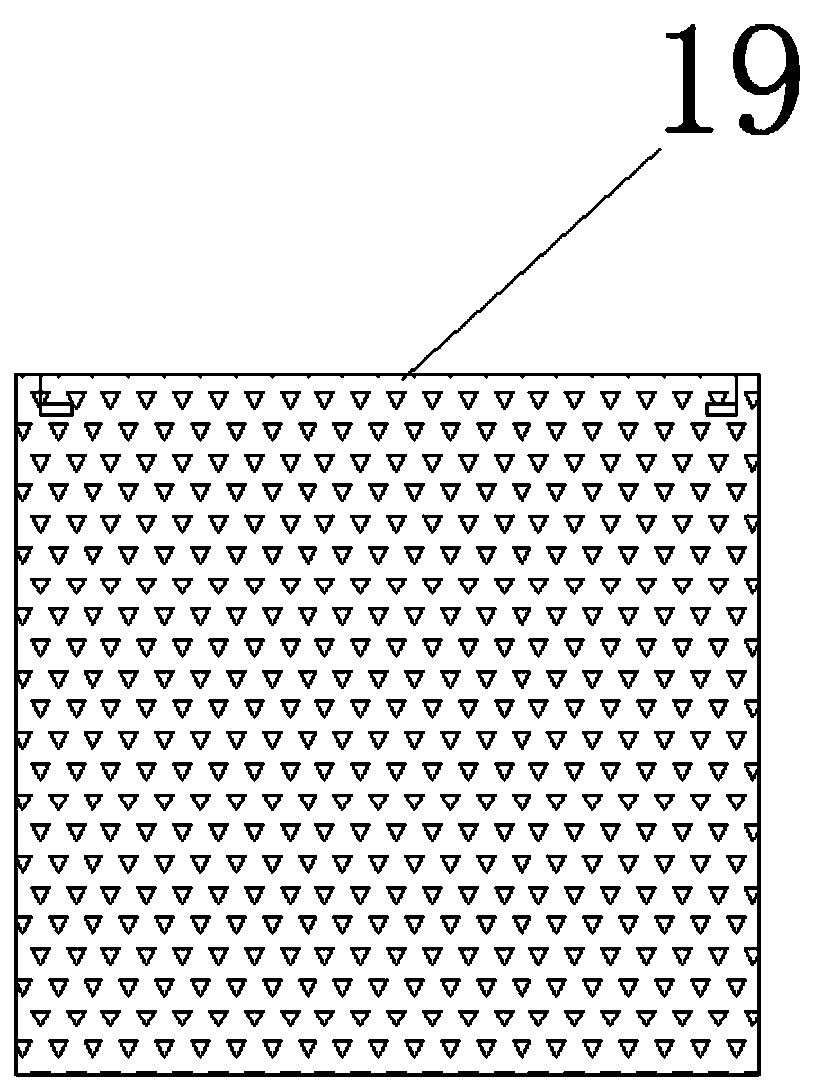

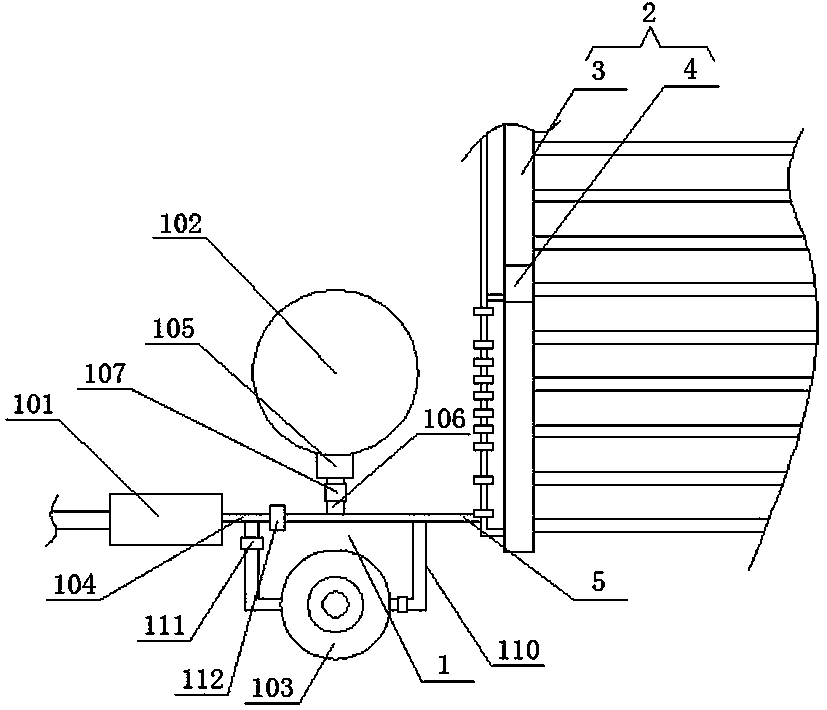

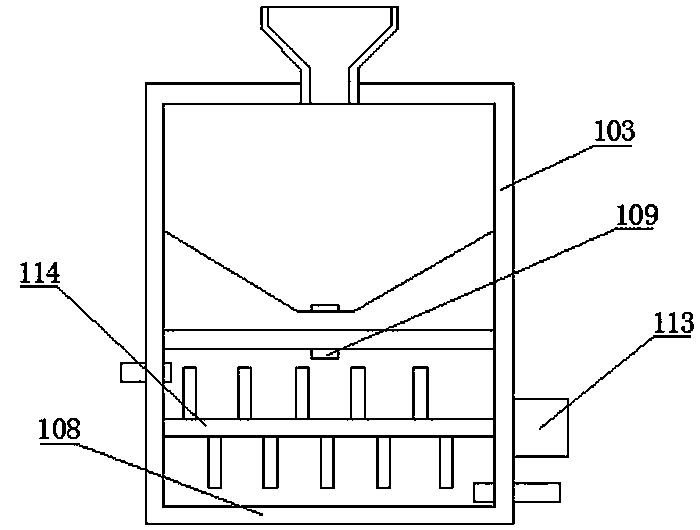

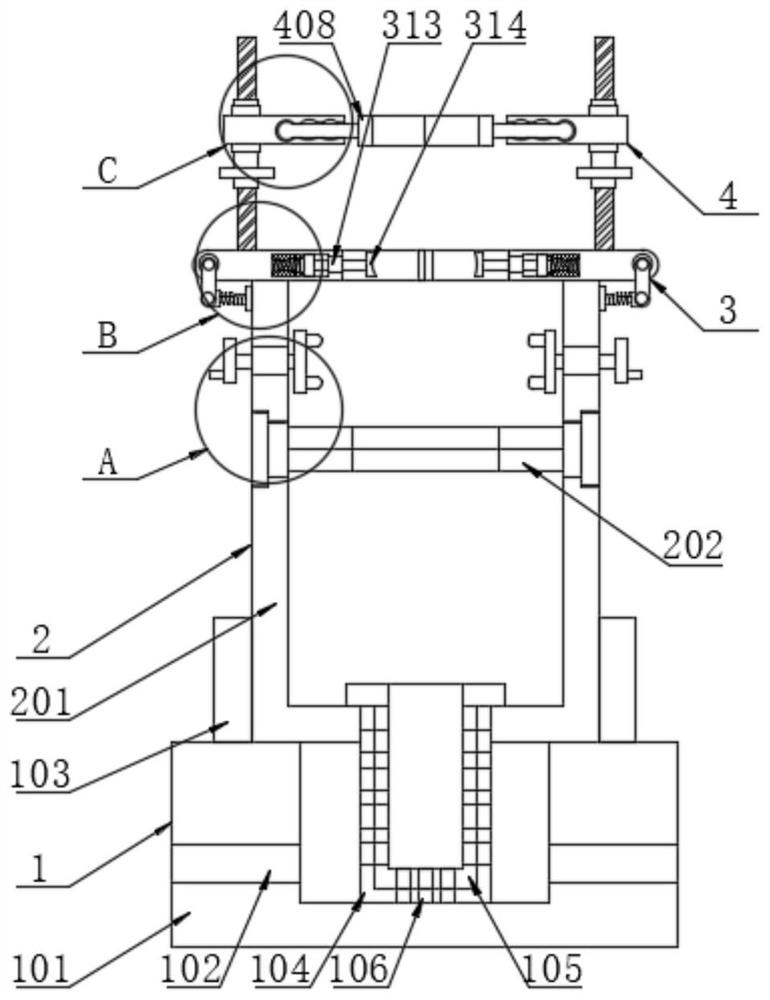

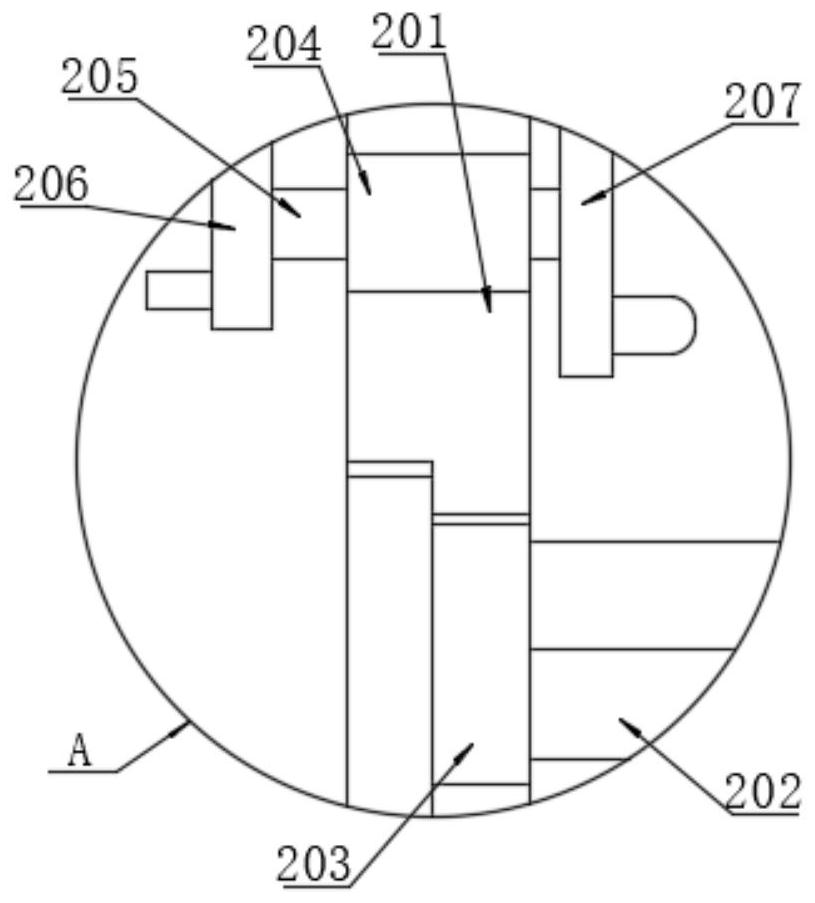

Extraction device for large-scale production of traditional Chinese medicine extracts

PendingCN108619756AAdjust height freelyAvoid Burnt SituationsPharmaceutical product form changeSolid solvent extractionInsulation layerFiltration

The invention discloses an extraction device for large-scale production of traditional Chinese medicine extracts. The device includes a handle, a motor switch, a motor, a furnace cover, a furnace body, a heat insulation layer, a furnace wall electric heating wire, a furnace tube, a furnace bottom electric heating wire, an outlet rotary cover, a discharging pipe, a valve, a soft fire switch, a strong fire switch, a pedestal, a cartridge filter cover, a ring buckle, an inner cartridge filter, an outer cartridge filter, a sling, an air pressure valve, an observation window, a winch and a rotatingshaft. Through observation with the observation window, the motor switch is turned on to allow the outer cartridge filter to be always under a water surface, thus avoiding a situation that medicine materials cannot be immersed with water because of water level decrease due to water evaporation. As different medicine materials have different requirements on optimal fire, the pedestal is provided with the soft fire switch and the strong fire switch to control working states of the furnace wall electric heating wire and the furnace bottom electric heating wire. When a medicine liquid is taken out, the bottom of the furnace tube, which has an inclined surface design, is free of medicine liquid residue, the medicine liquid passes through the discharging pipe and is filtered by a filtration screen disposed at the bottom of the outlet rotary cover, residual medicine dregs are removed, and taste of the medicine liquid is ensured.

Owner:洛阳伊尹实业有限公司

Water and fertilizer integrated automatic irrigation system based on Internet of Things

InactiveCN110226400AImprove uniformityEasy to useLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserPipingFertilizer

The invention discloses a water and fertilizer integrated automatic irrigation system based on Internet of Things and relates to the technical field of irrigation systems. The automatic irrigation system comprises a water supply device, a management center, a plurality of soil humidity sensors and a division device, wherein the water supply device comprises a water pump, a water and fertilizer tank and a solid fertilizer tank, a water delivery pipe is fixed at a water outlet of the water pump, a transfer pump is fixed on the circumferential surface of the water and fertilizer tank, a first water pipe is communicated between the water delivery pipe and the transfer pump, a first electric flow valve is arranged on the first water pipe, a mixing box is fixed on the bottom surface of the solidfertilizer tank, and a stirring mechanism is fixed in the mixing box. Partition plates are arranged in a division pipe to divide the division pipe into multiple compartments, meanwhile, slide rails are arranged on the division pipe, sliding connecting parts are arranged, water can be injected to different compartments for division irrigation, and the problem that fertilizer is not put uniformly due to longer division pipes under fertilizer-carrying irrigation condition at present is solved.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

Combined nickel-plating liquid for electroplating nickel on magnesium alloy and method for electroplating nickel on surface of magnesium alloy

ActiveCN106245070AImprove corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingSuperimposed coating processAcid washingSodium sulfate

The invention discloses combined nickel-plating liquid for electroplating nickel on magnesium alloy. The combined nickel-plating liquid is aqueous solution with the following components of nickel sulfate, water-soluble fluoride, ammonium citrate, sodium saccharin, sodium benzene sulphinate, 1,4-butynediol, lauryl sodium sulfate and a pH regulating agent. In addition, the invention also provides a method for electroplating the nickel on the surface of the magnesium alloy. The method comprises the following steps: mechanically polishing the magnesium alloy, removing oil on the surface of the magnesium alloy, carrying out alkaline washing and acid washing as well as activating treatment, chemically plating zinc for one time or multiple times, and electroplating nickel in the combined nickel-plating liquid to obtain the magnesium alloy with the nickel electroplated on the surface. The combined nickel-plating liquid and the nickel plating method disclosed by the invention are applicable to various magnesium-alloy substrates, and the plated part prepared is higher in bonding force between a matrix thereof and a plated layer, better in corrosion resistance, and flat and attractive in surface.

