Patents

Literature

326 results about "Amino acid nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yes, Every amino acid contains Nitrogen. So, All amino acids contain an amino(-NH2) group(bonded to the Alpha-Carbon), which contains Nitrogen. However, there are some Amino Acids, including Lysine, Arginine, Histidine, which contain more Nitrogen than the others.

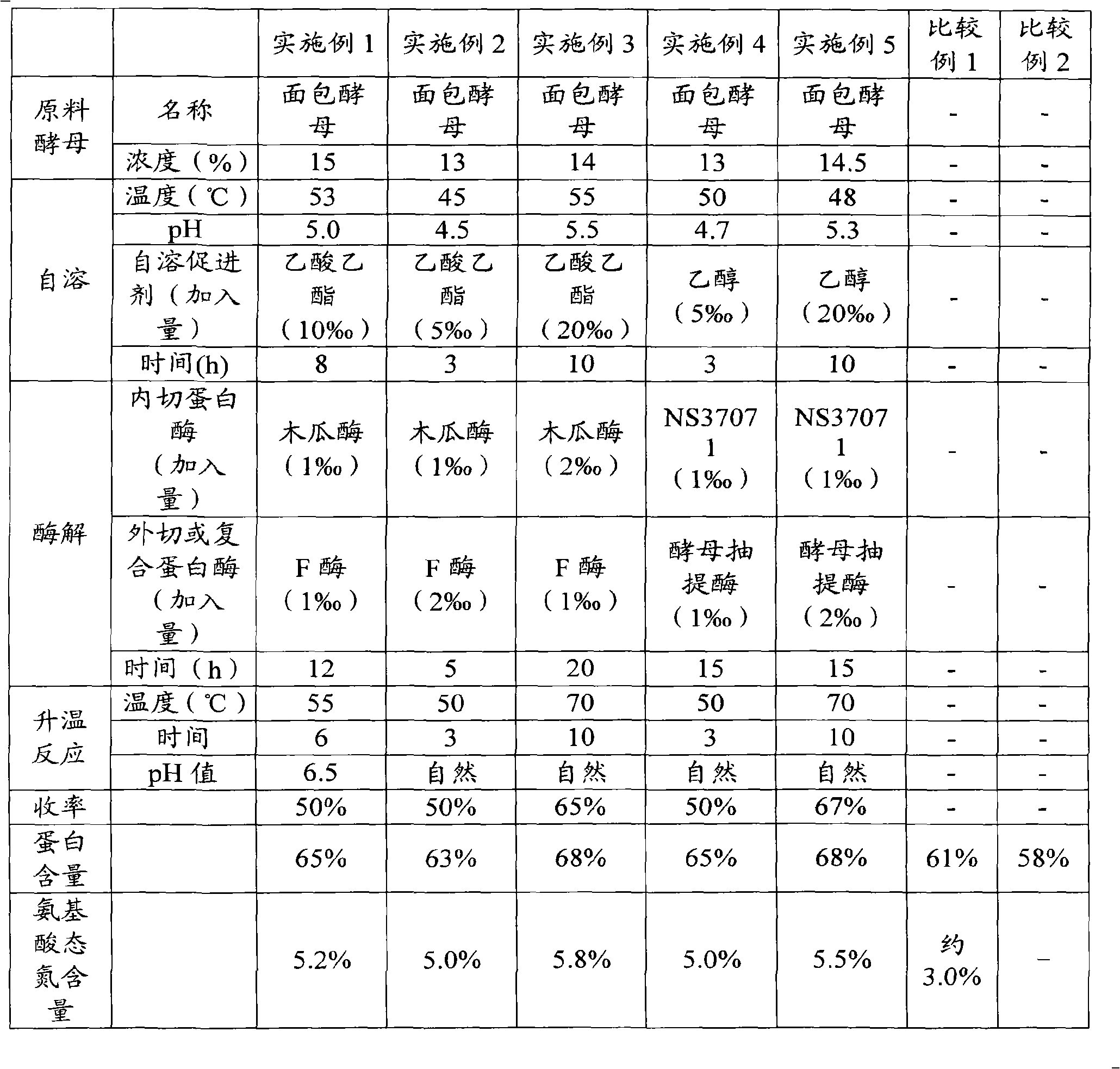

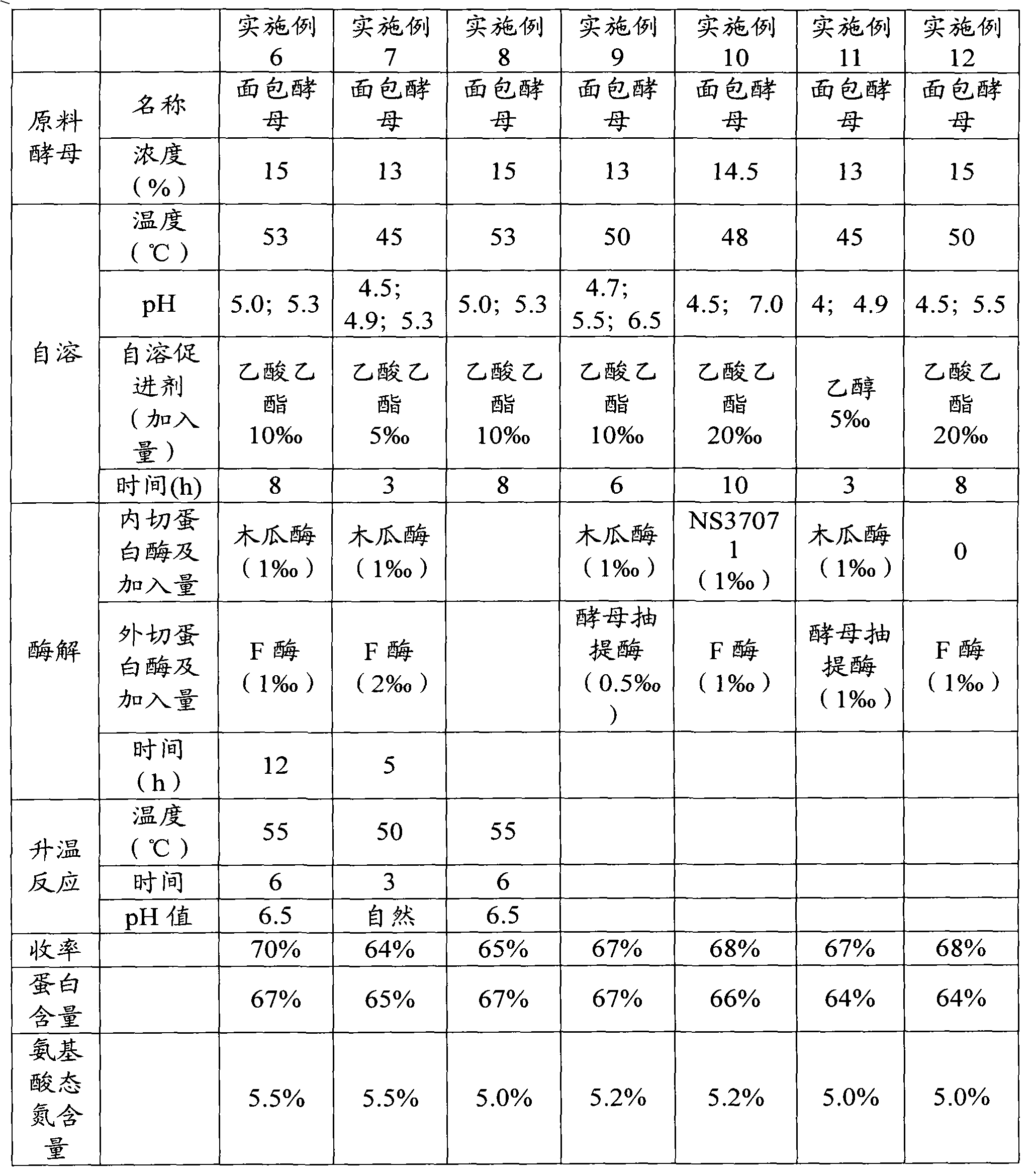

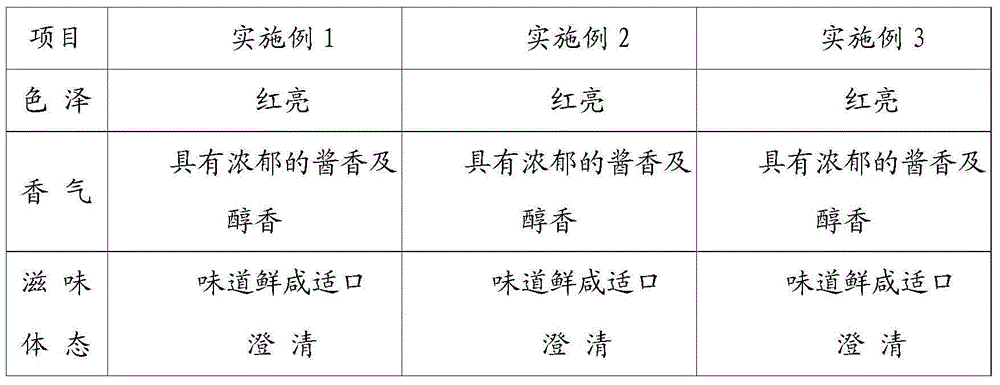

Method for producing yeast extract with high protein content and product

ActiveCN101513247AImprove conversion rateImprove the effect of enzymatic hydrolysisFood preparationYeast cell extractEnzyme

The invention relates to a method for producing yeast extract, which comprises the following step: (a) autolysis, namely performing autolysis under the condition of keeping the pH value of a liquid yeast between weak acidity and neutrality, and adjusting the pH value for at least one time in the autolysis process to perform the autolysis under the condition of different pH values. The invention also relates to the yeast extract obtained by the method. In the autolysis process, yeast entogenous enzyme is effectively activated by adjusting a pH value, and conversion rate of products is improved. The yeast extract produced by the method has obviously improved contents of protein and amino-acid nitrogen.

Owner:安琪酵母(柳州)有限公司

Brewing technology for soybean sauce

InactiveCN105053962AIncrease contentImprove protein utilizationFood thermal treatmentFood preparationWheat BransProtein

The invention discloses a brewing technology for soybean sauce. The brewing technology comprises the following steps: (1) soybean soaking: adding soybeans into water for soaking; (2) stewing: stewing the soybeans to obtain cooked soybeans; (3) mixing: mixing flour and roasted wheat bran to obtain a flour mixture, and mixing the cooked soybeans and the flour mixture to obtain a mixture; (4) inoculation: cooling the temperature of the mixture to be below 30 DEG C, and inoculating aspergillus oryzae; (5) distiller's yeast making: conveying the mixture into a leavening room for cultivation, wherein in the earlier stage of cultivation, the distiller's yeast temperature is 28-35 DEG C, and in the later stage of cultivation, the distiller's yeast temperature is 20-25 DEG C until the distiller's yeast is formed; and (6) fermentation: mixing the finished distiller's yeast and salty water, performing fermentation under normal temperature for more than 4 months. According to the brewing technology, the contents of reducing sugar and amino acid nitrogen in the soybean sauce can be effectively increased, the non-enzymatic browning effect in a soybean sauce brewing process is enhanced, and the flavor and the color of the soybean sauce are enhanced; and furthermore, the distiller's yeast contains rich protease, and the utilization rate of proteins in the soybean sauce brewing process is increased.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

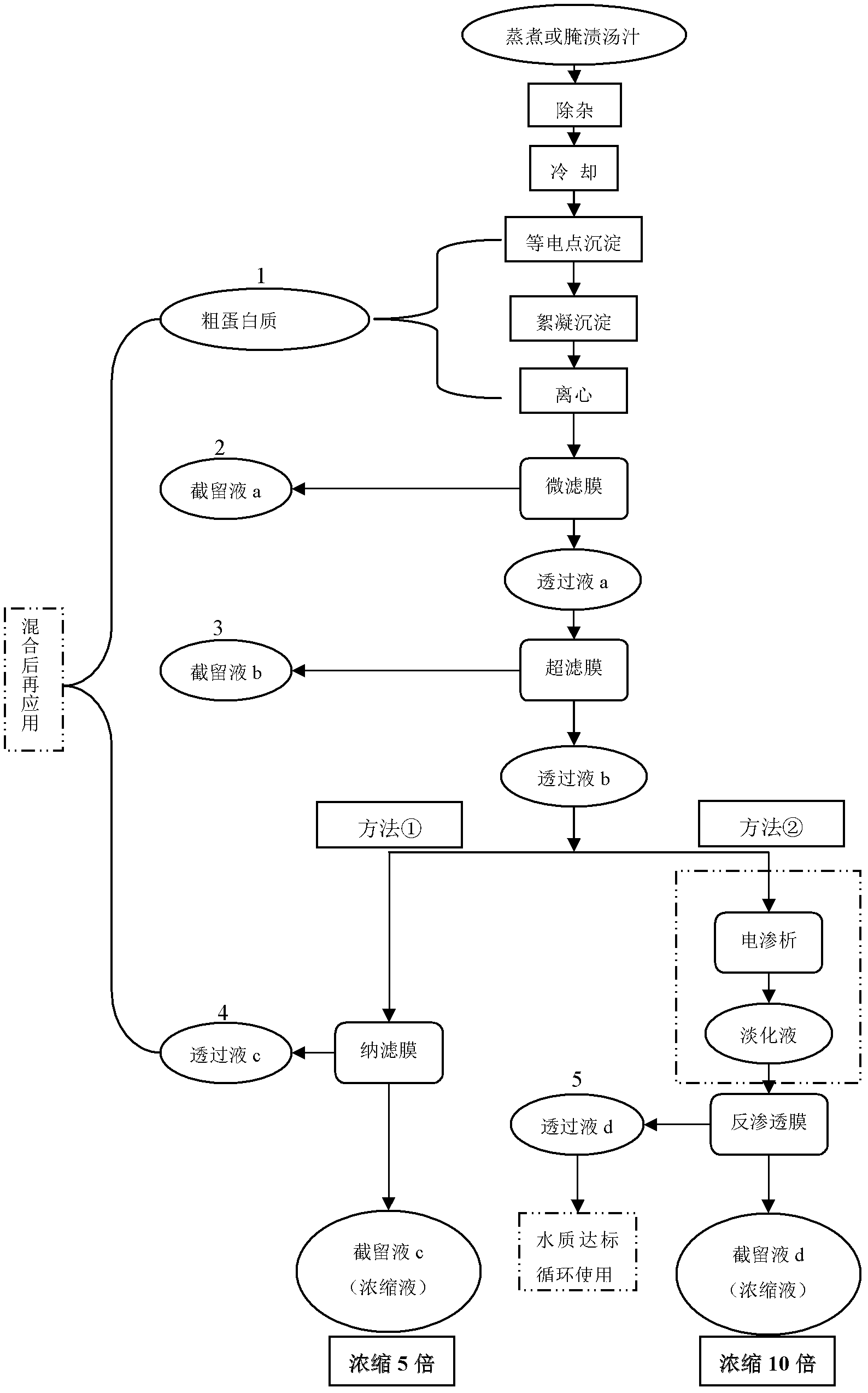

Cryo-concentration method of juice obtained by processing organisms

ActiveCN102657320AEmission reductionReduce pollutionTobacco treatmentFood preparationConcentration polarizationEnrichment methods

