A non-woven fabric production stereotypes equipment

A technology for non-woven fabrics and equipment, applied in the field of non-woven fabric production and shaping equipment, can solve the problems of high temperature resistance, non-thermoplastic fibers, natural fiber scorching, etc., and achieve the effect of avoiding scorching and enhancing heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

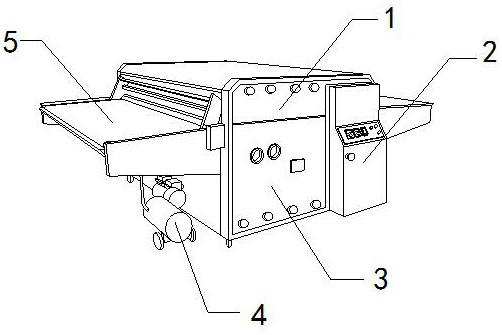

[0028] For example figure 1 -example Figure 6 Shown:

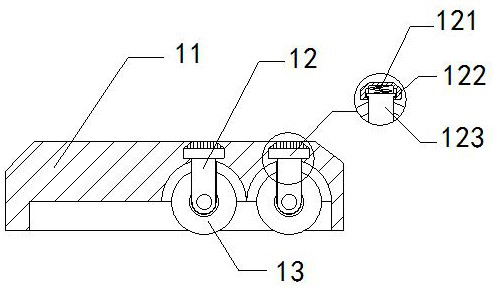

[0029] The invention provides a non-woven fabric production and shaping equipment, the structure of which includes a shaping warehouse 1, a control electric box 2, a base 3, a motor 4, and a transmission platform 5, the control electric box 2 is electrically connected to the base 3, and the motor 4 Installed at the front end position of the base 3, the transfer table 5 is embedded in the inner position of the base 3, and the shaping warehouse 1 is welded on the upper end position of the transfer table 5; the shaping warehouse 1 includes an outer frame 11, a pressure end 12, A shaping pressure roller 13 , one end of the pressing end 12 is embedded and connected to the upper end of the inner wall of the outer frame 11 , and the other end of the pressing end 12 is connected to the shaping pressing roller 13 .

[0030] Wherein, the pressure applying end 12 includes a push bar 121, a guide frame 122, and a lower pressure rod...

Embodiment 2

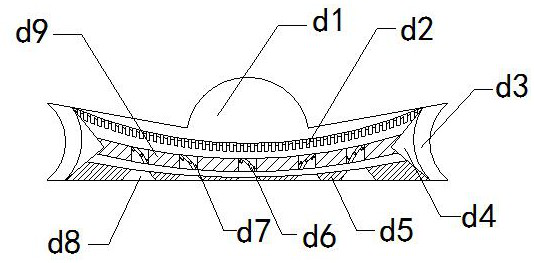

[0037] For example Figure 7 -example Figure 9 Shown:

[0038] Wherein, the heating liner a3 includes a shell c1, a partition c2, and a heat dissipation mechanism c3, the connecting block a2 is embedded in the upper and lower ends of the inner wall of the shell c1, and the heat dissipation mechanism c3 is installed on two adjacent partitions. Between the plates c2, there are eleven partitions c2, which are evenly distributed in parallel on the inner wall of the shell c1, so as to increase the heating speed of the mechanism to the heat transfer oil inside the shell c1.

[0039] Wherein, the heat dissipation mechanism c3 includes a top surface c31, a support frame c32, and a bottom block c33. The top surface c31 is installed on the upper end of the bottom block c33, and the support frame c32 is embedded and fixed between the top surface c31 and the bottom block c33. Between, the support frame c32 is provided with four, and is evenly distributed in a fan shape between the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com