Owner:XIANGTAN UNIV

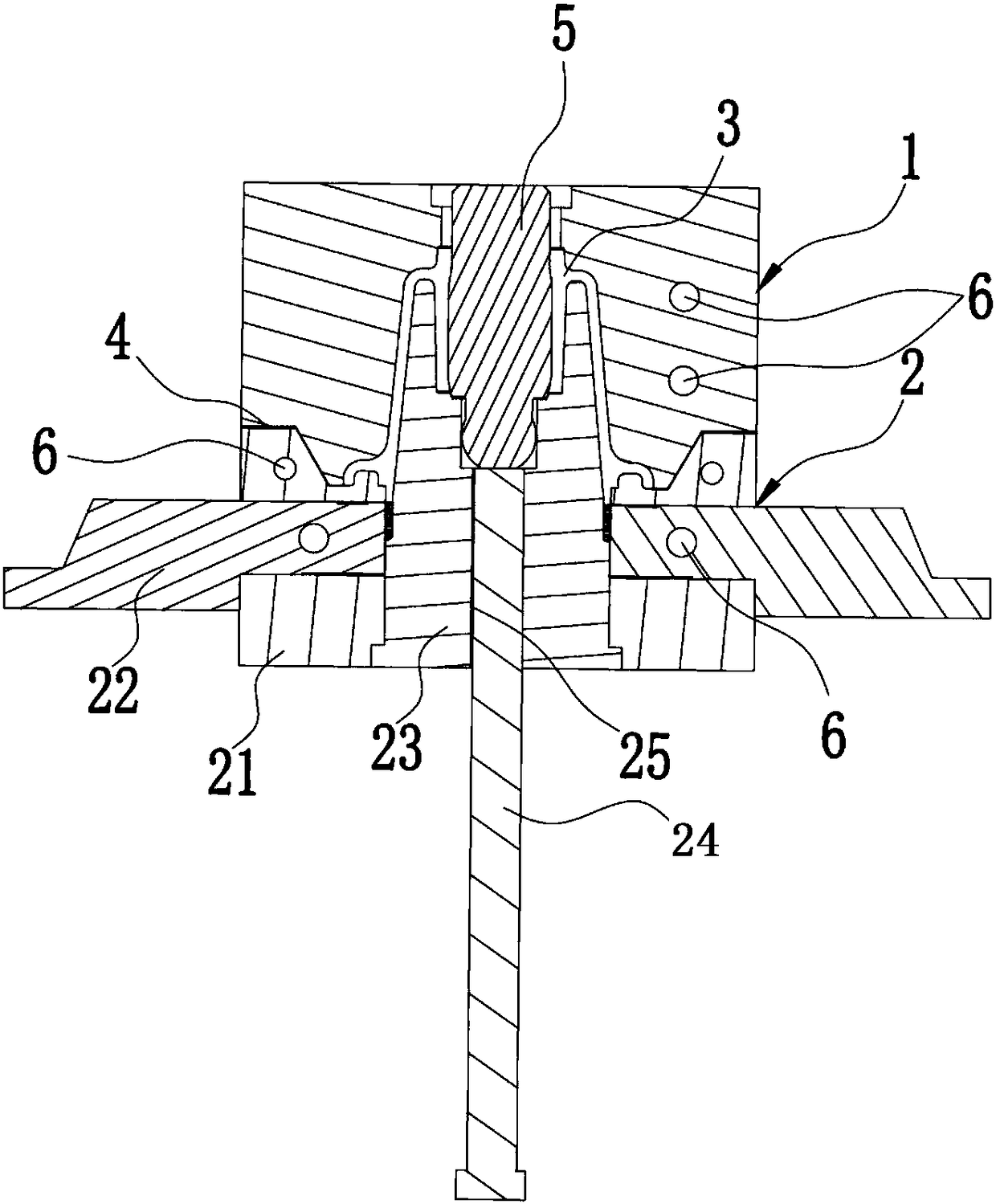

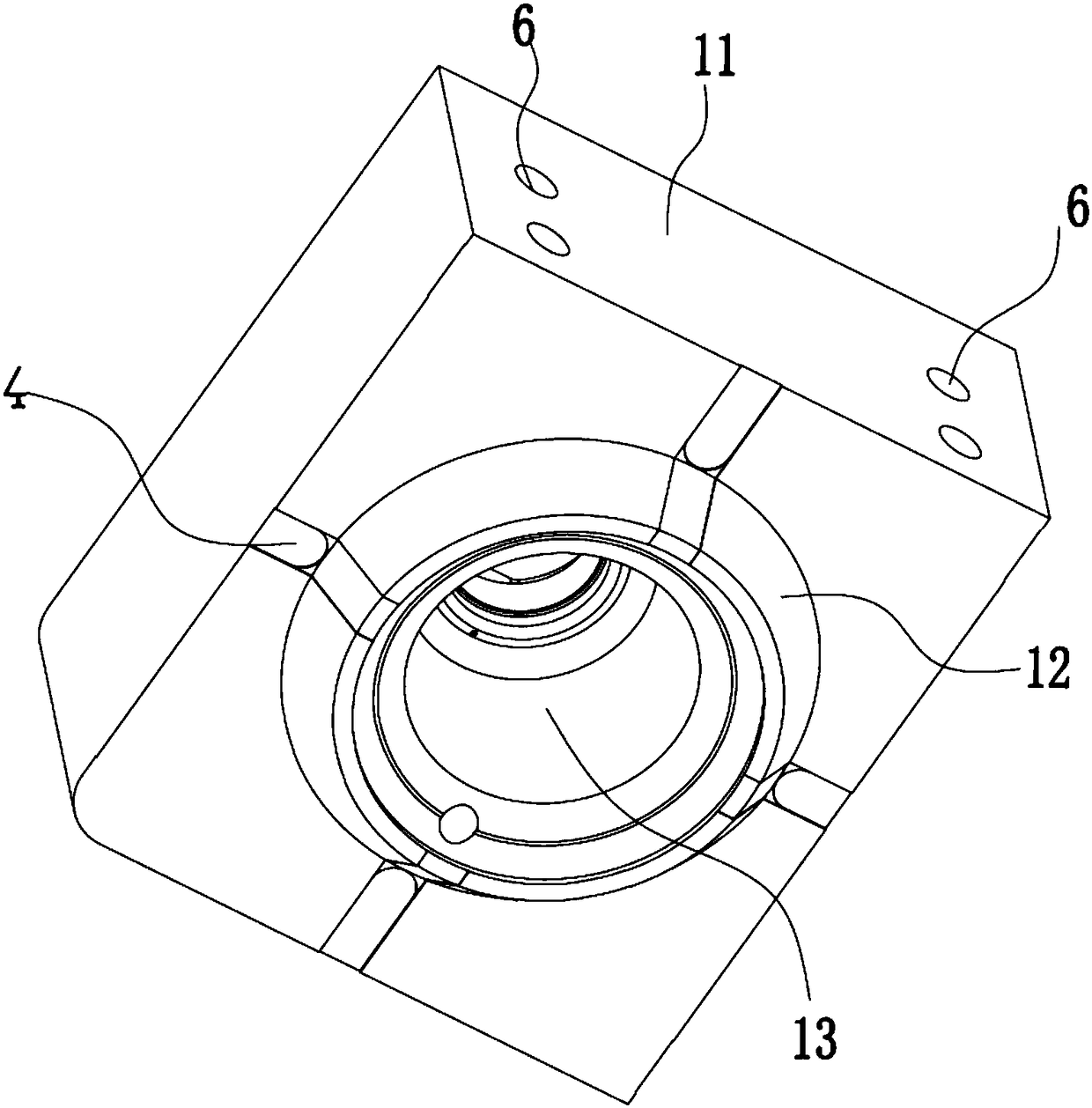

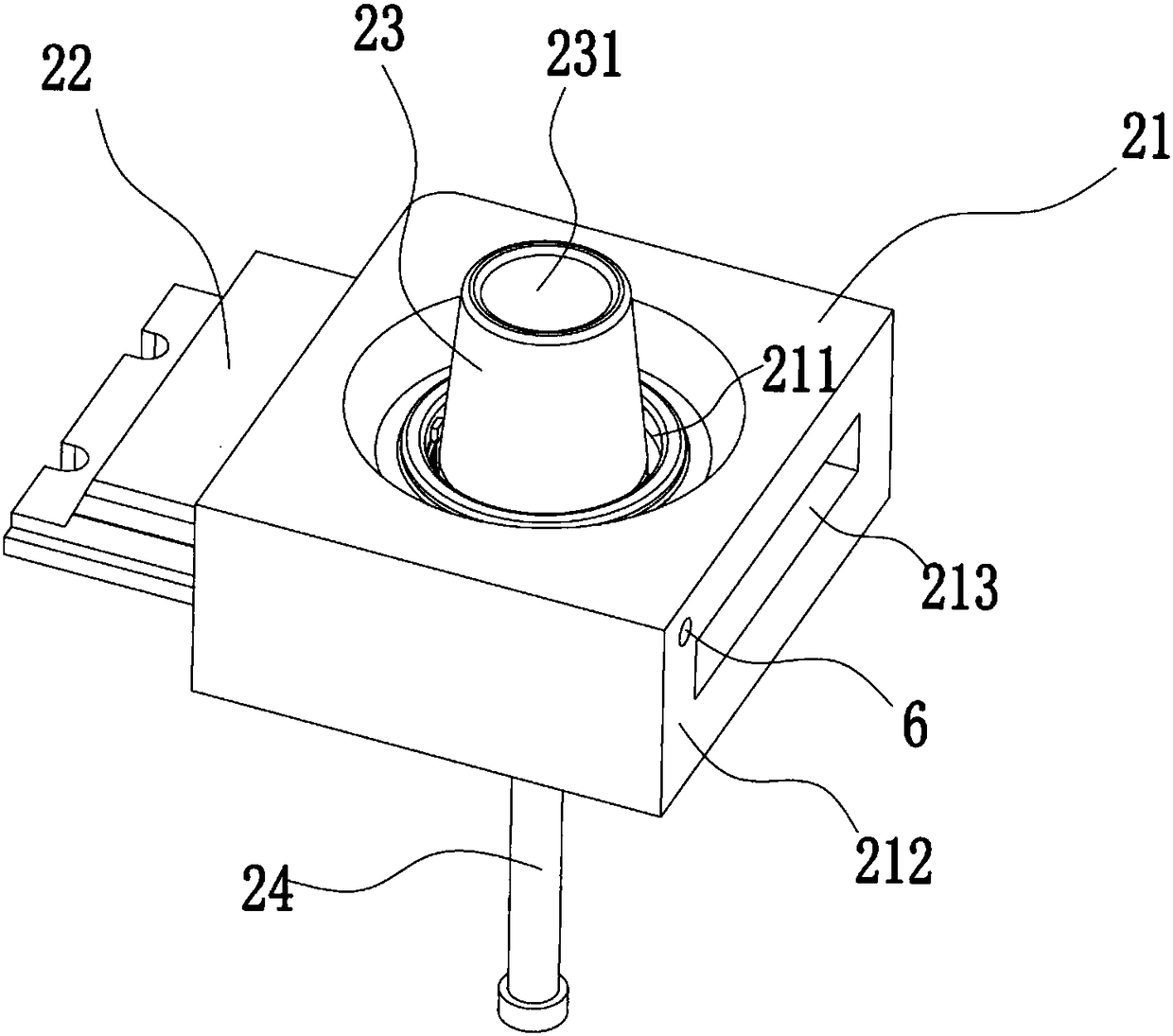

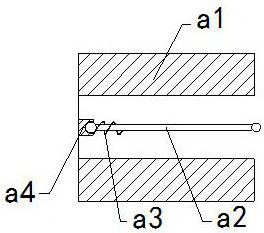

Injection mold

The invention discloses an injection mold. The injection mold comprises a first mold core and a second mold core which are matched to form a molding cavity; the second mold core comprises a body, twosliders and a shaping piece, and the body, the two sliders and the shaping piece can be combined into a local molding cavity; the two sliders can be inserted and connected into the body and can be spliced into a through hole coaxial with a center through hole in the body; the shaping piece can penetrate the center through hole and the through hole, and different areas of the peripheral wall of theshaping piece are attached to the inner walls of the center through hole and the through hole; and at least one exhausting channel communicating with the interior and the exterior of the molding cavity is formed on the two sliders. The scheme is ingenious in design and simple in structure, the second mold core is formed by joint cooperation of the body, the sliders and the shaping piece, exhausting channels are also added in cooperation gaps among the body, the sliders and the shaping piece, and exhausting is facilitated; and meanwhile the special-shaped exhausting channel is arranged on thesliders, it can be effectively achieved that gas in the molding cavity is fast discharged, the problem that scorching or incomplete filling occurs on a plurality of portions of a product is solved, and the product quality is guaranteed.

Owner:苏州精锐精密机械有限公司

Classical literature image display equipment for distance education

InactiveCN113436528AAvoid slow coolingSpeed up heat dissipationCleaning using toolsModifications by conduction heat transferSpider ProteinsTele education

The invention discloses a classical literature image display device for distance education, which structurally comprises a display screen, a base and a support frame, the bottom of the support frame is welded with the upper surface of the base, the display screen is mounted at the upper end of the support frame, and a rod body can swing along a connecting block through inertia force generated when the base moves for a long distance. Through cooperation of elastic strips, the rod body can repeatedly swing along the connecting block, so that the rod body can pull down spider silk at the outer end of the inner wall of the frame, and the situation that spiders can knot spider silk screens at the outer ends of the inner walls of the air holes, and heat dissipation of the air holes is slow due to long-time accumulation is effectively avoided; and part of heat passing through the interior of the frame can be guided into the ventilation cavity through the heat dissipation strips, the contact area between the connecting rods and the outside can be increased through cooperation of the contact reducing grooves and the cooling grooves, and therefore the heat dissipation speed of the heat dissipation strips can be increased.

Owner:厦门工学院

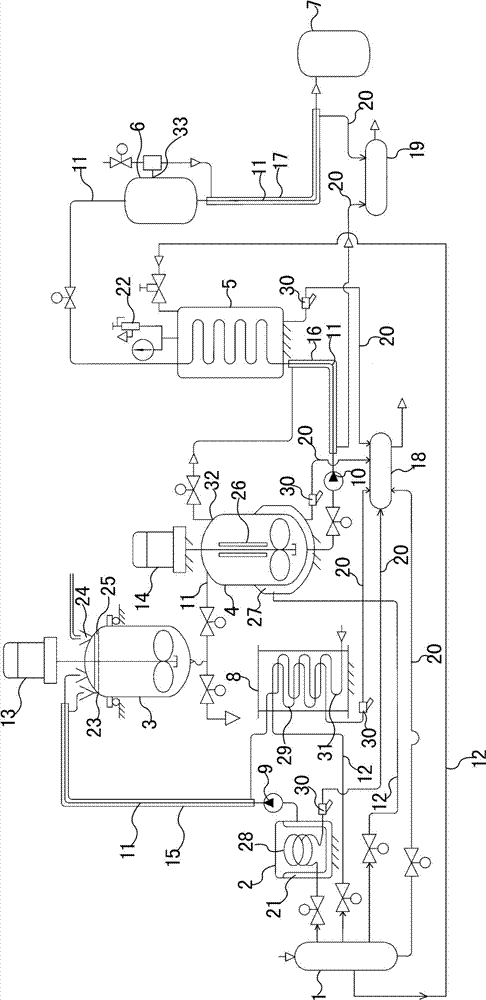

Energy-saving and environment-friendly syrup inverting equipment

The invention relates to energy-saving and environment-friendly syrup inverting equipment which comprises a steam supply device, a syrup preheating tank, a first syrup inverting tank, a second syrup inverting tank, a heating tank, an evaporating tank, a storage tank, a hot water supply device, a first booster pump, a second booster pump, syrup delivery pipes, steam delivery pipes, a first stirrer, a second stirrer, a first thermal insulation casing, a second thermal insulation casing, a third thermal insulation casing, a drainage balancing recovery tank, a residual heat recovery tank and recovery pipes. With the adoption of a sealed structure and secondary stirring, syrup is mixed more uniformly and has a lower water content; a produced sweet is more uniform and keeps the original taste and color; a burning situation can be avoided; used steam is subjected to centralized treatment; environmental pollution is avoided; the equipment is more environment-friendly and energy-saving; the first thermal insulation casing, the second thermal insulation casing and the third thermal insulation casing are additionally arranged for treating the steam generated in a production process, so that the generated steam is made full use of; and the equipment is more energy-saving.

Owner:广东果乡水秀生物科技有限公司

Spiced beef flavored peanuts

The invention discloses spiced beef flavored peanuts. The spiced beef flavored peanuts are prepared through the following steps: adding hawthorn and the seed of barley to water, boiling and collecting filtrate, and adding beef broth to the filtrate to obtain a solution A; adding the solution A to the stir-fried peanuts while hot; adding chilli, black pepper, paprika pepper, spicy hot pepper, green Chinese onion, onion, Jamaica pepper, thyme, pericarpium citri reticulatae, fennel, pericarpium zanthoxyli, radix angelicae, beautiful galangal fruit and rhizoma nardostachyos, heating and boiling to obtain a solution B, adding the solution B to the solution A in which the peanuts are soaked, and fishing the peanuts out; adding the table salt, isomaltooligosacharide, xylitol, stevioside and cooking wine, heating while stirring, adding the fish-out peanuts, soaking for 4-8 hours, taking the peanuts out, draining off water, cooling to room temperature, drying and cooling to room temperature. The spiced beef flavored peanuts disclosed by the invention are unique and fresh in taste and are spicy hot and delicious, the taste of the peanuts is enriched.

