Patents

Literature

98results about How to "Outstanding umami" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seasoning sauce and preparation method thereof

The invention relates to a seasoning sauce and a preparation method thereof. The seasoning sauce comprises main materials, auxiliary materials, seasonings and blend oil. The preparation method comprises the following steps: cooking the blend oil to 80 DEG C, putting 1 to 3 parts of dry chili powder into a pot, and constantly stirring in moderate heat for 10 seconds; adding fermented blank beans into the pot, and stirring for 20 seconds in moderate heat; putting cooked beef dices with bean size into the pot, and frying for 15 seconds in moderate heat; mixing powdered broad bean paste, pickled chilies and chopped chilies for 3-4 times, and constantly stirring in the pot with a scoop; putting 0.5 to 1.0 part of edible salt, 0.7 to 1.2 parts of monosodium glutamate, 1.0 to 1.2 parts of chicken essence powder, 0.2 to 0.5 part of concentrated chicken broth and 2.5 to 4.5 parts of white sugar into the pot for seasoning when the temperature is 80 DEG C; and putting the rest main materials simultaneously into the pot, cooking for 40 minutes, and cooling and packaging. The seasoning sauce has the beneficial effects of transparent and bright color, pure and rich flavor and emphasized freshness, is suitable for cooked wheaten foods, rice, rice noodles, coarse cereals and the like, can be particularly used for cooking, household and business trip, can be presented for friends, and is convenient to carry.

Owner:李建峰

Method for producing sea-crab seasoner products material

The invention discloses a method for producing the raw materials of a seasoning product of sea crab; the method comprises the following steps: wastes of the sea crab are smashed; the sea crab is used for processing and cooking the concentrated solution of soup ingredient (namely, sea crab juice), heating is carried out to inactivate the enzyme, the process of mixed acid is used for carrying out deordorization, and filtering is carried out so as to remove the residue, etc. As the invention uses the hydrolyzation of papain to lead the protein in the waste of the sea crab to be decomposed furthest and the allergen to be removed, the fresh substances are released completely, while flavourzyme is adopted to carry out debittering process and inhibit the reproduction of microorganism in the process of enzymolysis; besides, as the invention uses weak acid process of citric acid and malic acid to carry out deodorization to the hydrolyzate or further uses low-temperature concentration and spray drying, the original nutrient ingredients and unique flavor of the product materials are maintained to the utmost degree and the property of the allergen is reduced.

Owner:JIMEI UNIV

Method for processing poultry skeleton soup dried noodles with delicate flavor

The invention provides a method for processing poultry skeleton soup dried noodles with delicate flavor. The method is characterized by boiling out and dissolving the fresh poultry skeletons under pressure with drinking water and drinking water plus acid respectively to dissolve out matters with delicate flavor and the like; then drying and grinding the bone residues left after boiling out twice to carry out refining treatment; and adding the dissolved soup and the refined meal to flour in a certain ratio to prepare the dried noodles. The method has the following advantages: the utilization ratio of the poultry skeletons is 100%; the prepared dried noodles have good flavor, have calcium content equivalent to that in the fresh milk and are new calcium supplementing food; only the edible acid is used in the whole process, thus conforming to the standards related to food quality and safety; and the products have reasonable processing cost and good market prospects.

Owner:HUNAN AGRICULTURAL UNIV +1

Andrias davidiamus meat sauce and manufacture method thereof

The invention relates to andrias davidiamus meat sauce and a manufacture method thereof. The andrias davidiamus meat sauce comprises the following raw materials in parts by weight: 20 to 50 parts of andrias davidiamus meat zymolyte, 20 to 40 parts of chili bean sauce, 10 to 30 parts of chili powder, 2 to 4 parts of salt, 2 to 5 parts of cooking wine, 1 to 3 parts of ginger, 2 to 4 parts of garlic, 4 to 10 parts of sesame and 1 to 5 parts of edible vegetable oil. Andrias davidiamus meat is steamed and grinded into thick liquid, the liquid is added with protease for enzymolysis, and then the mixture is processed through vacuum concentration to obtain the andrias davidiamus meat sauce which has 60 to 80 percent of solid content. The andrias davidiamus meat sauce adopts artificially bred andrias davidiamus as raw material. Through the combination of traditional salting and modern biological enzyme treatment, the andrias davidiamus meat sauce obtained is red brown, with delicate flavour, spicy taste, mellow smell and pure taste.

Owner:张家界金鲵生物工程股份有限公司

Method for processing fish head soup noodles

The invention relates to a method for processing fish head soup noodles, which comprises the following steps of: respectively stewing fresh fish heads in boiling water and alkaline boiling water to remove fishy smell; respectively boiling the fish heads in drinking water and souring drinking water under pressure for dissolving, so that substances with delicate flavor are dissolved out; drying the fish head bone residues which are boiled twice, and crushing for refining; and adding dissolved and refined soup and powder into flour in a ratio to form the noodles. In the method, the utilization rate of the fish heads is 100 percent, the prepared noodles are excellent in flavor and high in calcium containing amount, and are new calcium supplement food. The method meets the relevant standard of food quality and safety completely, is reasonable in processing cost, and has a good market prospect.

Owner:HUNAN AGRICULTURAL UNIV +1

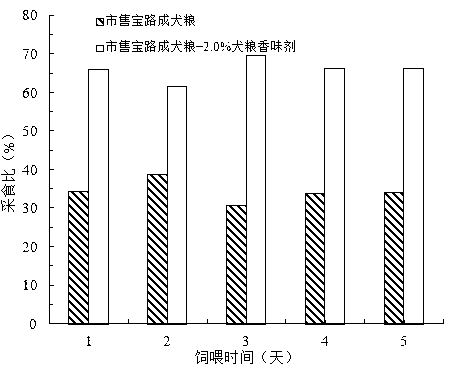

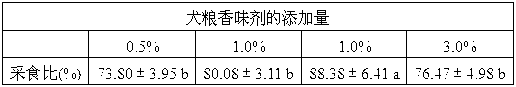

Preparation method for solid powder dog-food flavoring agent

InactiveCN103005155AIncrease profitIncrease added valueAnimal feeding stuffAdditive ingredientHydrolysate