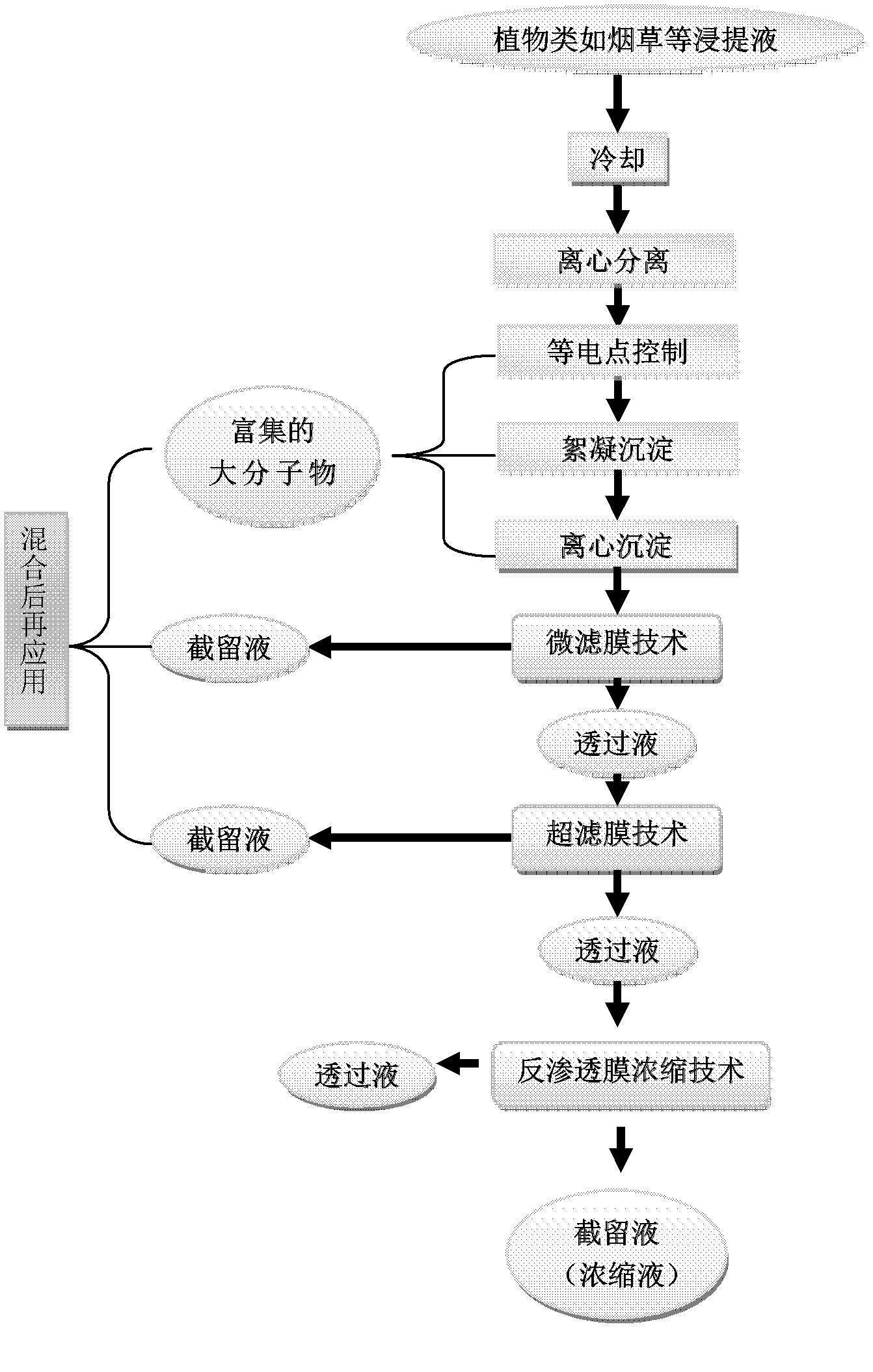

The invention discloses a cryo-concentration method of juice obtained by processing organisms, comprising the following steps: firstly pretreating the juice by using isoelectric precipitation, flocculation precipitation, centrifugal separation and the like to gather protein and reduce the protein content in the juice, so as to reduce the concentration polarization of membrane concentration; and then integratedly cascading membrane modules to concentrate small-molecule nutrient and flavor substances by fully utilizing the advantages of microfiltration, ultrafiltration, stepwise rejection of reverse osmosis, and desalination of electrodialysis to reduce osmotic pressure. The method is suitable for the juice obtained by processing organisms having a content of concentrated amino acid nitrogen being 5-100 mg / 100ml and has a wide application range. The method can not only concentrate and recover nutrient and flavor substances, transforms the juice into something valuable, raises the product additional values, reduces the discharge of food processing waste water, reduces environmental pollution, and can basically realize the basically complete recycling of the nutrient and flavor substances of the juice.

Owner:ZHEJIANG UNIV OF TECH

Bottle-contained yellow wine quality index on-line detection method and device

InactiveCN101216418AQuick analysisShorten detection timeColor/spectral properties measurementsBackground spectrumAlcohol

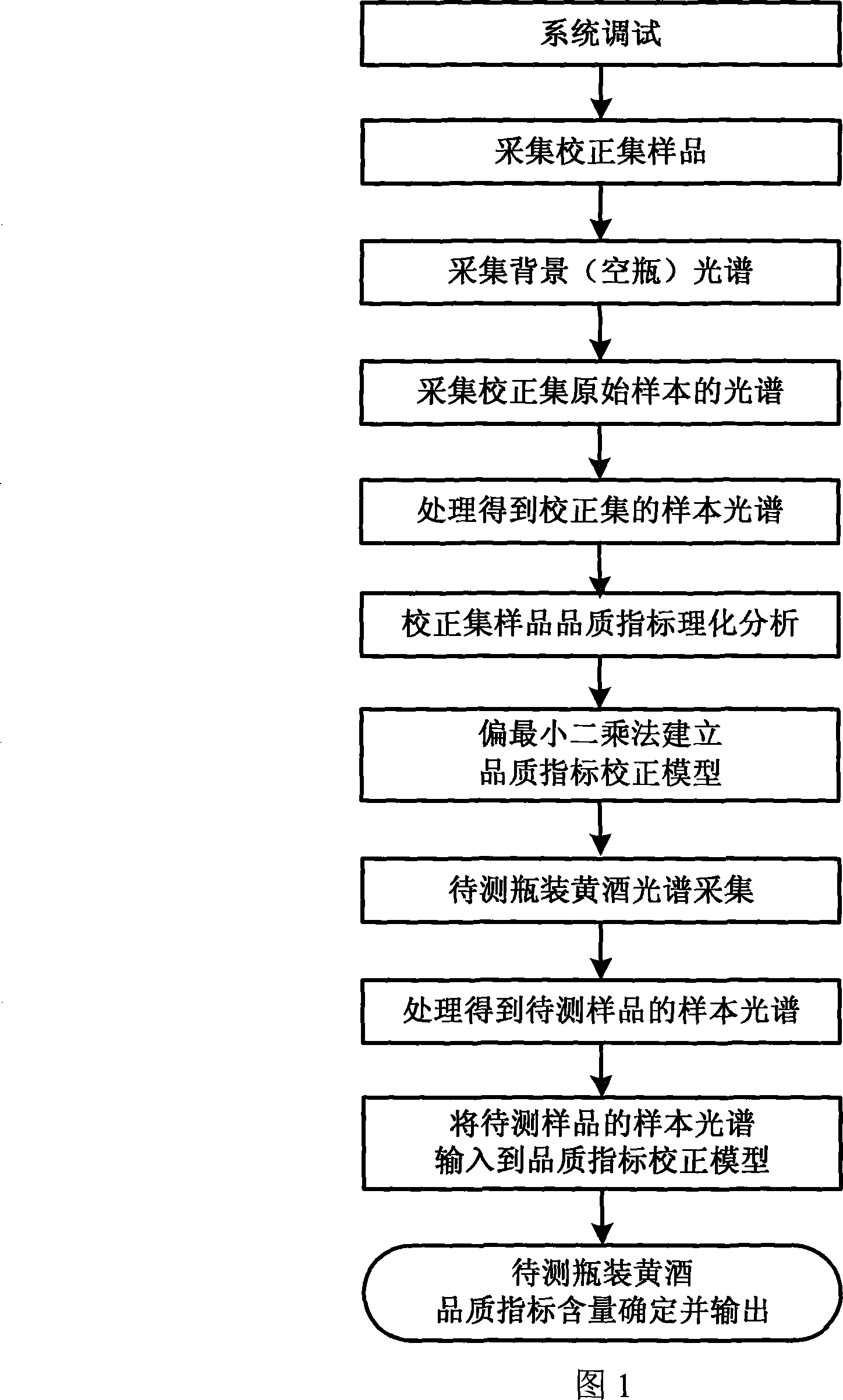

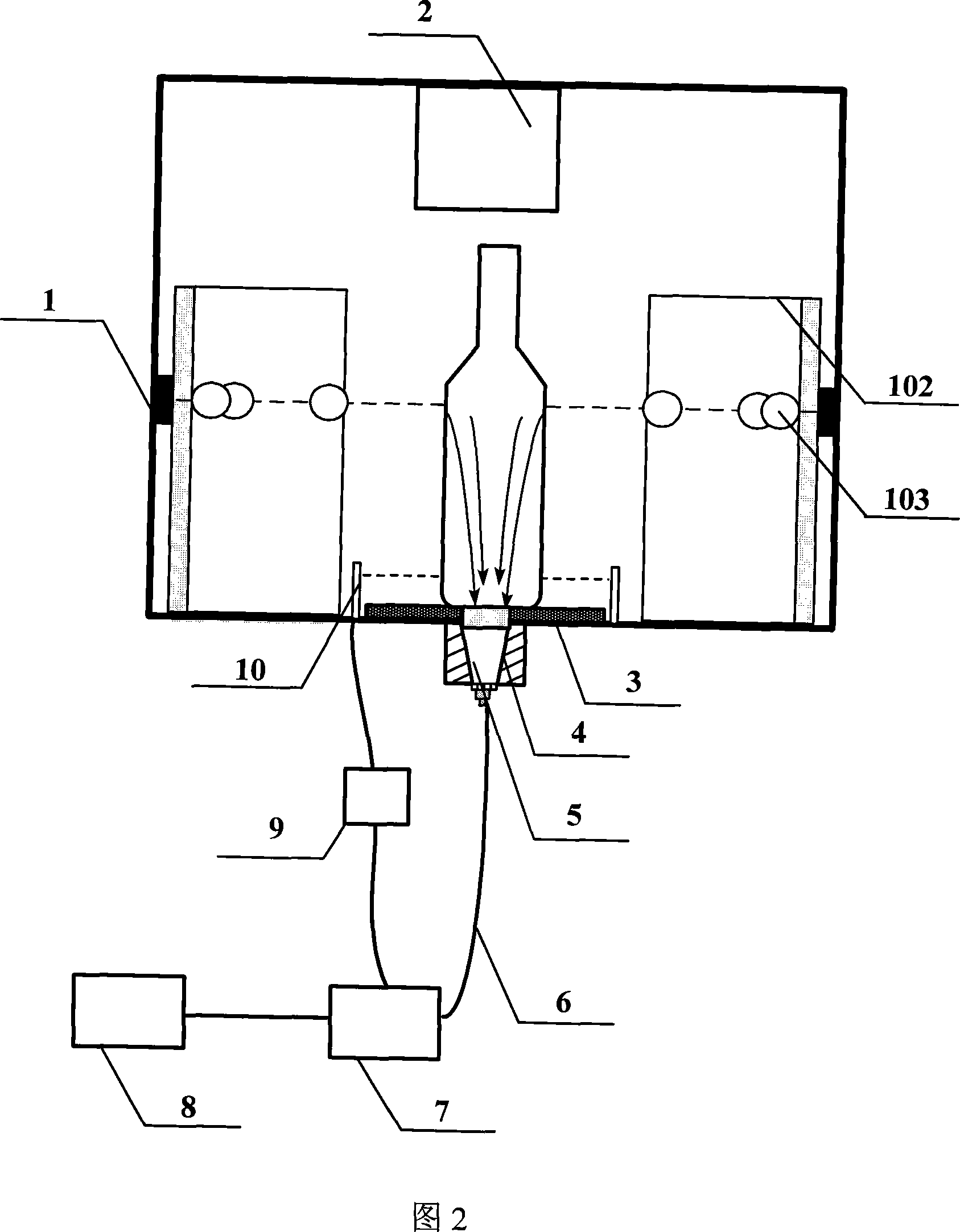

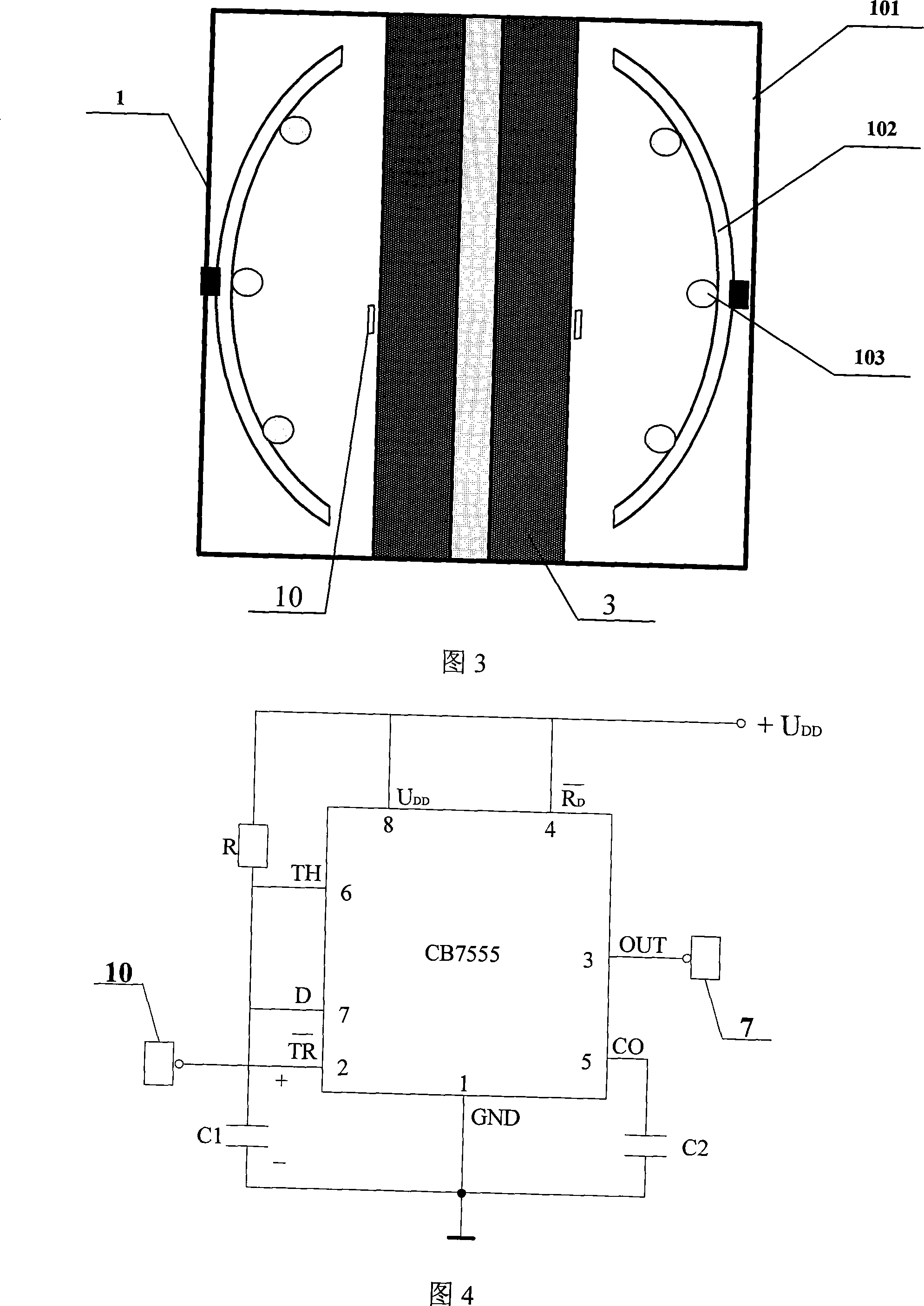

The invention discloses a method and a device for online detecting quality index of yellow rice wine in bottle. The online detection device comprises an illumination system, an air conditioning system, a conveying belt, a receiving lens fixing device, a receiving lens, an optical fiber, a spectrometer, a computer, a trigger circuit and a photoelectric switch. The method comprises the following steps of: collecting the near IR spectrum of an empty bottle of a yellow rice wine sample in the bottle as the background spectrum; reducing the background spectrum from the spectrum of an original yellow rice wine sample in bottle as the sample spectrum; constructing the correction model of the key quality index of yellow wine according to the spectra and a physical and chemical analysis result by adopting partial least-squares regression method; and online detecting the quality of the yellow rice wine according to corresponding model. Based on near IR spectral analysis technology, the invention can achieve online detection of the key quality indexes of the yellow rice wine sample, including total sugar, solids, alcohol degree, total acid, amino acid nitrogen as well as pH value, thus achieving online and rapid quality analysis of yellow rice wine product, reduced detection time and cost and ensured product quality.