Owner:WUHU FEIYUE FOOD

Preparation method of disinfectant used in pasture

The invention discloses a preparation method of a disinfectant used in pasture. The preparation method includes the steps of: 1) selecting the following raw materials including, by weight, 10-20 parts of folium artemisiae argyi, 9-17 parts of honeysuckle, 4-7 parts of garlic, 1-3 parts of cloves and 10-18 parts of anhydrous ethanol. In the method, the disinfectant is prepared by extracting active components from the plants, so that preparation process of the disinfectant is simplified and cost of the disinfectant is reduced. The disinfectant can effectively kill pathogenic bacteria in a pasture without damage on original ecologic balance in the pasture, thus achieving high-effective and environment-friendly sterilization. During the preparation, a filter residue is soaked repeatedly, so that waste on raw materials and economic loss are avoided, concentration of the disinfectant is increased, and disinfecting effect of the disinfectant is enhanced.

Owner:谈玉靓

Multi-layer smokeless automatic rotary barbecue oven

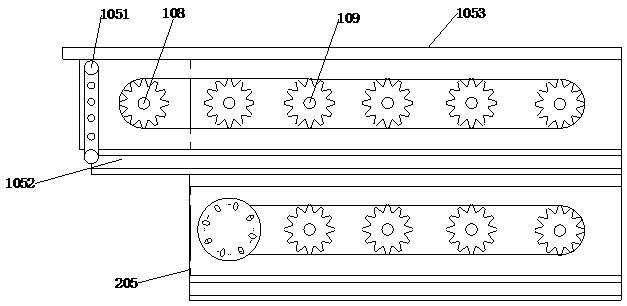

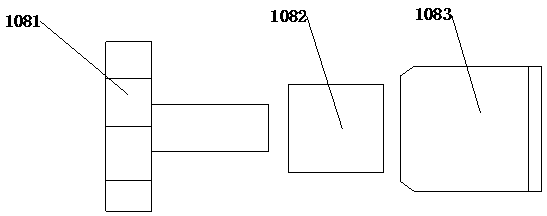

PendingCN108937623AImprove convenienceSolve a small number of problemsRoasting apparatusRoasters/grillsEngineeringMultiple layer

The invention discloses a multi-layer smokeless automatic rotary barbecue oven. The multi-layer smokeless automatic rotary barbecue oven comprises an upper layer oven, a heating tube, a lower layer oven and an oil accumulating plate, wherein the inner wall of the upper layer oven is in through connection with the heating tube, a label hole runs through the periphery of the heating tube, a drive box is welded to the outer wall of the right side of the upper layer oven, a drive gear is welded to the outer wall of the rear side of the drive box, a driven gear is welded to the outer wall of the rear side of the upper layer oven, the outer wall of the driven gear is movably connected with a drive chain, the drive gear comprises a gear chuck and a gear bearing, and the gear chuck is in sleeved connection to the inner wall of the gear bearing. The multi-layer smokeless automatic rotary barbecue oven has the advantages that the upper layer oven and the lower layer oven are arranged, the upperlayer oven can freely slide relative to the lower layer oven, multiple layers of the barbecue oven work and run simultaneously, the purpose of improving the barbecue efficiency is achieved, and the collection treatment of oil generated by barbecue is achieved through the oil accumulating plate.