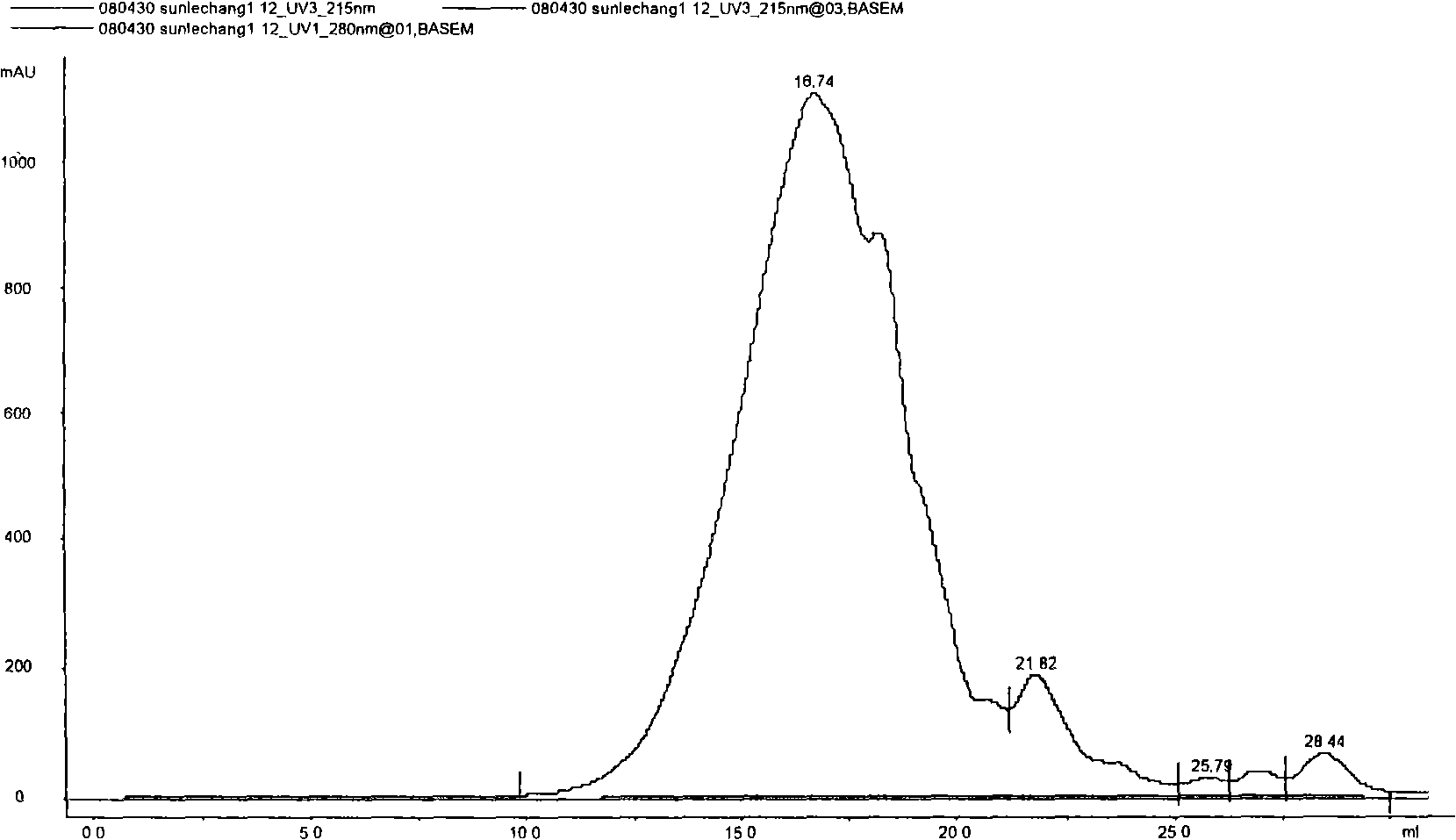

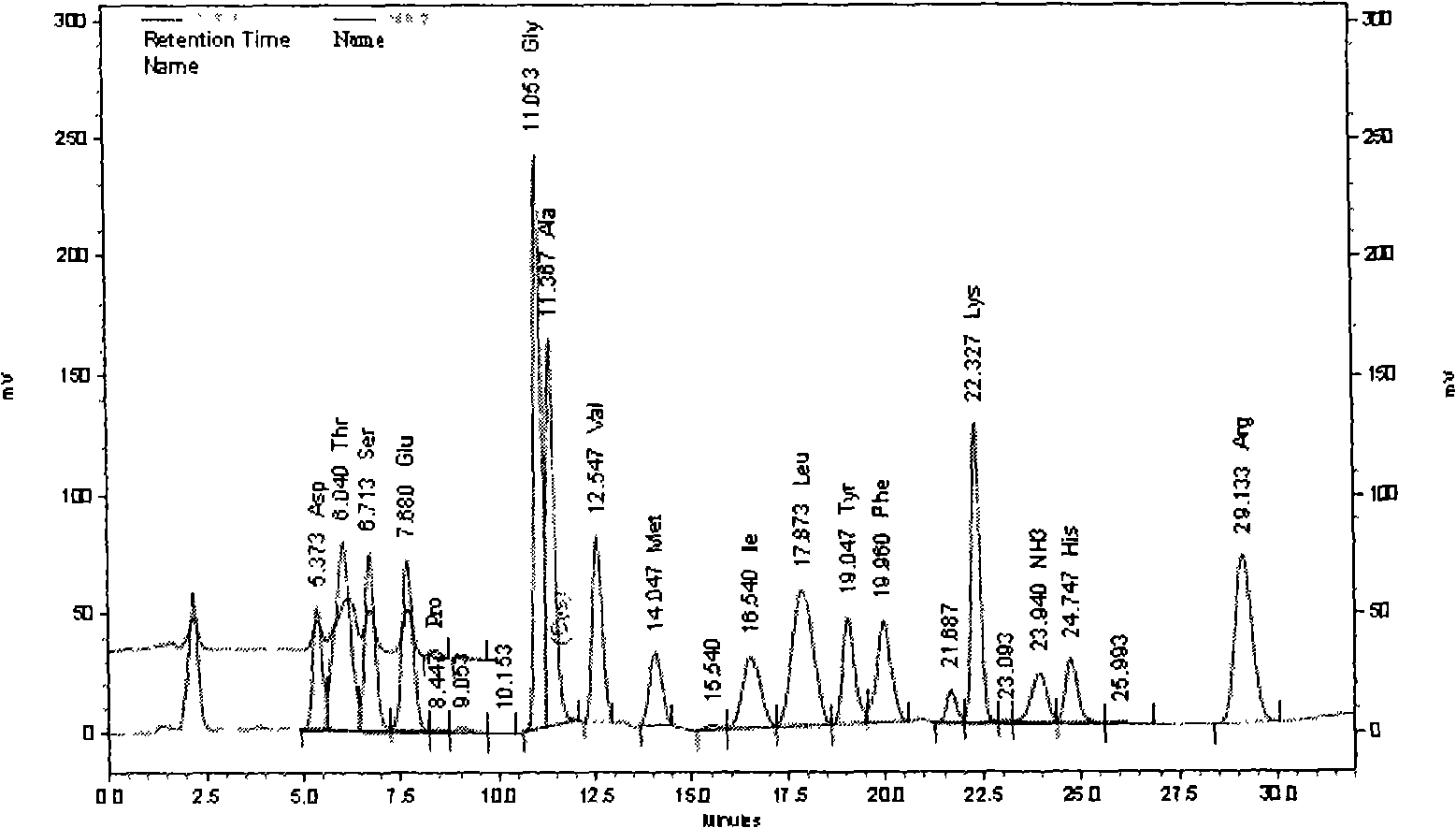

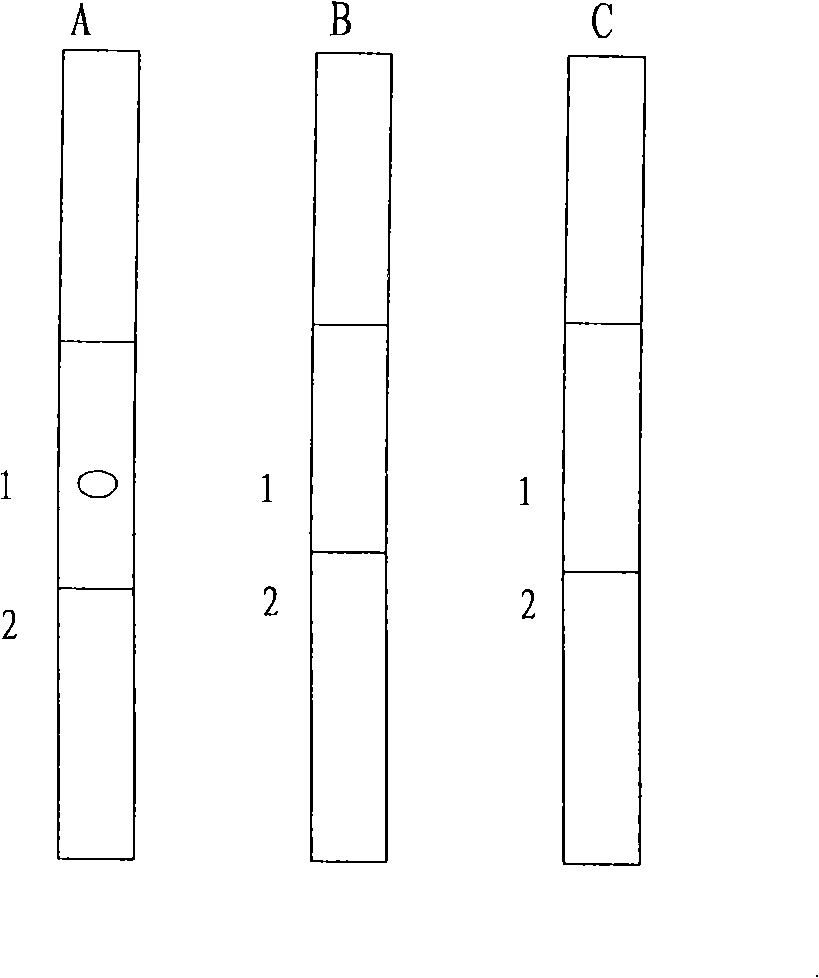

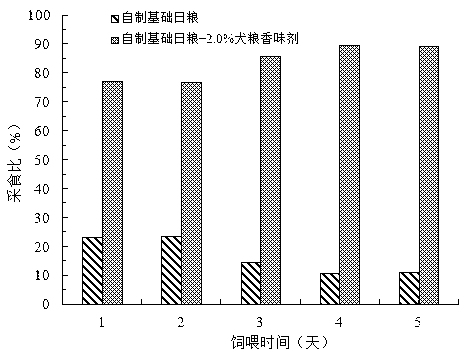

The invention discloses a preparation method for solid powder dog-food flavoring agent, belonging to the technical field of feeding process. The preparation method provided by the invention comprises the following steps of: using chicken breast meat as the main material; using protease to hydrolyze the main material; tracking and determining the degree of hydrolysis of enzymatic hydrolysate; obtaining enzymatic hydrolysate which is rich in amino acid, short-peptide and free of bitter taste; adding D-xylose, L-cysteine hydrochloride and vitamin B1 to the enzymatic hydrolysate for further reacting; adding tara gum and modified starch to mix and homogenize; and finally, spraying and drying to obtain the solid powder dog-food flavoring agent. The solid powder dog-food flavoring agent prepared by the preparation method provided by the invention has strong meat flavor and outstanding delicious taste, improves the utilization rate and additional value of the fresh chicken breast meat, and can cover the bad odor in the materials and the production process by re-dissolving and adding to the dog food. The solid powder is obtained by spraying and drying after being embedded by the tara gum and modified starch, so that the loss of the flavor components in the spraying and drying process is reduced. Compared with the market liquid dog-food flavoring agent, the solid powder dog-food flavoring agent prepared by the preparation method provided by the invention is more convenient to transport and store, and has good market prospect.