Owner:ZHEJIANG UNIV

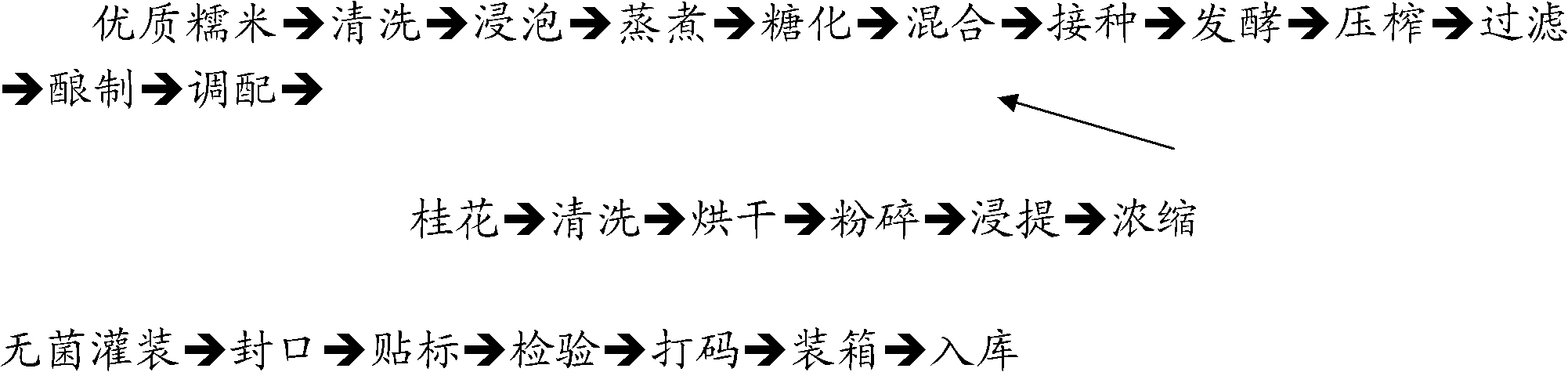

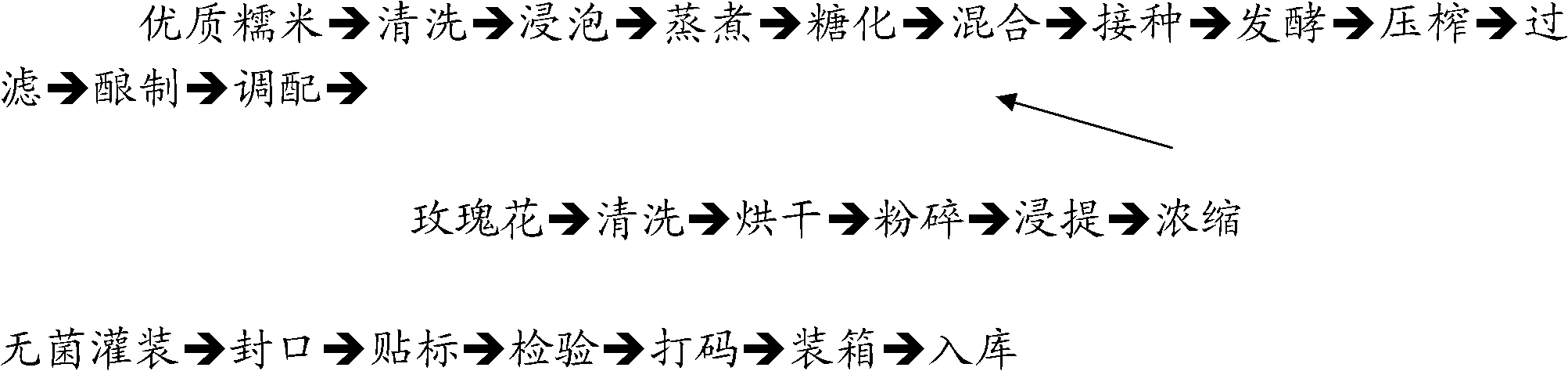

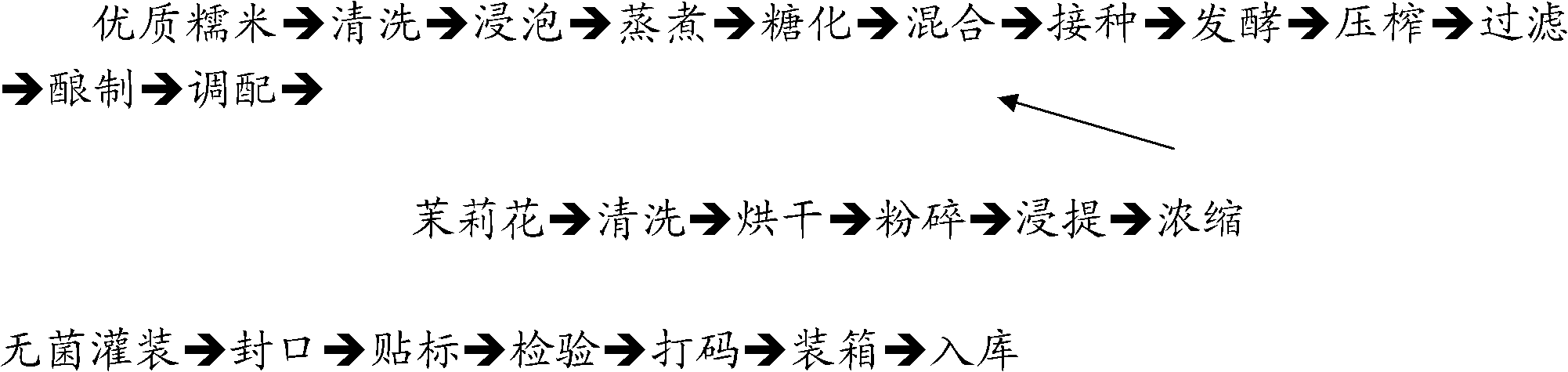

Preparation method of fermentation type plant flower rice wine

InactiveCN102604796ARich flavor ingredientsRich activityAlcoholic beverage preparationFlavorBeta-Phenylethanol

The invention discloses a preparation method of fermentation type plant flower rice wine, belonging to the technical field of food production. The preparation method comprises the following steps of: steaming sticky rice and adding saccharifying enzyme for saccharification; crushing sweet osmanthus, rose or jasmine and performing ultrasonic extraction and concentration; adding the concentrated solution into the saccharified sticky rice, and adding distiller yeast for fermentation, wherein the fermentation temperature is 28-32 DEG C, and the fermentation time is 24-48 hours; juicing the obtained product, collecting the juice and feeding the juice into a superfilter; filtering and collecting the juice, and brewing the juice in a storage tank at room temperature below 30 DEG C for 3-6 months; blending until the alcoholic strength is greater than or equal to 8.0 (vol), the total acid (based on lactic acid) is greater than or equal to 2.20g / L, the total sugar (based on glucose) is greater than or equal to 40.0g / L, the amino acid nitrogen is greater than or equal to 0.10g / L, and the beta-phenethyl alcohol is greater than or equal to 20.0mg / L; and filling. The preparation method disclosed by the invention has the beneficial effects that: the flavor components and physiological activators of the plant flower are richer than those in the product of the prior art.

Owner:YUNNAN ZHIWEIYUAN FOOD

Plant nutrition liquid fertilizer and preparation method thereof

InactiveCN101913960AImprove aggregate structureIncrease profitFertilizer mixturesPhosphateDecomposition

The invention discloses plant nutrition liquid fertilizer and a preparation method thereof. The liquid fertilizer comprises the following components in percentage by weight: 4 to 7 percent of compound amino acid liquid, 2 to 5 percent of ribonucleic acid concentrated solution, 1.5 to 3.5 percent of plant growth hormone concentrated solution, 0.4 to 0.5 percent of non-protein non-amino-acid nitrogen, 2.0 to 5.0 percent of potassium dihydrogen phosphate, 1.5 to 2.5 percent of potassium oxide, 0.1 to 0.25 percent of zinc, 0.4 to 0.6 percent of boron, 0.1 to 0.25 percent of magnesium, 0.1 to 0.25percent of copper and the balance of water. Compared with the prior art, the product of the invention can gradually regulate the soil acidity or alkalinity of plant rhizospheres, improve microbiological activity, accelerate the decomposition of organic substances, and improve a soil aggregation structure and the utilization rate of the fertilizer due to amino acid, plant growth hormone and ribonucleic acid. The resistance of crops to stress such as low temperature, drought, salt damage, disease, herbicide, phytotoxicity and the like is enhanced after the fertilizer is applied.

Owner:桂林撼天生态农业开发有限公司

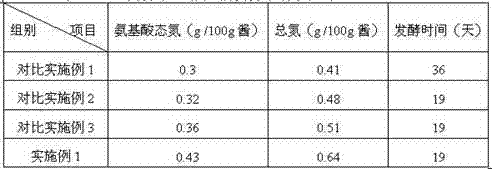

Low-salt and multi-strain segmented fermentation process for fermented soya beans

InactiveCN103535634AIncrease aromaIncrease contentMulti-step food processesFood preparationFlavorMicroorganism

The invention provides a low-salt and multi-strain segmented fermentation process for fermented soya beans. The low-salt and multi-strain segmented fermentation process comprises the following steps: selecting soy beans; immersing; cooking; inoculating and carrying out starter propagation; carrying out primary fermentation; inoculating a yeast and carrying out secondary fermentation to obtain a finished product. With the adoption of the low-salt and multi-strain segmented fermentation process, a process method for carrying out segmented fermentation after the starter propagation and adding microorganisms to increase the aroma is applied to the fermentation production of the fermented soya bean; pure strains are used for carrying out the starter propagation so as to improve the protease activity of a bean starter; the salt-free health-insulation fermentation is used for improving the content of amino acid nitrogen and shortening the time spent on the primary fermentation; in the secondary fermentation process, zygosaccharomyces rouxii is added to increase the aroma of the fermented soya beans and shorten the secondary fermentation time; a product not only has the unique aroma of the fermented soya beans, but also has the rich mellow flavor, sauce flavor and ester flavor; the mass percentage of the amino acid nitrogen of the product reaches 0.81g / 100g and the mass percentage of the salt of the product is about 8g / 100g and is reduced by more than 47.78% when being compared with that of conventional fermented soya beans (more than 12%); the fermentation time lasts for 19 days and is shortened by 3-6 days.

Owner:GUIZHOU SHUIXIANGZI FOOD CO LTD

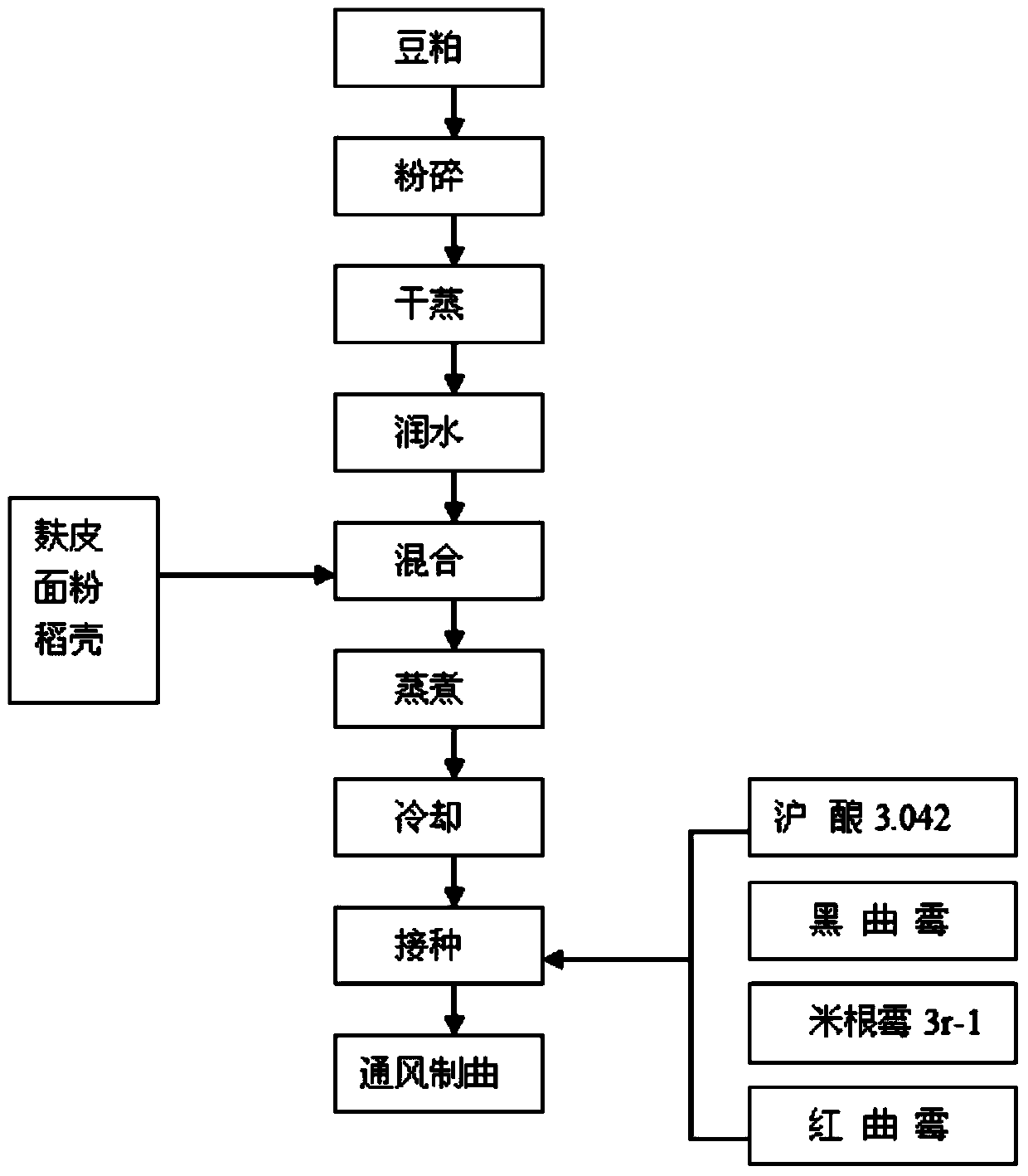

Soybean sauce brewing process

The invention provides a soybean sauce brewing process. The soybean sauce brewing process comprises the following steps: producing seed koji and finished koji by using a seed koji producer; fermenting by using multiple strains; and preparing, sterilizing and packaging to obtain a final product. The process realizes mixed fermentation of multiple strains, such as aspergillus oryzae, aspergillus niger, monascus and bacillus natto by adopting a process of inoculating at negative pressure, preparing the koji by one strain, mixing the finished koji into a tank to be fermented according to a ratio, and carrying out fixed fermenting, so that the content of amino acid nitrogen can be up to 1.44g / 100ml and the utilization rate of protein is up to about 90%; the soybean sauce brewing process is an advanced soybean sauce brewing process method.