Owner:钟才有

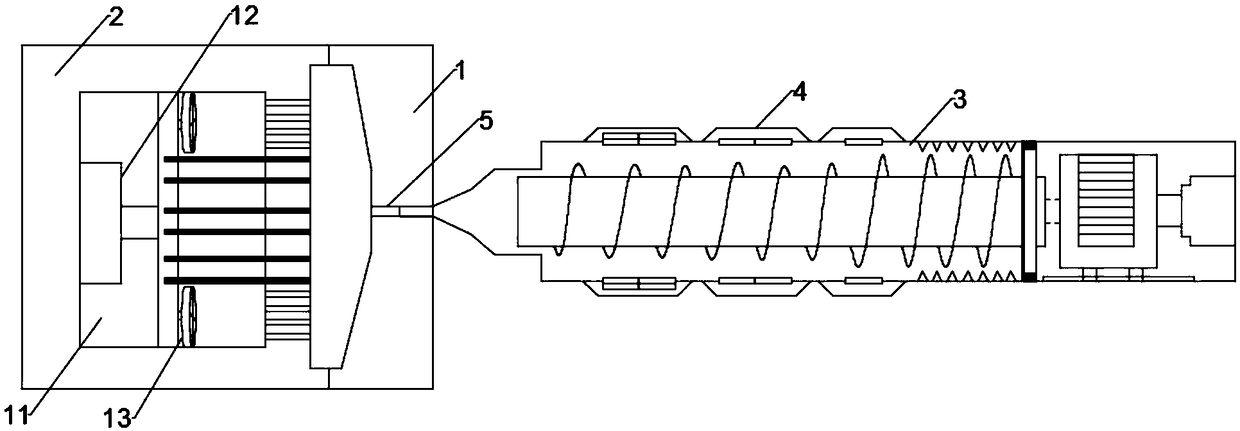

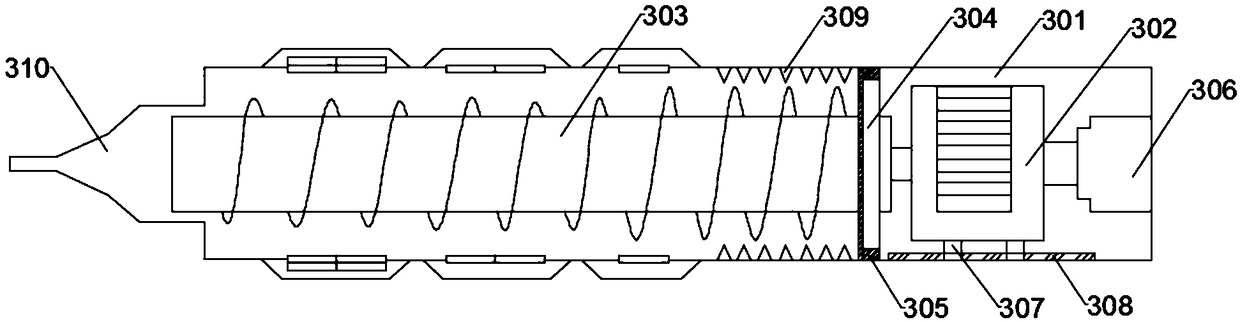

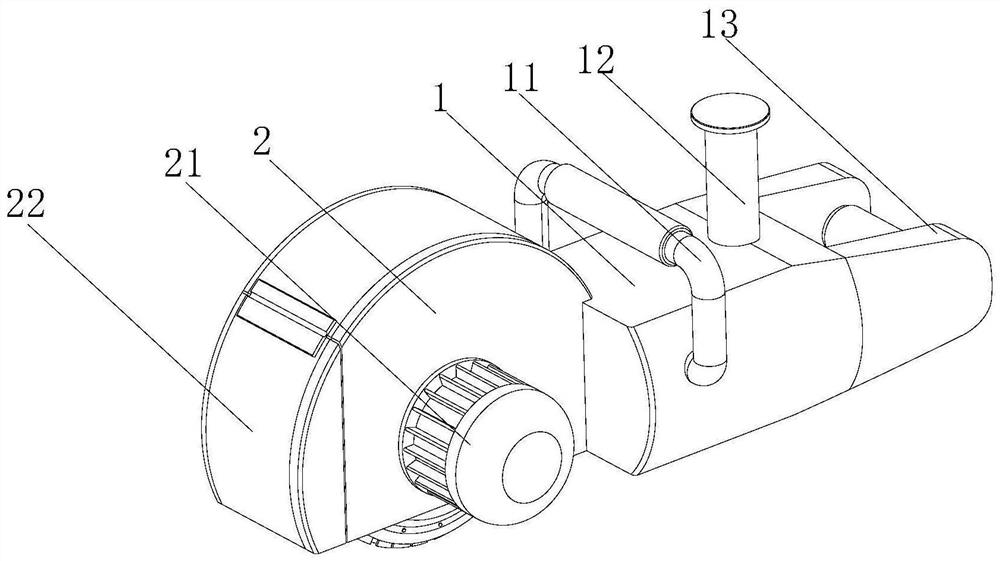

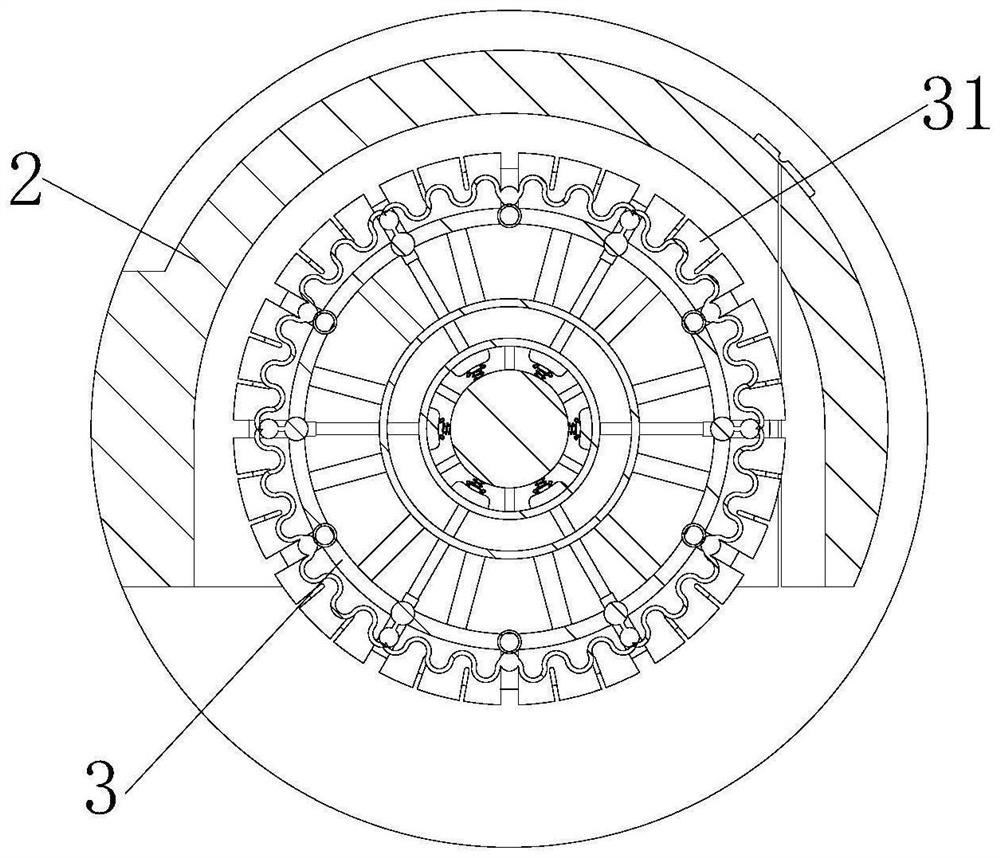

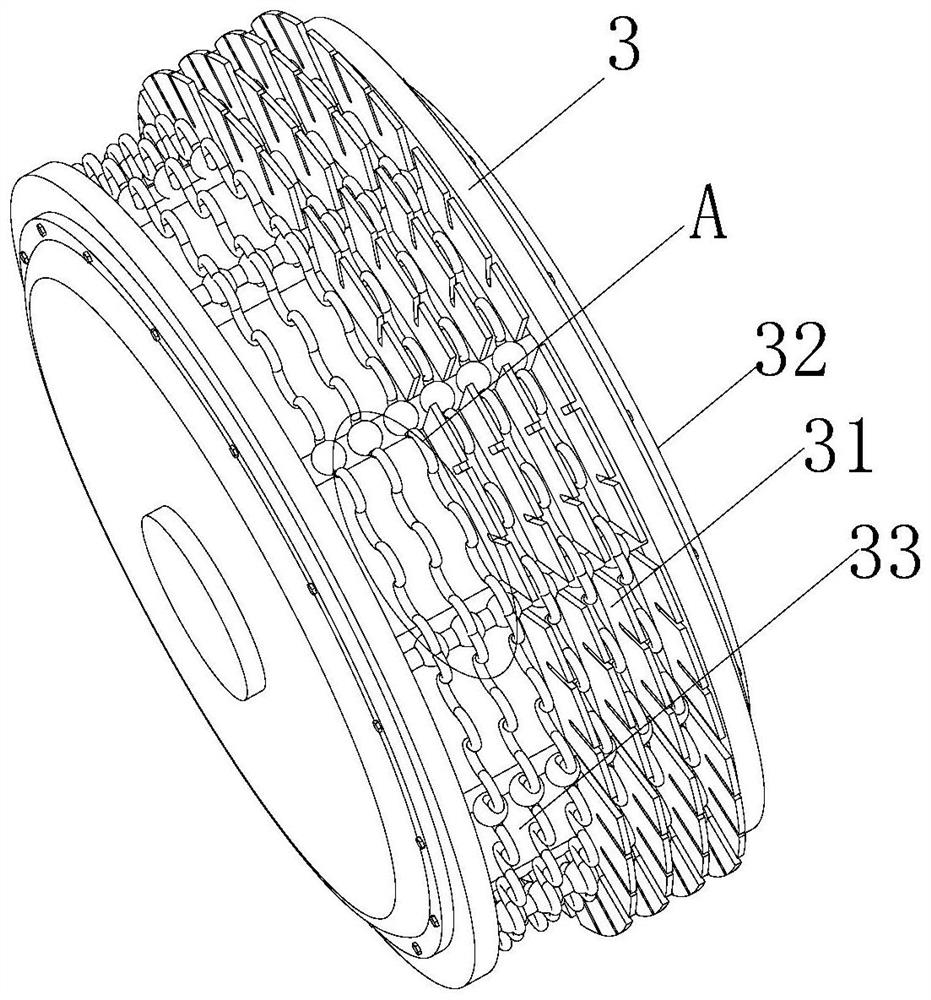

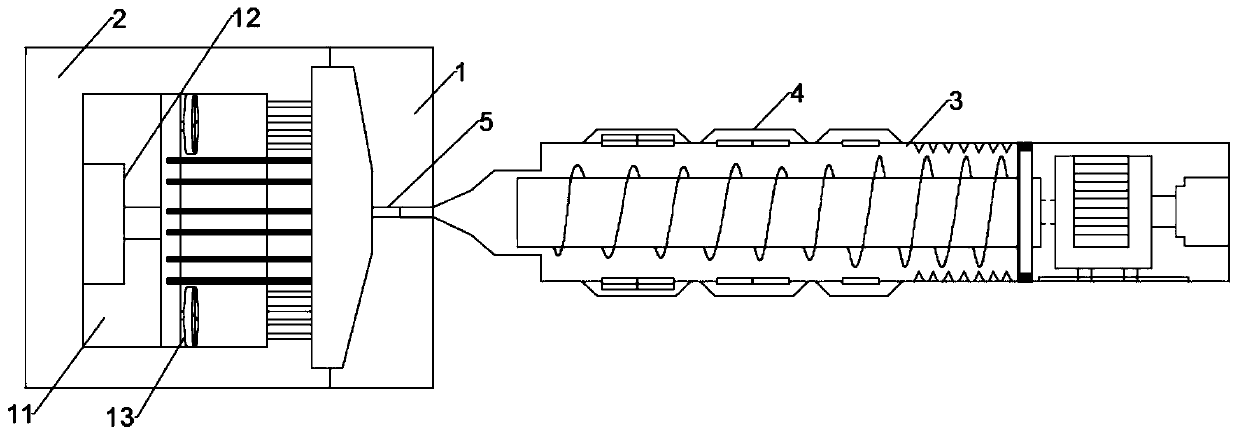

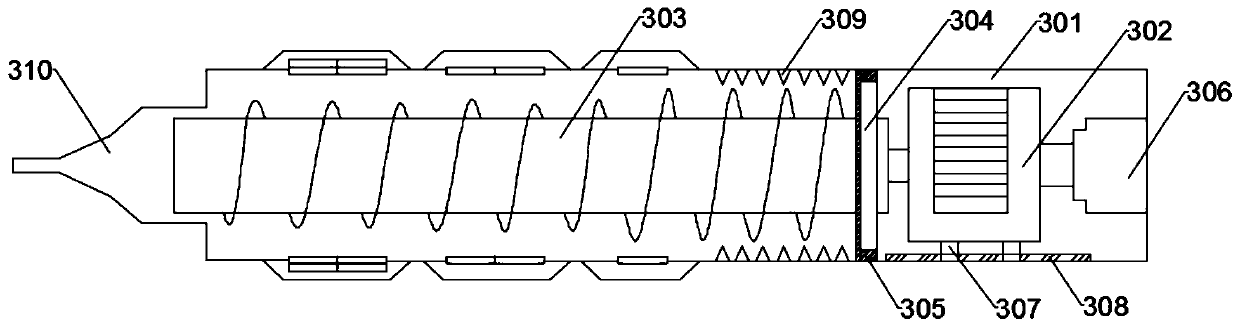

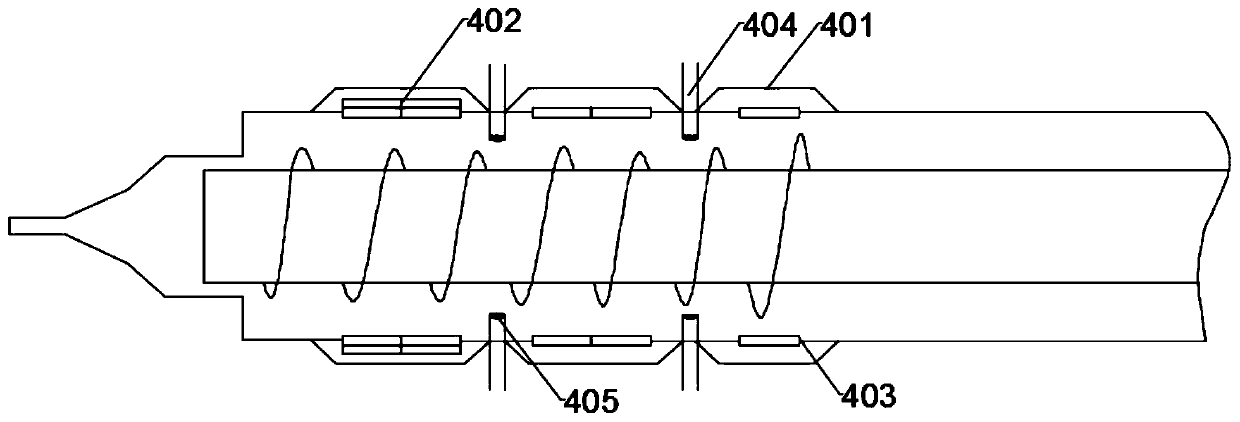

Plastic slipper injection molding injection mold and method

ActiveCN108790232AAvoid Burnt SituationsIncrease the amount of foamDomestic footwearSurface mountingDrive motor

The invention discloses a PVC blowing slipper injection mold which comprises a fixed mold base, a movable mold base and a plastic mixing crushing mechanism, wherein the plastic mixing crushing mechanism comprises an accommodating reaction cylinder and a drive motor; the drive motor is connected with a squeezing screw; a thermal insulating panel is arranged at one end of the squeezing screw and isconnected with a displacement air cylinder; a movable sliding block is mounted on the lower surface of the drive motor; a sliding rail is further arranged on the inner wall of the accommodating reaction cylinder; the squeezing screw is sequentially divided into a crushing section, a melting stirring section and a squeezing section from right to left; the accommodating reaction cylinder is providedwith a friction bulge; the accommodating reaction cylinder is provided with subsection heating mechanisms at the melting stirring section and the squeezing section separately; and an air blowing pipeis further arranged on the accommodating reaction cylinder. The subsection heating manner is adopted to avoid the situation that plastic is burnt; an air blowing mechanism is added to increase the foaming quantity; and water-cooling and air-cooling manners are adopted to carry out air blowing foaming treatment and efficient cooling function, so that the injection molding period is shortened and the operating convenience is also improved.

