Fermentation technology of novel thick broad-bean sauce special for seasoning

A fermentation process, Douban technology, applied in the field of new Douban fermentation technology for seasoning, can solve the problems of long production cycle, unstable product quality, poor product color, etc., achieve easy water absorption and starch gelatinization, and improve product safety , the effect of shortening the ripening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

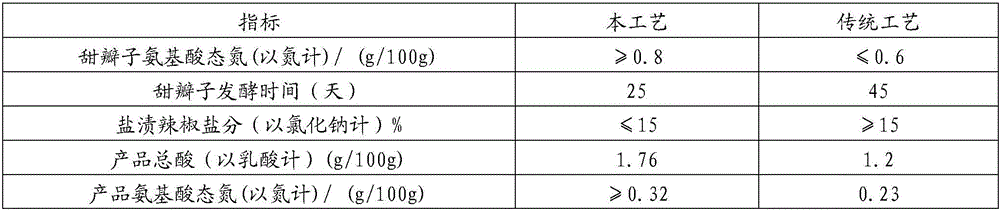

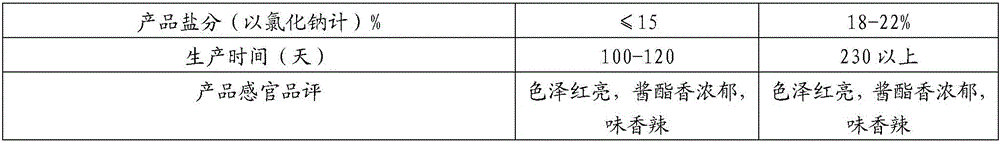

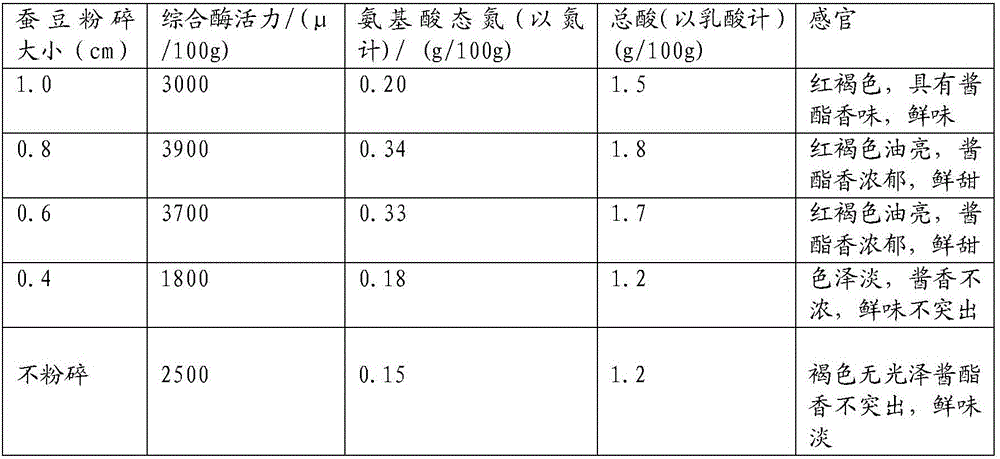

[0033] Screen broad beans with plump and uniform particles without mildew, remove sundries and slag shells, and crush 100 parts of shelled broad bean petals, the particle size is less than 1cm; put the crushed broad bean petals in hot water at about 96°C, and blanch Drain and cool for 2 minutes, add 20 parts of flour and 0.03 parts of soy sauce koji essence and mix evenly; then make koji with ventilation, keep the koji room at 28°C, and control the temperature of the product to not exceed 32°C. Qu weighing. Weigh 100 parts of koji, add 32 parts of salt and 0.25 parts of flavor protease into warm water, dissolve and mix into koji, and keep it warm at 45°C for 25 days to mature to obtain sweet beanzi sauce. Choose 100 parts of bright red high-quality peppers, and require the peppers to be capped or removed to remove moths, sundries and mildewed peppers. Soak peppers in clean water for 1-3 minutes, then spray and clean; chop and mix fresh peppers after cleaning, the particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com