Owner:ANHUI GOOD TASTE FOOD BREWING

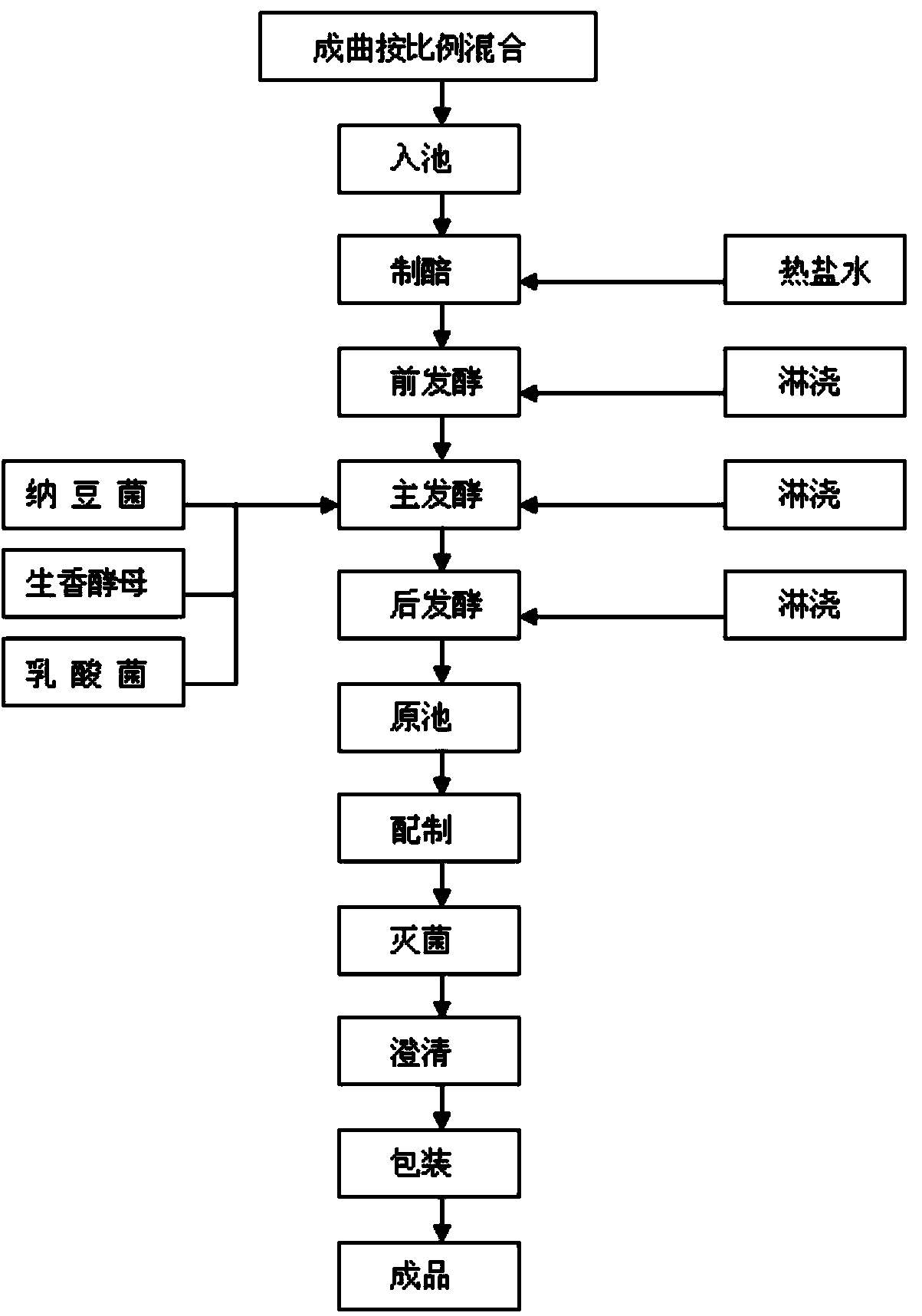

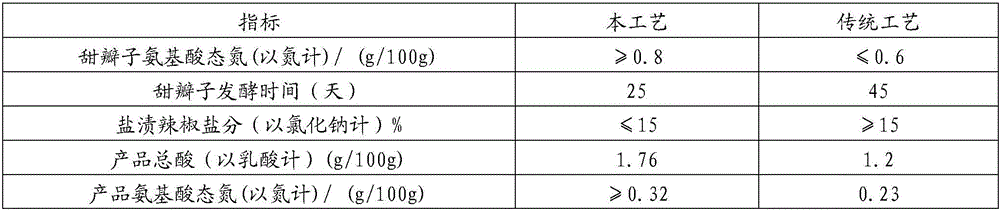

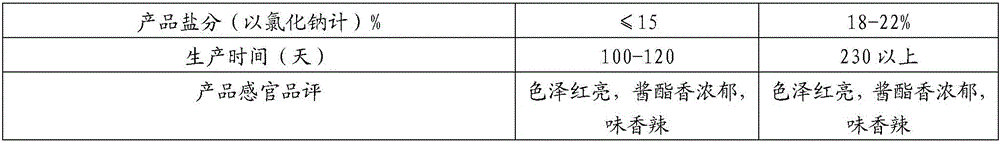

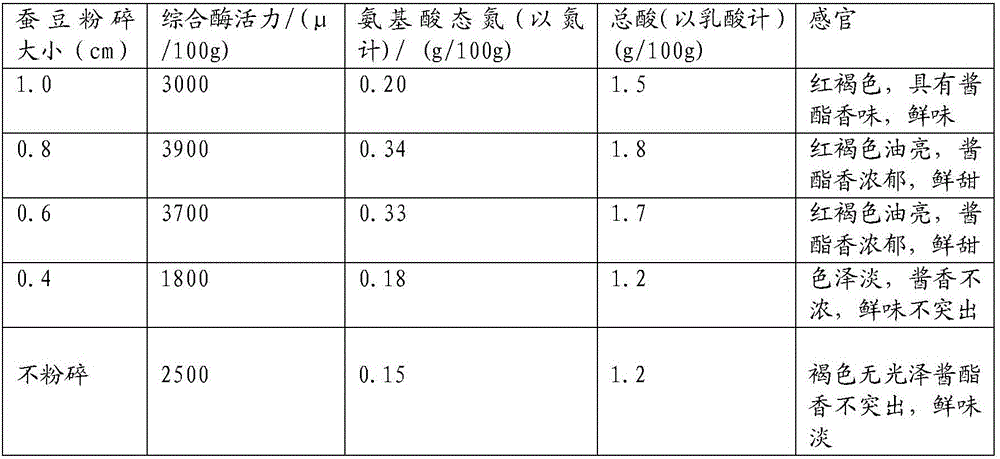

Fermentation technology of novel thick broad-bean sauce special for seasoning

The present invention belongs to the field of food and specifically discloses a fermentation technology of a novel thick broad-bean sauce special for seasoning. The technology comprises the following steps: broad bean halves are crushed; the crushed broad bean halves are put into hot water to be blanched, the blanched broad bean halves are drained, the drained broad bean halves are cooled, flour and soy sauce koji essences are added, and the materials are evenly blended; the mixture is subjected to ventilation to prepare a koji, and when the bean halves grow yellow cream spores, and the koji is taken out to be weighed; finished koji is weighed, edible salt and flavored protease are respectively added into warm water to be dissolved, the dissolved materials are blended into the finished koji, and an incubation fermentation is conducted for 25-30 days until the mixture is mature to obtain sweet broad bean sauce; red peppers are soaked in clean water, the soaked red peppers are washed clean using water, the washed red peppers are chopped, then edible salt is added to conduct salting, at the same time, lactic acid functional bacteria are added, and after the salt fermentation, the fermented peppers are obtained; the sweet broad bean sauce and the fermented peppers are mixed, eater producing yeasts are added, and the mixture is sun-dried for 30-40 days; and finally the mixture is sterilized and packaged. The technology can shorten the fermentation cycles to 100-120 days, the product salt is lower than or equal to 15%, the amino acid nitrogen content is larger than or equal to 0.32%, and the product amino acid nitrogen content is improved for 30% or more.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

Anti-cancer selenium-enriched soy sauce

The invention discloses anti-cancer selenium-enriched soy sauce. In the anti-cancer selenium-enriched soy sauce, the amino acid nitrogen content is 0.70 to 0.75 g / 100ml; and the organic selenium content is 50 to 100 ug / kg. The anti-cancer selenium-enriched soy sauce is prepared by the following steps of inoculating aspergillus oryzae into raw materials comprising soybean and wheat to prepare yeast; adding saline into the yeast; fermenting; pouring oil in the completely fermented sauce paste; adding traditional Chinese medicine soup cooked by the organic selenium and a traditional Chinese composition to anti-cancer selenium-enriched soy sauce; or adding traditional Chinese medicine soup cooked by the traditional Chinese composition into the completely fermented sauce paste, inoculating salt-tolerance lactic acid bacteria and salt-tolerance saccharomycetes, performing secondary fermentation, pouring oil after the fermentation is finished, and adding the organic selenium to prepare the anti-cancer selenium-enriched soy sauce. The organic selenium and the traditional Chinese composition can enhance the anti-cancer effect; and the traditional composition has the effects of tonifying spleen, soothing the nerves, replenishing blood and tonifying qi.

Owner:JINAN JUYI BREWING

Method for preparing composite Sichuan fermented bean curd

InactiveCN102018181AIncrease the degree of emulsificationImprove nutritional indicatorsFood preparationRhizopusBroad beans

The invention discloses a method for preparing composite Sichuan fermented bean curd, which has the outstanding characteristic that: broad bean paste koji is added in the mixed fermentation process. The method comprises the following steps of: adding mucor and rhizopus chinentis for primary fermentation, adding aspergillus oryzae to prepare the broad bean paste koji, and adding auxiliary materials, yeast powder and lactobacillus powder for secondary fermentation. Compared with the conventional fermented bean curd product, the composite Sichuan fermented bean curd prepared by the method has the advantages that: the emulsifying degree of the fermented bean curd is greatly improved, and the product is red or red brown, has bright color and fine mouthfeel, and is delicious, faint scent and nopeculiar smell; meanwhile, sanitation indexes such as coliforms, aflatoxin B1 and the like are effectively controlled, nutrition indexes such as water-soluble protein, amino acid nitrogen and the like are obviously improved, the fermentation period of the product is obviously shortened, the fermented bean curd can be produced in high-temperature summer, and seasonal production is changed into annual production.

Owner:XIHUA UNIV

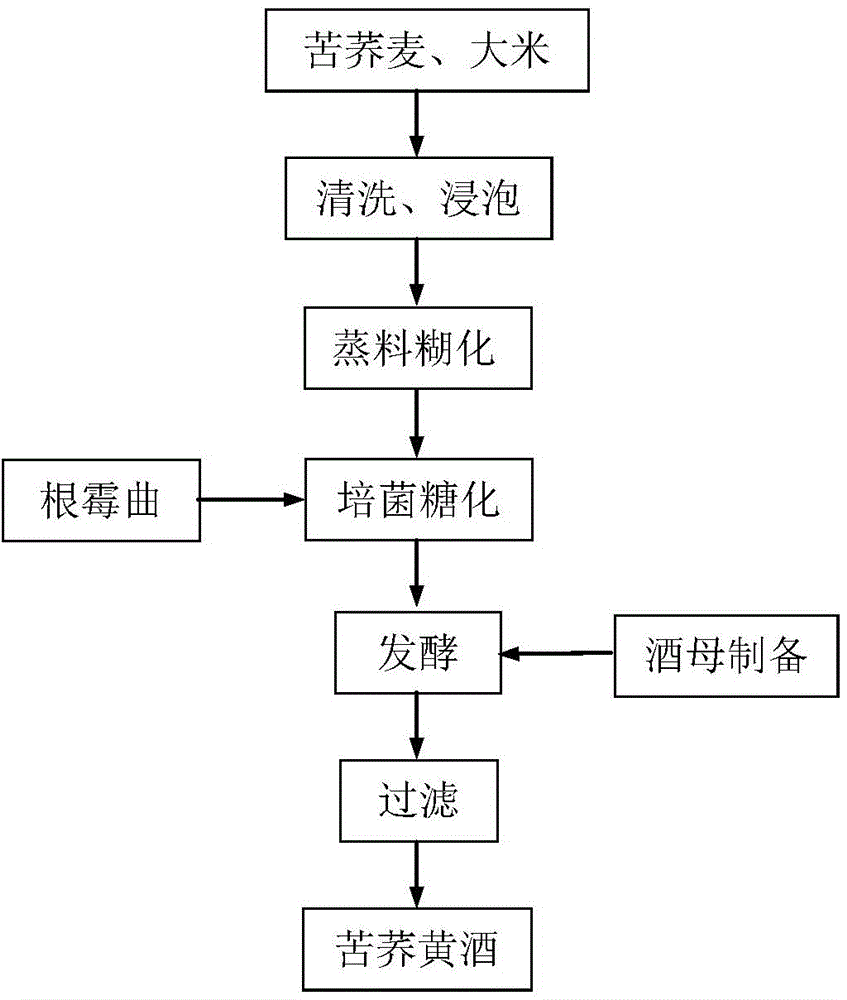

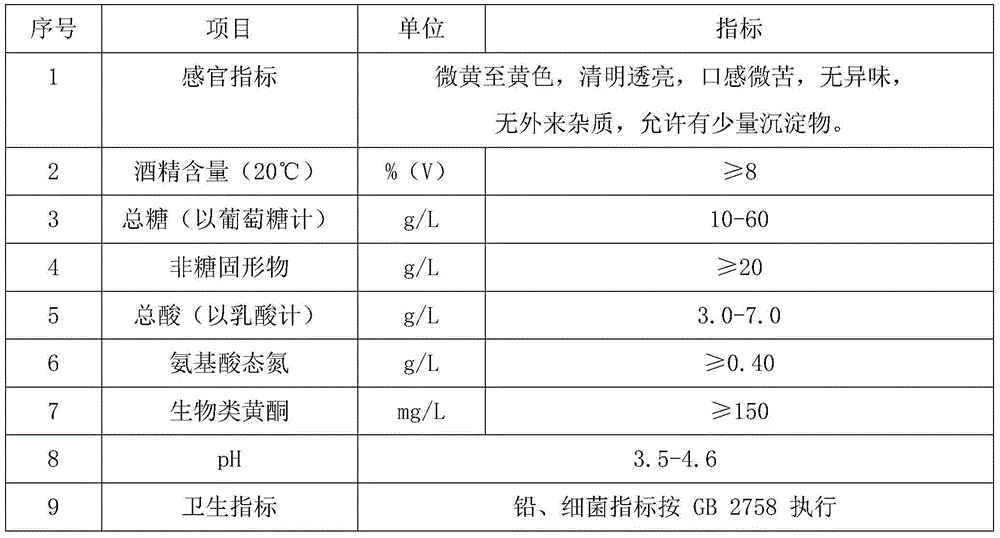

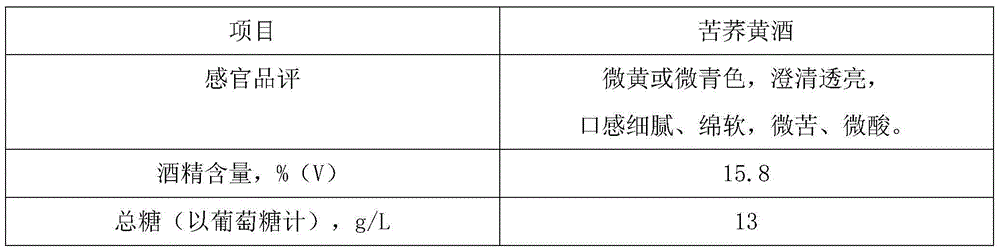

Preparation method for yellow bitter buckwheat wine

InactiveCN104403871AIncrease the content of beneficial substancesAchieve health effectsMicroorganism based processesAlcoholic beverage preparationPolygonum fagopyrumYeast

The invention relates to yellow bitter buckwheat wine and a preparation method of the yellow bitter buckwheat wine, and belongs to the technical field of wine brewing. The preparation method comprises the following steps: (1) preparing raw materials of bitter buckwheat and rice; (2) washing and soaking; (3) gelatinizing steamed materials; (4) performing culture saccharification; (5) activating active dry yeasts; (6) fermenting; (7) filtering. The yellow bitter buckwheat wine prepared by the method has the alcohol content of 8%-16% (V), the bioflavonoid content of 150-400 mg / L and the amino acid nitrogen content of being 1.8 times that of general yellow rice wine, has prevention and relief effects on blood pressure reduction, blood fat reduction, blood vessel softening, bacterial resistance and improvement on various physiological diseases of sub-health status and the like, and is novel healthcare yellow wine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method for brewing mushroom soy sauce

The invention discloses a production method for brewing mushroom soy sauce. According to the method, 30-35% of mushroom legs (dried mushrooms), 35-45% of soybeans and 25-35% of wheat in a mass proportion are adopted as raw materials for brewing via basic technologies of making yeast via a traditional method and natural fermentation. The method includes the steps of raw material treatment, sterilization, yeast making, fermentation, oil spraying, airing, preparation and blending, sterilization before filling, and the like. The mushroom soy sauce prepared by the method is 1.142g / 100mL in AN (amino acid nitrogen) content and 35.12g / 100mL in soluble salt-free solid content, and reaches special-grade standards; bioactive substance lentinan reaches 0.245g / 100mL, and Fe content is about 22.83mg / 100mL; total content of free amino acid in important flavoring materials is 4.78mg / 100mL and higher than that of ordinary soy sauce by 1.4mg / 100mL, and product yield is up to 86.6%; the mushroom soy sauce is nutritional, health caring and delicious in taste.

Owner:XIXIA COUNTY FUDAOJIA FOOD

High-concentration fermented milky flavor base, and preparation method and application thereof

The invention discloses a high-concentration fermented milky flavor base, and a preparation method and application thereof. The preparation method comprises the following steps of: (1), dissolving full-fat milk powder, dried skim milk powder or mixture of both, and anhydrous cream in water, to obtain high-concentration reconstituted milk; (2), homogenizing the obtained reconstituted milk, hydrating, sterilizing and cooling; (3), adding a lactic acid bacteria starter and enzyme preparation in the reconstituted milk obtained in the step (2), then fermenting and carrying out enzymolysis, to obtain high-concentration fermented milk base; and (4), milling the obtained fermented milk base by a colloid mill, homogenizing, sterilizing while stirring and finally cooling to normal temperature, so as to obtain the high-concentration fermented milky flavor base. In the flavor base, the protein content is between 5% w / w and 10% w / w, the titration acidity is between 250 degrees T and 450 degrees T, and the amino acid nitrogen content is 0.11g / 100mL at least; and the high-concentration fermented milky flavor base has the advantages of relatively high acidity, rich aroma and natural, mild and abundant fermented flavor, and can be used for aroma enhancement of baked foods.