Owner:定州市鼎足鞋业有限公司

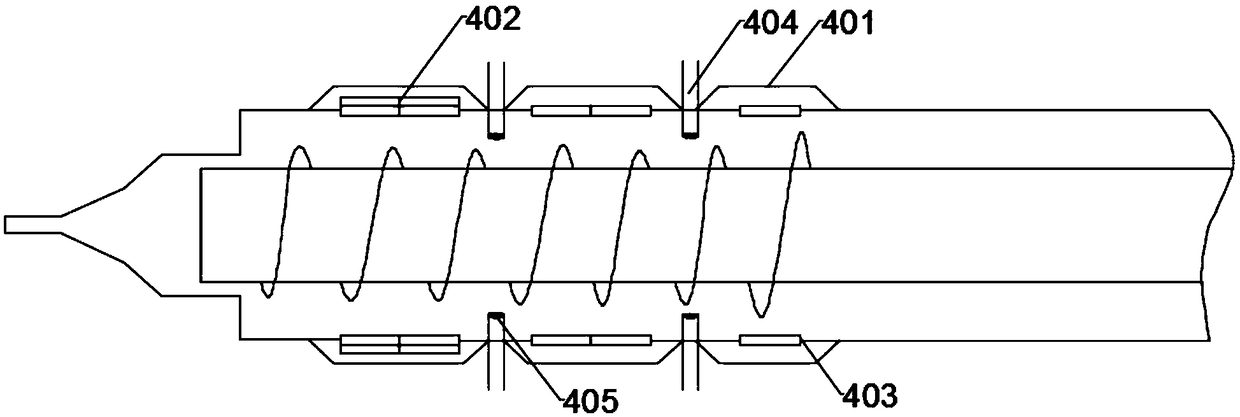

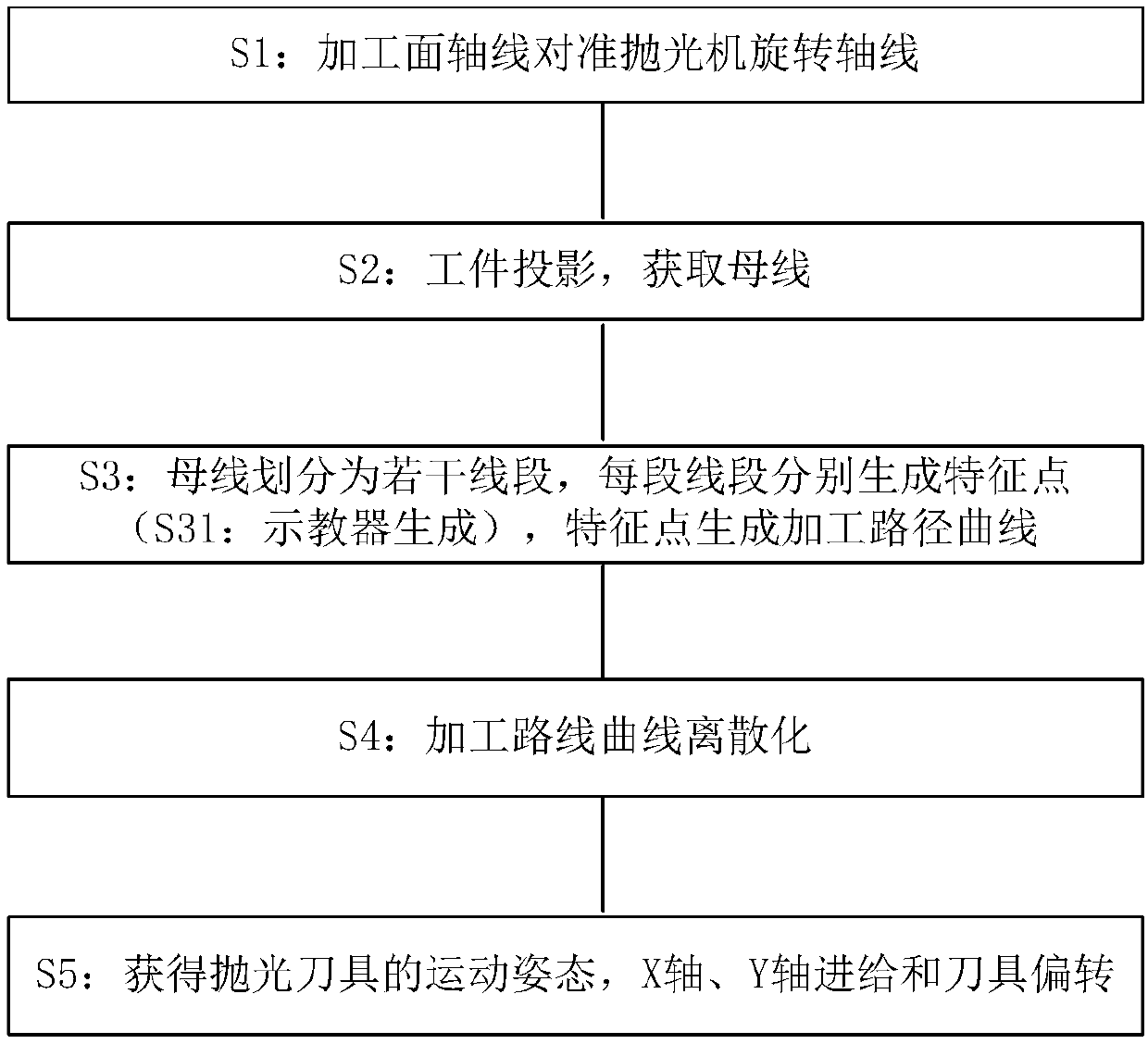

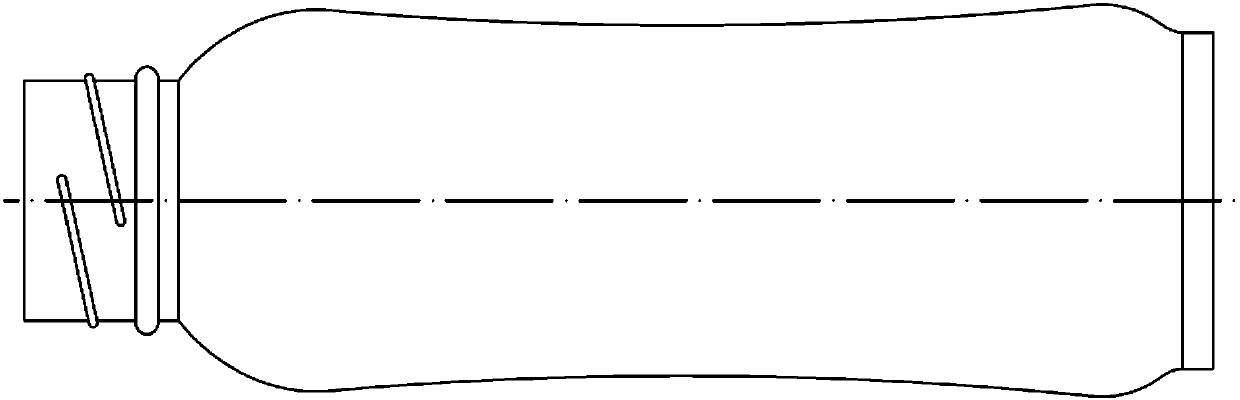

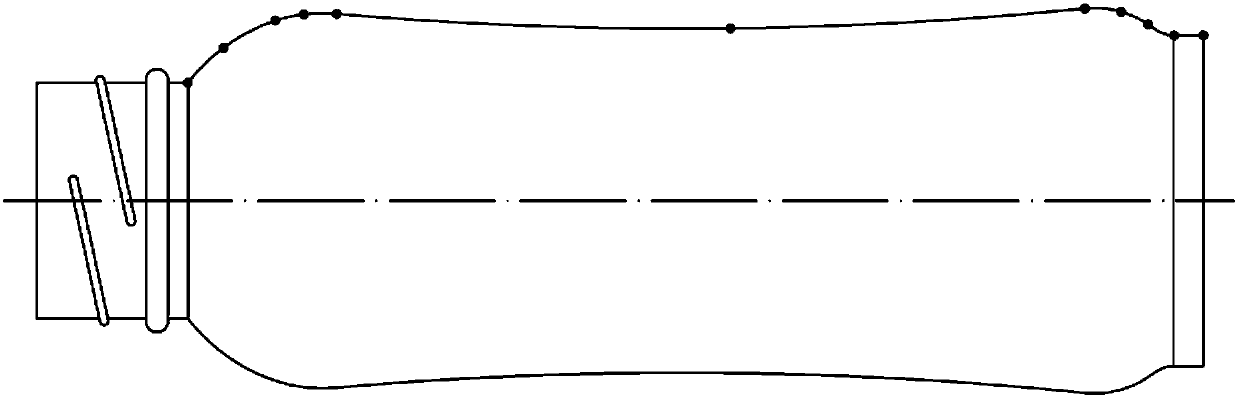

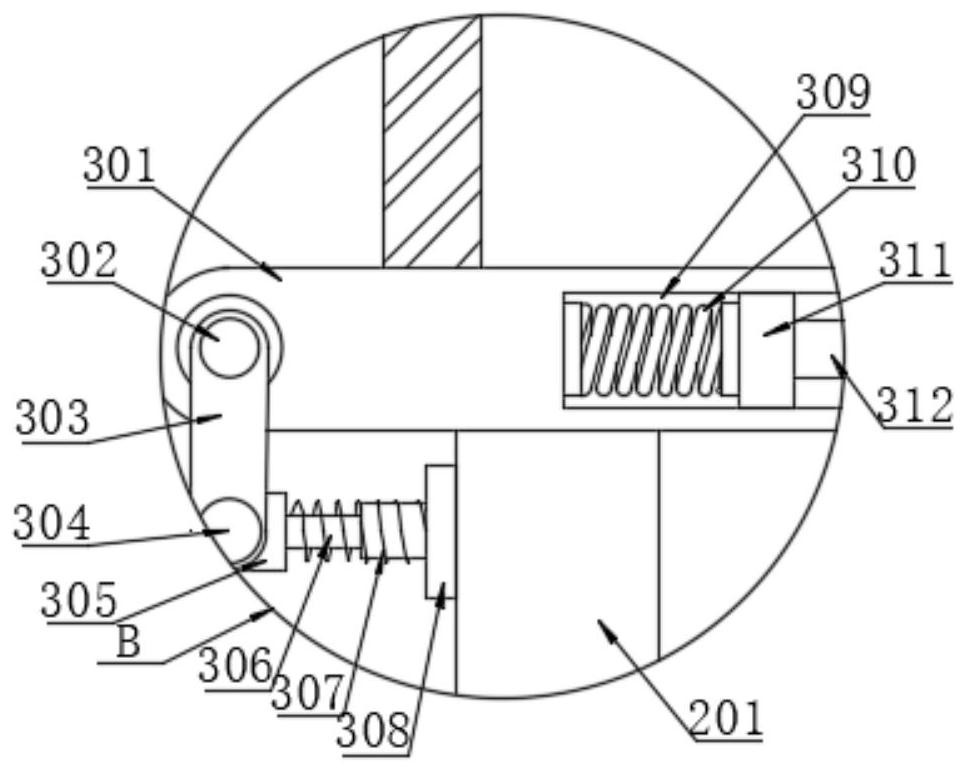

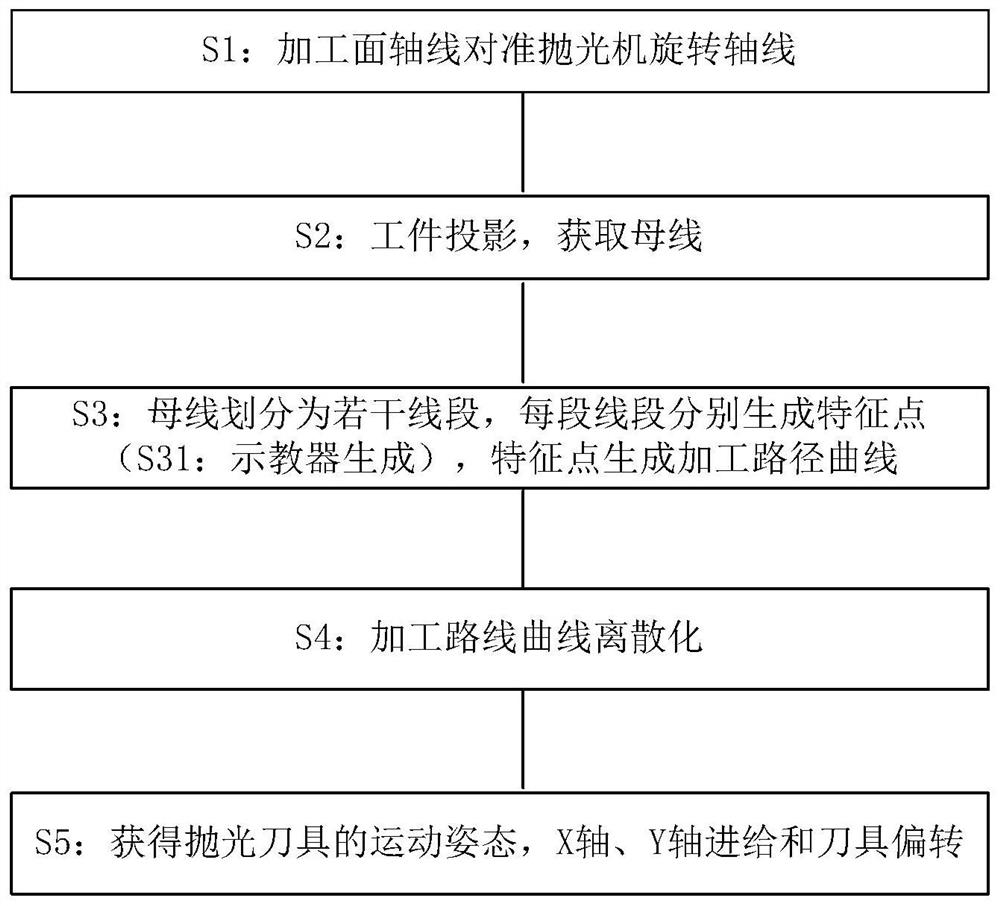

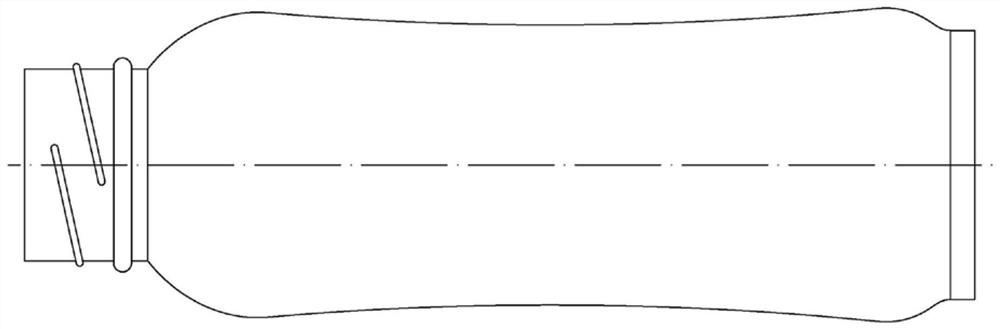

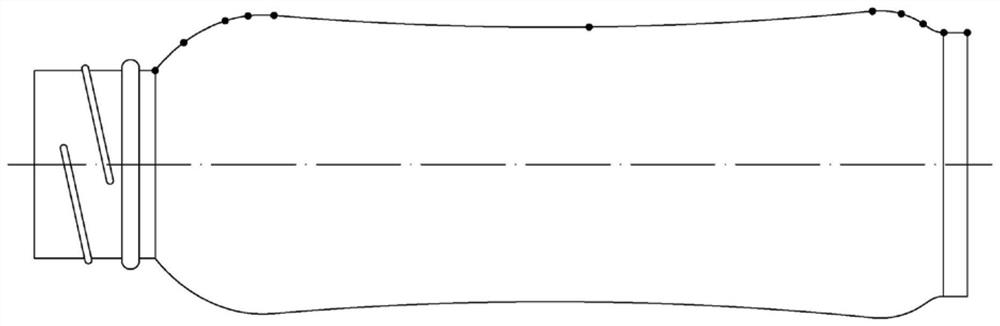

Implementation method of polishing machine machining path for vacuum cup

The invention discloses an implementation method of a polishing machine machining path for a vacuum cup. The method mainly comprises the following steps of making an axis of a machined surface of a workpiece coincide with a spindle of a polishing machine; obtaining one bus of the machined surface; dividing the bus into N characteristic line segments in sequence, generating one characteristic pointby each characteristic line segment, collecting the characteristic points by using a teach pendant and then restoring the characteristic points into a continuous machining path in sequence; discretizing the continuous machining path to generate polishing cutting points; adaptively generating X-axis feed and Y-axis feed of polishing tools according to the polishing cutting points and generating deflection of the polishing tools or deflection of the workpiece, wherein the workpiece rotates around the spindle of the polishing machine and the polishing tools also rotate; and achieving polishing of the workpiece according to the speed difference between the workpiece and the polishing tools. As a result, the automation degree of polishing work of the vacuum cup is improved, the polishing machine is suitable for polishing of the vacuum cup with various buses, the flexibility of the polishing machine is improved and the method is simple in programming and short in elapsed time.

