Brewing technology for soybean sauce

A technology and technology of soy sauce, which is applied in the field of soy sauce brewing technology, can solve the problems of high dependence on ambient temperature and light, and achieve the effects of improving protein utilization, bright red color, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

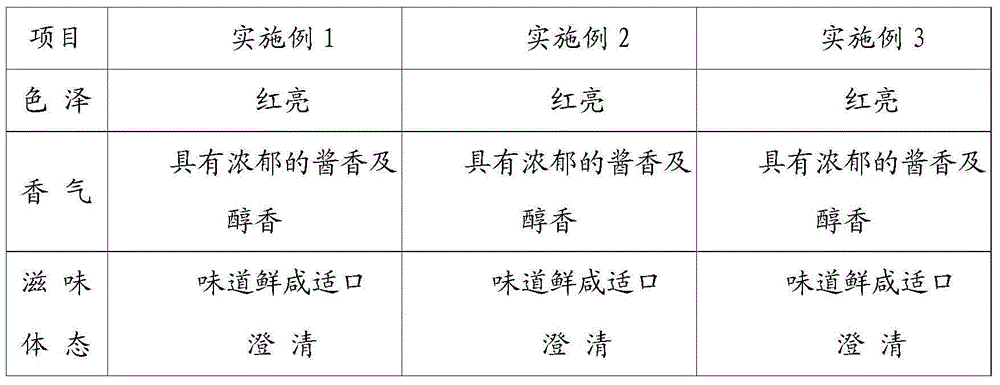

Examples

Embodiment 1

[0027] A brewing process of soy sauce is carried out in the following steps:

[0028] 1) Soaking beans: Pour soybeans and water into a steamer at a weight ratio of 1:2 to soak for 8 hours; when there is no groove between the watercress, it is judged as the end of soaking.

[0029] 2) Cooking: steaming the soaked soybeans with a cooking pressure of 0.1 MPa and a holding time of 5 minutes to obtain cooked beans.

[0030] 3) Mixing: mix flour and roasted wheat bran in a weight ratio of 7:3 to obtain a flour mixture; mix cooked beans and flour mixture in a weight ratio of 1:0.4 to obtain a mixture; The preparation method of the fried wheat bran is as follows: the wheat bran is fried at 120° C. for 3 minutes by using a drum-type roaster machine, and the obtained wheat bran is burnt yellow with a faint wheat fragrance, and the water content is reduced from 12% to 5.5%.

[0031] 4) inoculation: when the temperature of the mixture was reduced to below 30°C, inoculate Aspergillus oryz...

Embodiment 2

[0035] A brewing process of soy sauce is carried out in the following steps:

[0036] 1) Soaking beans: Pour soybeans and water into a steamer at a weight ratio of 1:2 to soak for 10 hours; during the soaking process, when there is no groove between the watercress, it is judged as the end of soaking;

[0037] 2) Cooking: steaming the soaked soybeans with a cooking pressure of 0.11 MPa and a holding time of 10 minutes to obtain cooked beans.

[0038] 3) Mixing: mix flour and roasted wheat bran in a weight ratio of 7:5 to obtain a flour mixture; mix cooked beans and flour mixture in a weight ratio of 1:0.5 to obtain a mixture; The preparation method of the fried wheat bran is as follows: the wheat bran is fried at 130° C. for 4 minutes by using a drum type roaster machine, and the obtained wheat bran is burnt yellow with a slight wheat fragrance, and the water content is reduced from 12% to 4.0%.

[0039] 4) inoculation: when the temperature of the mixture was reduced to below ...

Embodiment 3

[0043] A brewing process of soy sauce is carried out in the following steps:

[0044]1) Soaking beans: Pour soybeans and water into a steamer at a weight ratio of 1:2 to soak for 12 hours; during the soaking process, when there is no groove between the watercress, it is judged as the end of soaking.

[0045] 2) Cooking: steaming the soaked soybeans with a cooking pressure of 0.12 MPa and a holding time of 15 minutes to obtain cooked beans; the digestibility of the cooked beans is 90%.

[0046] 3) Mixing: mix flour and roasted wheat bran in a weight ratio of 7:6 to obtain a flour mixture; mix cooked beans and flour mixture in a weight ratio of 1:0.6 to obtain a mixture; The preparation method of the fried wheat bran is as follows: the wheat bran is fried at 140° C. for 5 minutes by using a drum-type roaster machine, and the obtained wheat bran is burnt yellow with a faint wheat fragrance, and the water content is reduced from 12% to 2.5%.

[0047] 4) inoculation: when the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com