Cryo-concentration method of juice obtained by processing organisms

A biological and cold concentration technology, which is applied in food science, tobacco, food preparation, etc., can solve the problems that heat-sensitive substances and aroma substances cannot be retained, and the energy consumption of vacuum concentration is large, so as to increase the added value of products, reduce emissions, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

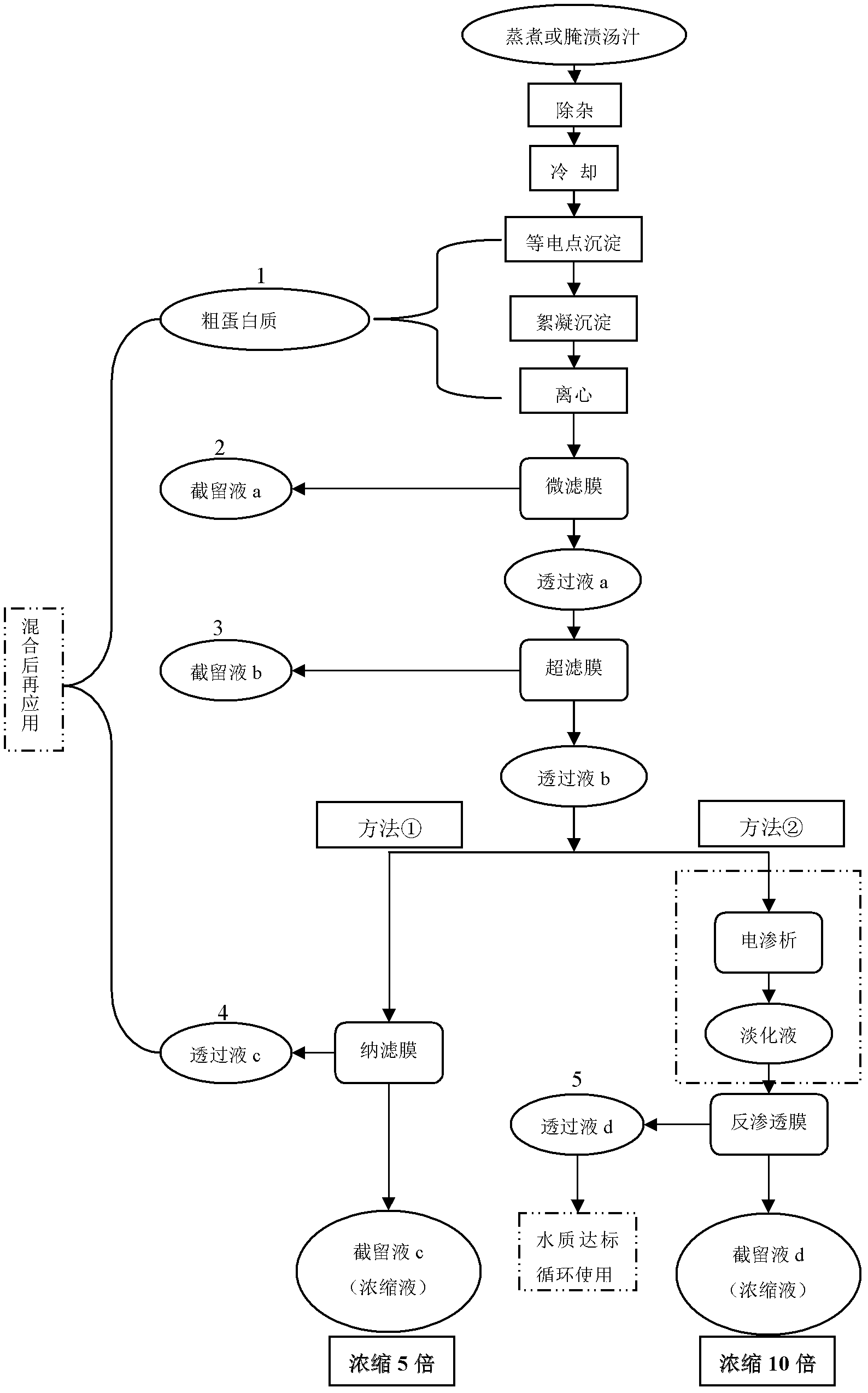

Method used

Image

Examples

Embodiment 1

[0030] During the processing of shrimp skin, a large amount of cooking soup of shrimp skin is produced, and the main components are nutrients and flavor substances such as polypeptides, amino acids, sugars, and nucleic acids.

[0031] First, filter 20L of shrimp skin cooking soup with a cloth bag to remove suspended matter, add citric acid or acetic acid to 20L of filtered cooking soup to make the pH value reach 3.3, then add 8g of chitosan flocculant, stir for 8 minutes and let it stand for 10 minutes. Produce flocculent sediment; finally through centrifuge (DBSDH5, Yixing Haide Separation Machinery Co., Ltd.) 8000rpm centrifugation for 10min, the clarified liquid that flows out is the cooking soup after pretreatment, and its salt content is 0.014g / mL, amino acid The state nitrogen content is 0.201mg / mL, and the soluble protein content is 1.46mg / 100mL.

[0032] Using a 0.22μm ceramic membrane as the microfiltration membrane, under the condition of operating pressure of 0.2MPa...

Embodiment 2

[0036] Embodiment 2 adopts clove fish to cook soup, other operations are the same as embodiment 1.

[0037] After the clove fish cooking soup was pretreated, the salt content was 0.0322g / mL, the amino acid nitrogen content was 0.327mg / mL, and the soluble protein content was 3mg / 100mL.