Owner:JIANGNAN UNIV

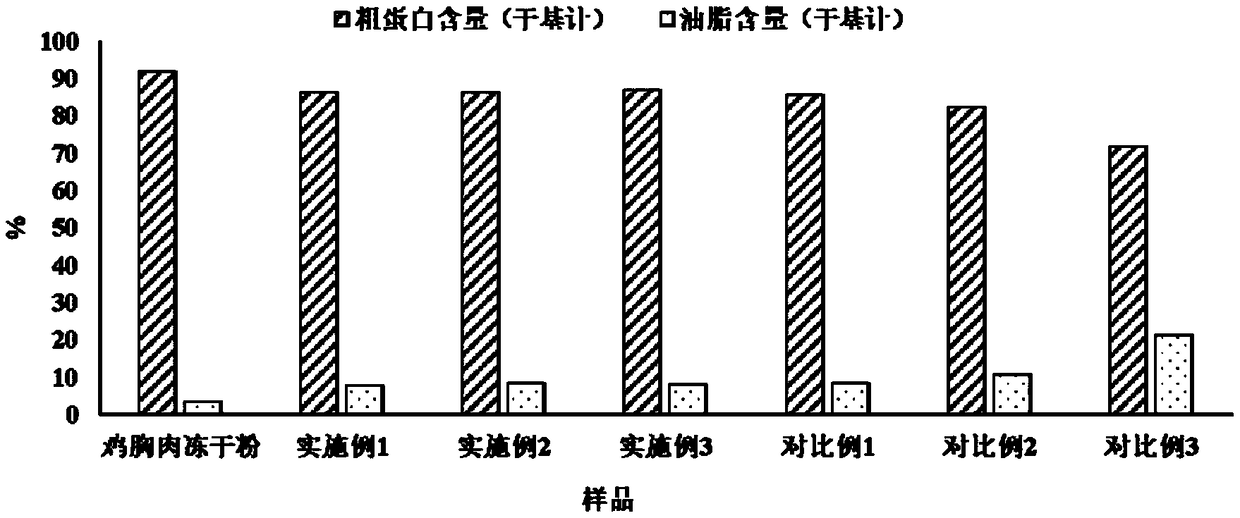

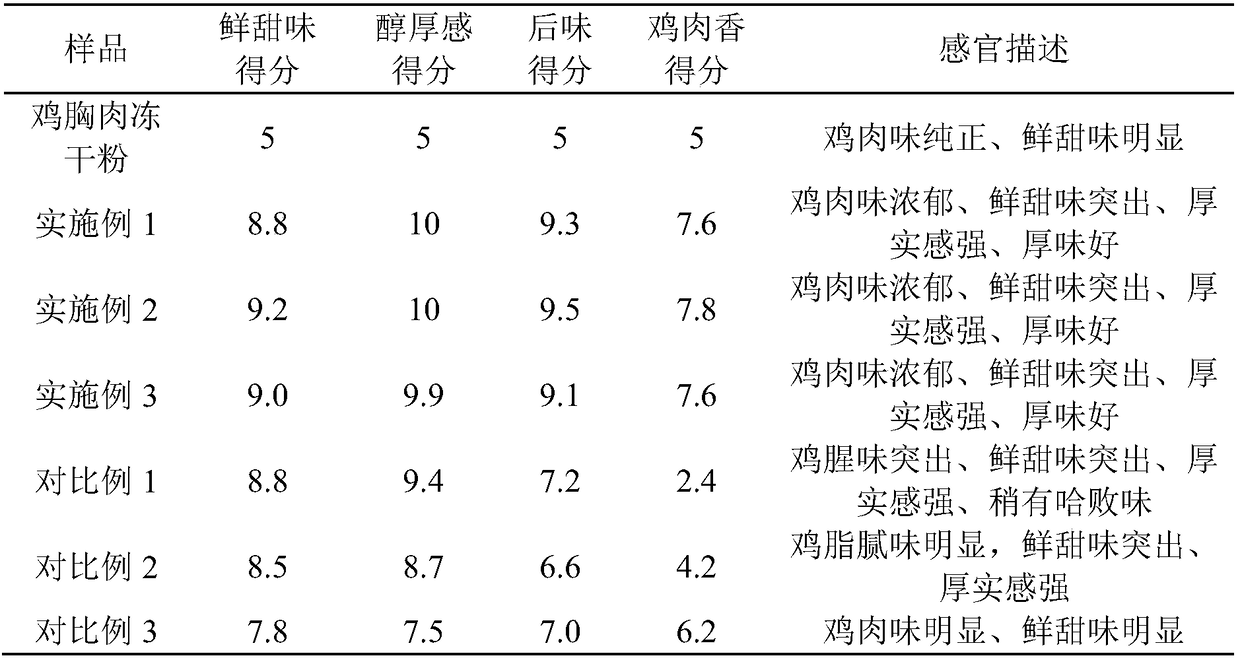

Chicken meat flavored peptide as well as preparation method and application thereof

ActiveCN109430513AGood flavor substancesEasy to separateProtein foodstuffs working-upProtein composition from meatProteinase activityTrypsin

The invention discloses chicken meat flavored peptide as well as a preparation method and application thereof. The method comprises the following steps of mincing a whole chicken, adding water, protease and spice powder, performing enzymolysis, and taking permeating liquid namely chicken meat enzymatic hydrolysate, wherein the protease is papain and / or alkali protease; then adding an emulsifying agent, protease, lipase and reducing sugar to the chicken meat enzymatic hydrolysate, performing emulsifying and enzymolysis treatment, then raising the temperature to 90-100 DEG C, performing heat-preservation stirring for 2-3 hours, and collecting a solution so as to obtain chicken meat flavored peptide liquid, wherein the protease is trypsin or flavored protease; and performing concentration orfreeze drying on the chicken meat flavored peptide liquid so as to obtain the chicken meat flavored peptide. The technology is simple to operate, low in production cost and free from any pollution, and the prepared chicken meat flavored peptide is outstanding in palatable taste and obvious in meat taste and is a superior flavor development base material.

Owner:厦门友和邦生物科技有限公司

Edible mushroom color-protecting antistaling agent and method for producing the same

InactiveCN101218973ABright yellow colorOutstanding umamiFruit and vegetables preservationFood preparationFlavorChlorine dioxide

The invention pertains to a food processing technical field, which provides a novel sulfur-less color-protected preservative used in the processing technique of edible fungi in water. The color-protected preservative comprises three effective components, 4-hexylresorcinol, sodium dehydroacetate and chlorine dioxide and the weight proportion thereof is 2: 2: 5. The invention also provides a method for preparing preservative which can not only prevent the canned edible fungi packed in water from browning but also keep the original flavor and nutrition. In addition, the product is safe and harmless to people.

Owner:刘魁

Squid bone seafood sauce and preparation method thereof

InactiveCN105747188AEasy to quantifyOutstanding umamiFood ingredient as taste affecting agentBiotechnologySpray dried

The invention belongs to the technical field of seasoning and particularly relates to squid bone seafood sauce and a preparation method thereof. The sauce is prepared with a sauce fermentation method after squid bones subjected to crushing, enzymolysis and spray drying treatment as a main auxiliary material are put into koji-making materials for sauce brewing. Squid bone meal zymolyte is obtained after the squid bones are subjected to enzymolysis and spray drying treatment according to the characteristic that the squid bones have rich protein, amino acid and other flavoring materials, and the quantification processing of fermentation raw materials is facilitated in the sauce brewing process; additionally, protein in the squid bones is decomposed into polypeptide and amino acid substances with more outstanding delicate flavors under the enzymolysis action, and accordingly, the sauce has a better flavor enhancing effect than common sauce and has a more outstanding flavor.