Owner:SOUTH CHINA UNIV OF TECH

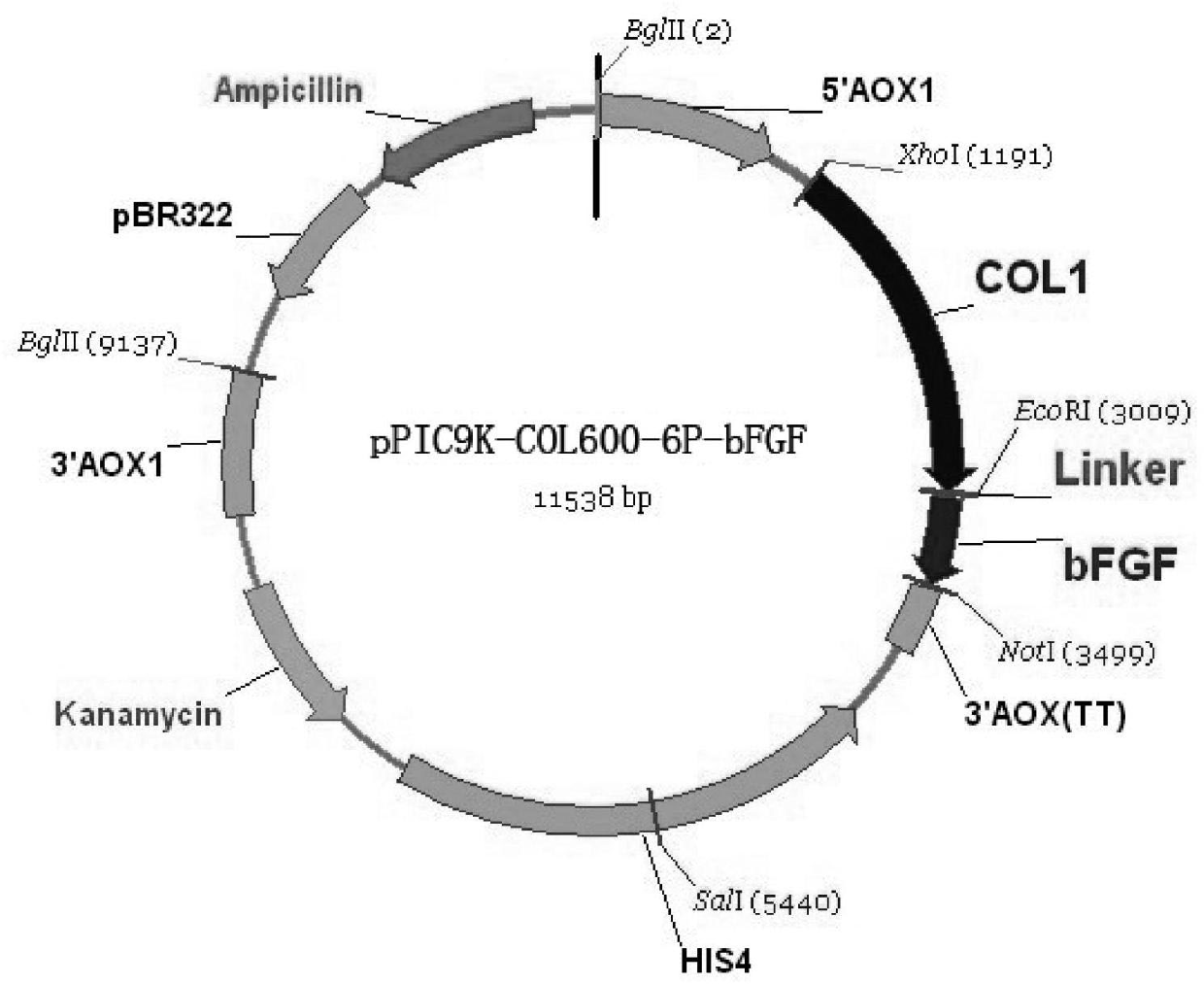

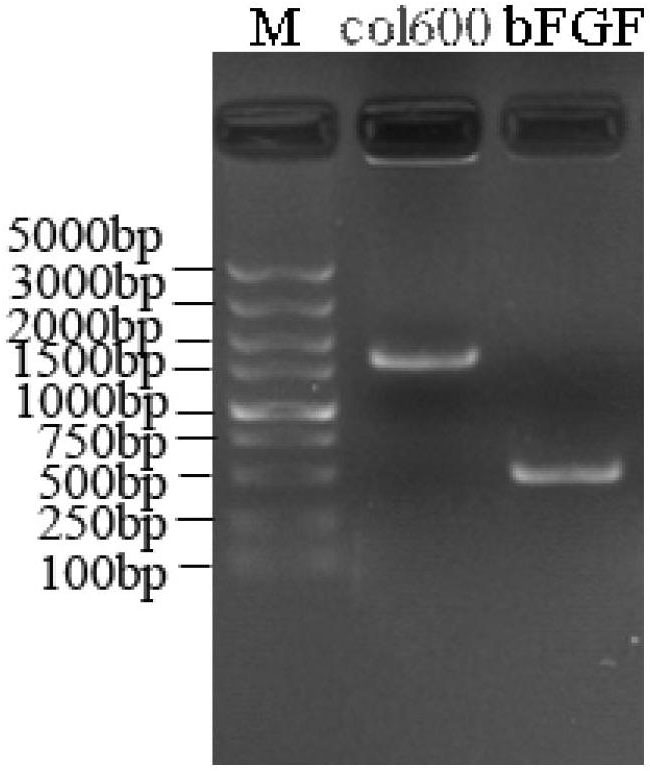

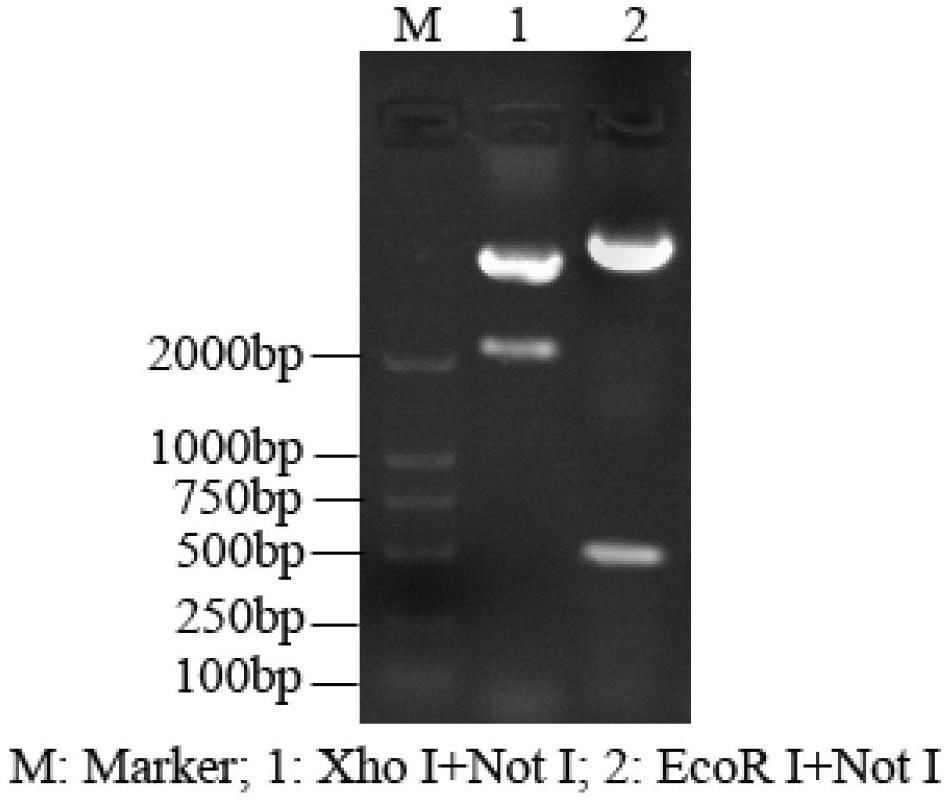

Gene recombinant human active basic fibroblast growth factor fusion protein, preparation method thereof and application thereof

The invention provides a gene recombinant human active basic fibroblast growth factor fusion protein, wherein the whole length of the fusion protein is 762 amino acids, the nitrogen end is I type human-like collagen 500-1099 peptide and jointly has 600 amino acids, the carbon end is human basic fibroblast growth factor and jointly has 154 amino acids, and two peptides are connected with each other by glutamic acid, phenylalanine and 6 amino acids-containing flexible peptide. A preparation method of the gene recombinant human active basic fibroblast growth factor fusion protein comprises the following steps of: constructing a gene recombinant human active basic fibroblast growth factor fusion protein expression vector, electrically transforming pichia pastoris, screening multi-copy inserting recon, fermenting the gene recombinant human active basic fibroblast growth factor fusion protein, and purifying the gene recombinant human active basic fibroblast growth factor fusion protein. Thegene recombinant human active basic fibroblast growth factor fusion protein is used for preparing the cosmetics.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

Method for processing flavor mushroom sauce

The invention relates to a method for processing flavor mushroom sauce in the field of sauce fermentation processing. The method comprises the following steps of: mixing soybean meal and wheat flour in a weight ratio of 6:4, adding yeast, kneading dough, fermenting, steaming completely, cooling, slicing, inoculating 41gCFU / g of aspergillus spores, culturing, and obtaining sauce yeast when the total number of the bacterial colony is 6 to 6.21gCFU / g; crushing the sauce yeast, adding a salt solution, fermenting for 48 hours at the temperature of between 48 DEG C and 50 DEG C at the initial stage, fermenting for 3 days at the temperature of 45 DEG C, adding a D110 glutamic acid bacteria solution, a lactic acid bacteria solution and sorbitol, and fermenting for 12 days at the temperature of between 38 DEG C and 40 DEG C to obtain primary sauce; and deactivating enzymes of mushroom, preparing the mushroom into mushroom pulp, mixing the mushroom pulp and the primary sauce uniformly in a weight ratio of 1:1, adding salt, fermenting for 6 days with heat preservation at the temperature of between 38 DEG C and 40 DEG C, and curing. The flavor mushroom sauce has rich nutriments, can be directly eaten, and can also be used as a seasoning and added during meal cooking; and the fermentation time can be effectively shortened, the amino acid nitrogen content is improved by over 43 percent, and the sauce has richer fragrance and a prominent delicious flavor.

Owner:山东创新源农业技术开发有限公司

Method for producing small peptide beverages by fermenting yellow serofluid produced by processing beancurd

InactiveCN101967437AGood health effectMask beany smellMicroorganism based processesAlcoholic beverage preparationAglyconeLactalbumin

The invention mainly relates to a method for producing small peptide beverages by fermenting yellow serofluid produced by processing beancurd, comprising the following steps: cooling the fresh yellow serofluid and adding flavourzyme (with activity being not lower than 120units / mg) for hydrolysis, and ensuring the content of amino acid nitrogen to be over 0.1% after hydrolysis of lactalbumin is completed; killing enzyme: heating the hydrolyzate to 90 DEG C and maintaining the temperature for 15min; adding 6-8% of dissolved white sugar while the hydrolyzate is hot, stirring the mixture uniformly and lowering the temperature to 28 DEG C; inoculating 0.5% of saccharomyces cerevisiae solution, maintaining the temperature between 28 DEG C and 32 DEG C for fermentation for 2d and finally maintaining the alcoholic strength between 1% and 2%; and carrying out post-fermentation, filtering and clarifying and pasteurization, thus producing the peptide beverages containing alcohol. The method has the following advantages: the method is reasonable in process, simple in operation and short in process period; fewer nutrients in the yellow serofluid are lost and the yellow serofluid contains soluble protein peptides; and isoflavone is transformed to active aglycone after microbial fermentation, thus the small peptide beverages are rich in nutrients and can realize industrial production.

Owner:HUNAN AGRICULTURAL UNIV

Process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans

ActiveCN103932077AEasy to operateReduce dependenceFood dryingFood preparationBiotechnologyNeutral protease

The invention discloses a process-controlled rapid fermentation processing method of pure strains of Liuyang salt black beans. The method comprises the following steps: removing impurities of fresh black beans; soaking; steaming at high pressure to ensure that proteins are denatured properly and cooling; inoculating aspergillus oryzae for enlarge cultivation and uniformly stirring for fermentation starter propagation; naturally cooling prepared cooked yeast, wherein protease activity is 800-1,200 unit / g dry basis (based on neutral protease); adding hot water and stirring; rapidly draining and adding small amount of salt or white spirit; uniformly stirring and compacting and putting into a sealing interlayer tank for heat-preservation fermentation so that fermented amino acid nitrogen is up to more than 0.55 percent; finally, dehydrating and drying by using continuous flow belt type drying equipment so that the water content of the product is less than 15 percent, the amino acid nitrogen is more than 0.85 percent, and the bacterial quantity is less than 103 cfu / g. The quality of the product is stable, the key procedures of each process are controlled in an interlocking mode and have synergistic effects, and the process from material input to acquisition of finished product only needs 15-25 days. The method is short in process period and stable in quality, and a production method and a production process with high efficiency, standardization, large scale, continuity and feasibility are provided for safe and convenient low-salt or salt-free Liuyang salt black bean products.

Owner:HUNAN AGRICULTURAL UNIV

Production technology for ultrafine low-salt low-fishy smell prawn paste

The invention relates to a production technology for an ultrafine low-salt low-fishy smell prawn paste. The method comprises the following steps: cleaning a raw material fresh prawn and removing impurities, performing superfine grinding, performing high pressure homogenization, adding salt and edible alcohol for assisting solubilization, fermenting, loading, killing enzyme and sterilizing. According to the prawn paste finished product, salinity content is 2-20% and amino acid nitrogen content is 1.5-2.0%. The prawn paste has the advantages of short production time (11-16days), fine mouthfeel, safety and healthy, and low salt content, has proper seafood flavor, changes the problems of heavy salty and fishy smell, rough mouthfeel and easy layering of a traditional shrimp paste, and accords with modern production and living requirements for people.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