[0038] The permeate after ultrafiltration treatment and the concentrated solution after nanofiltration membrane treatment have a salt content of 3.50g / 100mL and an amino acid nitrogen content of 1.285mg / m3, which is about 4 times concentrated;

[0039] The permeate after ultrafiltration treatment is treated with electrodialysis, and the salt content in the desalination solution is 0.0012g / mL, and the desalination rate is 96%. The salt content is 0.0083g / mL, the amino acid nitrogen content is 1.905mg / m3, and the soluble protein content is 15mg / 100mL, which is about 6 times concentrated.

Embodiment 3

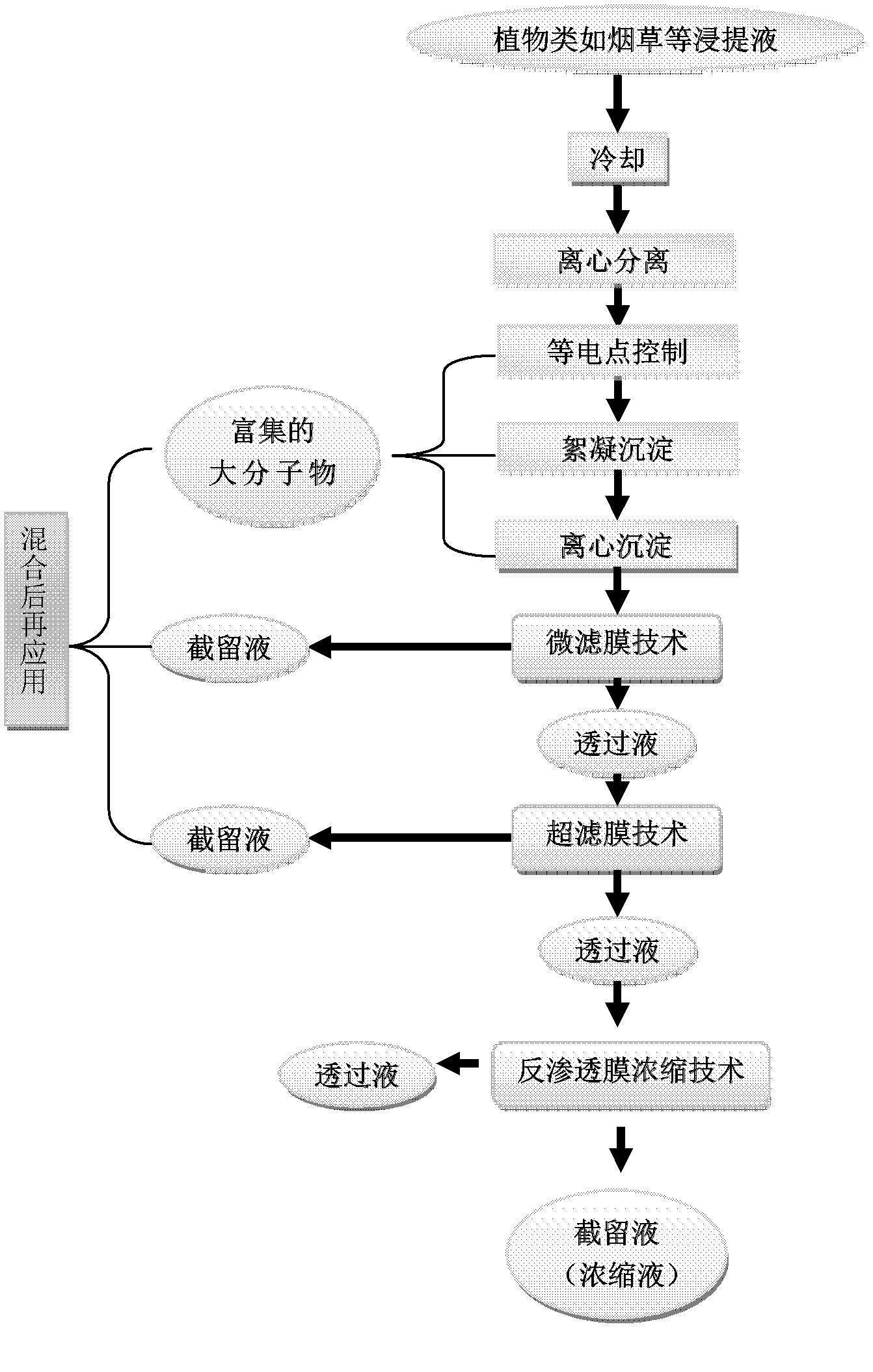

[0041] Use tobacco processing scraps or waste materials (low-grade tobacco, tobacco sticks, tobacco stems, etc.) to extract nicotine, use a volume concentration of 10% ethanol aqueous solution as the extraction solvent, and extract at 75°C with a liquid-solid ratio of 6:1. Under the condition of 5 hours, the nicotine content in the extract was 15 mg / mL. see the operating plan figure 2 shown.

[0042] The extract is first filtered with a cloth bag to remove the suspended solids of the tobacco leaves. Add 50L of the filtered extract to citric acid to make the pH value reach 4.2, then add 2g of diatomite flocculant, stir for 3 minutes and let it stand for 20 minutes to form flocculent precipitates. After centrifuge (DBSDH5, Yixing Haide Separation Machinery Co., Ltd.) 8000rpm centrifugation for 10min, the clarified liquid that flows out is the processed juice that can be concentrated through the membrane after pretreatment, and the soluble protein content of the processed juice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com