Owner:ZHEJIANG OCEAN UNIV

Sea worm seasoning and manufacturing method thereof

InactiveCN106036743APreserve freshnessGuaranteed naturalFood hydrolysisFood ingredient as taste affecting agentSodium GlutamatePre treatment

The invention belongs to the technical field of food processing and relates to sea worm seasoning and a manufacturing method thereof. The sea worm seasoning comprises, by weight parts, 70-105 parts of refined salt, 20-30 parts of natural yeast extract, 8-12 parts of clam nectar, 20-28 parts of youxiantai, 25-35 parts of white sugar, 4-6 parts of natural HVP, 0.3-0.6 part of allicin, 20-30 parts of corn starch, 12-18 parts of bonito powder, 6-12 parts of sea worm juice and 0.4-0.8 part of sodium glutamate and further comprises 60-120 parts of sauce. The sea worm seasoning is in a powder or sauce shape. The sea worm powder is formed by raw material pretreatment, enzymolysis, reaction and spray drying; and the sea worm sauce is formed by raw material pretreatment, mixing, reaction and forming. The product is free of any abnormal smell and fishy smell and is particularly outstanding in delicious taste; all natural young seafood raw materials are adopted, no chemical substance is added in the production process, and the sea worm seasoning is all natural and healthy.

Owner:王少琳

Method for preparing seasoning sauce from oyster water boiled liquid

The invention relates to a method for preparing a concentrated seasoning sauce from an oyster water boiled liquid, wherein the method comprises the steps: selecting the oyster water boiled liquid as a raw material, after concentrating under reduced pressure, carrying out enzymolysis, carrying out enzyme deactivation, concentrating under reduced pressure and carrying out alcohol precipitation to remove a precipitate, taking the supernatant, concentrating under reduced pressure, removing ethanol, and thus obtaining the oyster seasoning sauce. The preparation method has the advantages of low production cost, reasonable process, simple operation, and mild preparation process conditions; the prepared oyster seasoning sauce has less impurities, is not seasoned and compounded, is superior to a current oyster sauce product in fresh taste, sense, color and luster, is easily absorbed by human bodies when being eaten, and has high titer of physiological functions.

Owner:SHANDONG HOMEY AQUATIC DEV

Method for producing series porcupine meat food by comprehensively utilizing porcupine carcass meat

The invention discloses a method for producing series porcupine meat food by comprehensively utilizing porcupine carcass meat. The series porcupine meat food takes fresh porcupine carcass meat as a raw material, and is prepared by cutting, removing the smell, cooking, weighing, packaging, sterilizing, cooling, and externally packaging. In the cutting process, fat meat with skin and lean meat in the porcupine carcass meat are separated; in the smell removal process, a smell removal solution is prepared at first, the fat porcupine meat with skin is cut to pieces with the proper size, is soaked in the smell removal solution, is rinsed, is boiled for 1-3 minutes and is drained, the process is repeated for 1-3 times to fully remove the smell in pores of the porcupine meat, and the porcupine meat is cut into small pieces for later use; in the cooking process, the porcupine carcass meat is fried, smoked, marinated or sterilized at high temperature. According to the method, a smell removal mode of efficiently removing the smell of the porcupine meat is adopted, so that the smell of the porcupine meat is fully removed, possible trace toxic materials in the porcupine meat are also removed, and the umami of the porcupine meat is relatively outstanding.

Owner:TAOYUAN YUANLIN HYSTRIX HODGSONI BREEDING SPECIALIZED COOP

Spiced salt powder

InactiveCN105876392AWide variety of sourcesMulti seasoning ingredientsFood preparationMonosodium glutamateGreen pepper

The invention discloses spiced salt powder in the technical field of food seasonings. The spiced salt powder comprises, by weight, 38-42% of table salt, 9-11% of Chinese prickly ash powder, 13-17% of fennel powder, 4-6% of dried orange peel powder, 4-6% of green pepper powder, 9-11% of monosodium glutamate and 13-17% of cumin powder. The spiced salt powder has plump seasoning effects, a full aroma, a delicious taste and balanced nutrition, is prepared from raw materials with a wide source and has a low manufacturing cost.

Owner:朱修圣

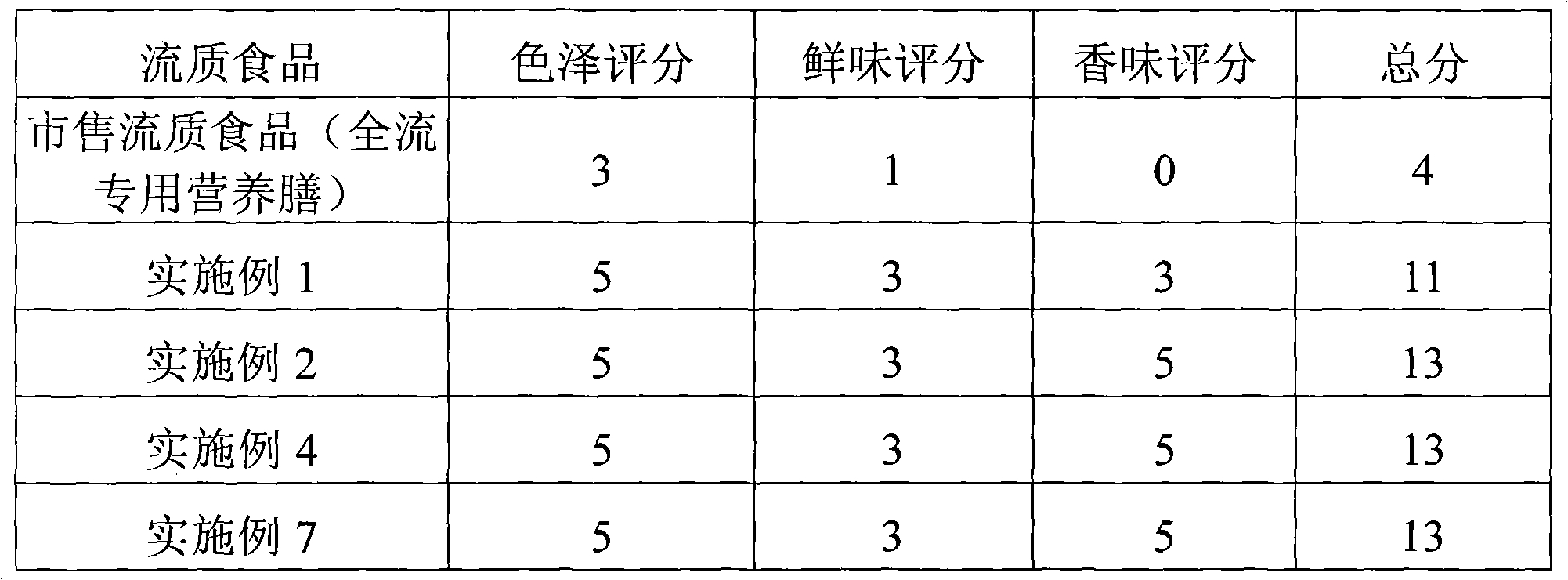

Fluid food and preparation method thereof

The invention relates to a salty and fresh flavor fluid food made of chick soup and a preparation method thereof. The fluid food comprises the following components in percentage by weight: 69.25-89.69 percent of chick soup, 0.44-1.66 percent of table salt, 8.99-22.16 percent of malto dextrin and 0.88-6.93 percent of thickener. The chick soup is prepared by a method comprising the following steps of: (1) raw material pretreatment: after cleaning the whole chick removing internal organs and the head, leaching; and (2) adding water into the whole chick leached in the step (1) according to the mass proportion of the chick to water of 1:1-1:2 and heating for boiling at the boiling temperature of 70-90 DEG C for 2-6 hours. The fluid food provided by the invention has salty and fresh flavor, abundant nutrition and reasonable matching, contains abundant amino acid, polypeptide and protein and proper fat, has attractive color and good taste in addition to have special odour of chicken and can strengthen the appetite of people.

Owner:SHANGHAI TOTOLE FOOD LTD

Traditional Chinese medicine pesticide for vegetables

InactiveCN103300078AGive full play to the comprehensive efficacy of pharmacologyFast insecticideBiocideFungicidesCnidium monnieriChinese herbology

The invention relates to a traditional Chinese medicine pesticide for vegetables. The traditional Chinese medicine pesticide comprises the following traditional Chinese medicines in parts by weight: 10-20 parts of cnidium monnieri, 10-20 parts of Radix Stemonae, 1-10 parts of Arisaema aridum, 1-10 parts of radix euphorbiae lantu, 1-10 parts of Huechys, 1-5 parts of toosendan fruit, 5-15 parts of Laurocapam and 1000-1500 parts of water. The pesticide has the advantages of high pest killing speed, good effect, high safety and simplicity in production; and raw materials are easily available.

