A kind of retarding type high-efficiency dispersant and preparation method thereof

A dispersant and retarder-type technology, applied in the field of chemical building materials, can solve the problems of poor adaptability of high-efficiency water reducers, retarder does not have water reducing effect, complex preparation process of retarder, etc., to achieve good retardation Effect, retarding effect is remarkable, the effect of strong market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

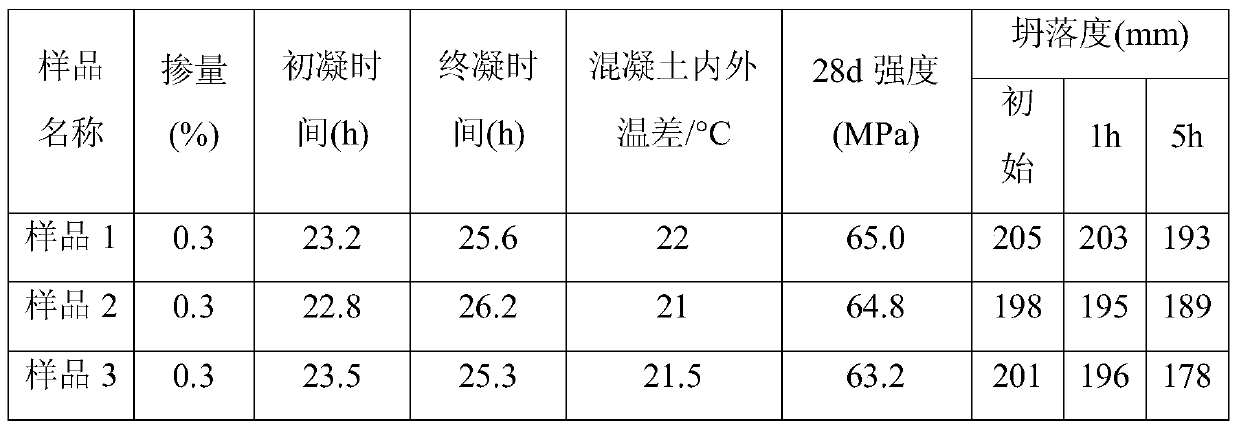

Examples

preparation example Construction

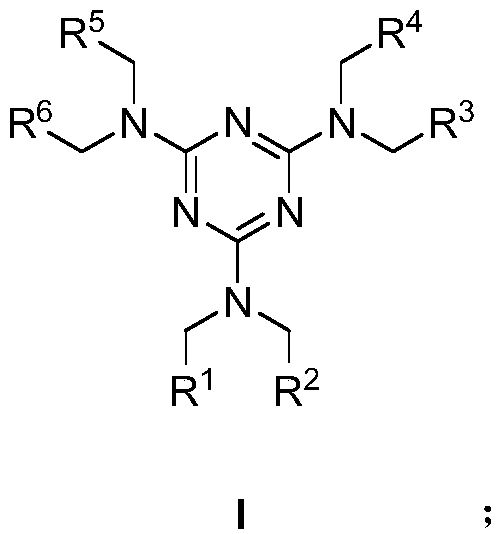

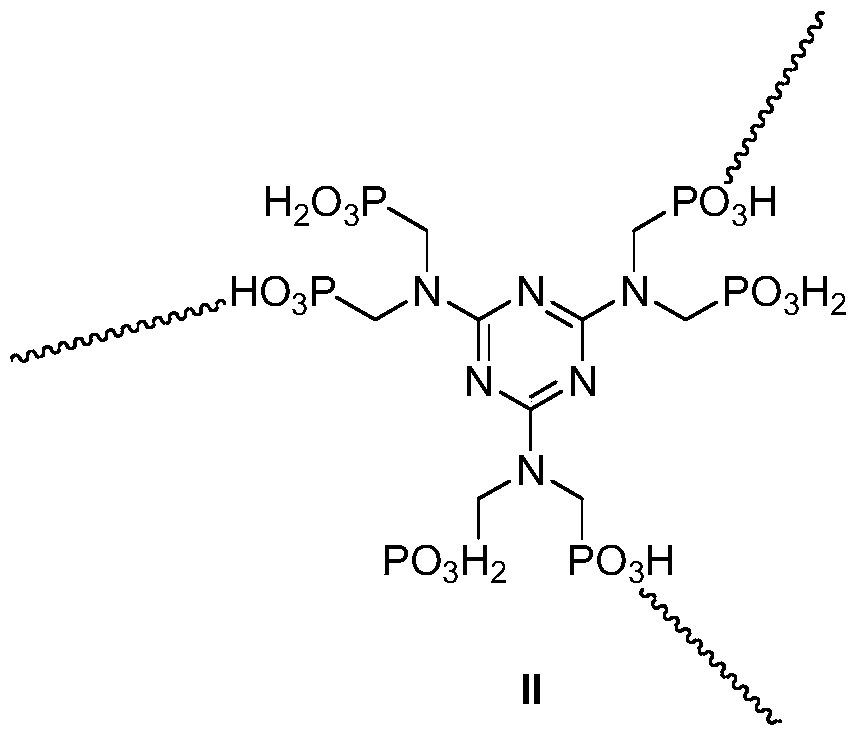

[0057] (1) Preparation of Monomer A

[0058] Put 126.04g (1.0mol) of melamine, 574.05g (7.02mol) of phosphorous acid and 1400ml of water into a 2000ml reaction bottle, add 294.05g (3.0mol) of sulfuric acid, raise the temperature to 110°C, keep it for 10min, then add 37% formaldehyde dropwise Aqueous solution 648.02g (8.0mol), installed a condenser, heated to reflux for 4h, after cooling, set aside.

[0059] (2) Esterification reaction

[0060] In a 5000ml round bottom flask, add monomer B (polyether) 600.1g (0.3mol, Mn=2000), monomer A (hexaphosphite melamine) 69.0g (0.1mol) and water-carrying agent cyclohexane 1004g , install a condenser, raise the temperature to 130°C, react for 6 hours, then cool down to about 50°C, add 1004g of water, enter the separation device, separate the lower aqueous solution, collect the upper layer, and continue to recycle.

[0061] (3) Neutralization

[0062] Add 53.3 g (0.4 mol) of 30% sodium hydroxide solution to the aqueous solution of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com