Owner:上海捷至翔智能设备有限公司

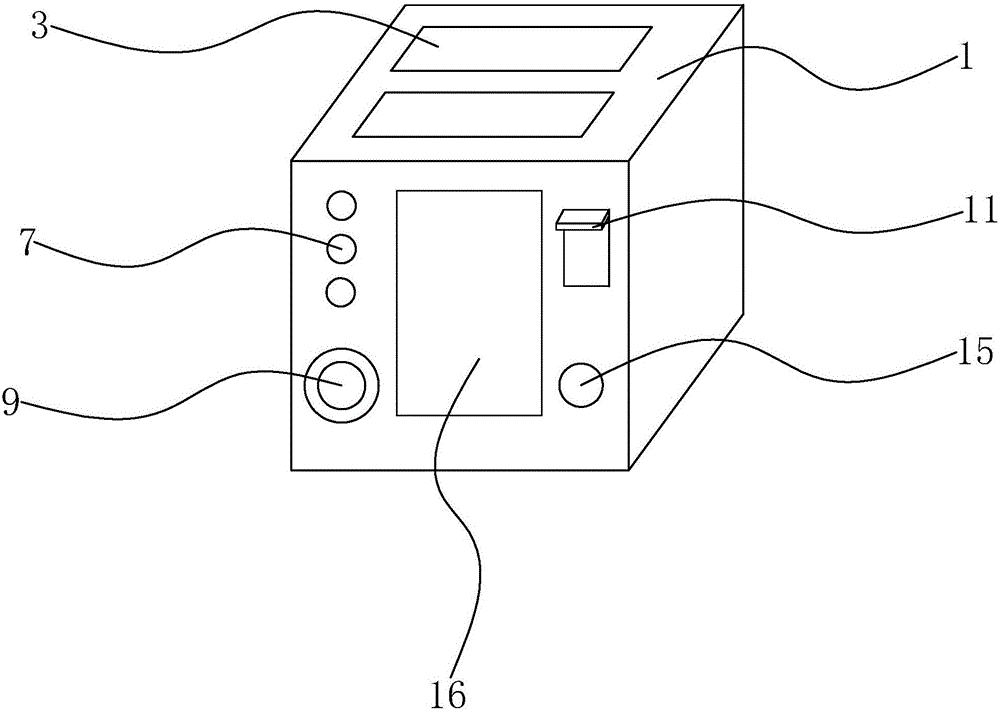

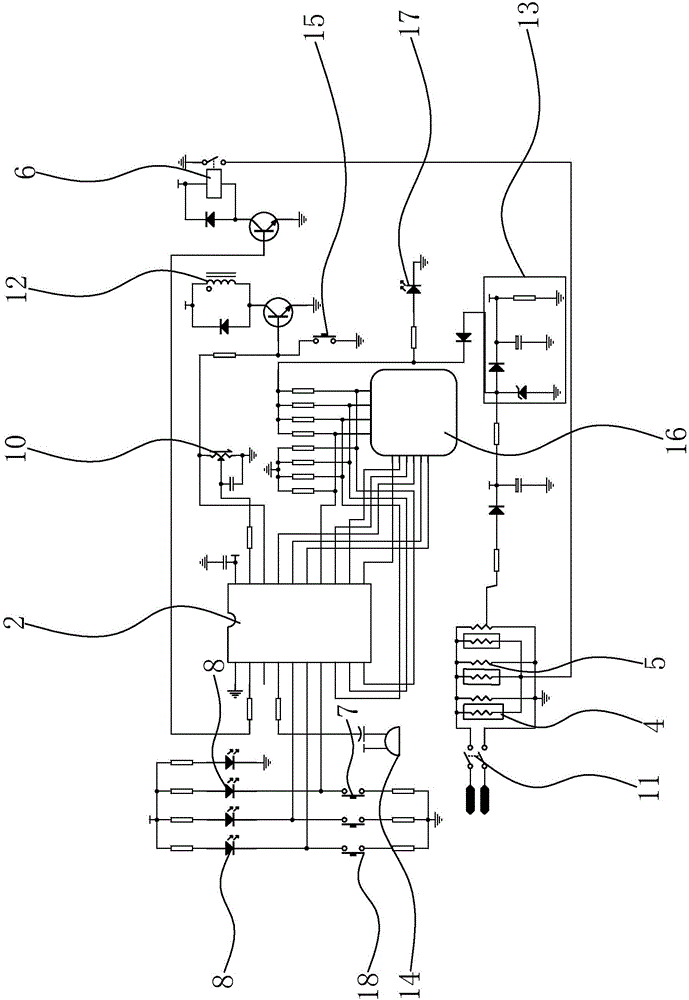

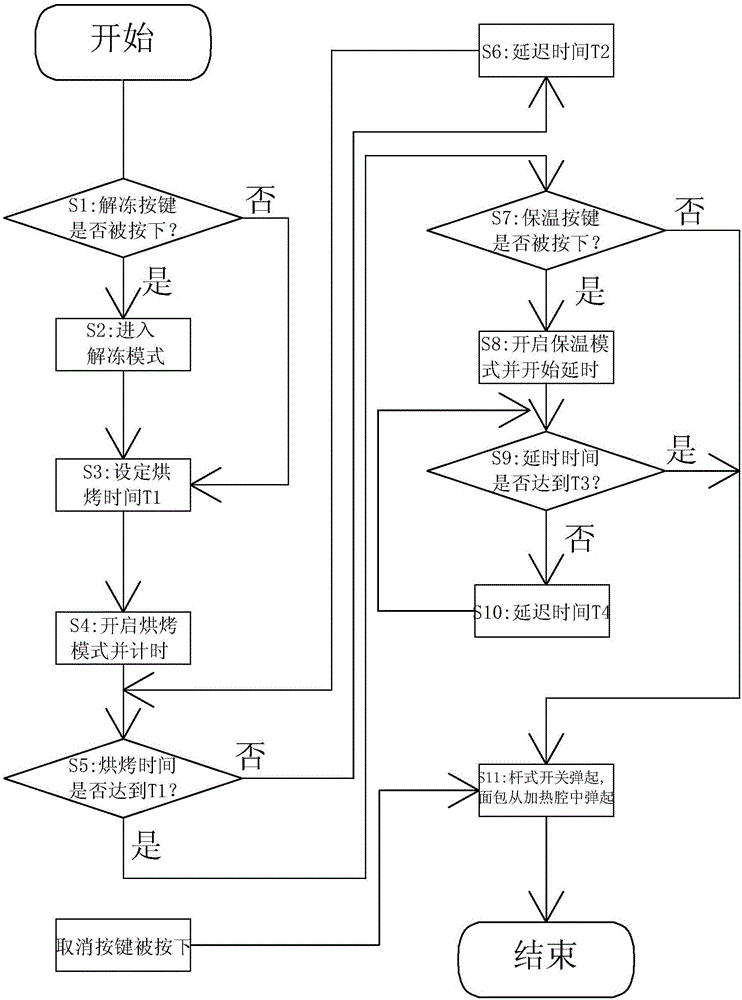

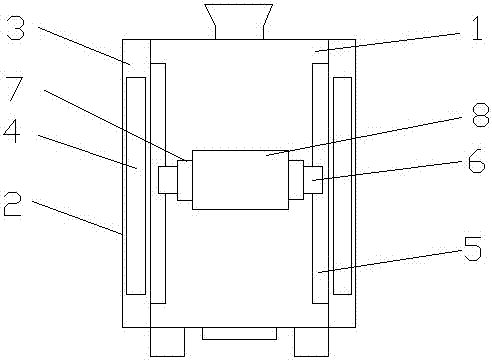

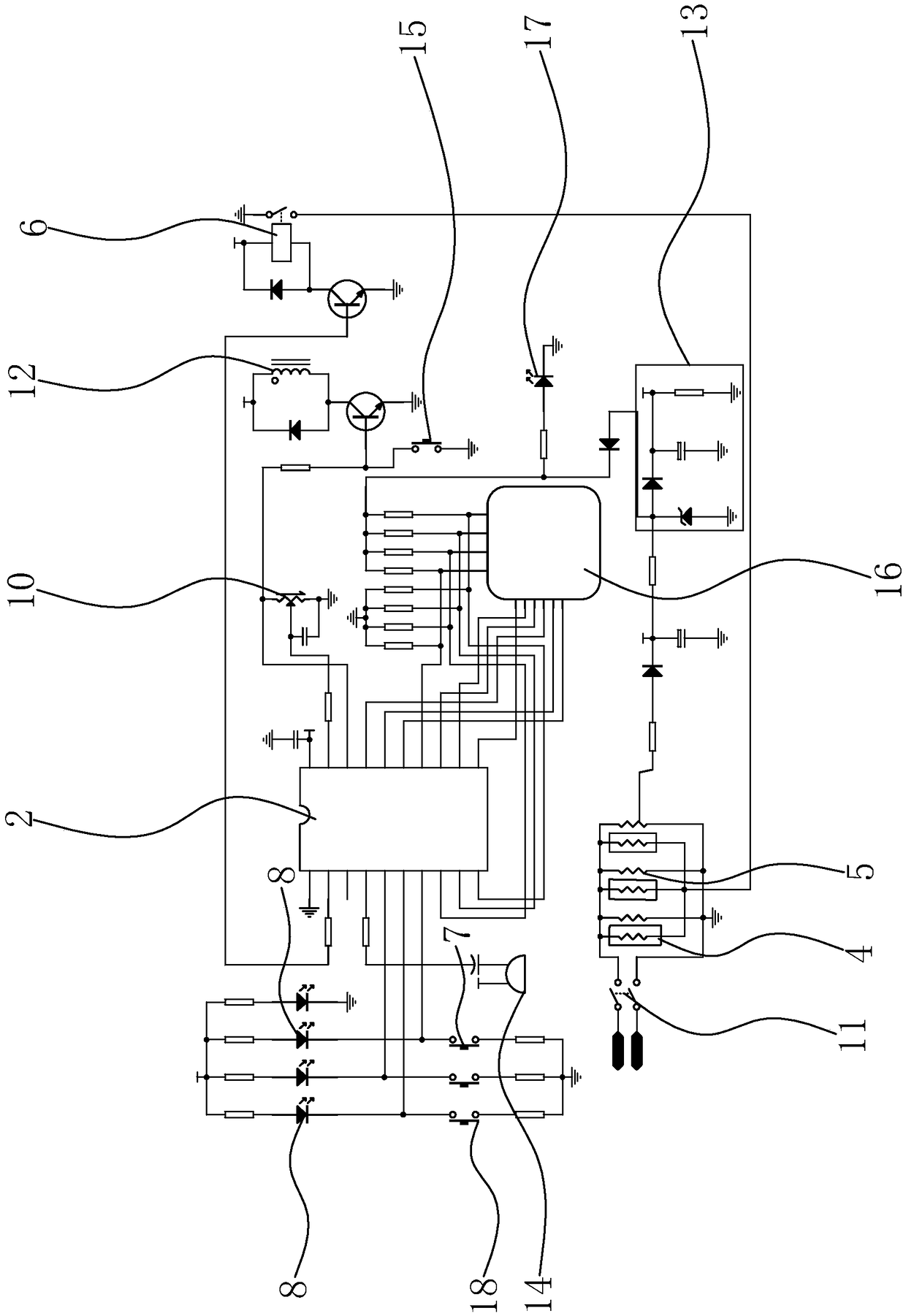

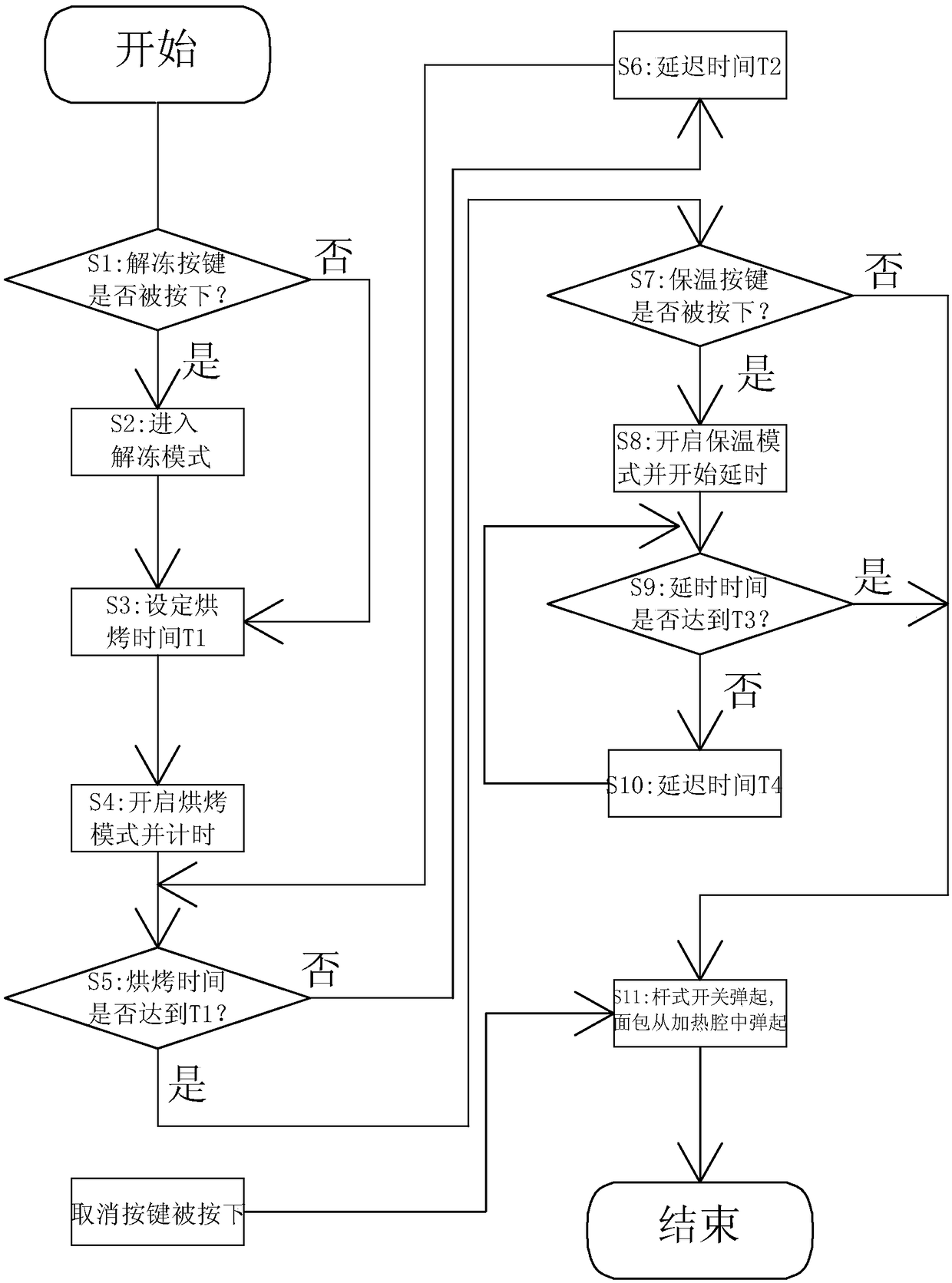

Heat preserving toaster and control method thereof

ActiveCN105996814AExtension of timeAvoid Burnt SituationsTemperature control using electric meansBread-toastersElectronic switchControl circuit

The invention discloses a heat preserving toaster and a control method thereof. The heat preserving toaster comprises a shell, wherein a heating cavity for putting to-be-toasted bread is arranged on the shell; a heater for toasting bread is arranged in the heating cavity; the heater comprises a first heater for toasting bread and a second heater for toasting bread and preserving heat. The heat preserving toaster also comprises a control circuit for controlling the heating state of the toaster, wherein the control circuit comprises a control chip and an electronic switch for controlling the on / off of the first heater, and the electronic switch is connected with the control chip. In the invention, the control chip controls the work of the first heater and the second heater; in heating, the first heater and the second heater work together; in heat preservation, the first heater is switched off through a relay while the second heater is used for preserving heat; and therefore, the heat preservation effect is good, external interference can be effectively avoided, the control is precise, and the situation of burnt bread is prevented.

Owner:咸宁市汇欣电器实业有限公司

Drying barrel for stirring materials by using overturning mechanisms

InactiveCN107449245AEvenly heatedAvoid Burnt SituationsDrying machines with non-progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention discloses a drying barrel for stirring materials by using overturning mechanisms. The drying barrel for stirring the materials by using the overturning mechanisms comprises a drying barrel body, wherein a jacket surrounds the outer side of the drying barrel body; a cavity is formed between the jacket and the drying barrel body; a heating tube is arranged in the cavity; linear guide tracks are vertically arranged on inner walls of two sides of the drying barrel body; the two linear guide tracks are symmetrically arranged in the left-right direction; the inside of each linear guide track is vertically connected with a sliding block slidably; one end of each sliding block is provided with the corresponding overturning mechanism; one end of each overturning mechanism is connected to the center of the corresponding sliding block; the other end of each overturning mechanism is connected with a shovelling plate; the shovelling plate is horizontal; the left end and the right end of the shovelling plate are separately connected with the two overturning mechanisms; and a cavity is formed in the shovelling plate and is filled with a heating plate. By the mode, the overturning mechanisms drive the arc-shaped shovelling plate to rotate so as to stir the materials, and therefore, the materials are heated uniformly.

Owner:无锡市强力干燥设备厂

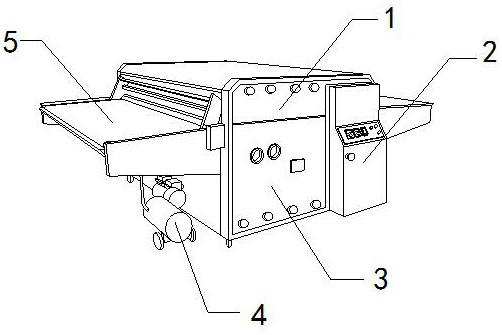

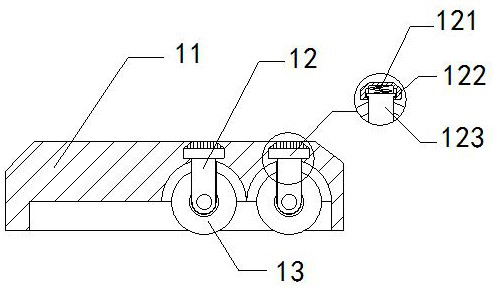

A non-woven fabric production stereotypes equipment

ActiveCN111893646BAvoid Burnt SituationsFast shapingNon-woven fabricsAdhesivesElectric machineryNatural fiber

The invention discloses a non-woven fabric production and shaping equipment, the structure of which comprises a shaping chamber, a control electric box, a base, a motor, and a transmission table, the control electric box is electrically connected to the base, the motor is installed at the front end of the base, and the transmission table is embedded in the The inner position of the base, the shaping chamber is welded to the upper position of the conveying table, and the heated shaping roller can crush the fibers conveyed to the bottom, and the thermoplastic fiber can be softened rapidly while rolling, so that the shaping pressing roller can The pressure generated by the roller can quickly shape the natural fibers and thermoplastic fibers together, and through the gap between the top surface and the bottom block on the heat dissipation mechanism, the heat generated by the heat transfer oil above the top surface can be avoided from being directly introduced into the inside of the bottom block. Therefore, it can be prevented that the heat generated at the bottom of the heated inner tank is used for a long time, directly affecting the bottom of the outer cylinder, and the temperature at the bottom of the outer cylinder is greatly increased.

Owner:嘉兴鸿恩生物科技有限公司

A thermal insulation toaster and its control method

ActiveCN105996814BExtension of timeAvoid Burnt SituationsTemperature control using electric meansBread-toastersElectronic switchEngineering

Owner:咸宁市汇欣电器实业有限公司

A kind of circulating fir oil production equipment and the production process of fir oil

ActiveCN103966028BImprove extraction efficiencyIncrease temperatureEssential-oils/perfumesKitchen equipmentOil canThermodynamics

The invention discloses circulating sanmon oil production equipment which comprises a steam generating device, a sanmon oil extraction device, a condenser pipe device, an oil-water separation device and a sanmon oil collection device, wherein the sanmon oil extraction device comprises a sanmon oil extracting tank; the sanmon oil extracting tank comprises an extracting pot and an external jacket; the external jacket and an outer wall of the extracting pot define a containing space; the extracting pot comprises a main dispersing steam pipe and multiple auxiliary dispersing steam pipes; one ends of the auxiliary dispersing steam pipes are communicated with the containing space, and the other ends of the auxiliary dispersing steam pipes are converged and communicated with the main dispersing steam pipe; and an air hole is formed in the bottom of the main dispersing steam pipe. The invention also discloses a process for preparing the sanmon oil by using the equipment as well as the prepared sanmon oil. The sanmon oil attached to steam can be completely isolated from an external heat source, and the temperature of the sanmon oil cannot be over high, so that the condition that the sanmon oil is burnt is avoided, and the quality of the sanmon oil is powerfully guaranteed.

Owner:水木海清生物科技(福建)有限公司

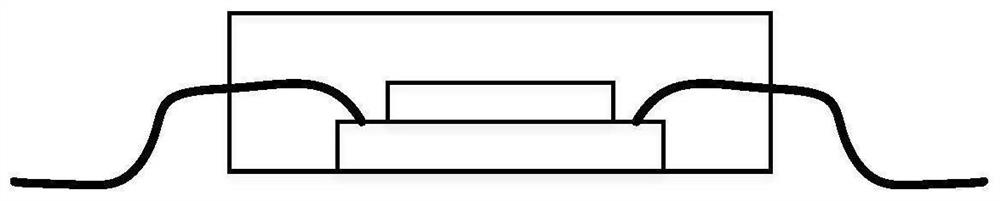

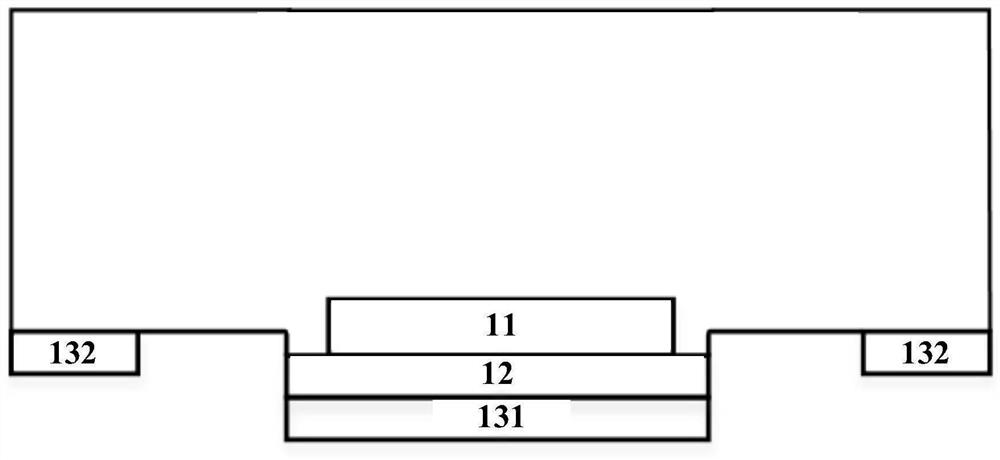

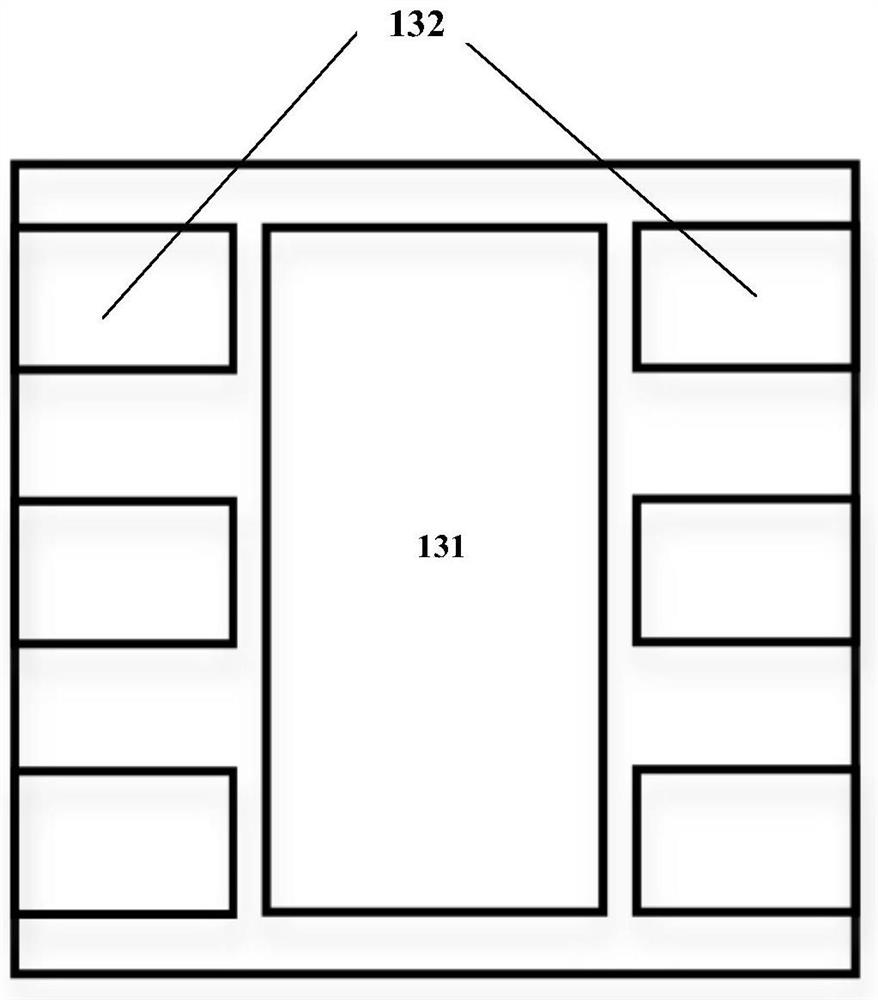

Temperature sensor, printed circuit board and server

PendingCN112945408AHigh precisionAvoid Device FailureThermometers using electric/magnetic elementsUsing electrical meansPrinted circuit boardTemperature measurement

The invention discloses a temperature sensor, a printed circuit board, a server, and a board card temperature measurement module arranged at an internal bottom layer, the board card temperature measurement module comprises a crystal grain, a substrate and a bonding pad which is provided with a groove structure and comprises a bare bonding pad and a bonding pad pin, the crystal grain is arranged above the substrate, and the substrate is arranged on the bare bonding pad. The bonding pad pin is arranged on the edge of the groove; and the bare bonding pad is arranged at the bottom of the groove, has no electrical property, and is in direct contact connection with the bonding pad of the circuit board to be subjected to temperature measurement. The crystal grain comprises a temperature sensitive element and a temperature calculation unit and is used for calculating the temperature value of the circuit board to be subjected to temperature measurement according to the temperature information transmitted by the circuit board to be subjected to temperature measurement through the bare bonding pad. According to the invention, the problem that the finally measured temperature cannot accurately reflect the temperature on the board card due to the fact that the pin extending out of the chip body is relatively long, the pin is relatively thin, the heat conduction efficiency is relatively low and the pin is influenced by the air temperature in the existing SOP package is solved, and the temperature measurement precision of the PCB board card is improved.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

Freshness-enhancing seasoning for roasting chicken wings

InactiveCN106262639AProtect active ingredientsRaise the ratioFood scienceRoast chickenAdditive ingredient

The invention provides freshness-enhancing seasoning for roasting chicken wings and relates to the field of food seasoning. The freshness-enhancing seasoning is prepared from the following raw materials in parts by weight: 100 parts of fresh bamboo roots, 1.2 parts of pomegranate wine, 1.5 parts of ethyl maltol and 0.16 part of silicon dioxide powder. The flavor-enhancing seasoning is used for preparing roasted chicken wings, and is simple in raw material proportion; the fresh bamboo roots are taken as a main material, pomegranate wine is taken as an accessory, ethyl maltol is taken as a combination carrier, and all ingredients achieve a synergetic effect, so that oxidation resistance can be achieved, and active ingredients in the seasoning can be protected for a relatively long time. The seasoning is mixed with marinade or pulp during preparation of the roasted chicken wings, has the effects enhancing the freshness and improving the flavor, and has special fragrance.

