Seasoning with edible mushroom flavor and production method of seasoning

A technology of edible mushrooms and condiments, which is applied in the field of food processing, can solve the problems of low nutritional content and difficulty in direct utilization, and achieve the effects of wide sources, reduced loss of flavor substances, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

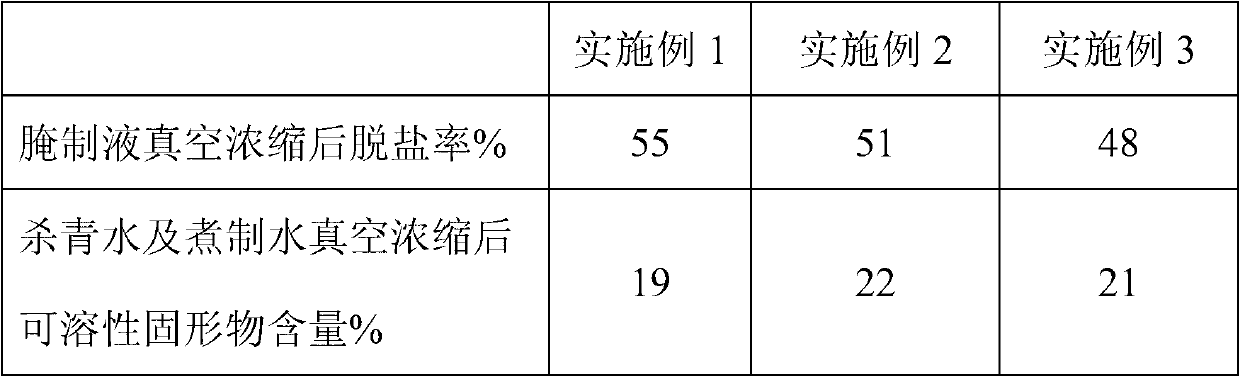

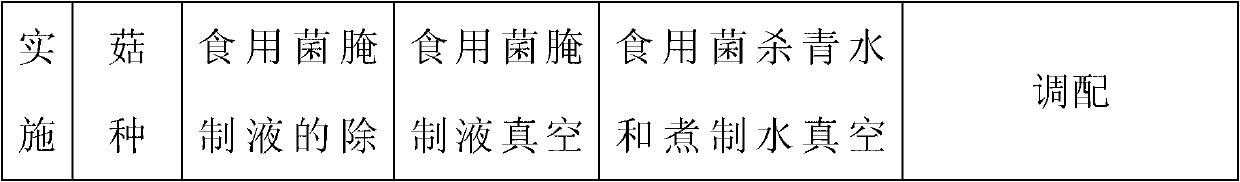

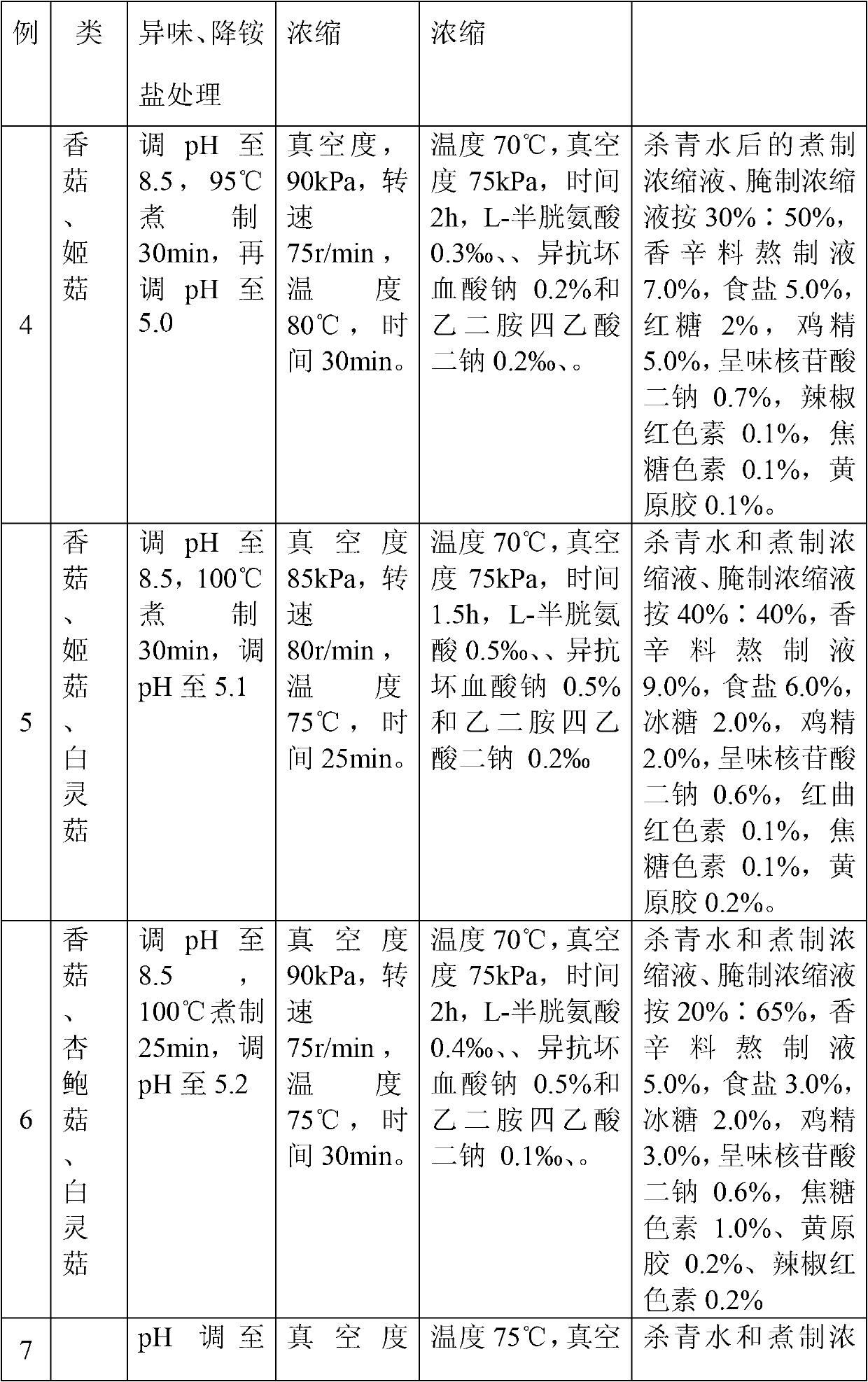

Examples

example 1

[0043] A. Raw material preparation

[0044] Deodorization and ammonium reduction treatment of tea tree mushroom pickling solution: filter the tea tree mushroom pickling solution through four layers of gauze and let it stand at 4°C for clarification, take the supernatant, and adjust the pH to 8.5 with 1mol / L sodium hydroxide aqueous solution , boil it at 95°C for 30 minutes, then use 1mol / L lactic acid aqueous solution to adjust the pH to 5.0, and let it cool naturally to room temperature;

[0045]After the deodorization and ammonium reduction treatment, the tea tree mushroom pickling solution is concentrated in vacuum for 30 minutes at a vacuum degree of 80kPa, a rotation speed of 60r / min, and a temperature of 75°C, and then centrifuged to obtain the tea tree mushroom pickling concentrate;

[0046] Filter the greening water and boiling water of tea tree mushroom with four layers of gauze, let it stand at 10°C for clarification, take the supernatant, concentrate it at a tempera...

example 2

[0051] A. Raw material preparation

