An automatic stir-fry machine for nut food processing

A food processing and automatic turning technology, applied in the field of food processing, can solve the problems of affecting the effect of nut frying, unable to completely change the position, uneven heating of nuts, etc., achieving good applicability, reducing fuel size, and frying effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

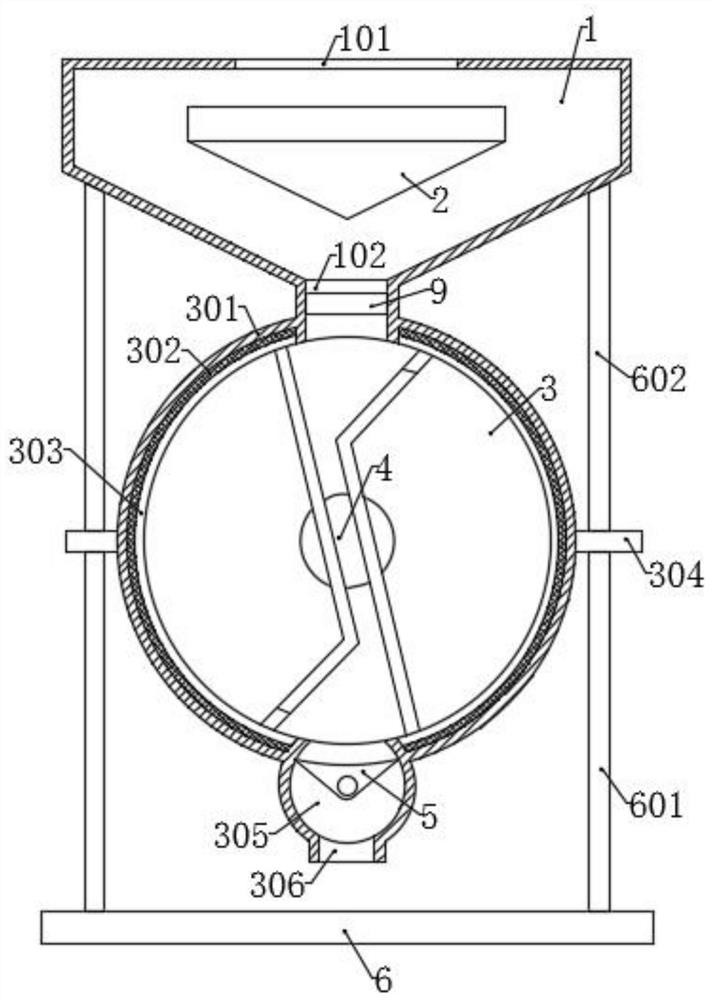

[0031] Please refer to the accompanying drawings, the present invention provides a technical solution: an automatic stir-fry machine for nut food processing, including a storage hopper 1 and a stir-fry box 3, and a feed inlet 101 is provided in the middle of the top surface of the storage hopper 1 , the middle of the bottom surface is provided with a feeding pipe 102 and a feeding assembly 9 is arranged in the feeding pipe 102, the top of the stir-frying box 3 communicates with the bottom of the feeding pipe 102, and the bottom is provided with a discharge cavity 305, and the discharge chamber 305 is arranged at the bottom. A discharge pipe 306 is provided at the bottom of the chamber 305 , and a discharge assembly 5 is provided in the discharge chamber 305 , and a stir-frying mechanism 4 is provided in the stir-frying box 3 .

[0032] The stir-frying box 3 includes a box body 301, and the box body 301 is cylindrical, the inner side of the arc surface of the box body 301 is pro...