Owner:宋末有

Method for producing eight-treasure sauce

The invention discloses a method for producing eight-treasure sauce, comprising the following steps: various raw materials are prepared and the ratio of flour, soy beans, horsebeans, rice, millet, peanut, wheat germ and medlar is 7:1:0.5:0.3:0.3:0.3:0.5:0.1 by weight proportion; flour is added with water and stirred evenly and brewing material is produced by cooling after cooking; the soy beans, the peeled horsebeans, the rice, the millet, the peanut and the wheat germ are soaked respectively, ground into juice and cooked; the medlar is added with water for soaking, squeezed into juice and cooked; various juices are mixed, salt is added and the mixture is evenly mixed with the brewing material; and a finished product is obtained by fermentation, homogenization and sterilization. The eight-treasure sauce produced by the method has richer and more unique flavour, nutrition and quality, the content of the amino acid is increased by times, and the sauce is more refined and moderately salty and sweet with excellent delicate flavour.

Owner:吴德辉

Method for processing flavored agrocybe cylindracea sauce

InactiveCN103494174AUnique flavorFull of nutritionFood preparationBiotechnologyLactic acid bacterium

The invention relates to a method for processing flavored agrocybe cylindracea sauce, belonging to the field of sauce fermentation. The method comprises the following steps: grinding sauce yeasts, adding salt water, fermenting at the temperature of 48-50 DEG C for 48 hours and then at the temperature of 45 DEG C for 3 days at an initial stage, adding a D110 glutamic acid bacteria solution, a lactic acid bacteria solution and sorbitol, and fermenting at the temperature of 38-40 DEG C for 12 days to obtain a primary sauce; deactivating enzymes of agrocybe cylindracea, beating to obtain agrocybe cylindracea pulp, uniformly mixing the agrocybe cylindracea pulp with the primary sauce in a weight ratio of 1 to 1, adding salt, fermenting at the temperature of 38-40 DEG C for 6 days, and curing. The flavored agrocybe cylindracea sauce is rich in nutrition, and can be directly eaten or added as a seasoning in a cooking process; the fermenting time can be effectively shortened, and the content of amino acid nitrogen can be increased to be more than 43%, so that the sauce is rich in fragrance and outstanding in delicate flavor.

Owner:王硕

Carp soup formula and making method thereof

The invention provides a carp soup formula and a making method thereof. The method comprises the following steps: adding condiments (calculated according to 1000g of carp) which respectively comprise 9-11g of fresh ginger, 14-16g of green Chinese onion, 9-11g of white vinegar, 45-55g of cooking wine, 14-16g of salt and 1.45-1.55g of white granulated sugar under the condition that a mass ratio of the fish to water is 1:(1.25-1.35), boiling and cooking by using big fire for 3-5 minutes, stewing by using slow fire for 30-50 minutes, adding 0.28-0.32g of monosodium glutamate, and taking the soup out of the pan. In the process of stewing by using the slow fire, the carp soup is slightly boiling, and no vapor or extremely small vapor rises after a pot cover covers the pan.

Owner:SHANDONG UNIV OF TECH

Seafood condiment sauce and preparing method thereof

InactiveCN105725155AImprove uniformityRich tasteClimate change adaptationFood preservationVegetable oilAllium sativum

The invention provides a seafood condiment sauce. The seafood condiment sauce comprises a mixed condiment, aginomoto, edible salt, chicken powder, white granulated sugar, rock candy, yeast extract, 5'-sodium inosinate+5'-sodium guanylate, chicken flavor essence, vegetable oil and aged vinegar. The mixed condiment is composed of ginger, garlic and chili according to the mass ratio of 1:1:1. A stabilizer and a preservative are also added. The invention further provides a preparing method of the seafood condiment sauce. The defects that a traditional seafood condiment sauce needs to be blended manually and the taste is not rich are overcome; meanwhile, by adding the combined stabilizer in proper proportion, the defects that the seafood condiment sauce is not even and prone to layering are overcome. The prepared seafood condiment sauce has a strong delicate flavor, comprehensive tastes and rich nutrients, can be digested and absorbed by the human body easily, and can be used for family food seasoning, food application and the like. Furthermore, the preparing process is reasonable, operation is easy, material selection is scientific, and the preparing method is suitable for industrial production and has great market potential.

Owner:SHANGHAI INST OF TECH

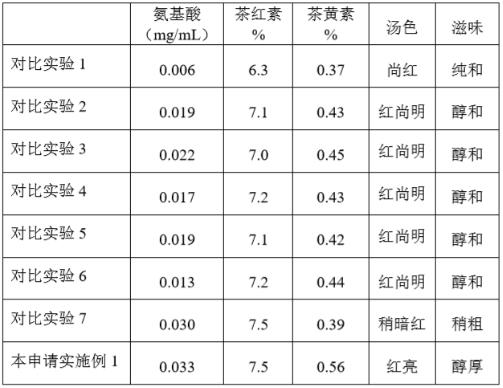

Method for preparing flavored black tea

ActiveCN112042775ASweet in the mouthOutstanding umamiPre-extraction tea treatmentBiotechnologyPhenolic content in tea

The invention relates to a method for preparing flavored black tea. The method comprises the following steps: (1) selecting varieties of foreign aid enzymes and determining a compounding ratio; (2) sprinkling a mixed-enzyme solution during withering of tea leaves; (3) continuing to sprinkle the mixed-enzyme solution during rolling of the tea leaves; (4) fermenting the tea leaves; and (5) finally drying the fermented black tea leaves, thereby obtaining a finished product. According to the method disclosed by the invention, the black tea is produced by employing mixed fermentation of alkaline proteinase and papain, proteins in the tea leaves are hydrolyzed into micromolecular peptides and amino acids by these foreign aid enzymes at appropriate temperatures, and meanwhile, the condition thattea polyphenols are converted into thearubigin and theaflavin by polyphenol oxidase is not cut off, so that the content of nutrient amino acids in tea soup can be effectively increased, and the quality of the black tea is improved; and meanwhile, L-cysteine is added to prevent the tea leaves from excessive fermentation, so that the prepared black tea is better in mouth feel and good in soup color.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