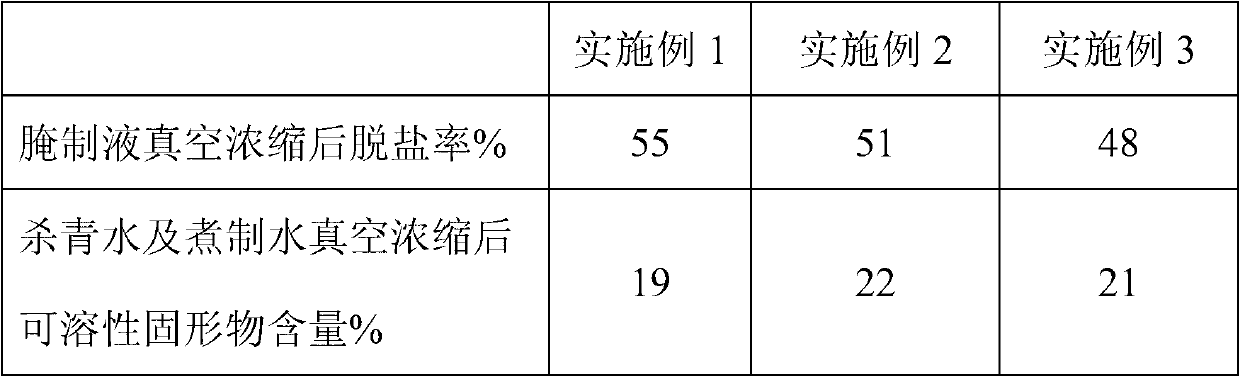

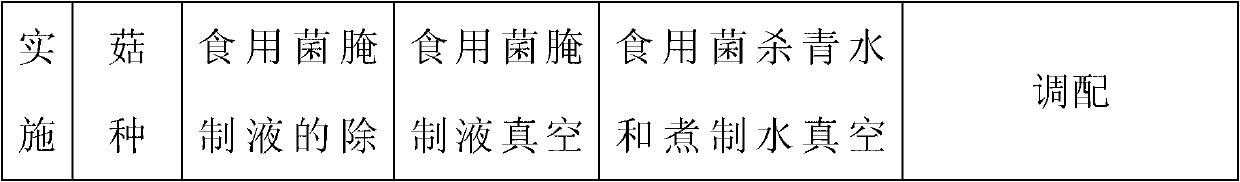

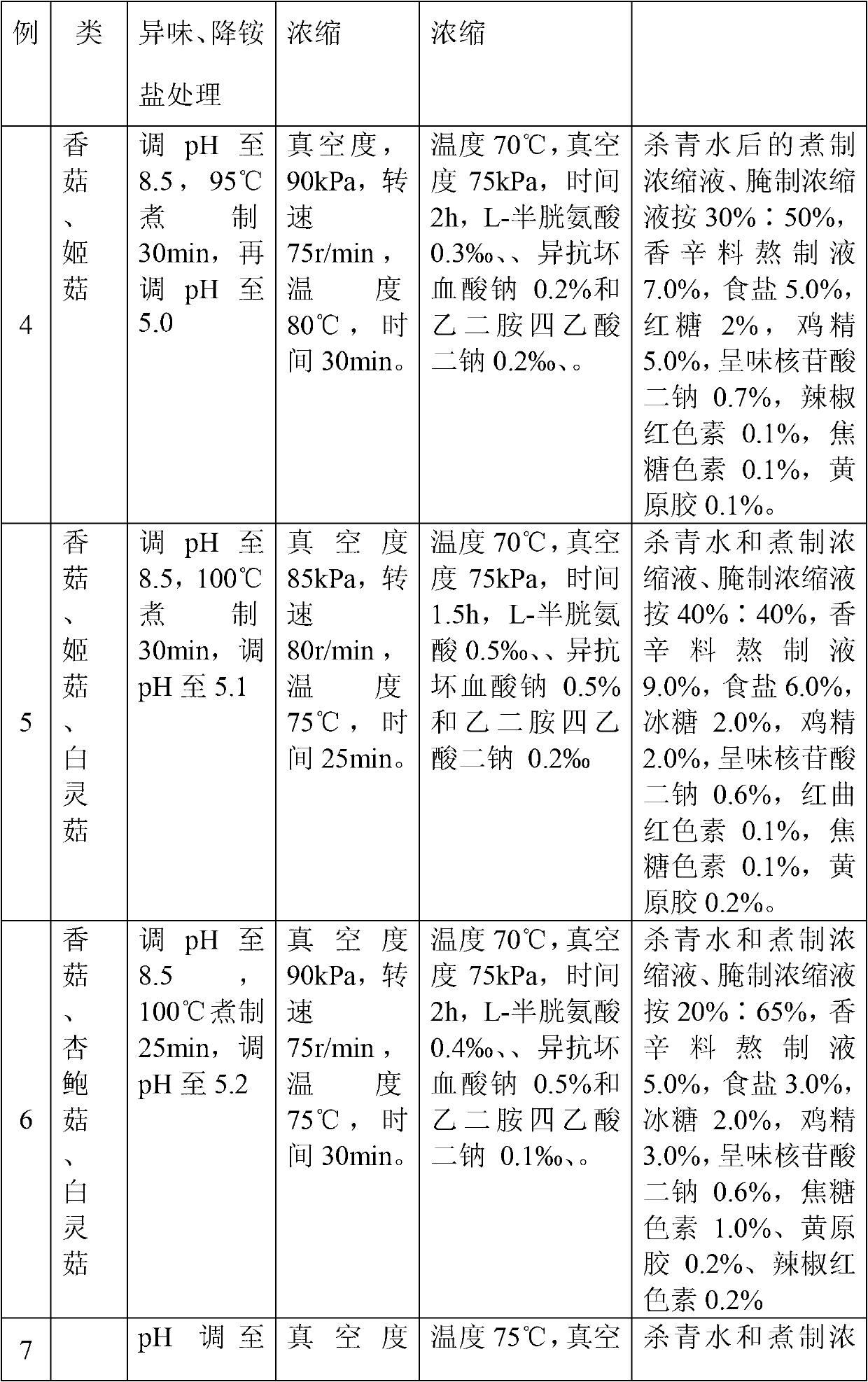

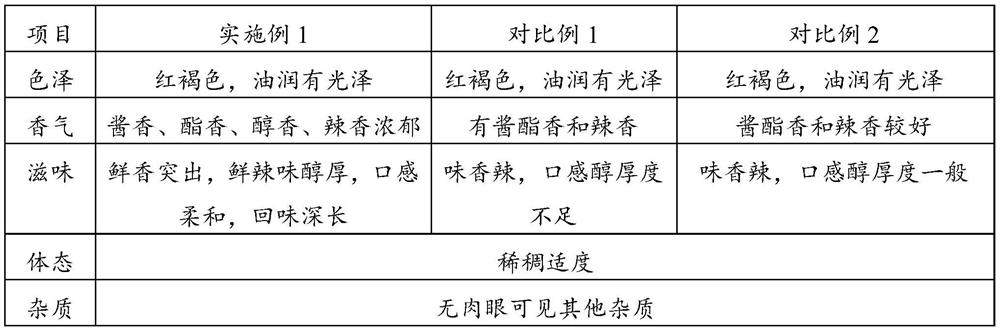

Seasoning with edible mushroom flavor and production method of seasoning

InactiveCN102715486AMaintain Nutritious FlavorStrong fragranceFood preparationSoluble solidsChemistry

The invention discloses a seasoning with edible mushroom flavor. The seasoning comprises the following raw materials in percentage by mass: 30-70 percent of edible mushroom curing concentrated liquid, 20-50 percent of edible mushroom green-removing water and boiling water concentrated liquid, 5.0-15.0 percent of spicery boiling liquid, 1.0-12.0 percent of salt, 2.0-5.0 percent of sugars, 0.5-8 percent of essence of chicken; 0.1-1.0 percent of disodium 5'-ribonucleotide, 0.1-1.5 percent of caramel pigments, 0.1-0.3 percent of xanthan gums and 0.1-0.5 percent of haematochrome. The seasoning with the edible mushroom flavor is prepared by carrying out odor removal, ammonium salt drop treatment, vacuum concentration desalting treatment on edible mushroom processing waste water, boiling, mixing the raw material components and sterilizing at the high temperature. The seasoning contains components such as amino acid nitrogen, protein type nitrogen-containing compounds, saccharides, vitamins, mineral substances, organic acid, organic ester, organic alcohol and organic aldehyde, so that the original nutrition flavor of the edible mushroom is maintained, and the product has the characteristics of color, aroma, taste and the like; the production method is simple to operate, is high in desalting ratio, stable in soluble solid contents, wide in sources and considerable in economic value; and moreover, the raw materials is cheap and available. The method turns waste into treasure so as to facilitate environment friendliness.

Owner:CHONGQING ACAD OF AGRI SCI

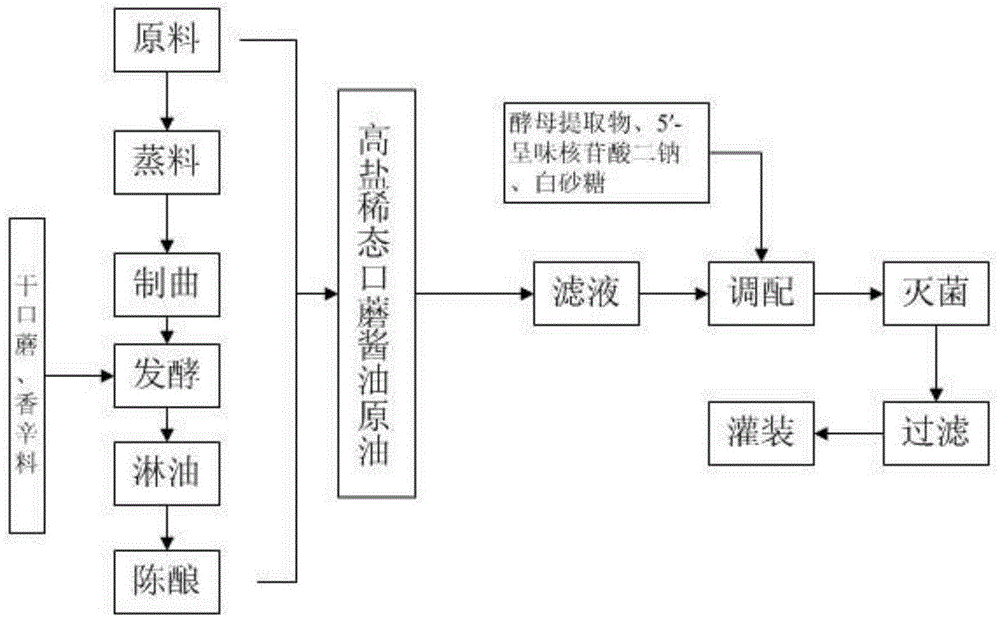

Tricholoma soybean sauce and preparation method thereof

ActiveCN105211833AAvoid koji making difficultiesAvoid the disadvantage of low formation rate of amino acid nitrogenFood preparationMonosodium glutamateAdditive ingredient

The invention discloses tricholoma soybean sauce and a preparation method thereof. The tricholoma soybean sauce is prepared from, by mass, 100 parts of high-salt liquid-state tricholoma soybean sauce crude oil, 0.1-1 part of yeast extract, 0.01-0.5 part of disodium 5'-ribonucleotide and 0.5-5 parts of white granulated sugar. The preparation method includes the steps that raw materials are fermented to prepare the high-salt liquid-state tricholoma soybean sauce crude oil first; then the yeast extract, the disodium 5'-ribonucleotide and the white granulated sugar are blended; at last, sterilizing and filling are carried out, and accordingly a finished tricholoma soybean sauce product is obtained. According to the tricholoma soybean sauce and the preparation method thereof, the defects that starter-making by fresh mushroom is difficult, and the production rate of amino acid nitrogen is low in the prior art are overcome; preparation is not limited by tricholoma harvesting seasons, and the prepared tricholoma soybean sauce is strong in fragrance, obvious in delicate flavor and more abundant in nutritional ingredient; besides, various spices are participated in fermentation, and thus the purposes of not adding monosidum glutamate and preservatives are achieved.

Owner:四川清香园调味品股份有限公司

Preparation method of soybean and chili compound fermented sauce, hotpot condiment and preparation method thereof

ActiveCN111838644ARich sauceStrong ester aromaYeast food ingredientsClimate change adaptationBiotechnologySaccharomyces rouxii

The invention provides a preparation method of soybean and chili composite fermented sauce, a hotpot condiment and a preparation method of the hotpot condiment. The preparation method of the compositefermented sauce comprises the following steps: mixing fermented soybeans and fermented chilies, and carrying out secondary fermentation to obtain the soybean and chili composite fermented sauce. Thefermented soybeans are prepared by the following method: baking soybeans, moistening the soybeans with water, mixing the soybeans with broad bean powder, inoculating aspergillus oryzae yeast refined koji to obtain soybean koji, mixing the soybean koji with saline water, and adding lactobacillus casei liquid, saccharomyces rouxii liquid and torulopsis liquid in the fermentation process to obtain fermented soybeans, and the fermented chilies are prepared by the following steps: crushing chilies, mixing the crushed chilies with saline water, and adding lactobacillus brevis liquid in the fermentation process to obtain the fermented chilies. The composite fermented sauce has relatively high contents of amino acid nitrogen, total phenols and total flavonoids. Compared with traditional Pixian thick broad-bean sauce, the composite fermented sauce is low in cost, excellent in quality and high in nutritional value. The hotpot condiment prepared from the compound fermented sauce is better in sauce flavor and high in taste acceptability.

Owner:四川川娃子食品有限公司 +1

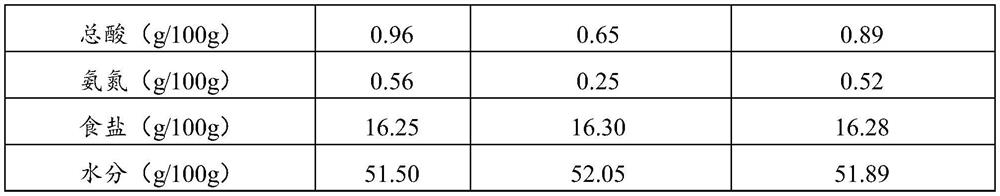

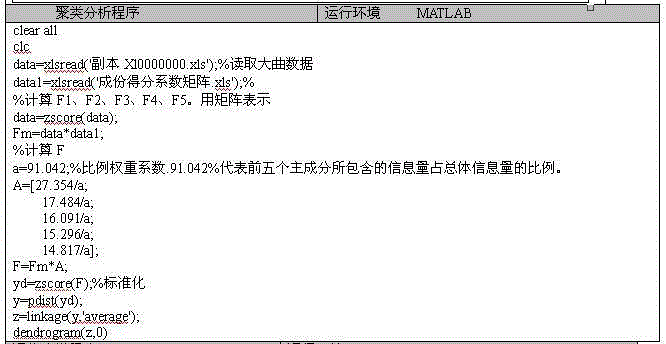

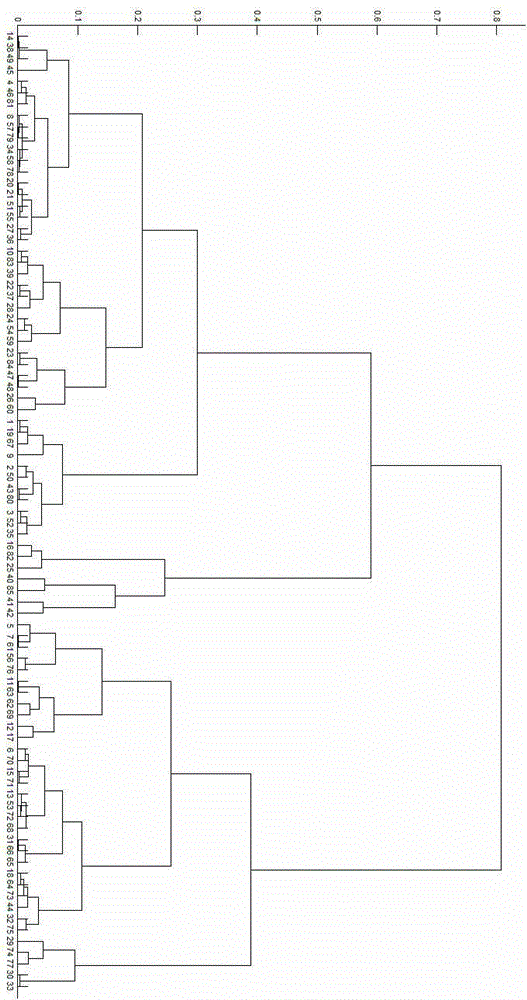

Quality evaluation method and system for strong-flavor distiller's yeast

InactiveCN104865360AReduce the impact of Daqu quality judgmentEvaluation scienceTesting beveragesPrincipal component analysisOperability

The invention belongs to the technical field of wine brewing, and particularly relates to a quality evaluation method and system for strong-flavor distiller's yeast. The quality evaluation method is characterized by comprising the following steps: selecting a whole block of distiller's yeast from a strong-flavor finished distiller's yeast store, carrying out sensory quality evaluation, and determining the finished distiller's yeast with qualified sensory evaluation by seven indicators, namely the acidity, the moisture, the volume weight of the distiller's yeast block, the liquor-producing power, the esterifying power, the amino acid nitrogen and the starch conversion ratio; carrying out analysis and computation on the seven physical, chemical and biochemical indicators of the distiller's yeast sample by virtue of a principal component analysis method of SPSS13.0; selecting a few of previous principal components, determining the weights through the information proportion of various components, building a comprehensive evaluation model for the distiller's yeast quality, and then calculating quality characterization values F of each distiller's yeast through matlab software; carrying out clustering analysis on the values F, and then dividing the distiller's yeast quality into four grades. According to the method and the system, human disturbance factors are reduced; the method and the system are objective, scientific, simple and convenient to use, high in operability and accurate.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

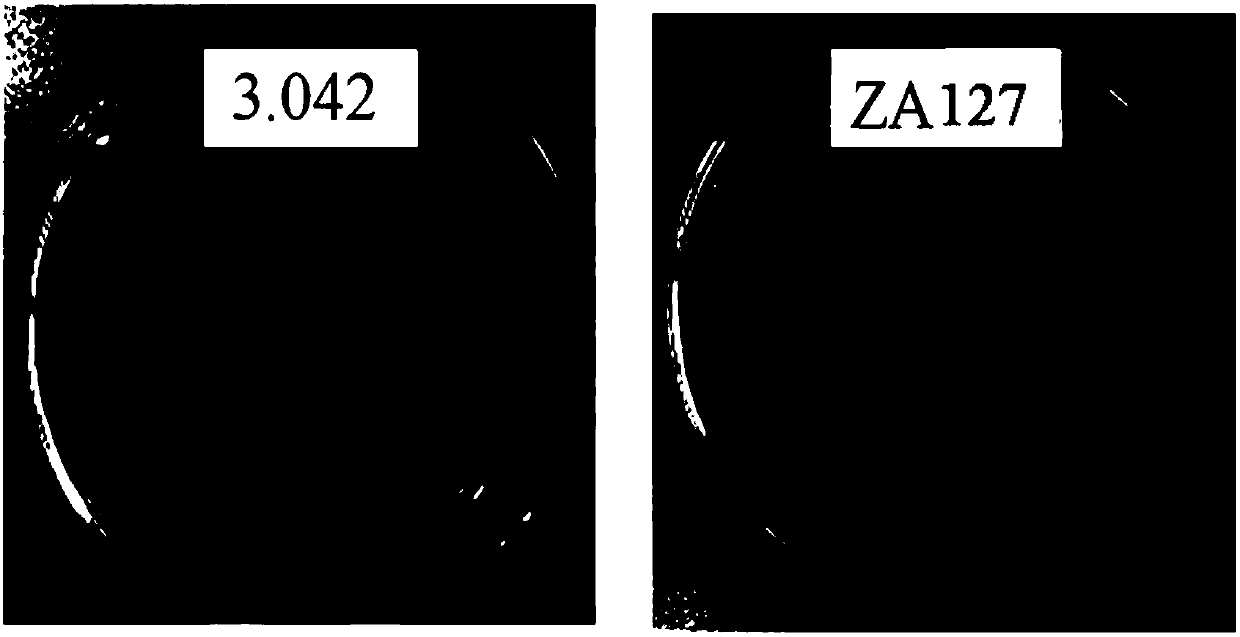

Aspergillus oryzae ZA127 and application thereof

ActiveCN107699499AEasy to trainGood strain substitutionFungiMicroorganism based processesProteinase activityAspergillus oryzae

