Production method of cooking wine

A production method and product technology, applied in the preparation of alcoholic beverages, food preparation, food science, etc., can solve the problems of short production history, extensive products, substandard production, etc., to ensure product quality and hygienic quality, and clear and thorough products , Improve the effect of product freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

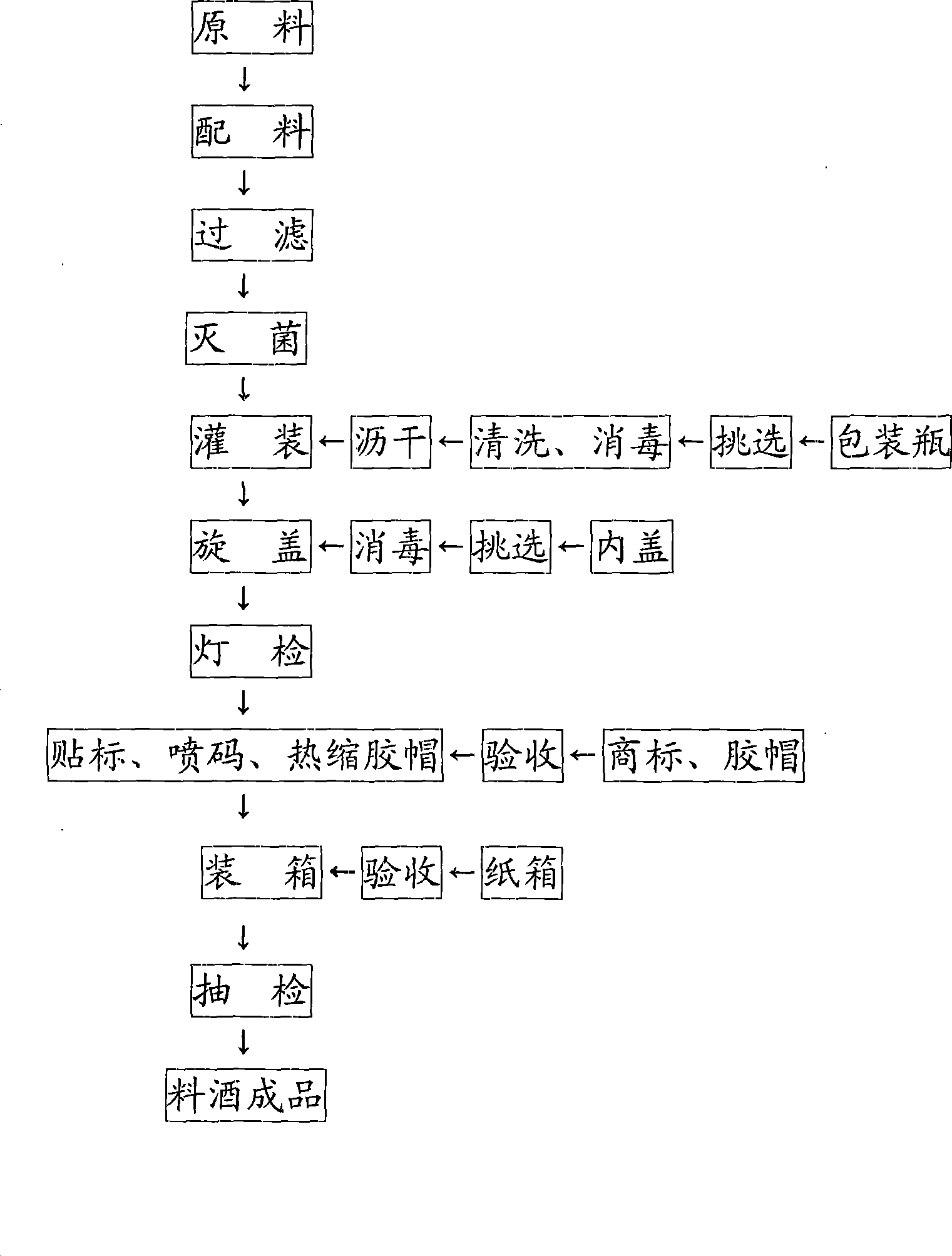

Image

Examples

specific Embodiment approach 2

[0084]Carry out according to specific embodiment 1, just described alcohol degree (20 ℃) is implemented with 5, 6, 7, 8, 9, 10V / V as a grade, with 10.1, 11, 12, 13, 14, 15V / V was implemented as a grade, and 15.116, 17, 18, 19, 20, 21, 22, 23V / V were implemented as a grade; the expected good results were obtained.

specific Embodiment approach 3

[0085] Carry out according to specific embodiment one, just described total acid (calculated as lactic acid) is implemented as a grade with 3,4,5g / L, with 5.1,6,7,8,9,10,11,12, 13, 14, 15g / L were implemented as a grade, and 15.1, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30g / L were implemented as a grade Grades were implemented; also with good results as expected.

specific Embodiment approach 4

[0086] Carry out according to specific embodiment 1, just described total sugar (in terms of glucose) is implemented with 0 as a grade, with 0.1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20g / L were implemented as a grade, with 20.21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32 , 33, 34, 35, 36, 37, 38, 39, 40g / L were implemented as a grade, with 40.1, 41, 42, 43, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67, 68, 69, 70, 71, 72, 73, 74, 75, 76, 77, 78, 79, and 80g / L were implemented as a grade; the expected good results were also obtained.

[0087] After the implementation of the test of the present invention, the seasoning wine products produced were tested, and all of them met the standards; experts in the industry evaluated and agreed that the method was scientific and reasonable, and had wide application value, and the color, aroma, taste and shape of the product were excellent. , added new varieties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com