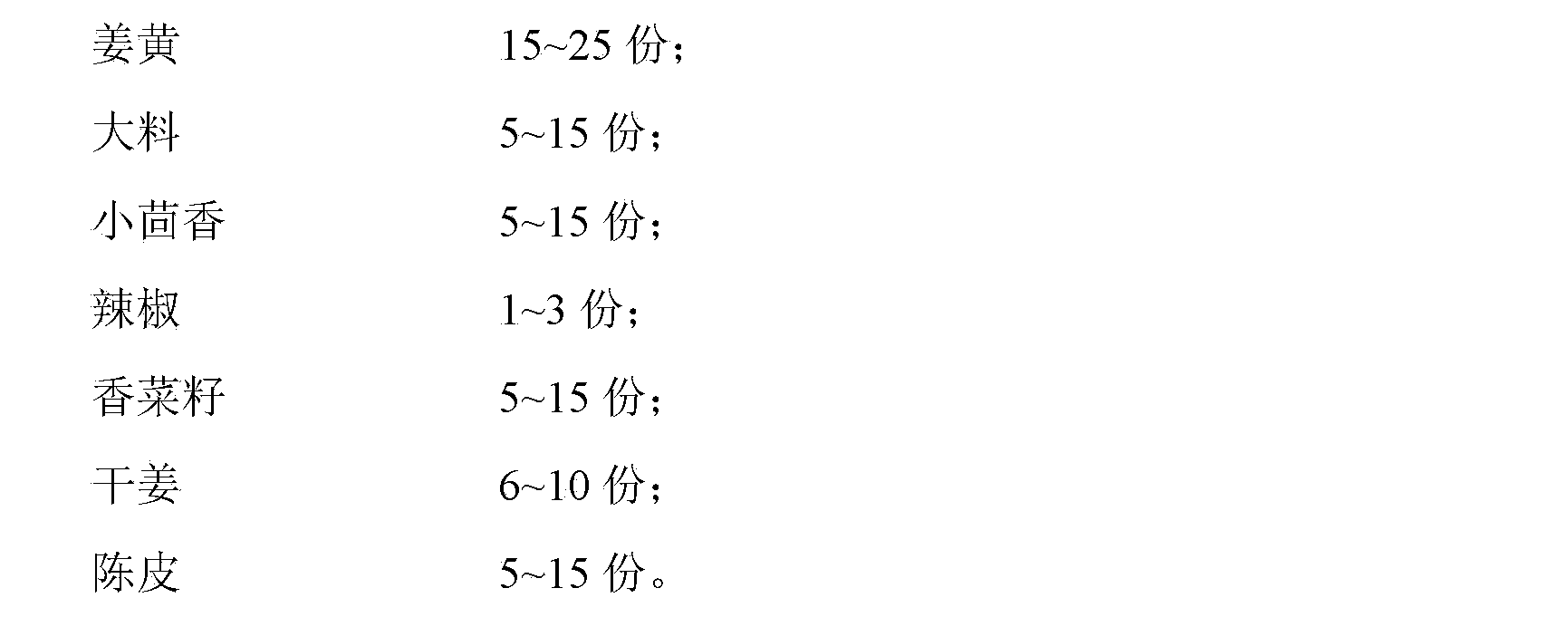

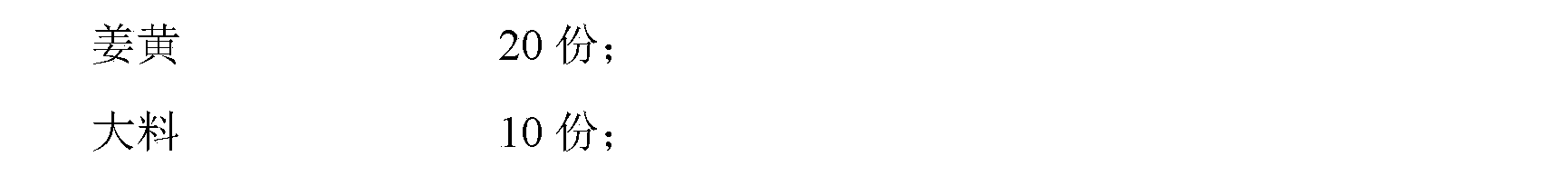

Curry powder

InactiveCN103876090ADelicious and uniquePure Natural Nutritional IngredientsFood shapingFood preparationAdditive ingredientUmami

The invention relates to a curry powder. The curry powder is composed of the following components in parts by weight: 15 to 25 parts of turmeric, 5 to 15 parts of aniseed, 5 to 15 parts of fennel, 1 to 3 parts of pepper, 5 to 15 parts of caraway seed, 6 to 10 parts of dry ginger, and 5 to 15 parts of dried orange peel. The curry powder has a unique flavor, is composed of pure natural nutrients, and has the advantages of palatable taste, rich fragrance, and rich nutrients. Moreover, the raw materials of the curry powder are all normal materials in the markets, thus the cost is low, and the curry powder has a vast market prospect.

Owner:TIANJIN LANSHI SEASONING

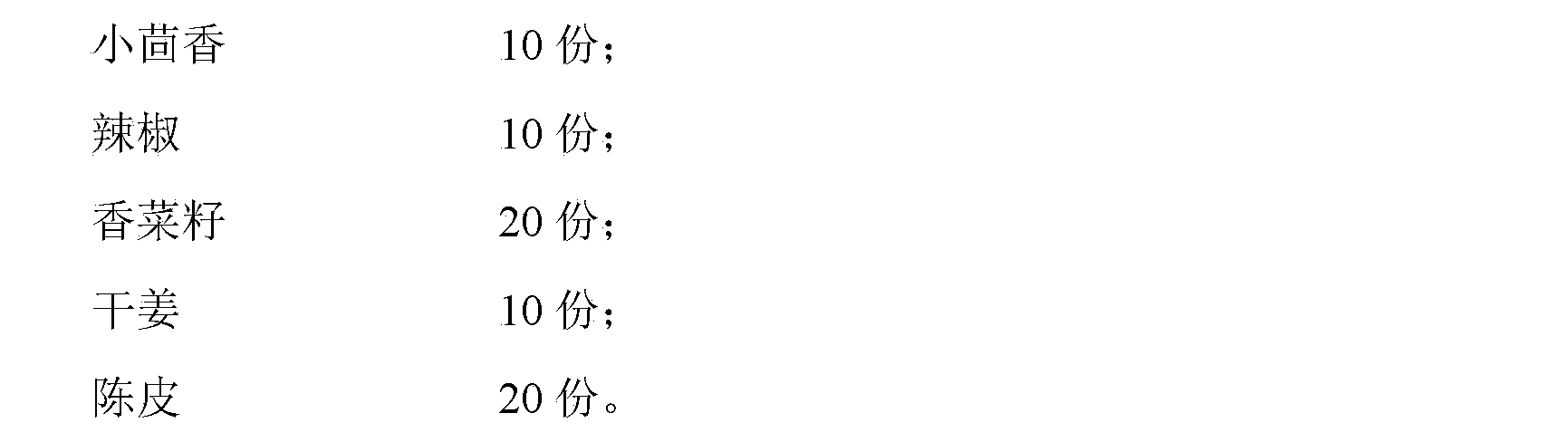

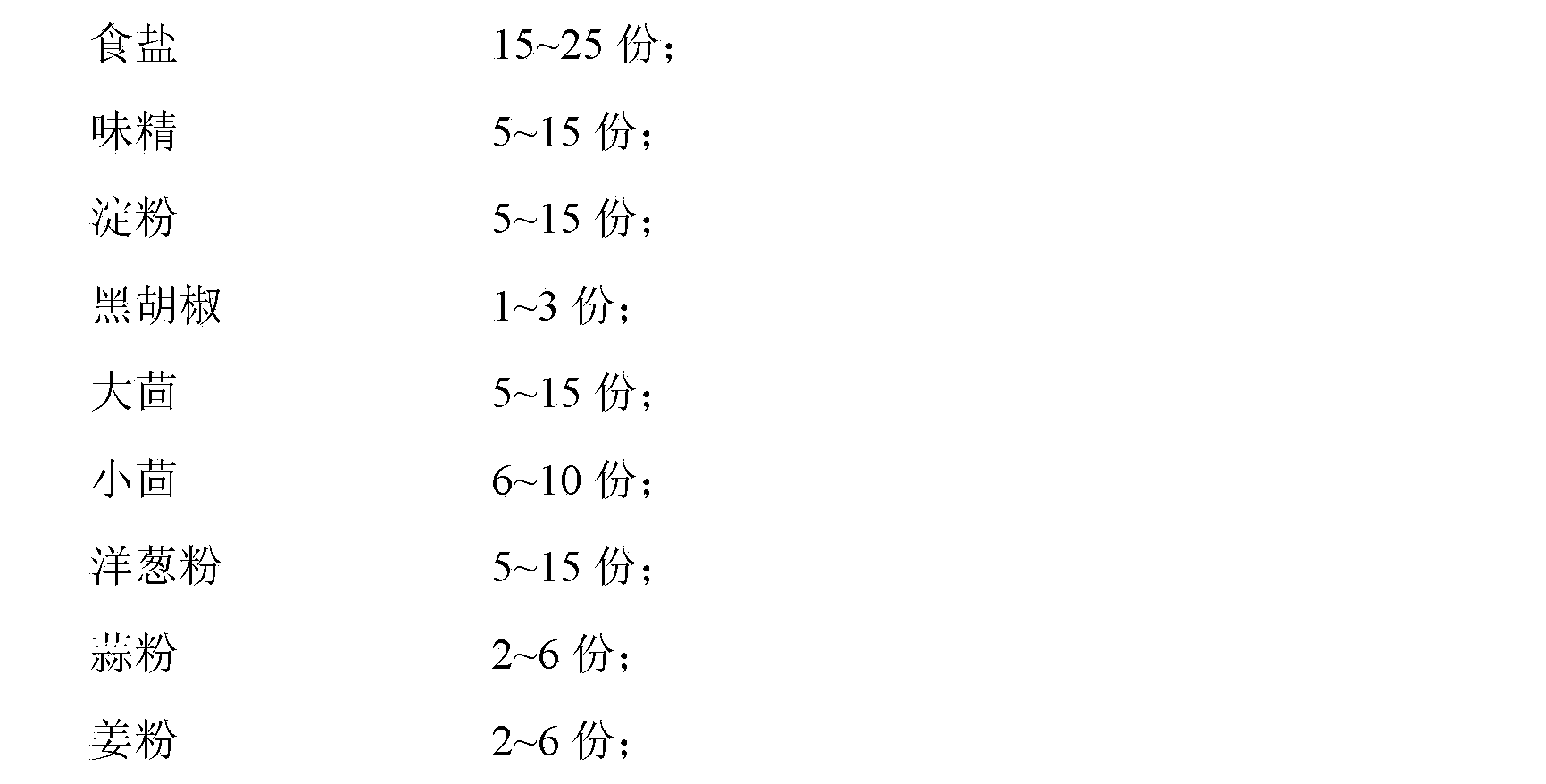

Steamed stuffed bun stuffing composite condiment

InactiveCN103876095ADelicious and uniquePure Natural Nutritional IngredientsFood preparationMonosodium glutamateFlavor

