Method for quickly dissolving powdered milk

A milk powder and fast technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of residual milk residue, milk powder mixing, affecting milk quality, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

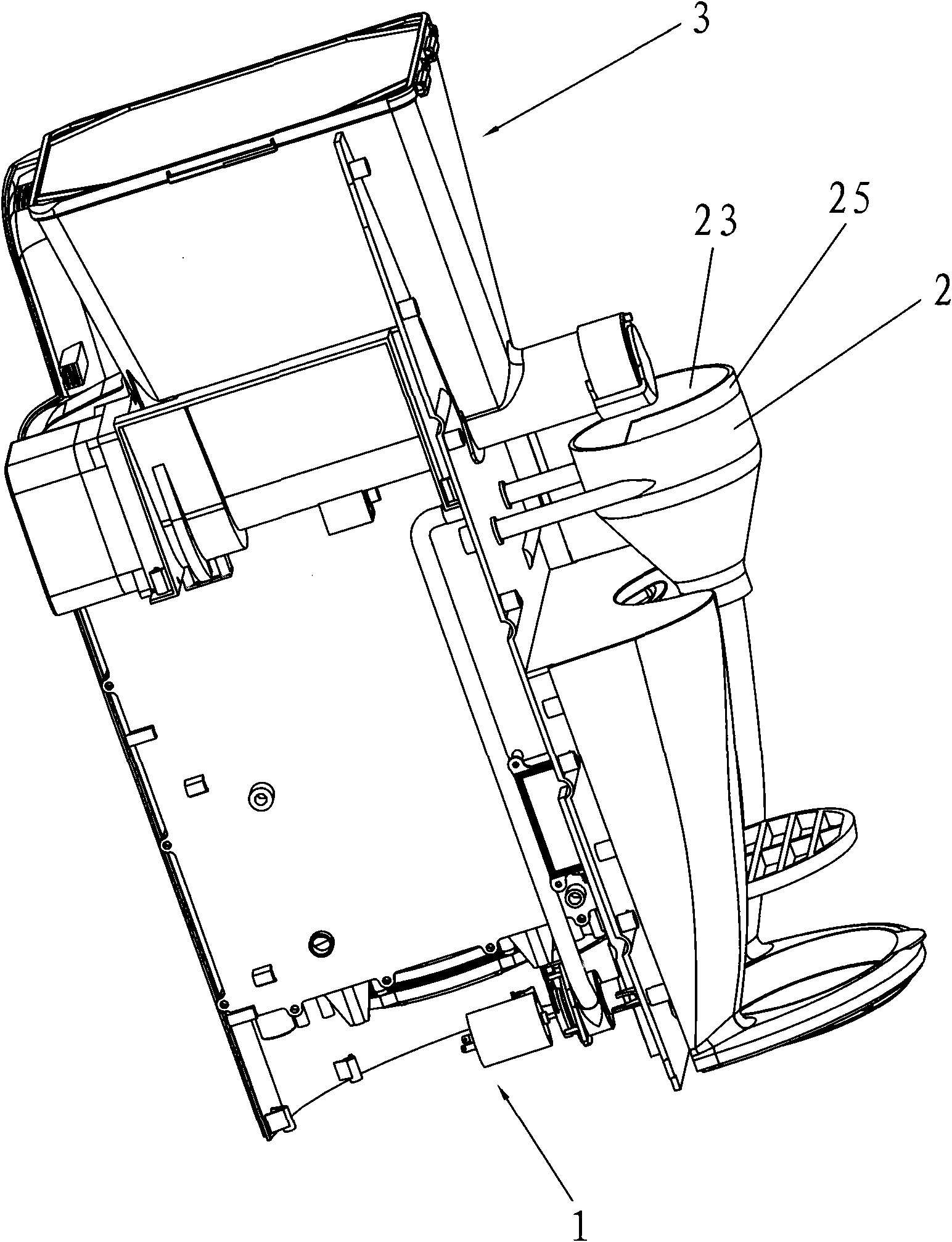

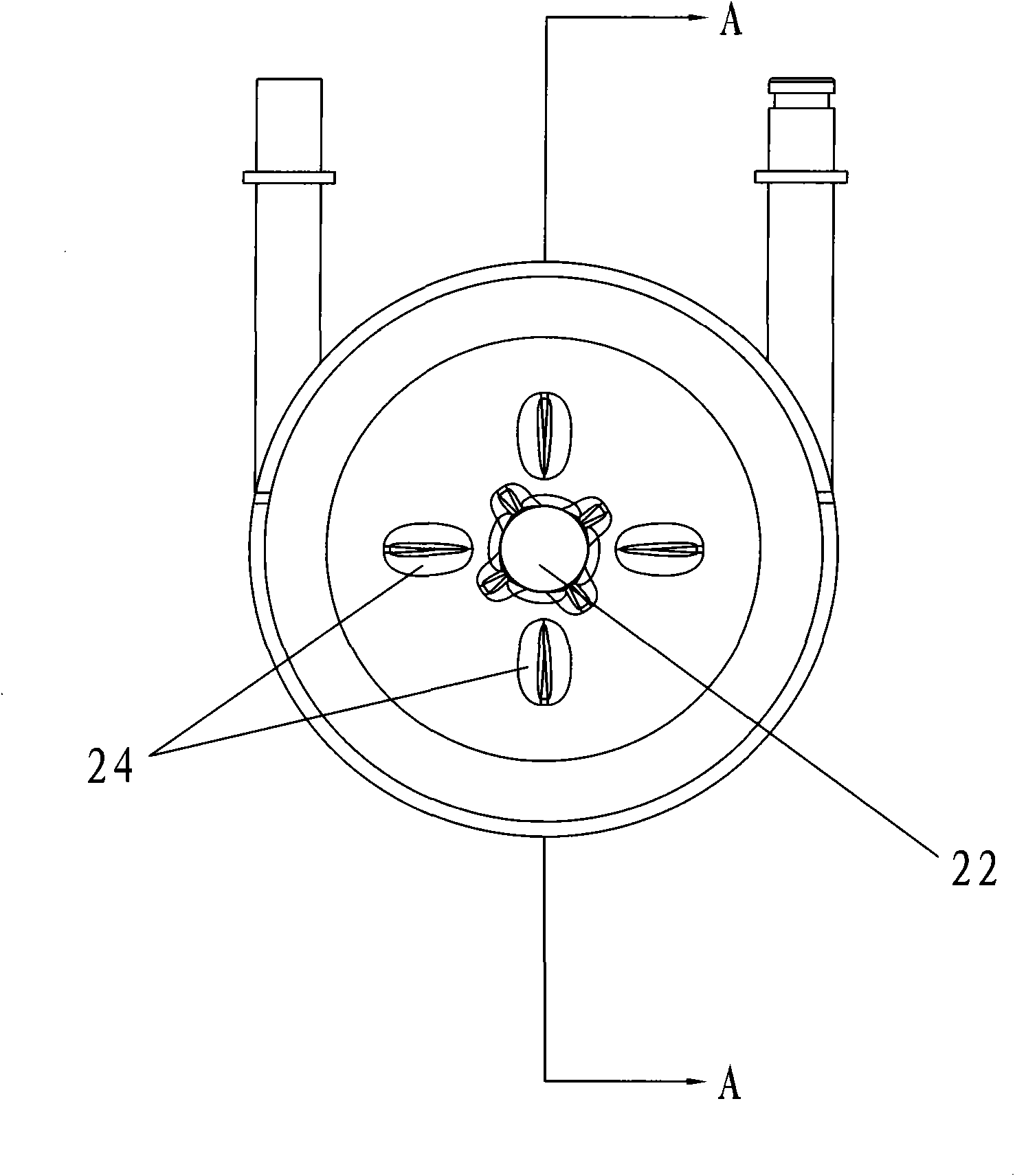

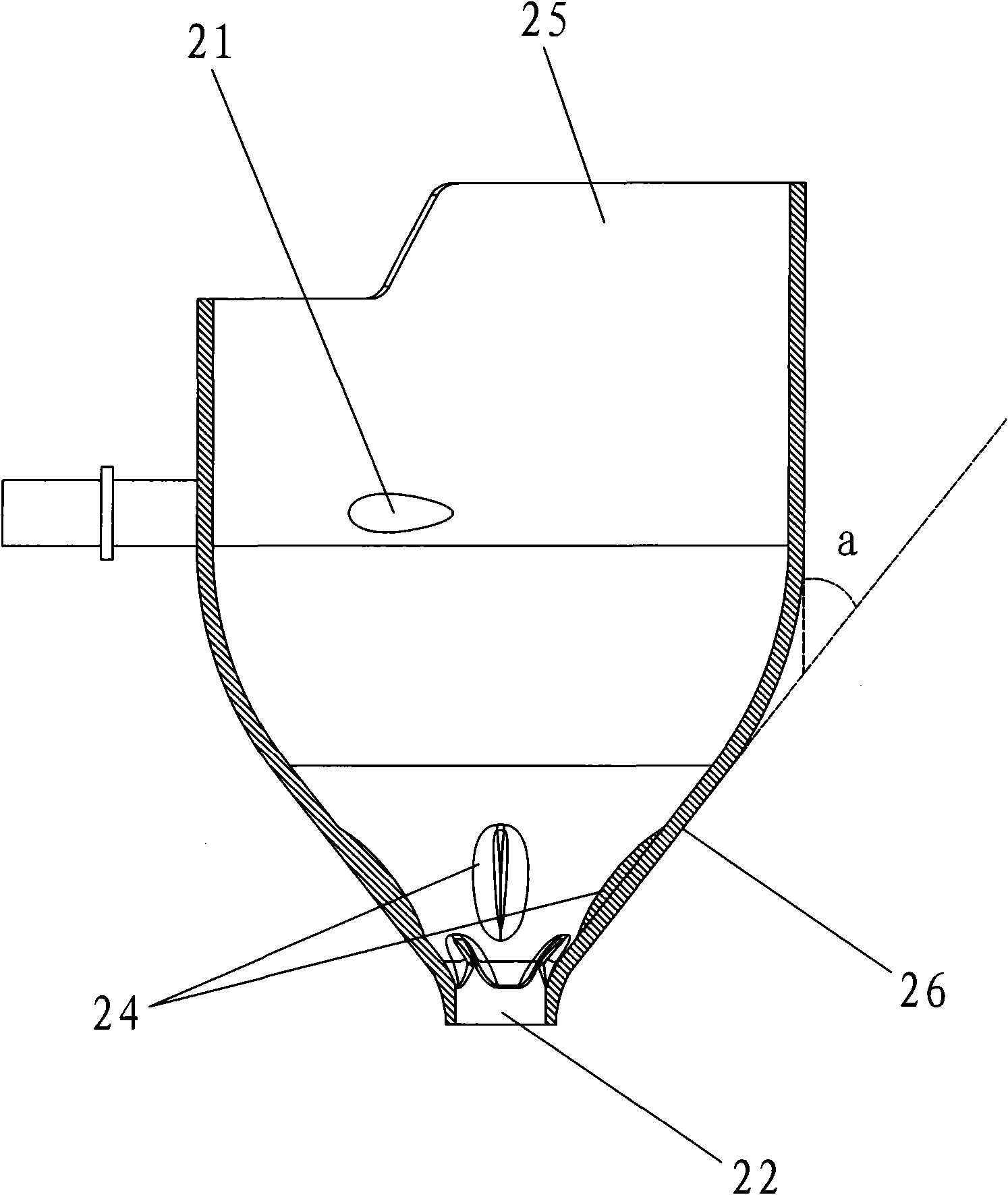

[0031] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1~3 As shown, a kind of milk powder fast dissolving method provided by the present invention, it is first to spray water flow into water guide seat 2 (namely milk mixing vessel) through water outlet mechanism 1, and water flow forms clockwise rotation flow or counterclockwise in water guide seat 2 The vortex water that rotates clockwise, wherein the water flow is sprayed from the water inlet 21 of the water guide seat 2 at a constant speed, and rotates and flows on the inner wall of the water guide seat 2 at a certain speed, forming a vortex water with a faster rotation speed, avoiding milk powder Directly falling on the inner wall of the water guide seat 2 can also speed up the dissolving time of the milk powder.

[0032] Then, the milk powder is evenly sent into the water guide seat 2 by the milk powder outlet mechanism 3, (for example: the uniform feeding of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com