The invention provides an aspergillus oryzae ZA127 suitable for vinegar production and also relates to an application of the aspergillus oryzae in increasing the contents of amino acid nitrogen and ester in liquid fermented edible vinegar and comprehensively promoting the flavor and quality of the liquid fermented edible vinegar. The aspergillus oryzae ZA127 provided by the invention is high in protease activity and esterifying enzyme activity and is suitable for producing raw fresh vinegar. The invention also relates to a preparation technology for aspergillus oryzae complex enzyme culture. According to the preparation technology, the amino nitrogen and total ester content in the liquid fermented edible vinegar can be obviously promoted and the taste and flavor of the liquid fermented edible vinegar can be greatly improved.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

Millet sake and preparation method thereof

ActiveCN102329709AGolden colorMild and soft tasteAlcoholic beverage preparationMicroorganism based processesRhizopusSolid matter

The invention discloses millet sake, which is characterized by being prepared by using millet powder as a raw material and carrying out liquid primary fermentation and secondary fermentation on the millet powder; a strain used in the fermentation is rhizopus koji with a content which is 1-2% of the weight of the millet powder and yellow wine dry yeast with a content which is 0.15-0.2% of the weight of the millet powder; the temperature of the primary fermentation is 28-30 DEG C; the time is 4-6 days; the temperature of the secondary fermentation is 15-18 DEG C; and the time is 15-20 days. The color and the luster of the sake prepared by the invention are natural and golden; the taste is mellow, mild, gentle, clean and dainty, and has a faint scent, harmonious flavors, a long aftertaste and a unique style; the main physicochemical indexes of the sake are as follows: the alcoholic strength is not less than 11.0 %voL; the total acid is 3.0-7.0 g / L; the total sugar is not more than 15.0 g / L; the nonsugar solid matter is not less than 15.0 g / L; and the amino acid nitrogen is 0.20-0.30 g / L.

Owner:邯郸市禾黍农业开发有限公司

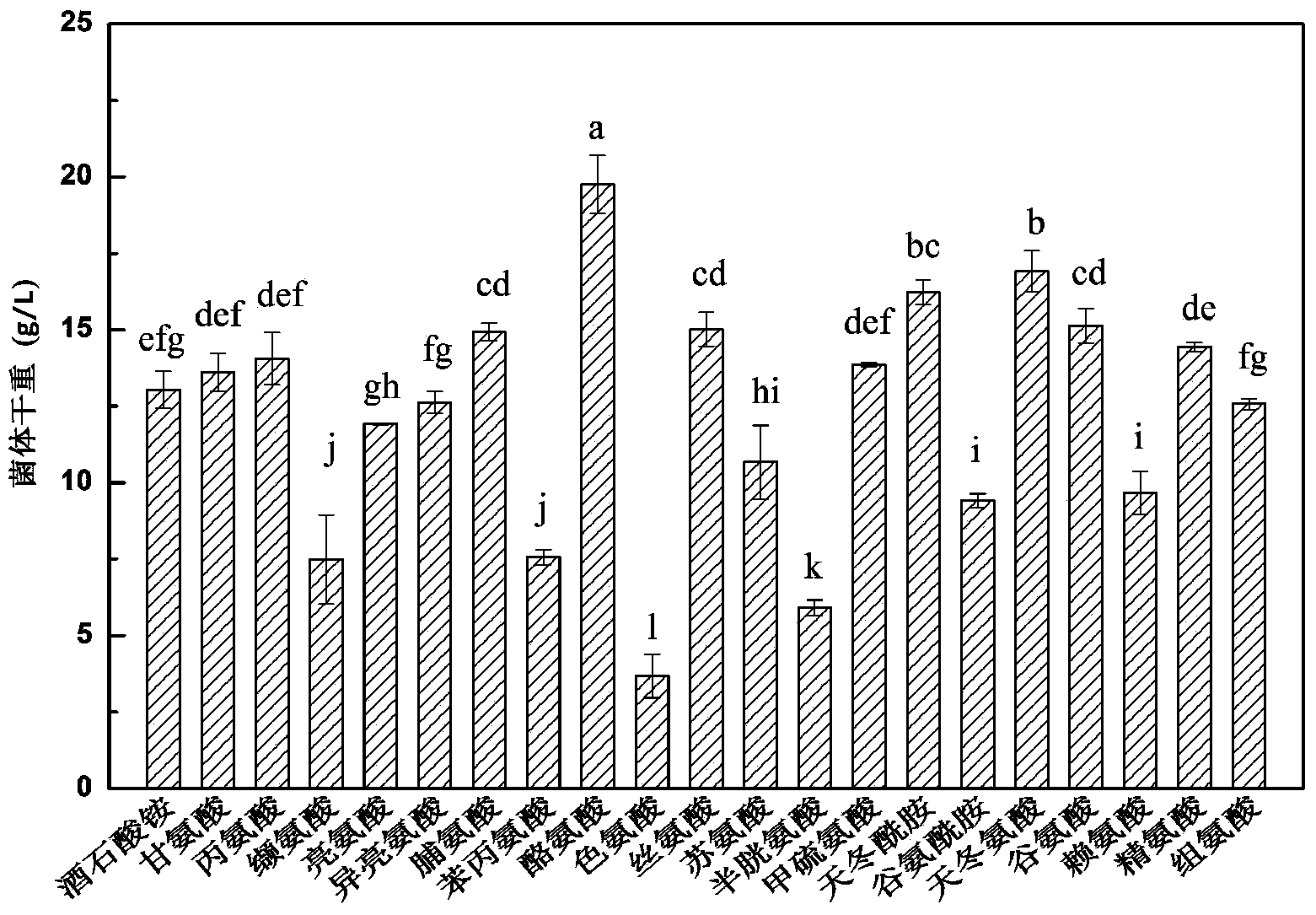

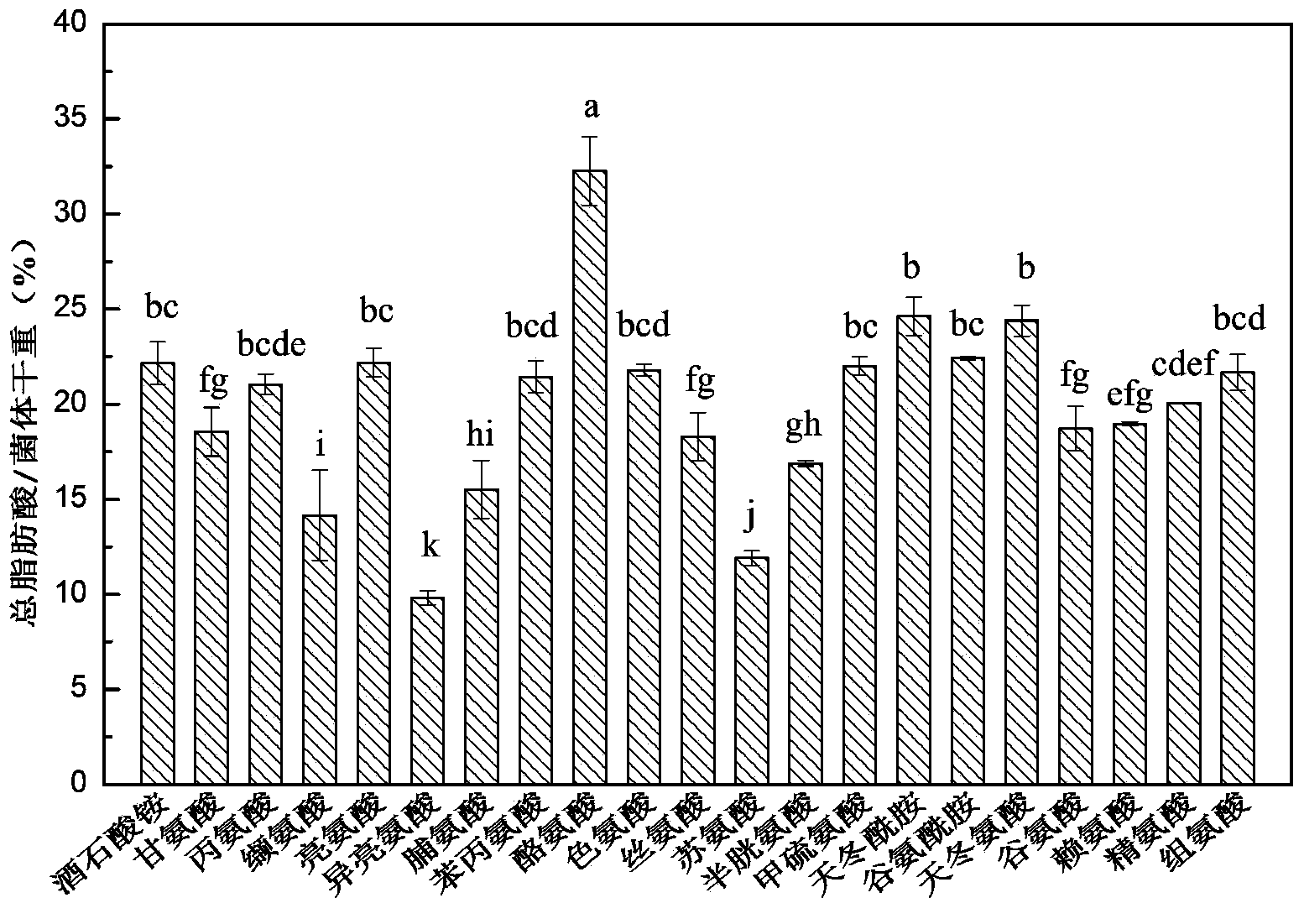

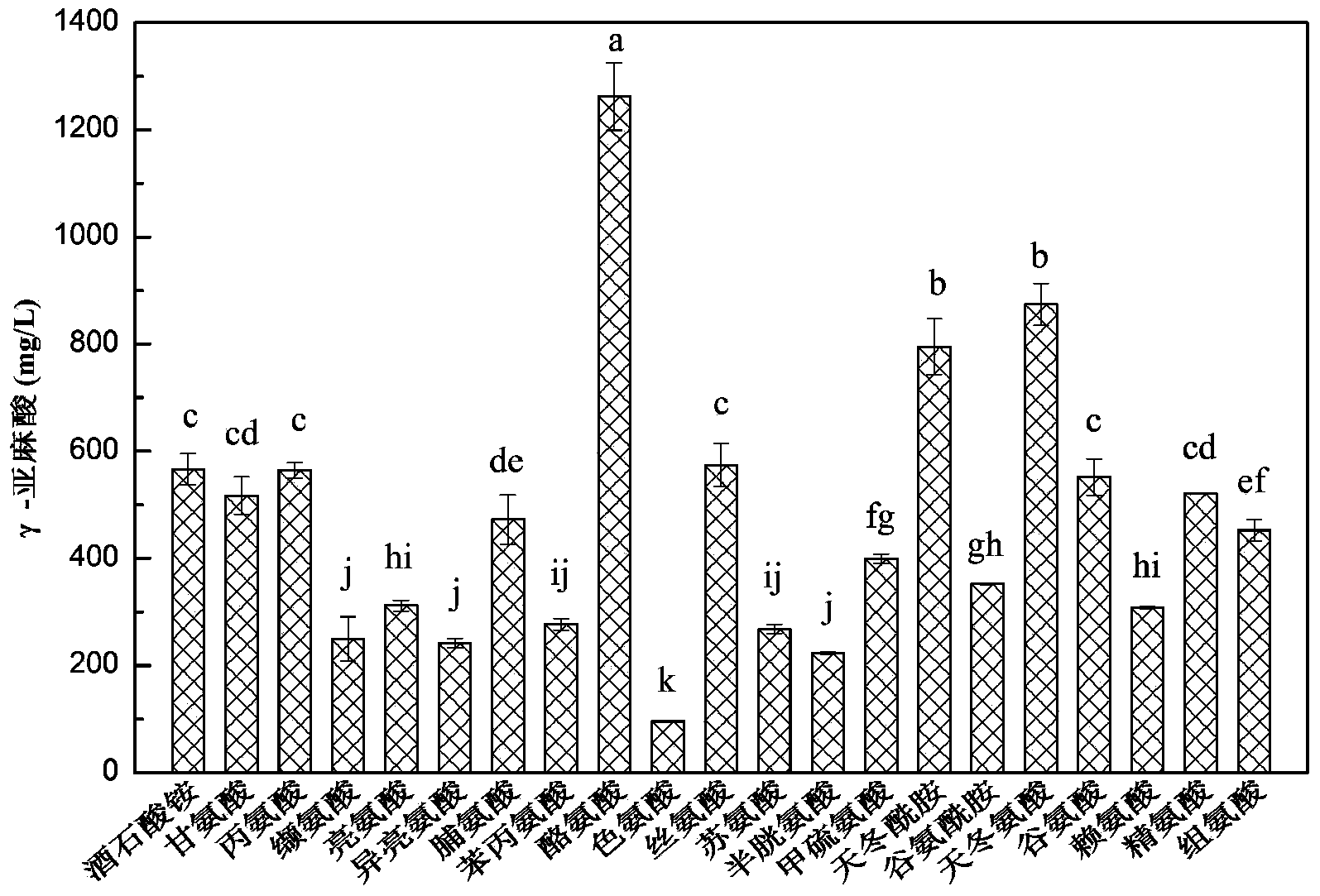

Fermentation medium for improving yield of gamma-linolenic acid produced from mucorcircinelloides and use

InactiveCN103642859AIncrease productionLower requirementMicroorganism based processesFermentationTyrosineBiological activation

The invention relates to a fermentation medium for improving the yield of gamma-linolenic acid produced from mucorcircinelloides CBS108.16. The fermentation medium contains amino acid nitrogen sources of tyrosine, asparagine or aspartic acid. The invention also relates to a method for improving the yield of gamma-linolenic acid produced from the mucorcircinelloides CBS108.16 by using the fermentation medium. The method comprises the steps of strain activation, seed culture, fermentation culture, drying and the like. According to the fermentation medium and the method, the biomass of a mucorcircinelloides CBS108.16 thallus reaches 16.5 to 19.8g / L, and is increased by 25 to 52 percent compared with that of a control group; the fatty acid content of the mucorcircinelloides CBS108.16 thallus reaches 24 to 35 percent, and is increased by 11 to 48 percent compared with that of the control group; the content of gamma-linolenic acid in fermentation broth reaches 810 to 1300mg / L, and is increased by 41 to 124 percent compared with that of the control group. An operating process is simple and convenient, requirements on processing equipment are low, and the yield is remarkably improved, so that the method has broad application prospect.

Owner:JIANGNAN UNIV

Fresh waxy corn brewed wine brewing method

InactiveCN101709253AExtended shelf lifeIncrease nutritionMicroorganism based processesAlcoholic beverage preparationWaxy cornAlcohol content

The invention provides a fresh waxy corn brewed wine brewing method, relating to the production method of wine; fresh waxy corn is taken as raw material, and then the processes of gelatinization, grinding, enzymolysis, tank containing, harrowing primary fermentation, secondary fermentation and winepress are carried out to prepare the wine; in the invention, proteinase is used for carry out enzymolysis to rich protein in fresh waxy corn pulp, so as to lead the amino acid nitrogen content of product to be more than 0.02 percent; the alcoholic strength of the product is 8-12 percent, the color and luster are golden yellow, clean and clear, the product has special sweet smell of fresh waxy corn brewed wine, has pure and mild and full taste and aftertaste, is rich in amino acids, vitamins and trace elements, and has long shelf life, therefore, the fresh waxy corn brewed wine has high nutrition and low alcohol content.