Owner:BENGBU DACHENG FOOD

Plate grooving machine for building construction

InactiveCN114425808AAvoid Burnt SituationsQuality assuranceWood mortising machinesBark-zones/chip/dust/waste removalOil canArchitectural engineering

The plate grooving machine for building construction comprises an equipment body, a protective cover is fixedly connected to one side of the equipment body, a movable cover is rotationally arranged on the side, with the equipment body, of the protective cover, a driving motor is fixedly installed on the surface of the protective cover, and a rotating disc is rotationally arranged at the output end of the driving motor; the other end of the equipment main body is fixedly connected with a pair of connecting plates, the connecting plates are symmetrically arranged, a grip is fixedly connected between the connecting plates, the surface of the equipment main body is fixedly connected with a supporting rod, a rubber sleeve is clamped on the surface of the supporting rod, two sides of the equipment main body are fixedly connected with supporting grips, and the surfaces of the supporting grips are fixedly connected with anti-skid sleeves; compared with the prior art, under the action of centrifugal force, a driving rod can move outwards, cooling oil can be conveyed to a liquid discharging opening through a liquid discharging pipeline, the bottom of a grinding piece can be cooled, the situation that the interior of a wire groove is burnt due to the fact that the temperature is too high in the grinding process can be avoided, and the grooving quality can be guaranteed.

Owner:桐乡市亨立科技有限公司

Injection mold and method for injection molding of plastic slippers

ActiveCN108790232BAvoid Burnt SituationsIncrease the amount of foamDomestic footwearElectric machineEngineering

The invention discloses a PVC blowing slipper injection mold which comprises a fixed mold base, a movable mold base and a plastic mixing crushing mechanism, wherein the plastic mixing crushing mechanism comprises an accommodating reaction cylinder and a drive motor; the drive motor is connected with a squeezing screw; a thermal insulating panel is arranged at one end of the squeezing screw and isconnected with a displacement air cylinder; a movable sliding block is mounted on the lower surface of the drive motor; a sliding rail is further arranged on the inner wall of the accommodating reaction cylinder; the squeezing screw is sequentially divided into a crushing section, a melting stirring section and a squeezing section from right to left; the accommodating reaction cylinder is providedwith a friction bulge; the accommodating reaction cylinder is provided with subsection heating mechanisms at the melting stirring section and the squeezing section separately; and an air blowing pipeis further arranged on the accommodating reaction cylinder. The subsection heating manner is adopted to avoid the situation that plastic is burnt; an air blowing mechanism is added to increase the foaming quantity; and water-cooling and air-cooling manners are adopted to carry out air blowing foaming treatment and efficient cooling function, so that the injection molding period is shortened and the operating convenience is also improved.

Owner:定州市鼎足鞋业有限公司

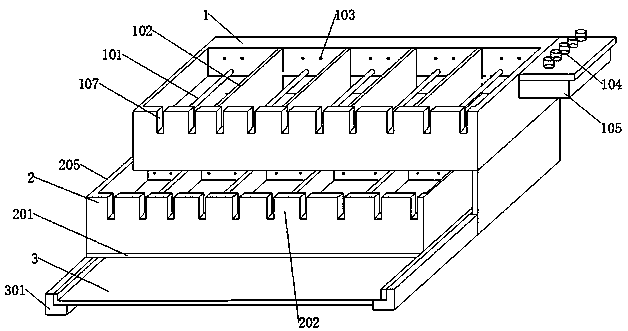

Turf cultivation device adopting clean domestic sludge for composting and medium for turf cultivation device

PendingCN112889595AAvoid Burnt SituationsMeet the needs of useBio-organic fraction processingHops/wine cultivationWater storageSludge compost

The invention discloses a turf cultivation device adopting clean domestic sludge for composting and a medium for the turf cultivation device, and belongs to the technical field of cultivation of medium flower, grass and turf. The turf cultivation device comprises a placing mechanism, wherein a cultivation mechanism is movably connected to the top of the placing mechanism, closing mechanisms are arranged on the two sides of the top of the cultivation mechanism, limiting mechanisms are arranged at the tops of the closing mechanisms, and a cultivation medium is arranged in the placing mechanism. According to the invention, after seedlings are put into a fixed seat of the cultivation mechanism, water can be discharged through liquid leakage holes at the corresponding positions on the two sides, the drainage amount can be adjusted according to different flower, grass and turf water storage requirements, so that the cultivation requirements under different conditions can be met, clean domestic sludge can be directly composted at the top of a partition plate; and a top cover plate is used for sealing, and meanwhile, water liquid during composting is guided, the seedling burning condition is avoided, and therefore, the overall use requirement is effectively met.

Owner:王和法

The realization method of the processing path of the vacuum flask polishing machine

The invention relates to a method for realizing a machining path of a thermos cup polishing machine, which mainly includes the following steps: the axis of the machining surface of the workpiece coincides with the main shaft of the polishing machine; obtaining a bus bar of the machining surface; dividing the bus bar into N characteristic line segments in turn, each Segment feature line segments to generate feature points, and use the teach pendant to collect the feature points, and then restore the feature points to a continuous processing path in turn; discretize the continuous processing path to generate polishing cutting points; according to the polishing cutting points, adaptive The X-axis feed and Y-axis feed of the polishing tool are generated, and the deflection of the polishing tool or the deflection of the workpiece is generated. The workpiece rotates around the main shaft of the polishing machine, and the polishing tool also rotates. The speed difference between the two realizes the polishing of the workpiece. Accordingly, the degree of automation of the polishing process of the thermos cup is improved, the polishing machine is suitable for the polishing process of the thermos cup with various busbars, and the flexibility of the polishing machine is improved, and the programming is simple and time-consuming.

Owner:上海捷至翔智能设备有限公司

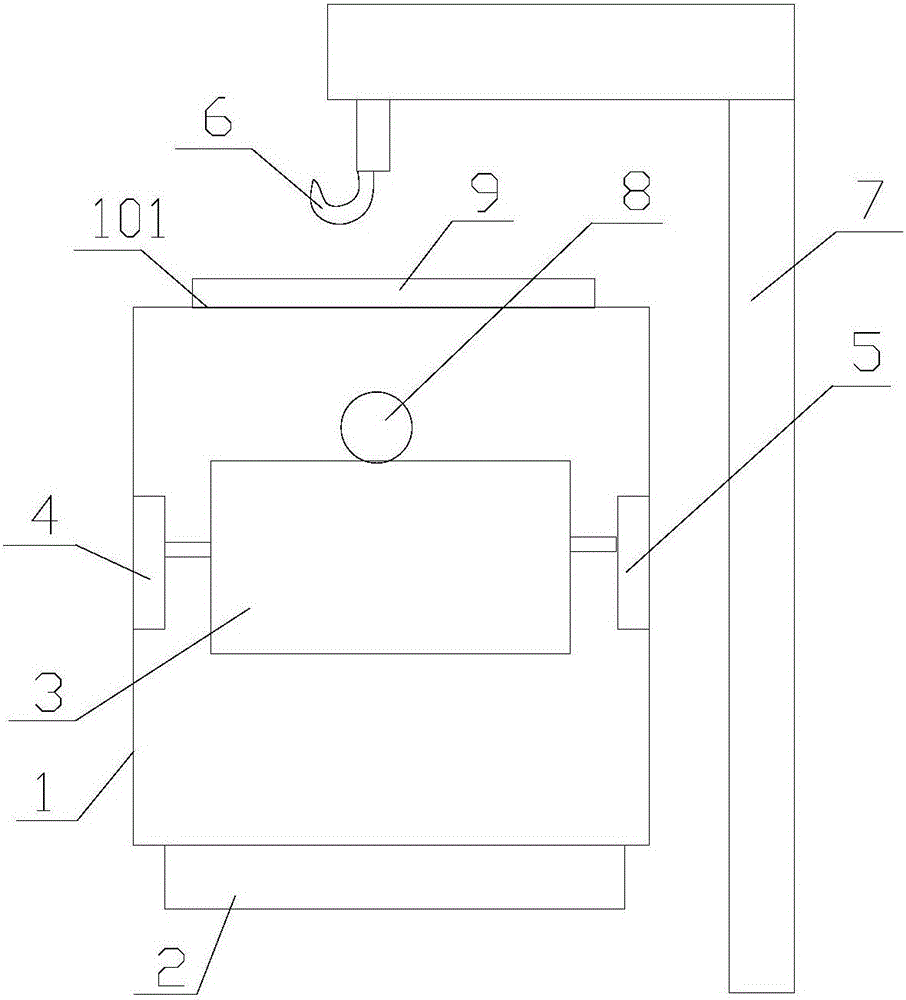

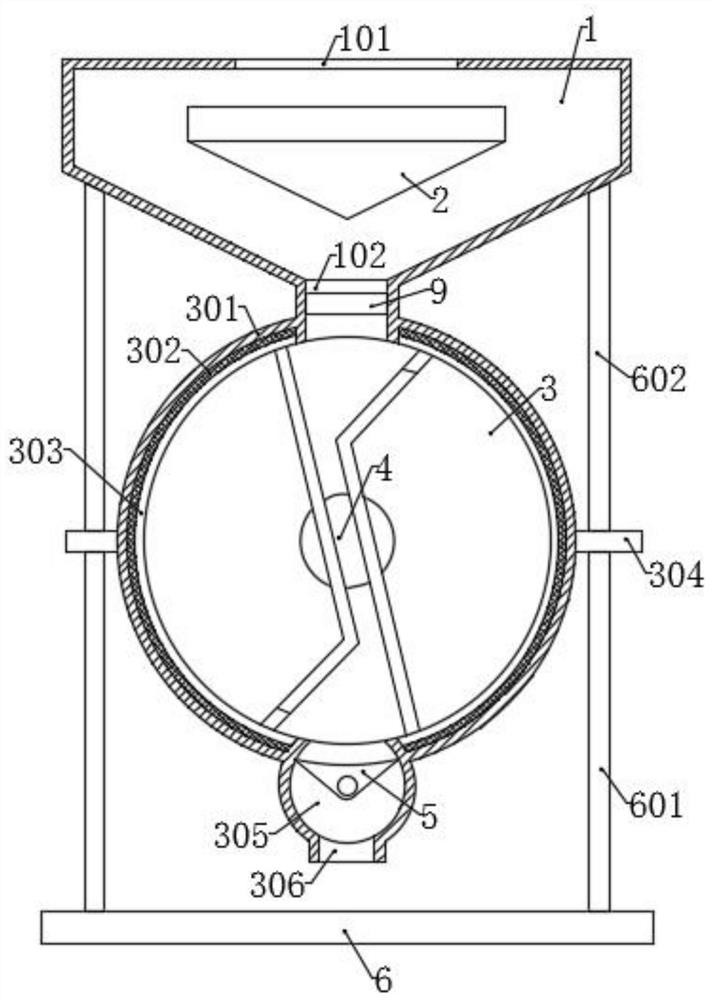

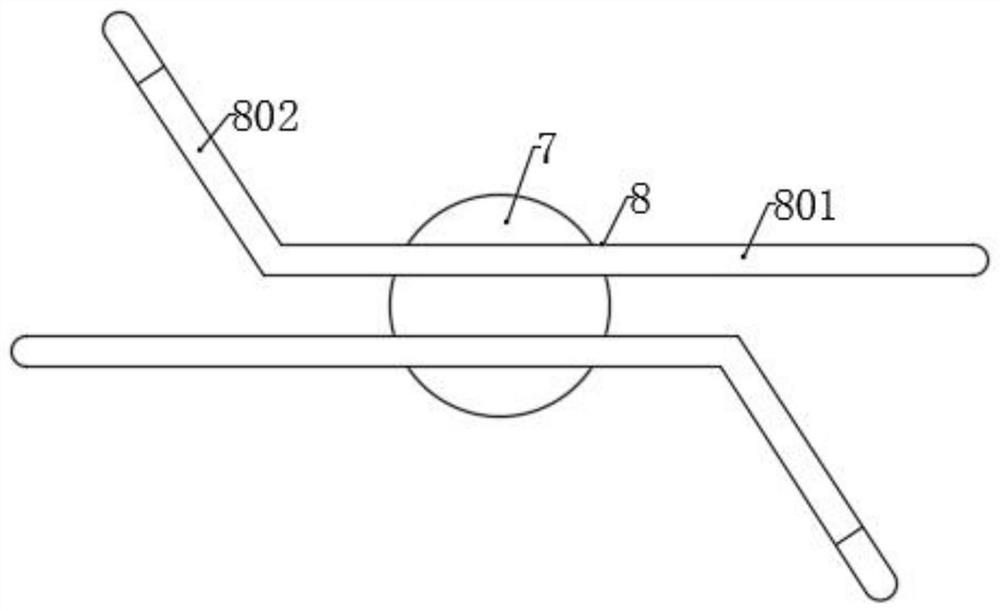

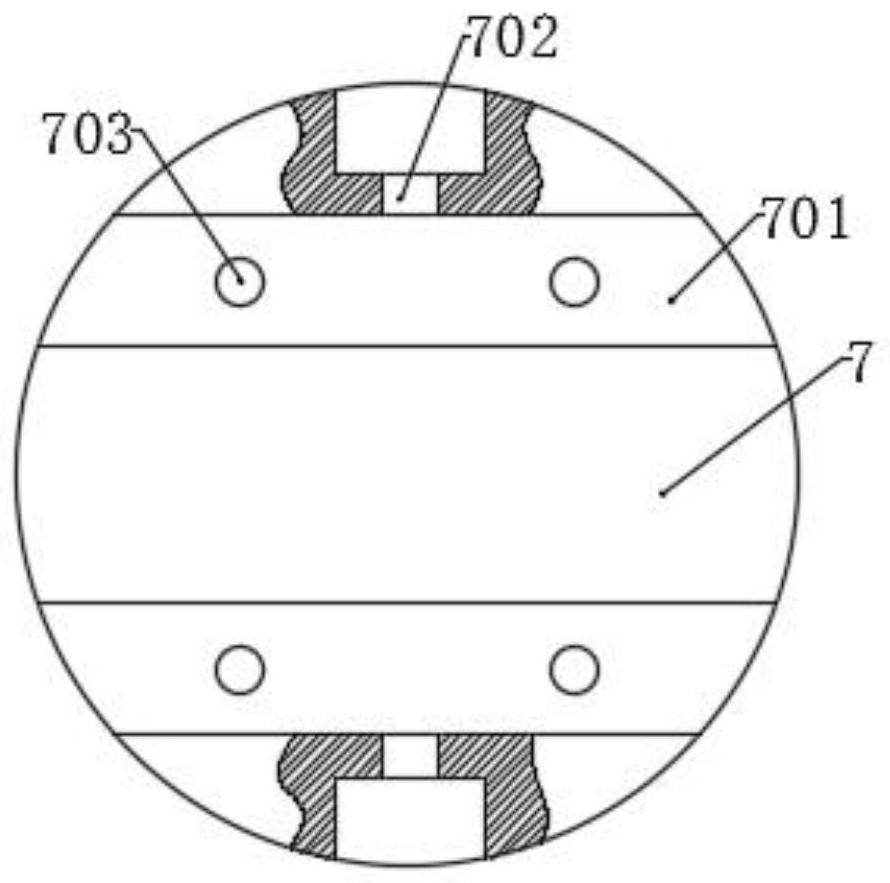

Peanut frying device with built-in rotary container

The invention provides a peanut frying device with a built-in rotary container. The peanut frying device comprises an oil tank, a heating mechanism, the rotary container, a first clamping piece, a second clamping piece, a lifting hook and a support frame, wherein an opening is formed in the top of the oil tank; the heating mechanism is mounted at the bottom of the oil tank; the first clamping piece and the second clamping piece are mounted in the oil tank and located on two opposite sides and can rotate in the same direction; the rotary container adopts a hollow structure and can be mounted in the oil tank through the first clamping piece and the second clamping piece, a plurality of through holes and a discharging gate are formed in the rotary container; the first clamping piece and the second clamping piece are both connected with a first driving mechanism which drives the two clamping pieces to rotate, and are also connected with a second driving mechanism which drives the two clamping pieces to respectively clamp the two ends of the rotary container. Through rotation of the rotary container, peanuts are continually turned over in the frying process to be in full contact with edible oil and uniformly heated, so that the peanut frying quality and flavor are improved, and the phenomenon that some peanuts are not cooked but others are burned is avoided.

