Heating method of soy milk and its application on soy milk machine

A heating method and a technology for a soymilk machine are applied in the heating device and the field of soymilk heating, which can solve the problems of the quality and taste of soymilk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

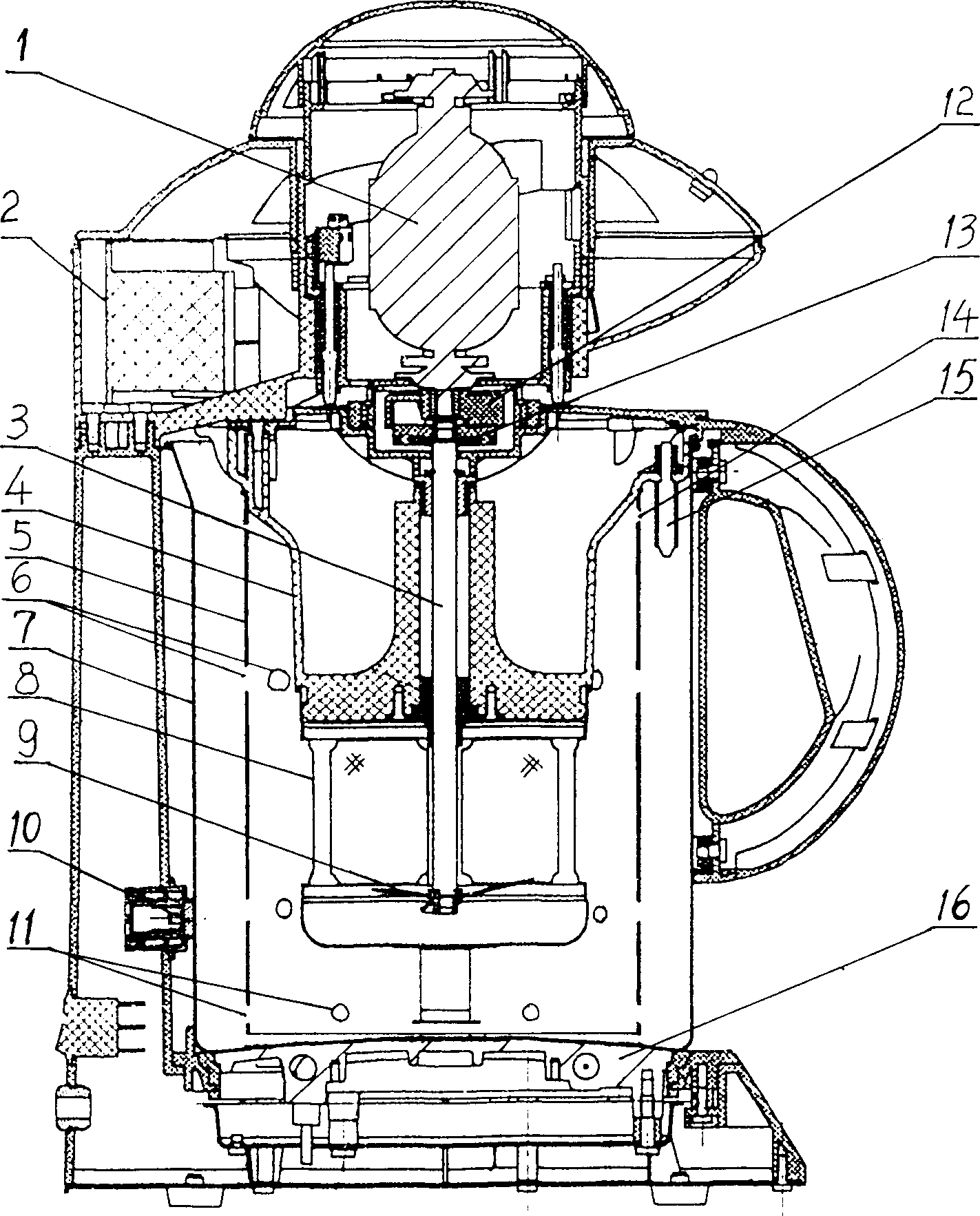

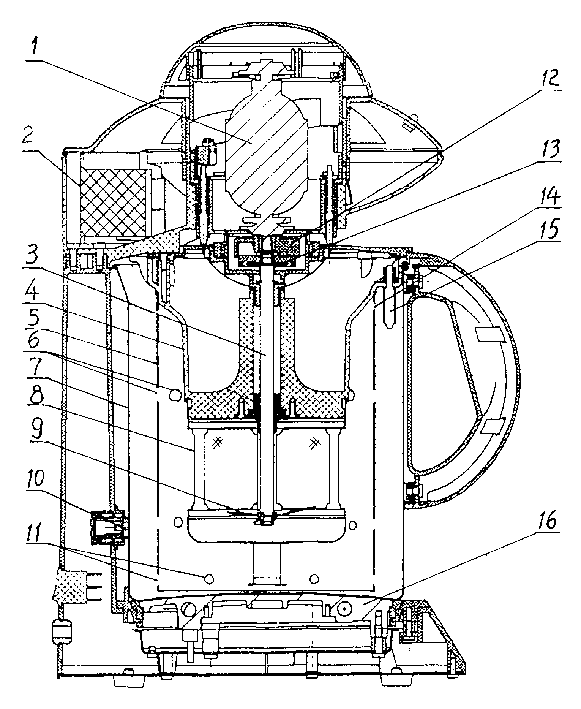

[0010] A kind of household automatic soybean milk machine, such as figure 1 As shown, it includes a motor 1, a cutter shaft 3, a blade 9, a filter cover 8, a temperature measuring device, a heater, a temperature control device, a soybean milk heating device, a circuit board 2, a power supply and a circuit control device, and the soybean milk heating device includes an external Barrel 7, inner barrel 5 and barrel cover 4, the upper end of the inner barrel 5 is clamped on the inner surface of the barrel cover 4, the barrel cover 4 is buckled on the upper end of the outer barrel 7, the side wall of the inner barrel 5 is provided with a communication hole 6, and the motor 1 is the upper Mounted type, the upper coupling 12 is fixed on the motor shaft, the lower coupling 13 is fixed on the upper end of the cutter shaft 3, the cutter shaft 3 passes through the barrel cover 4 and extends into the inner cylinder 5, and the front end of the cutter shaft 3 is fixed with a blade 9 and a fi...