Embodiment 2

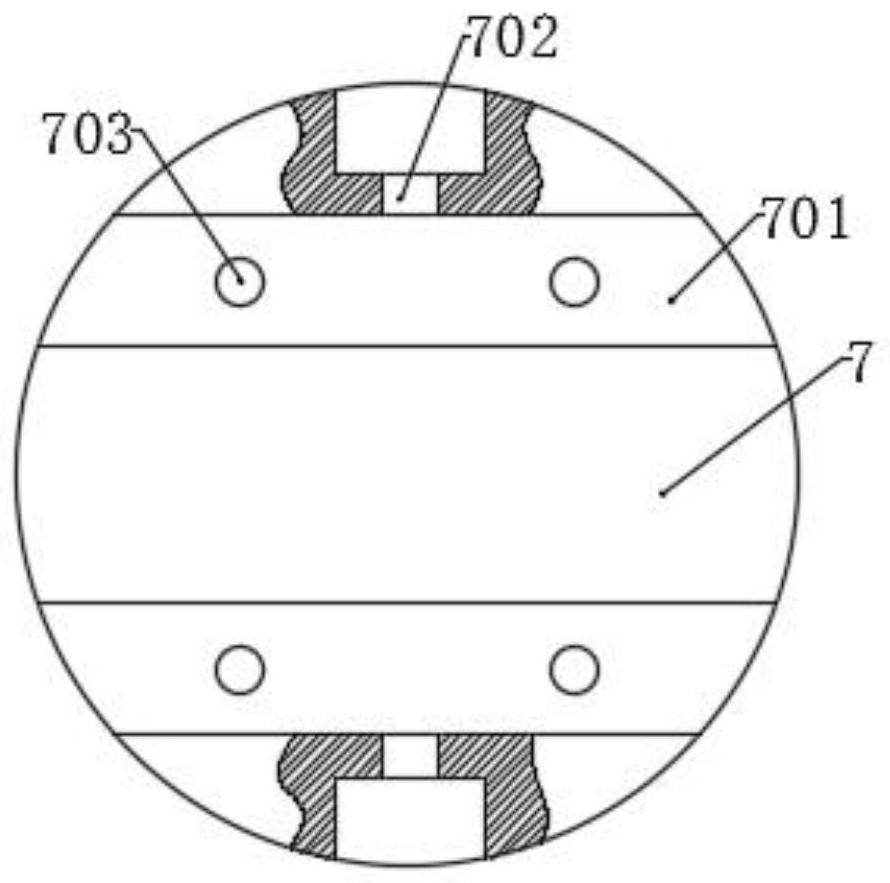

[0037] On the basis of the first embodiment, gaskets 806 are provided on the upper, lower and vertical sides of the mounting plate 804 .

[0038] During installation, the friction force between the mounting plate 804 and the mounting groove 701 is increased through the gasket 806, and when the set screw fixes the mounting plate 804, the mounting plate 804 contacts the mounting groove 701 through the gasket 806 to increase friction and avoid two Long-term contact between sides or wear caused by installation, etc.

Embodiment 3

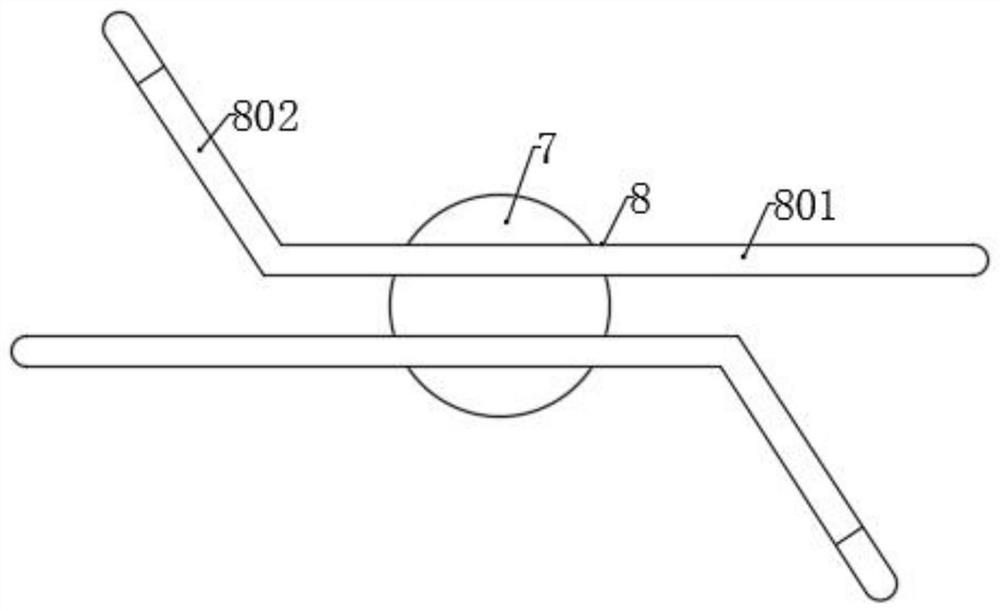

[0040] On the basis of the second embodiment, the outer end of the short plate 802 is evenly provided with a plurality of tooth grooves, and a comb-shaped extension plate 803 is connected through the tooth grooves, and a plurality of third As for the positioning hole, the extension plate 803 is provided with a fourth positioning hole, and the fourth positioning hole is connected to one of the third positioning holes through a positioning screw.

[0041] By positioning and connecting the fourth positioning hole on the extension plate 803 with a different third positioning hole, the distance between the heat conduction layer 303 and the short plate 802 can be adjusted, so as to tile and stir-fry nuts of different types and sizes , with better applicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com