Implementation method of polishing machine machining path for vacuum cup

A technology of processing path and realization method, applied in the direction of program control, instrument, electrical program control, etc., can solve the problems of scrapping the thermos cup, difficult CNC code, single applicable shape, etc., so as to reduce manual polishing operations and avoid environmental problems. The effect of exposure and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

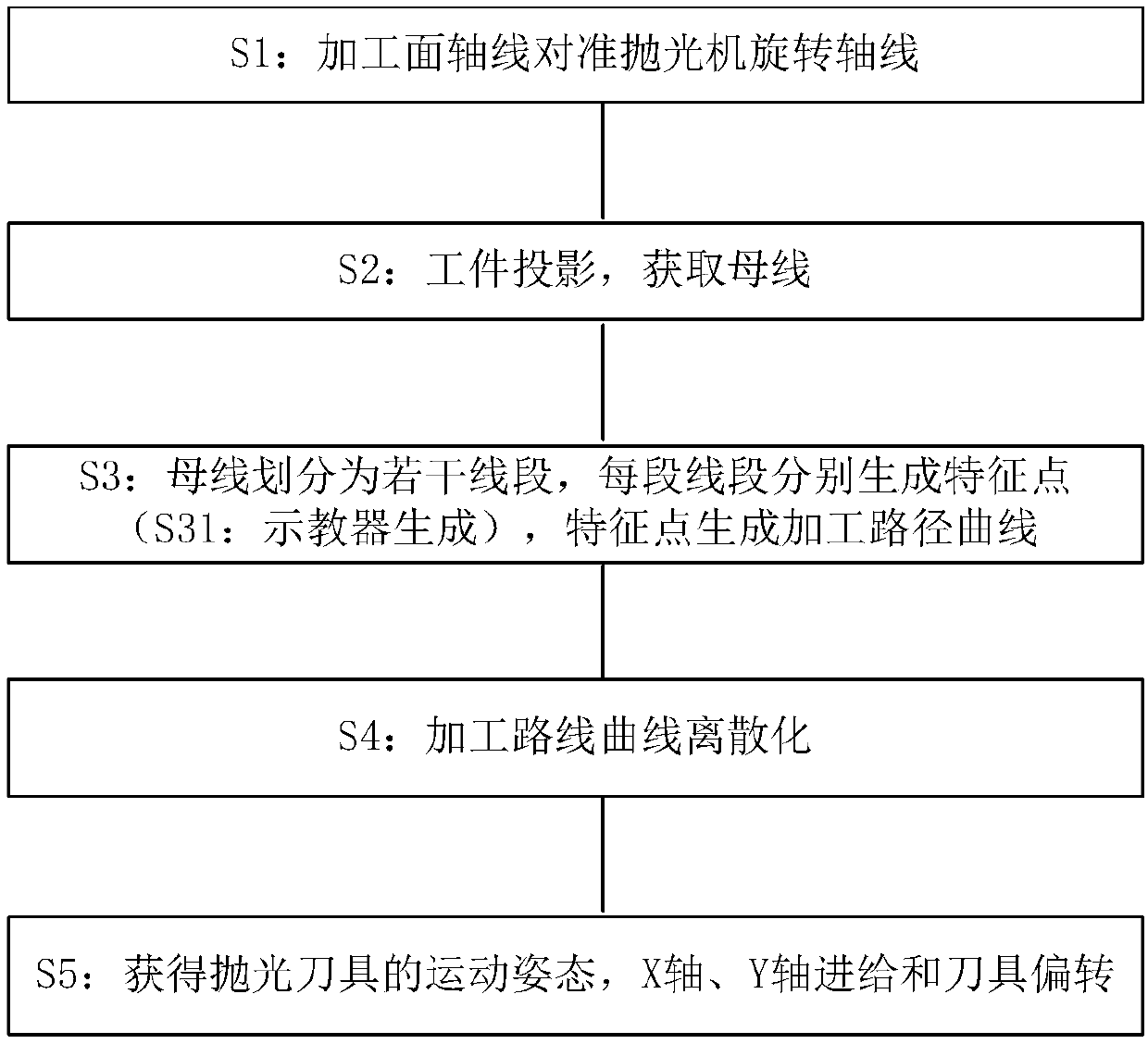

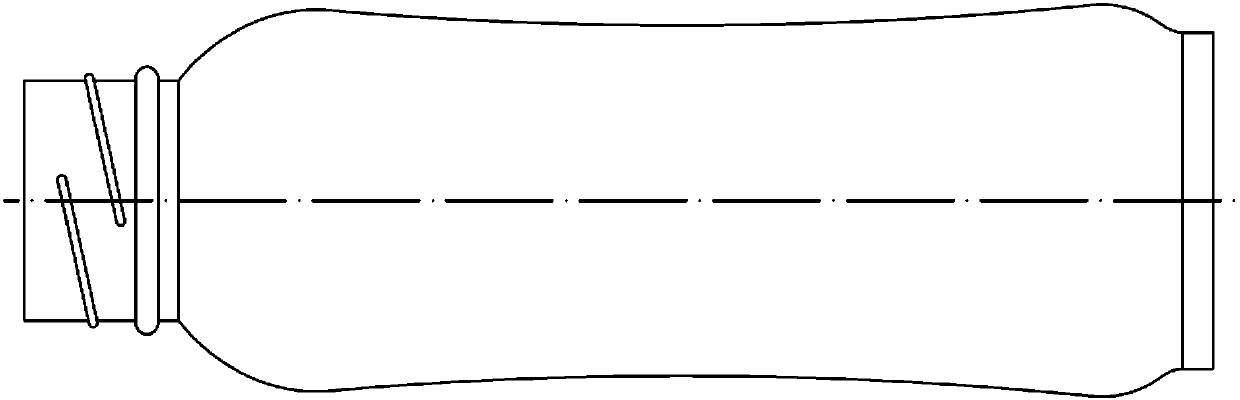

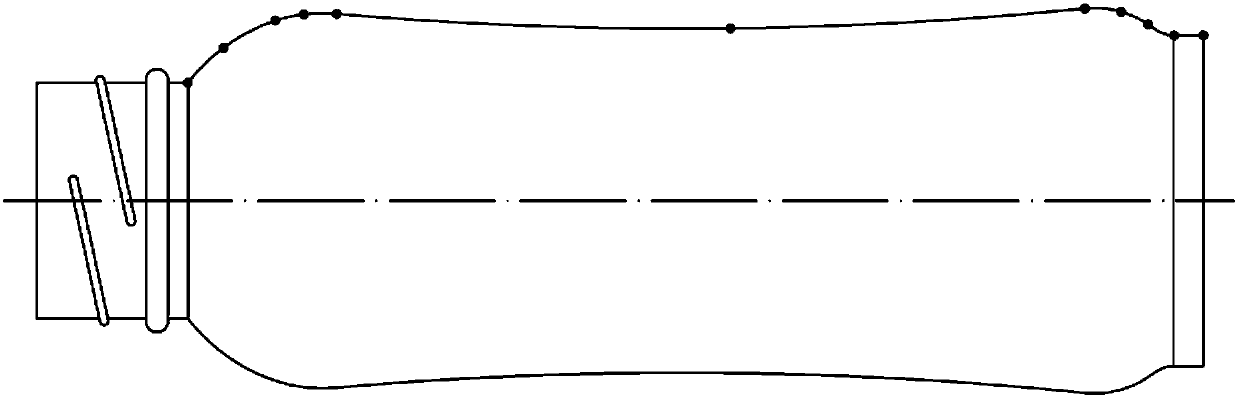

[0046] The surface of most thermos cups is a surface of revolution. The surface of revolution is a curved surface formed by the busbar rotating around the axis. According to this characteristic, the axis and busbar of the revolution surface can be completely restored to the surface of revolution. Polishing tools are also usually bodies of revolution (basically cylinders). In one embodiment, as figure 1 As shown, a method for realizing the processing path of a thermos cup polishing machine is shown, which mainly includes the following steps: Step 1: First fix the axis, and the polishing machine has a clamping part that can clamp and rotate the workpiece to ensure The axis of the rotary surface coincides with the rotary spindle of the polishing machine; the second step S2: determine the busbar of the rotary surface, generally select one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com