Embodiment 2

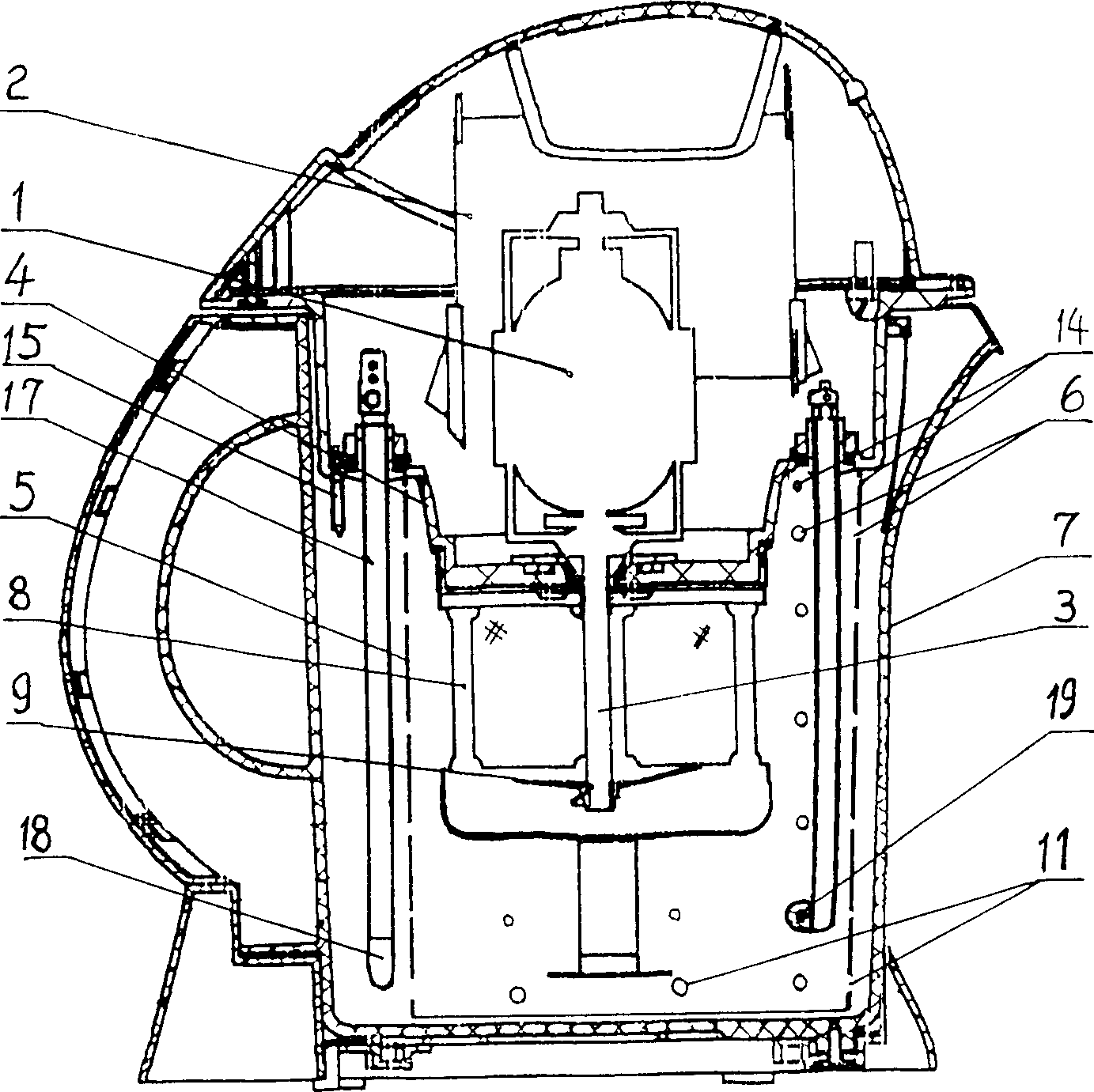

[0012] A kind of household automatic soybean milk machine, such as figure 2 As shown, it includes a motor 1, a cutter shaft 3, a blade 9, a filter cover 8, a temperature measuring device, a heater, a temperature control device, a soybean milk heating device, a circuit board 2, a power supply and a circuit control device, and the soybean milk heating device includes an external Barrel 7, inner barrel 5 and barrel cover 4, the upper end of the inner barrel 5 is clamped on the inner surface of the barrel cover 4, the barrel cover 4 is buckled on the upper end of the outer barrel 7, the side wall of the inner barrel 5 is provided with a communication hole 6, and the motor 1 is the upper The long axis of the motor 1 is the cutter shaft 3, the cutter shaft 3 passes through the barrel cover 4 and extends into the inner cylinder 5, the front end of the cutter shaft 3 is fixedly installed with the blade 9, the upper end of the filter cover 8 is clamped on the inner surface of the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com