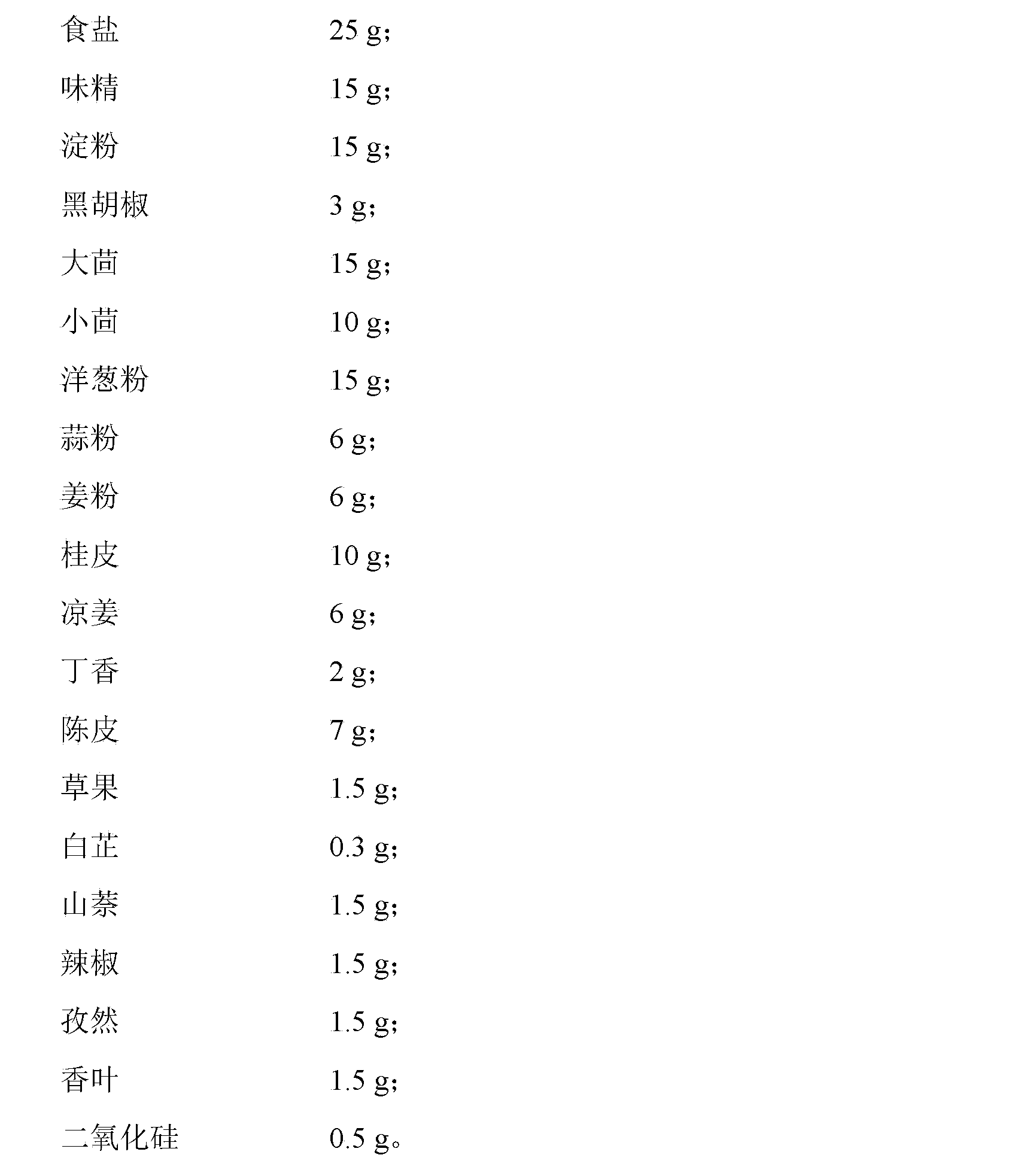

The invention relates to a steamed stuffed bun stuffing composite condiment. The condiment comprises compositions in parts by weight: 15-25 parts of edible salt, 5-15 parts of monosodium glutamate, 5-15 parts of starch, 1-3 parts of black pepper, 5-15 parts of Illicium verum, 6-10 parts of foeniculum vulgare, 5-15 parts of onion powder, 2-6 parts of garlic powder, 2-6 parts of ginger powder, 6-10 parts of cinnamomum tamala, 2-6 parts of alpinia officinarum Hance., 1-2 parts of clove, 3-7 parts of dried orange peel, 0.5-1.5 parts of tsaoko fruit, 0.1-0.3 part of angelica dahurica, 0.5-1.5 parts of rhizoma kaempferiae, 0.5-1.5 parts of pepper, 0.5-1.5 parts of cuminum cyminum, 0.5-1.5 parts of laurel leaf and 0.1-0.5 part of silicon dioxide. The steamed stuffed bun stuffing composite condiment has unique taste and also has pure natural nutrition compositions, and is palatable in saltiness degree, protruding in delicate flavor, nose-greeting in fragrance, abundant in nutrition and delicious in taste. Also, the employed food materials are common materials in the market, and therefore the composite condiment is low in cost and has wide market prospect.

