A kind of circulating fir oil production equipment and the production process of fir oil

A kind of production equipment and fir oil technology, applied in the field of fir oil production, can solve the problems that the product contains a lot of tar and the yield of fir oil is low, and achieve the effect of improving the quality of fir oil, increasing the oil yield, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

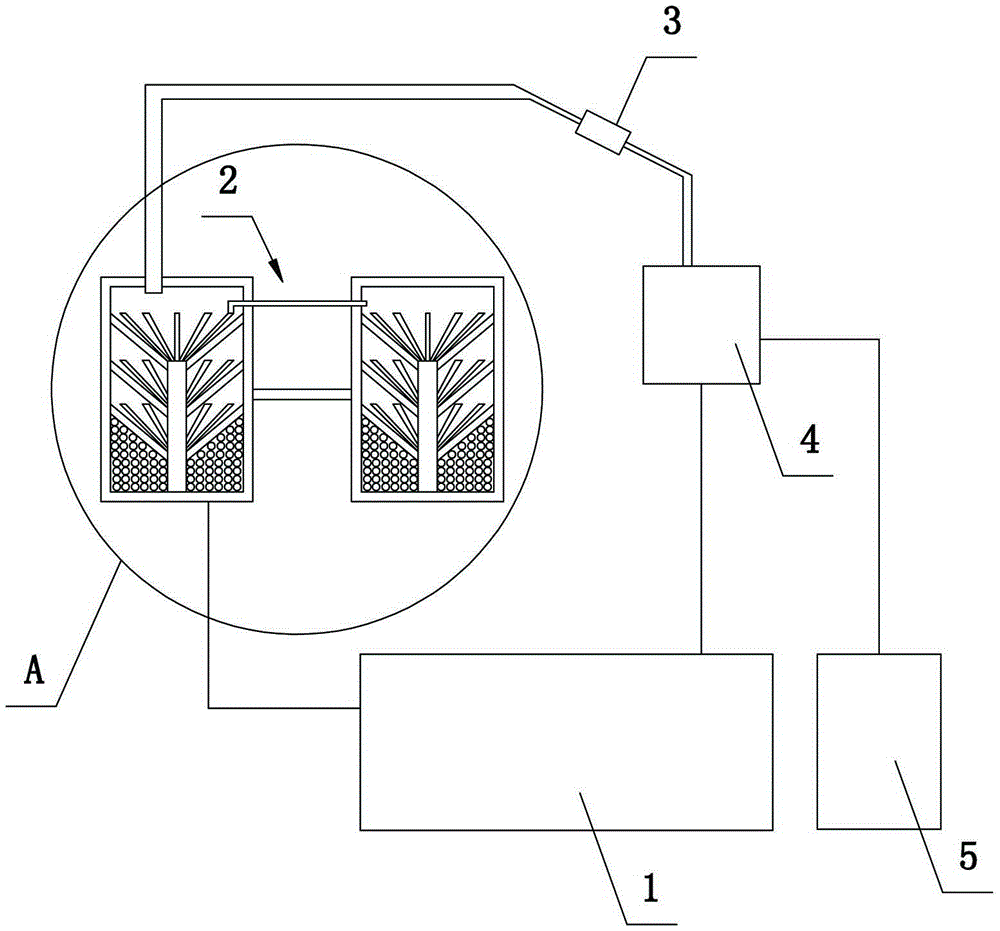

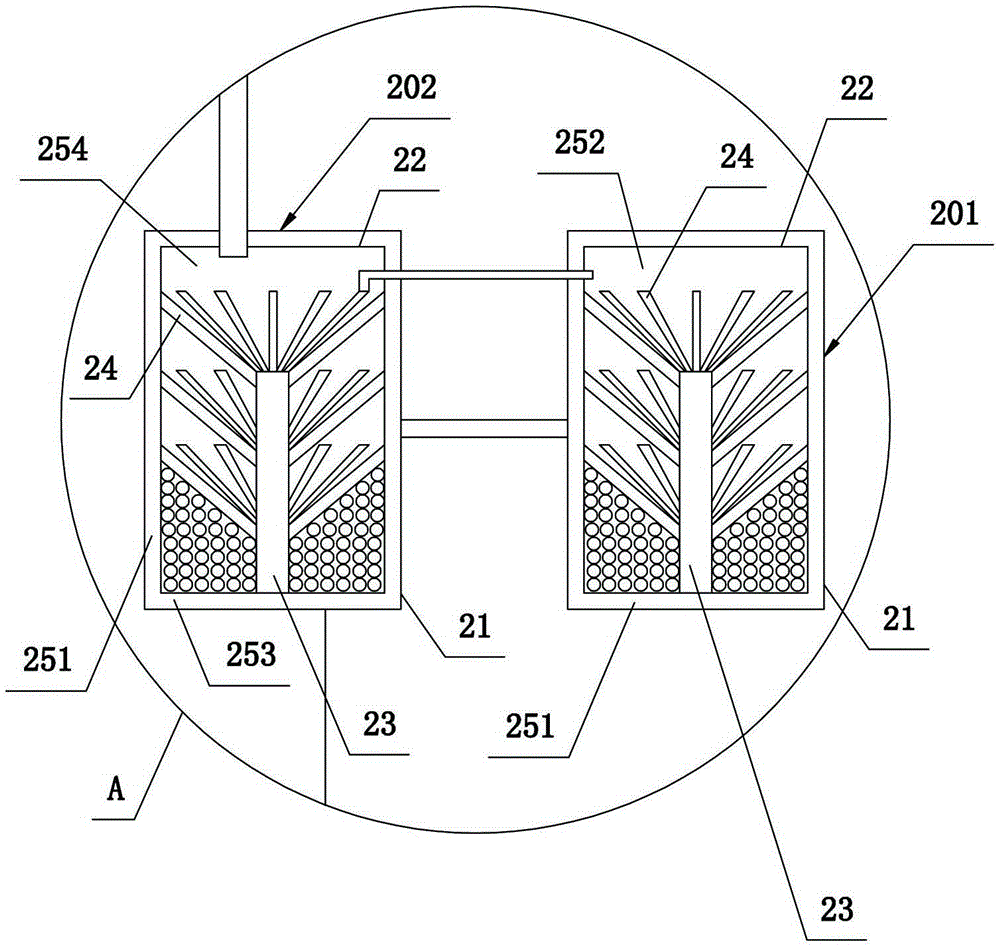

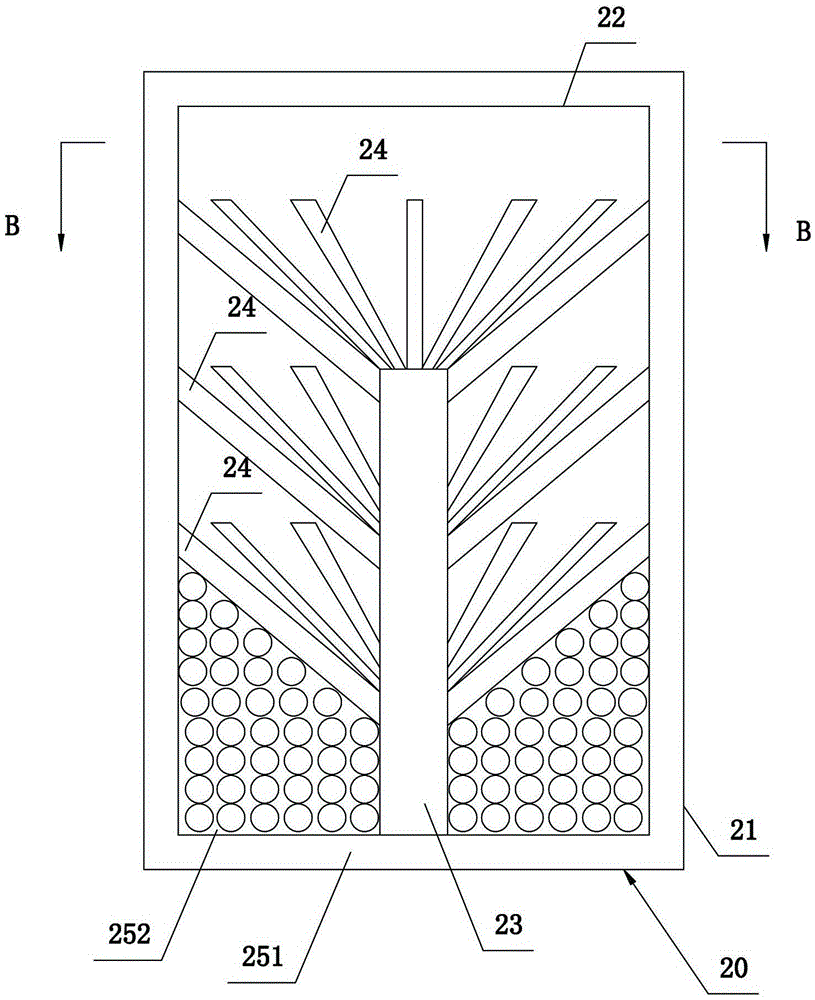

[0031] refer to Figure 1-Figure 4. A kind of circulating Chinese fir oil production equipment, comprising steam generating device 1, Chinese fir oil extraction device 2, condensation tube device 3, oil-water separation device 4 and Chinese fir oil collecting device 5, the outlet of said steam generating device 1 communicates with said Chinese fir The inlet of the oil extraction device 2, the outlet of the fir oil extraction device 2 is connected to the inlet of the condensation pipe device 3, and the outlet of the condensation pipe device 3 is connected to the inlet of the oil-water separation device 4, and the oil-water separation device 4 is provided with two outlets, one communicates with the steam generator 1, and the other communicates with the fir oil collection device 5; the fir oil extraction device 2 includes at least one fir oil extraction tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com