[0052] Deodorization and ammonium reduction treatment of Flammulina velutipes pickling solution: Filter the Flammulina velutipes pickling solution through four layers of gauze and let it stand for clarification at 4°C, take the supernatant, adjust the pH to 9.0 with 1mol / L sodium hydroxide aqueous solution, and then Cook at 98°C for 25 minutes, then use 1mol / L lactic acid aqueous solution to adjust the pH to 4.8, and cool naturally to room temperature;

[0053] After deodorizing and ammonium-reducing treatment, the enoki mushroom pickling solution was vacuum-concentrated for 25 minutes at a vacuum degree of 90kPa, a rotating speed of 75r / min, and a temperature of 80°C, and then centrifuged to obtain the enoki mushroom pickling concentrate;

[0054] Use four layers of gauze to clear the greening water of Flammulina velutipes, let it stand at 10°C for clarification, take the supernatant, concentrate it for 2 hours at a temperature of 80°C, an...

example 3

[0059] A. Raw material preparation

[0060] Deodorization and ammonium reduction treatment of Pleurotus eryngii pickle solution: filter the Pleurotus eryngii pickle solution through four layers of gauze, let it stand at 4°C for clarification, take the supernatant, and adjust the pH with 1mol / L sodium hydroxide aqueous solution to 8.5, cook at 95°C for 30 minutes, then adjust the pH to 5.0 with 1mol / L lactic acid aqueous solution, and cool naturally to room temperature;

[0061] The Pleurotus eryngii pickling solution treated with deodorization and ammonium salt reduction is vacuum-evaporated and concentrated for 35 minutes at a vacuum degree of 75kPa, a rotation speed of 60r / min, and a temperature of 80°C, and then centrifuged to obtain the Pleurotus eryngii pickle concentrate;

[0062] Filter the boiling water of Pleurotus eryngii with four layers of gauze, let it stand at 10°C for clarification, take the supernatant, concentrate it for 2 hours at a temperature of 70°C and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com