Owner:WUHU FEIYUE FOOD

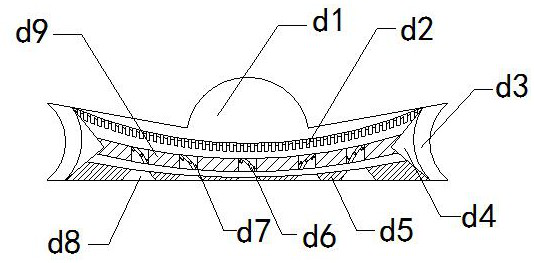

Microfiber leather not prone to scorching and manufacturing method of microfiber leather

InactiveCN112477350AImprove aestheticsImprove heat resistanceLamination ancillary operationsSynthetic resin layered productsPolyesterYarn

The invention discloses microfiber leather not prone to scorching and a manufacturing method thereof. The microfiber leather comprises a protective layer, a microfiber leather base layer, a flame-retardant layer, an insulating layer, a breathable layer, a thermal insulating layer, a wear-resisting layer and edge covering cloth, wherein the protective layer, the microfiber leather base layer, the flame-retardant layer, the insulating layer, the breathable layer, the thermal insulating layer and the wear-resisting layer are sequentially arranged from outside to inside; the protective layer is aleather finishing agent sprayed on the surface of the microfiber leather base layer; the flame-retardant layer is composed of flame-retardant polyester yarns; the insulating layer is made of a phenolic resin material; and the breathable layer is made of mercerized cotton. The microfiber leather is reasonable in design; the outer surface of the microfiber leather base layer is coated with the leather finishing agent, so the heat-resisting and high-temperature-resisting effects of the microfiber leather base layer are improved; and the flame-retardant layer, the insulating layer and the thermalinsulating layer are arranged, so the effects of heat dissipation and insulation can be achieved in time when the microfiber leather base layer bears heat, the surface of the microfiber leather base layer is prevented from being burnt, and product quality is guaranteed.

Owner:泉州美联合塑胶工艺有限公司

Preparation method of freshness-enhancing seasoning for roasting chicken wings

The invention provides a preparation method of freshness-enhancing seasoning for roasting chicken wings. The preparation method comprises the following steps: taking fresh bamboo roots, which prick into soil, of moso bamboo, washing the fresh bamboo roots, feeding the washed fresh bamboo roots into an environment with the temperature of 17 DEG C below zero, freezing the washed fresh bamboo roots for 2.5 hours, then heating the fresh bamboo roots to 0 DEG C, keeping the temperature for 5 minutes, then performing ultrasonic vibration treatment, recovering to a room temperature, and flushing the fresh bamboo roots with high-pressure jet so that bamboo root tissues are stripped and dispersed; 2) putting the dispersed bamoo root tissues into a centrifugal mixing drum, fully filling the centrifugal mixing drum with ice water, performing hydraulic fracturing, and filtering to remove coarse impurities, thereby obtaining bamboo root slurry; 3) concentrating the bamboo root slurry, adding pomegranate wine, ethyl maltol and silicon dioxide powder, and uniformly mixing all the ingredients; and 4) performing spray drying, thereby obtaining the freshness-enhancing seasoning. The flavor-enhancing seasoning is used for preparing roasted chicken wings, and is simple in raw material proportioning; all ingredients achieve a synergetic effect, so that oxidation can be resisted, and active ingredients in the seasoning can be protected for a relatively long time. The seasoning is mixed with a pickling substance or slurry during preparation of the roasted chicken wings, has the effects enhancing the freshness and changing the flavor, and has special fragrance.

Owner:BENGBU DACHENG FOOD

An automatic stir-fry machine for nut food processing

The invention discloses an automatic stir-frying machine for nut food processing, and belongs to the technical field of food processing. The machine comprises a storage hopper, a stir-frying box, a feeding assembly, a discharging assembly and a stir-frying mechanism. A certain amount of nuts stored in the storage hopper are put into the stir-frying box through the feeding assembly, an electrical heating layer is energized, heat is transferred through a heat conduction layer, the stir-frying motor drives two stir-frying plates to rotate through a rotating shaft and a rotating disc; during rotation, the nuts on the upper layer of a nut pile are driven by a short plate to move during rotation of the two stir-frying plats in order to make the nut pile flatly laid along an arc surface, then thenuts are driven by long plates to move along the arc surface of the heat conduction layer, when the long plate rotates to a certain angle, the nuts move along a space between the two long plates, move along the short plate, penetrate through the gap between the short plate and the heat conduction layer and enter a space between the short plate and the long plates, and then the spreading and moving processes are repeated to stir-fry the nuts in the continuous rotating process.

Owner:广西诚杨食品有限公司

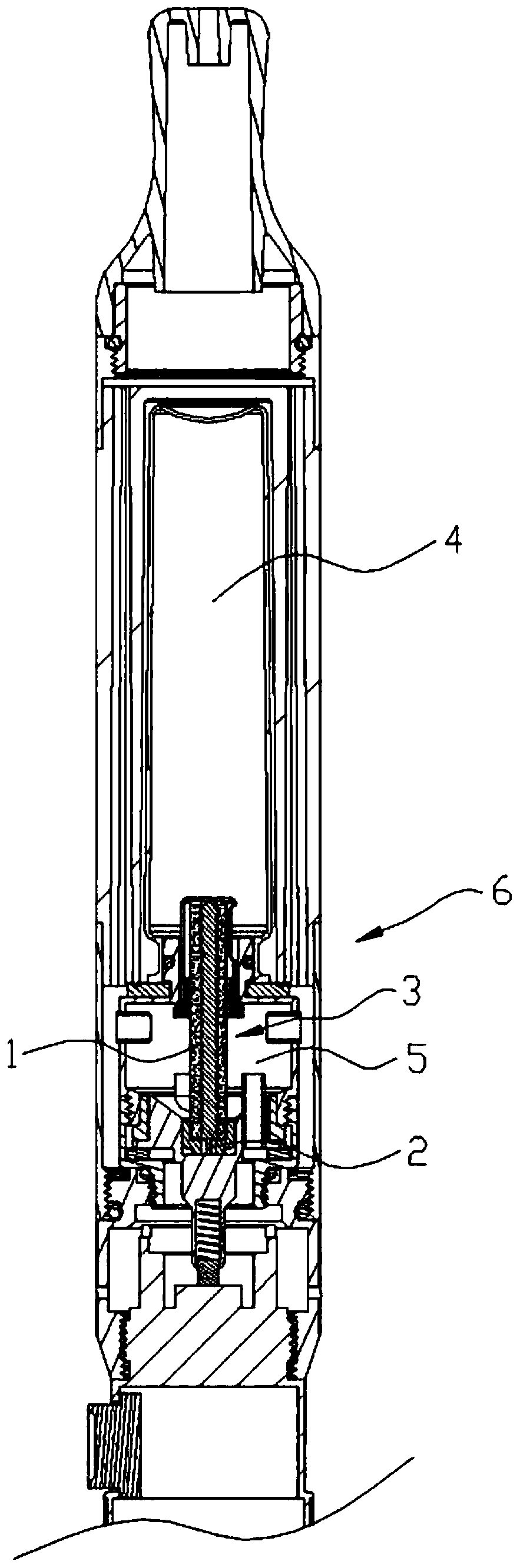

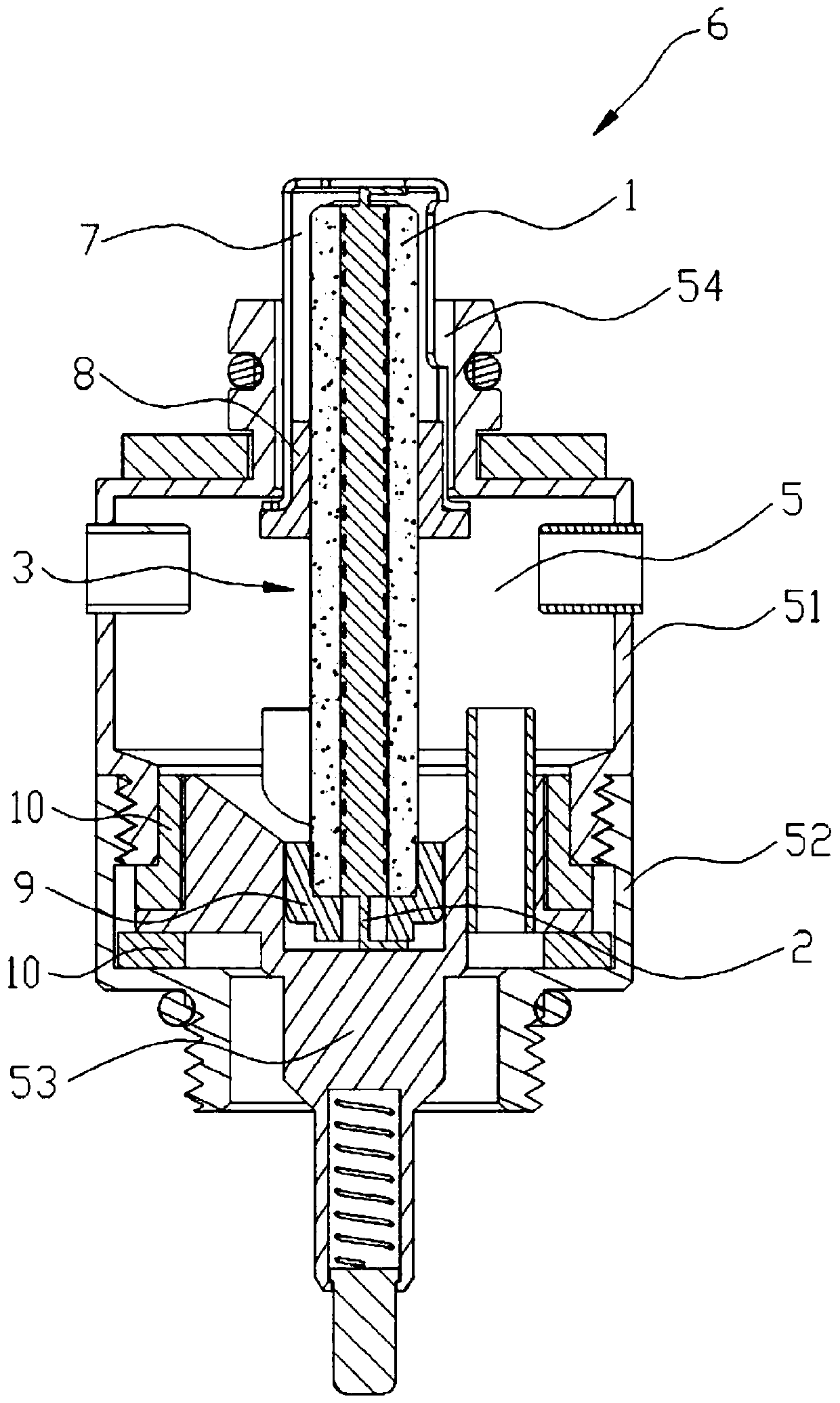

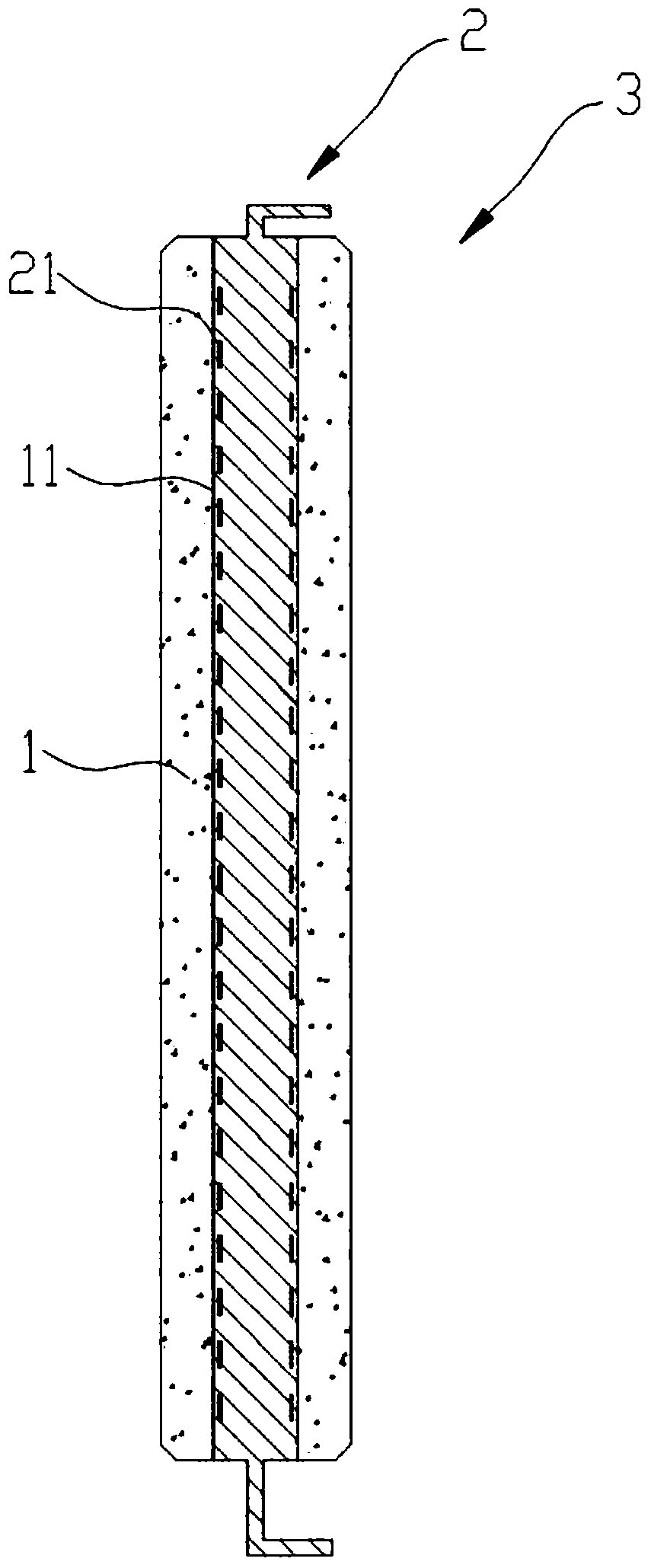

A heating structure and atomizing device with the heating structure

ActiveCN104770899BEnables indirect heatingAvoid it happening againTobacco devicesOhmic-resistance heatingElectricityEngineering

Owner:广州吉瑞吉香料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com