Owner:吉林粮食集团长白山天池生态食品股份有限公司

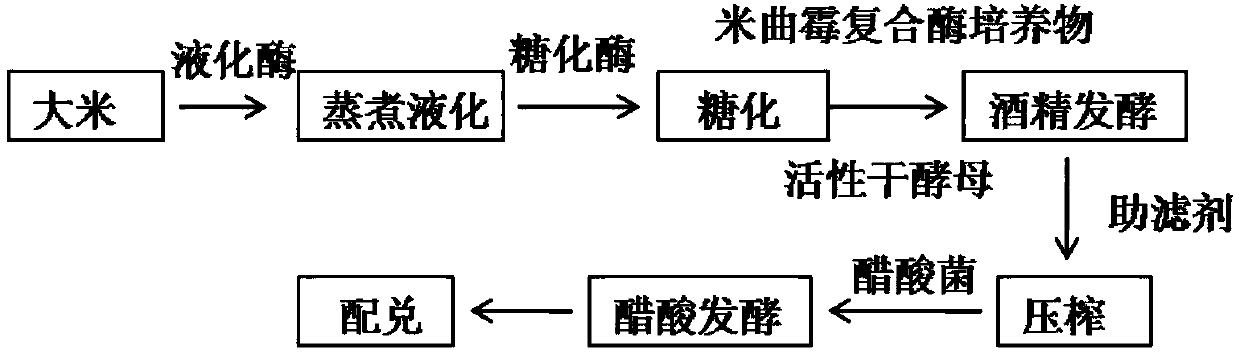

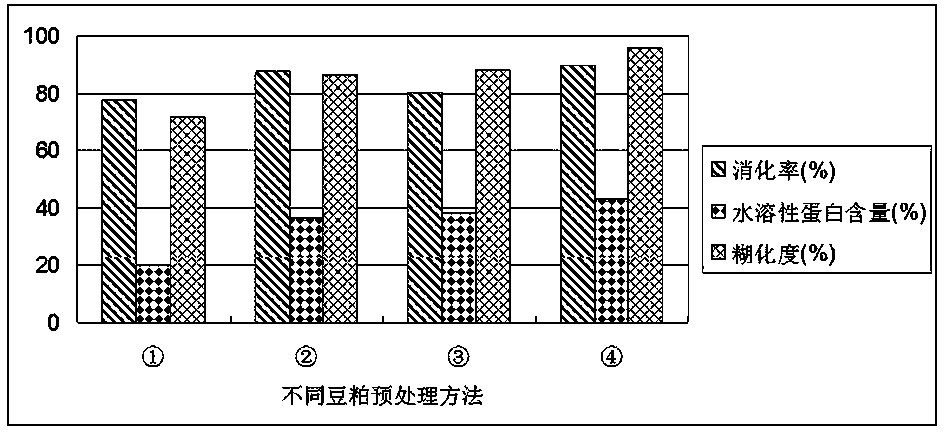

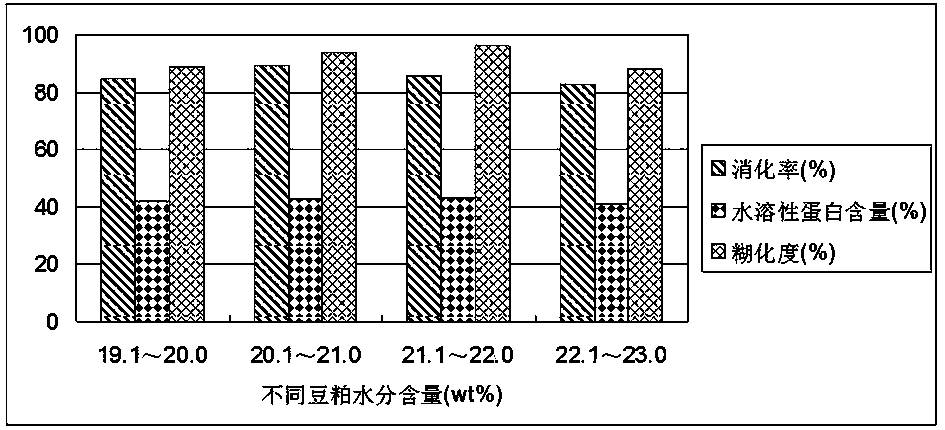

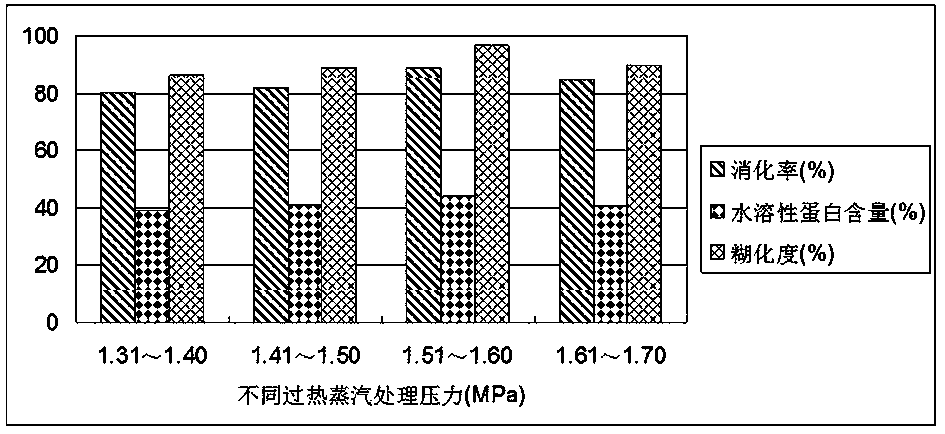

Method for making high-freshness soy sauce through starter propagation by bean dregs

InactiveCN107927709AImprove digestibilityIncrease water soluble protein contentFood scienceGeneration rateDecomposition

The invention discloses a method for making high-freshness soy sauce through starter propagation by bean dregs. The method comprises the following steps that the bean dregs are subjected to normal pressure steam pretreatment, bean dreg overheat steam puffing treatment, material mixing, inoculation starter propagation and big tank fermentation. The bean dregs subjected to steam pretreatment is subjected to overheat steam puffing treatment; then, bran and red kojic rice powder mixed materials are matched for performing a temperature control and humidity control starter propagation process; finally, an open air glass fiber tank is used for high-salt diluted state fermentation. The raw material protein degradation and starch particle disaggregation can be stably controlled; the decomposition of aspergillus oryzae Huniang 3.042 self enzyme system on the protein and the starch can be promoted; the raw material protein utilization rate and amino acid generation rate can be improved; the economic benefits are obvious. The obtained fermented soy sauce has good flavor, intense and mellow fragrance and high amino acid nitrogen content.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for producing biological feed with palm meal

InactiveCN110463828AImprove farming efficiencyReduce the cost of farmingFungiBacteriaOligosaccharideLysine

The invention discloses a method for producing biological feed with palm meal. The palm meal is used as a raw material, and palm meal fermented feed good in palatability, high in energy and protein utilization, and rich in probiotics, small molecular peptide, lactic acid, biological enzyme and oligosaccharide is obtained by using a way of combining enzymatic hydrolysis and microbial fermentation.According to the palm meal fermented feed obtained by the method, as for testing results, the pH is 4.2-5.0, NDF is 33-40%, the small molecular peptide content is 27-33%, the amino acid nitrogen content is 1.89-2.10%, the crude protein content is 13.5-17.0%, the crude protein content is slightly higher than that of a starting material, the lactic acid bacterial colony number is 5.1-7.0*10<8> cfu / g, the bacillus subtilis number is 6.2-8*10<9> cfu / g, the protease activity is 120-210 u / g, the saccharifying enzyme activity is 310-620 u / g, the mannase activity is 1.5-2.8 u / g, certain amount of vitamins, trace elements, lysine and methionine are added, 20-40% (1 to 1 equivalent replacement) of animal full-price diets can be replaced, the cultivation cost is lowered, and the cultivation benefit is improved.

Owner:宁夏健力肽生物科技有限公司

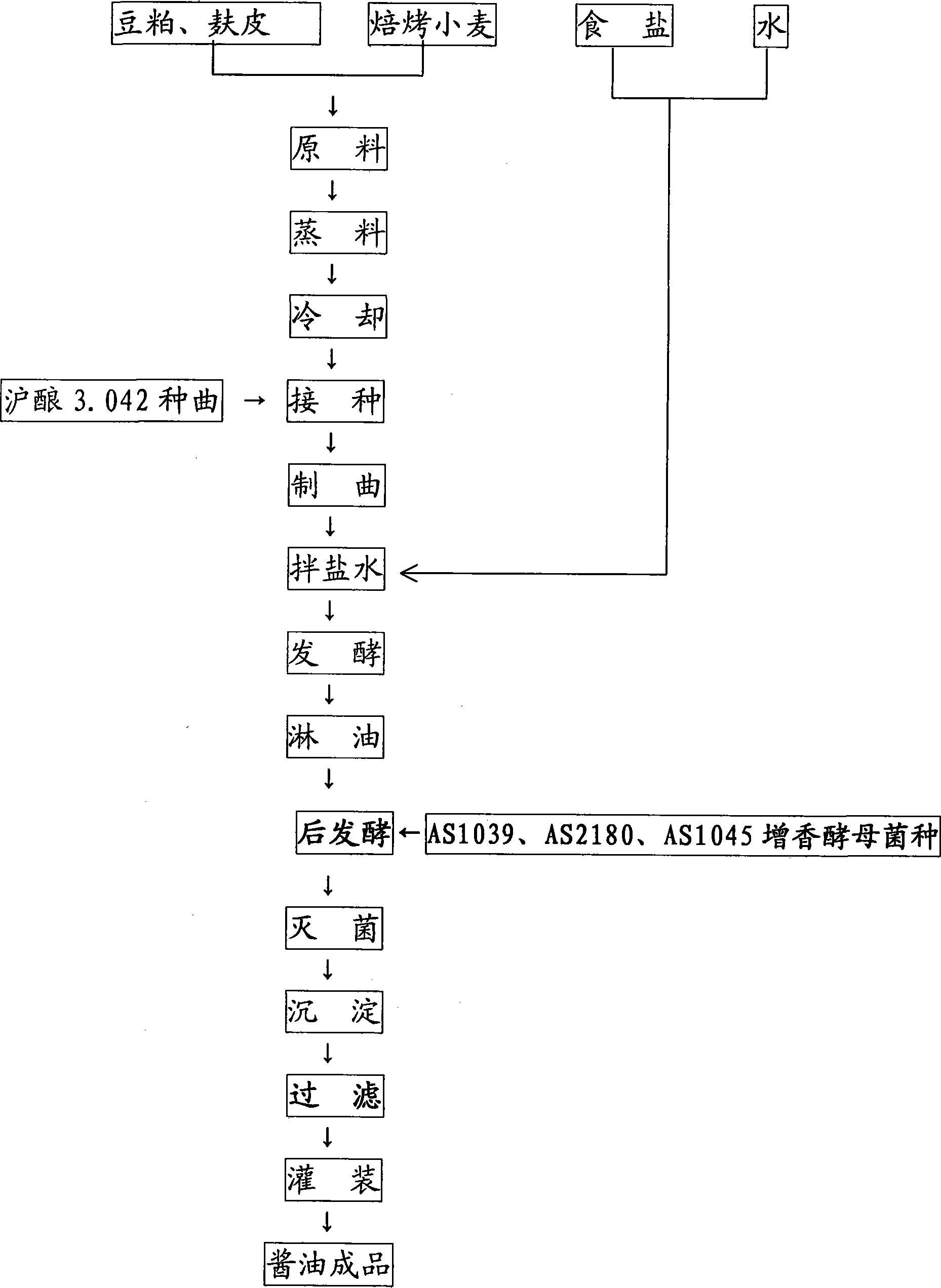

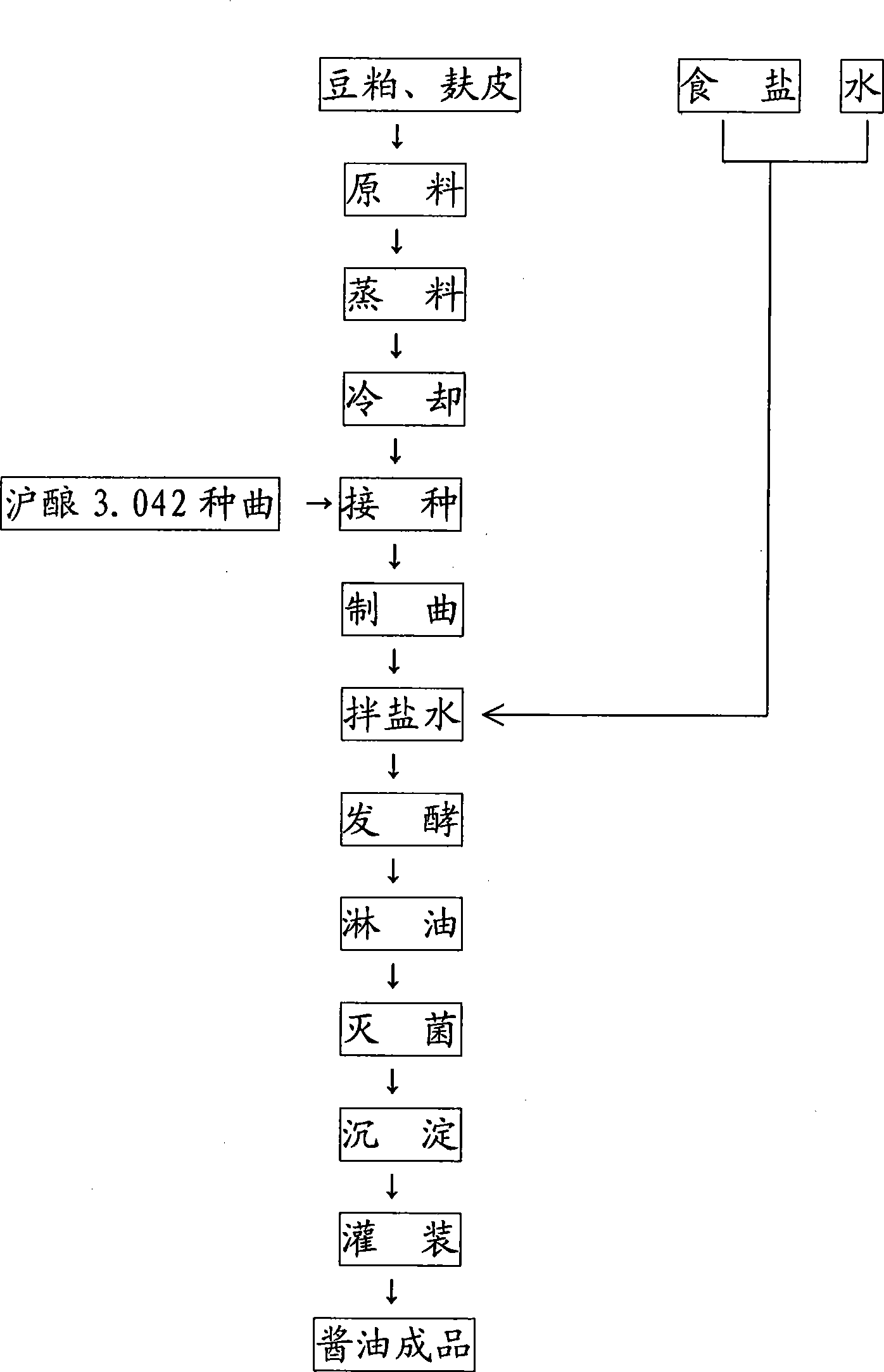

Production method of soy sauce

InactiveCN101380093AEnsure safetyIncreased vegetable protein contentFood preparationBenzoic acidEscherichia coli

The invention relates to a production method of soy sauce products, belonging to the field of soy sauce production. The method of key point top optimizing includes the following production steps: raw material stewing, cooling, inoculation, starter propagation, salt solution blending, fermentation, oil spraying, sterilizing, precipitation and filling to obtain the soy sauce; the raw materials are added with baked wheat which is non-transgenic product and can meet green standards, over 45% of vegetable protein and 80 parts of bran; bean pulp : bran: baked wheat is equal to 55: 33: 12; starter propagation is carried out at 32 DEG C and lasts for 38-40 hours; fermentation is carried out at 40 DEG C and lasts for 35 days; secondary fermentation is additionally carried out at 30 DEG C for 10 days and aroma yeast is added; filtering is additionally carried out; the soy sauce indexes include the indexes of amino-acid nitrogen, total nitrogen, soluble non-salt solid matter, aminium salt, total acid, aflatoxin, colon bacillus and total number of bacterial colony which meet the national standards, benzoic acid and chloro-propanediol are not allowed to be detected, and sorbic acid, lead and total arsenic are strictly controlled, the indexes of chroma and clarity are improved, and except for potassium sorbate, no additive is added. The production method, used for producing soy sauce, is scientific and can produce high-quality products.

Owner:北京六必居食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com