Method for processing flavor mushroom sauce

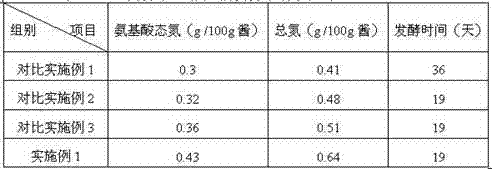

A processing method and technology of mushroom sauce, applied in the fields of application, food preparation, food science, etc., can solve the problems of cumbersome processing technology, limited variety, and insufficient richness, shorten fermentation time, increase amino acid nitrogen content, and enrich nutritional components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Mix soybean flour and wheat flour evenly at a weight ratio of 6:4, add 0.15wt% yeast and knead the dough, keep it warm and ferment for 1.5 hours at 25°C, then cut into pieces, steam in a pot, and let it dry thoroughly. Cut into thin slices with a thickness of less than 0.5 cm, and evenly inoculate rice koji spores, the inoculation amount is 4 lgCFU / g, the temperature of the material is controlled at 30-38 ° C, the humidity is 60-75%, and the thickness is not greater than 5 cm in a clean and disinfected wooden box. Carry out shallow aerated culture, turn the material 2-4 times a day, when the total number of colonies is 6-6.2 lgCFU / g, it is made into sauce;

[0018] (2) Crush the koji, put it into a clean and sterilized large tank, add salt water at a weight ratio of 1:1 to the koji, control the concentration of the salt water at 12wt%-20wt%, stir well to get the primary mixture, seal it and keep it warm for fermentation During the fermentation period, use a clean sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com