Energy-saving and environment-friendly syrup inverting equipment

An energy-saving, environmentally friendly, and equipment-friendly technology, which is applied in the fields of confectionery, confectionery industry, and food science, can solve the problems of poor taste, waste, and difficulty in reducing the moisture content of syrup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

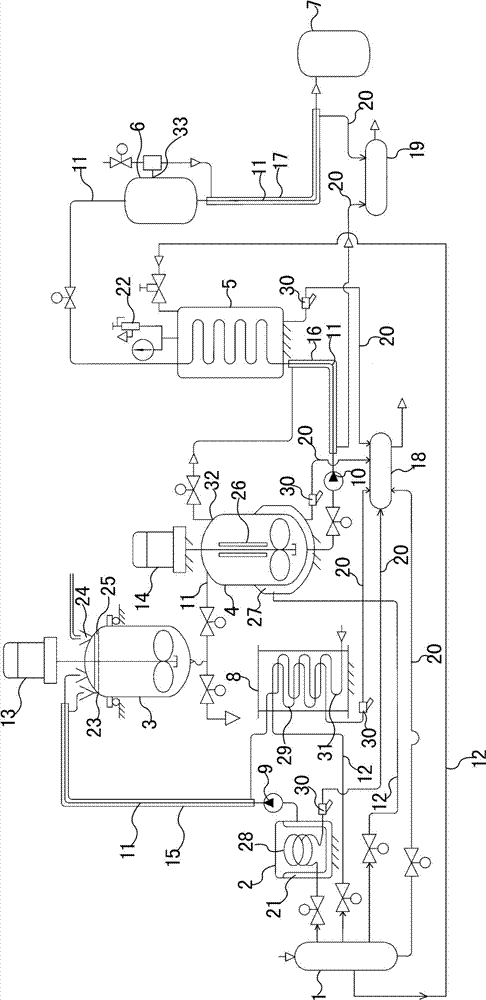

[0018] Such as figure 1 As shown, this energy-saving and environment-friendly sugar melting equipment includes a steam storage tank 1, a syrup preheating tank 2, a first sugar melting tank 3, a second sugar melting tank 4, a heating tank 5, an evaporation tank 6, a storage tank 7, a heating tank Water supply device 8, first pressurized pump 9, second pressurized pump 10, syrup delivery pipe 11, steam delivery pipe 12, first agitator 13, second agitator 14, first heat preservation sleeve 15, second Insulation sleeve 16, third insulation sleeve 17, drainage balance recovery tank 18, residual heat recovery tank 19 and recovery pipe 20; syrup preheating tank 2, first sugar conversion tank 3, second sugar conversion tank 4, heating tank 5. The evaporating tank 6 and the storage tank 7 are arranged in sequence from front to back and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com