Cooling of milk in an automatic milking system

a technology of automatic milking and milk cooling, which is applied in the field of dairy farming, can solve the problems of sluggish temperature response, large risk of cooling milk, and sluggish response, and achieve the effect of not exposing to risk the milk freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following description, for purpose of explanation and not limitation, specific details are set forth, such as particular techniques and applications in order to provide a thorough understanding of the present invention. However, it will be apparent for a person skilled in the art that the present invention may be practiced in other embodiments that depart from these specific details.

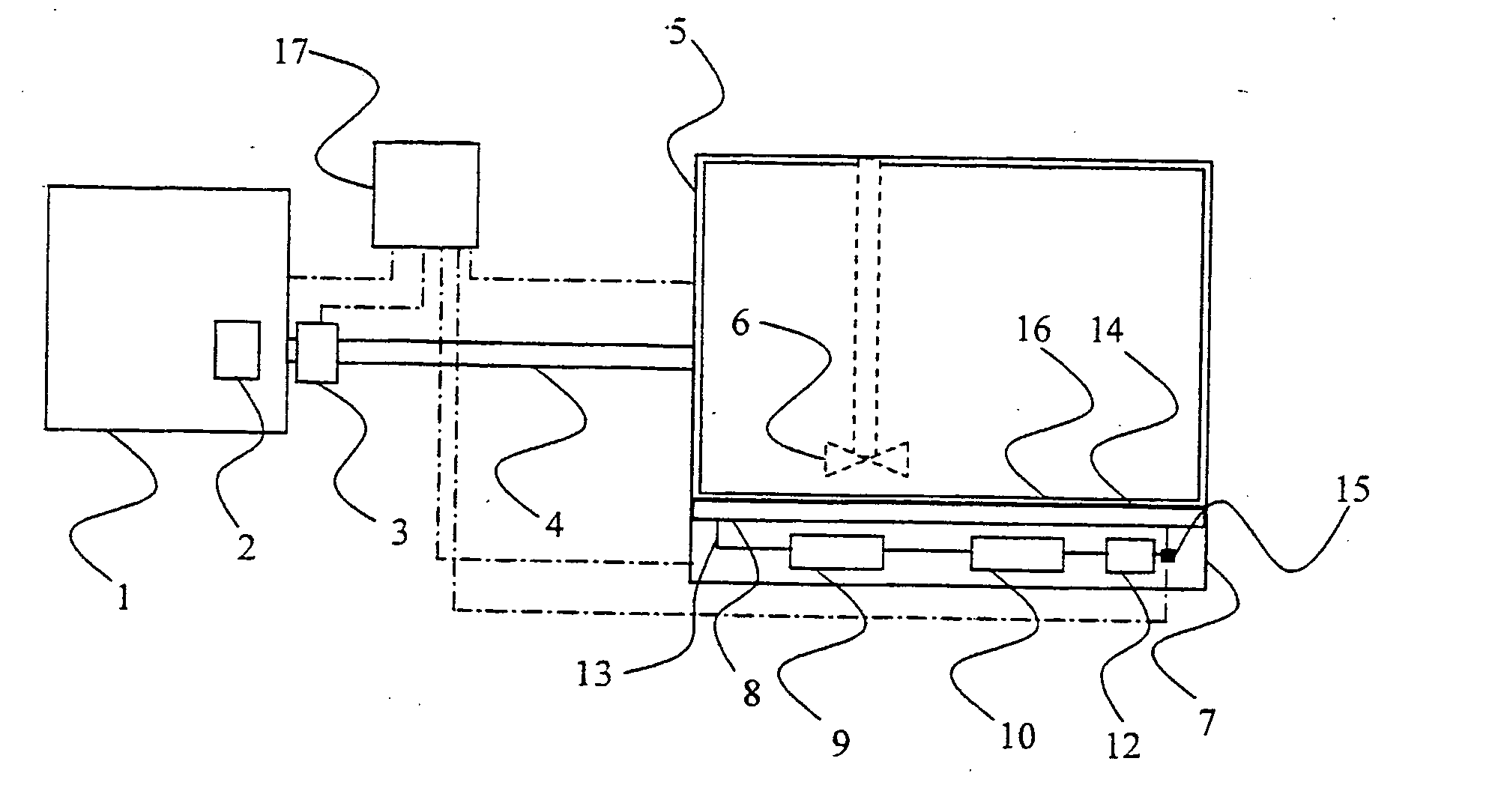

[0017] An automatic milking system, as shown in FIG. 1, comprises a milking robot 1 for milking animals, such as cows, including a milk flow meter 2 for measuring the milk flow during milking; a milk storage tank 5 which stores milk for collection on a regular time basis; a milk line 4 connecting the milking robot 1 with the milk storage tank 5; a milk pump (not shown) for pumping milk from the milking robot 1 to the milk storage tank 5; and a pre-cooling device 3 for cooling milk, which is pumped over to the milk storage tank 5.

[0018] The milk storage tank 5 is provided with a stirrer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com