Owner:TIANJIN LANSHI SEASONING

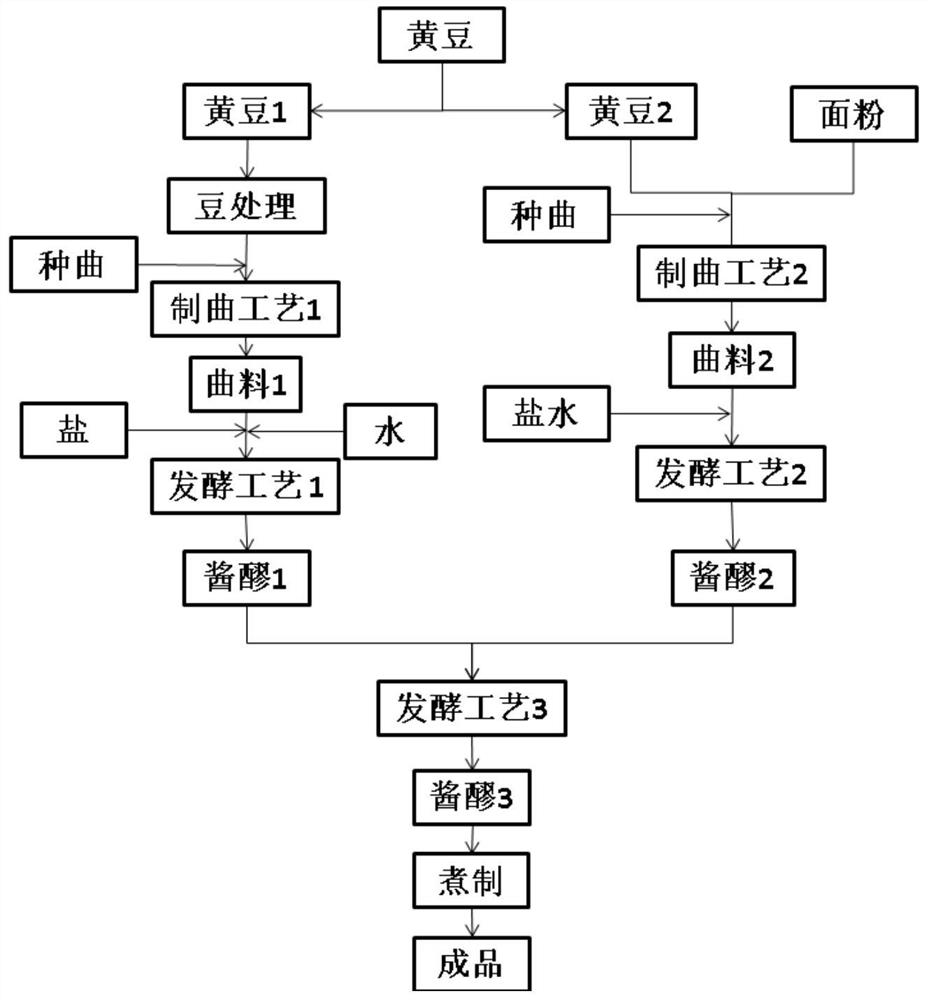

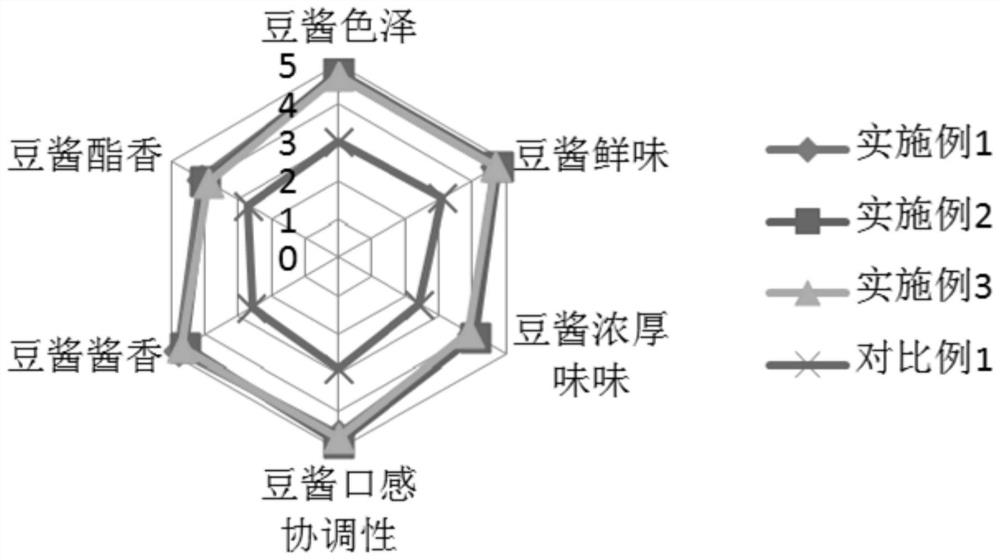

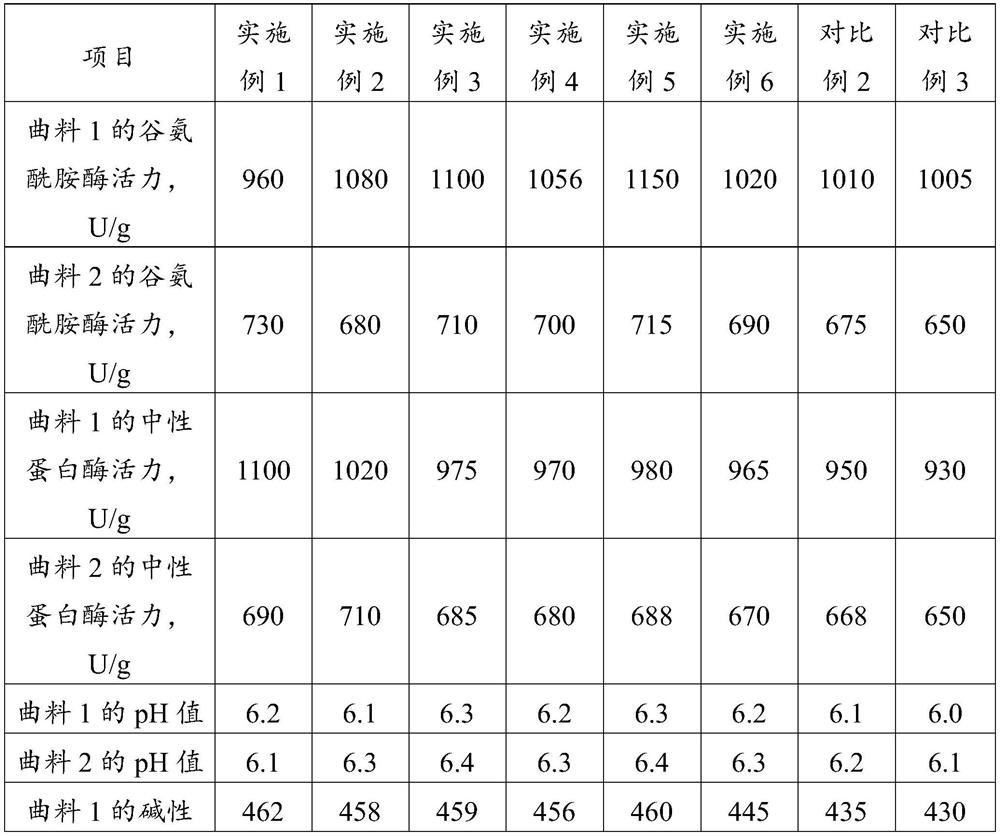

Soybean paste brewing process

ActiveCN113367283AQuality improvementIncrease enzyme activityFood scienceFlavouring agentProcess engineering

The invention discloses a soybean paste brewing process which comprises the following steps: (1) dividing soybeans into two parts, namely soybeans 1 and soybeans 2; (2) cooking soybeans 1, crushing, cooling, inoculating yeast seed for starter propagation, adding salt and a small amount of water, and performing sun-curing fermentation to obtain a semi-finished product of soy sauce mash 1; (3) steaming and cooking soybeans 2, cooling, adding flour, uniformly mixing, inoculating yeast seed for starter propagation, adding saline water, and carrying out sun-curing fermentation to obtain a semi-finished product of soy sauce mash 2; (4) uniformly mixing the semi-finished soy sauce mash 1 and the semi-finished soy sauce mash 2 with saline water, and fermenting to obtain soy sauce mash 3; and (5) adding a flavoring agent into the soy sauce mash 3 for blending, boiling for 10-40 minutes, sterilizing, cooling and filling to obtain the soybean paste. According to the brewing process, the quality, enzyme activity and decomposition degree of finished koji are improved, the fermentation time is short, and the utilization rate of raw materials is high; compared with the traditional technology, the physicochemical indexes of the obtained soybean paste blank are obviously improved, and the soybean paste is red and strong in color, rich in fragrance and prominent in delicate flavor and mellow taste.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +1

Method for producing wheat germ sauce

InactiveCN101473930ARich in nutrition and qualityOutstanding umamiFood preparationAmino acid contentWheat germ

The invention discloses a method for producing wheat germ sauce, comprising the following steps: flour and wheat germ are prepared with the weight ratio of 7:3; flour is added with water and stirred evenly and brewing material is produced by inoculating after the flour is cooked and cooled; the wheat germ is soaked, ground into juice and cooked; the cooked wheat germ juice is added with salt, and then mixed evenly with the brewing material; and a finished product is obtained by fermentation, homogenization and sterilization. The content of amino acid of the wheat germ sauce produced by the method is increased by times, the sauce has richer and more unique flavour, nutrition and quality, and the sauce is more refined and moderately salty and sweet with excellent delicate flavour.

Owner:吴德辉

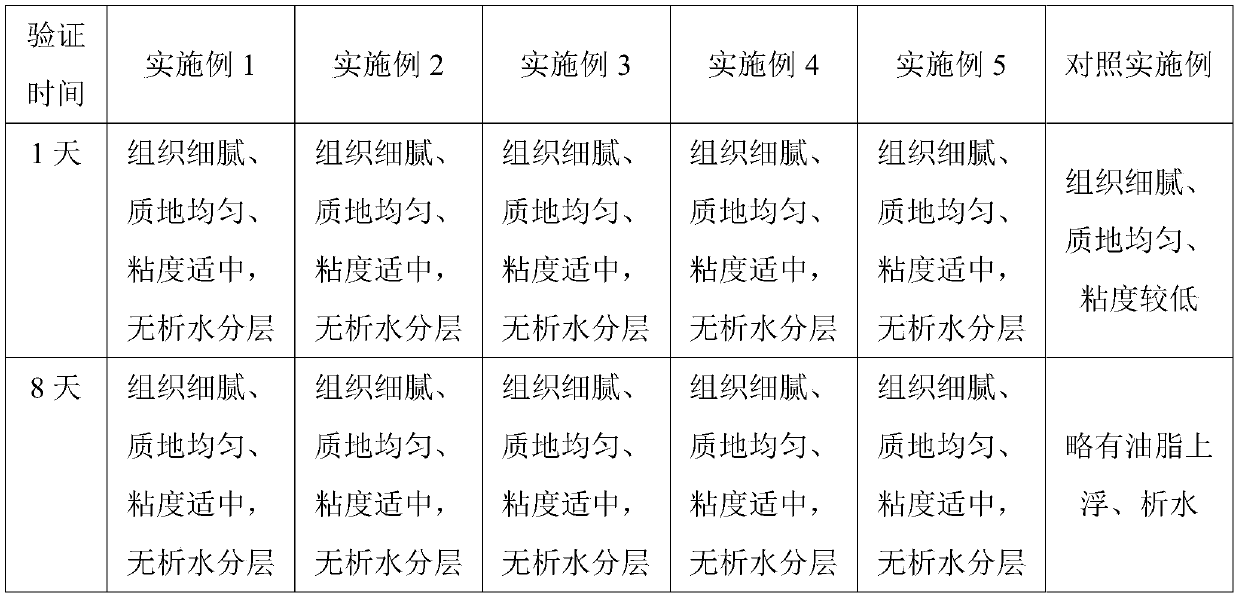

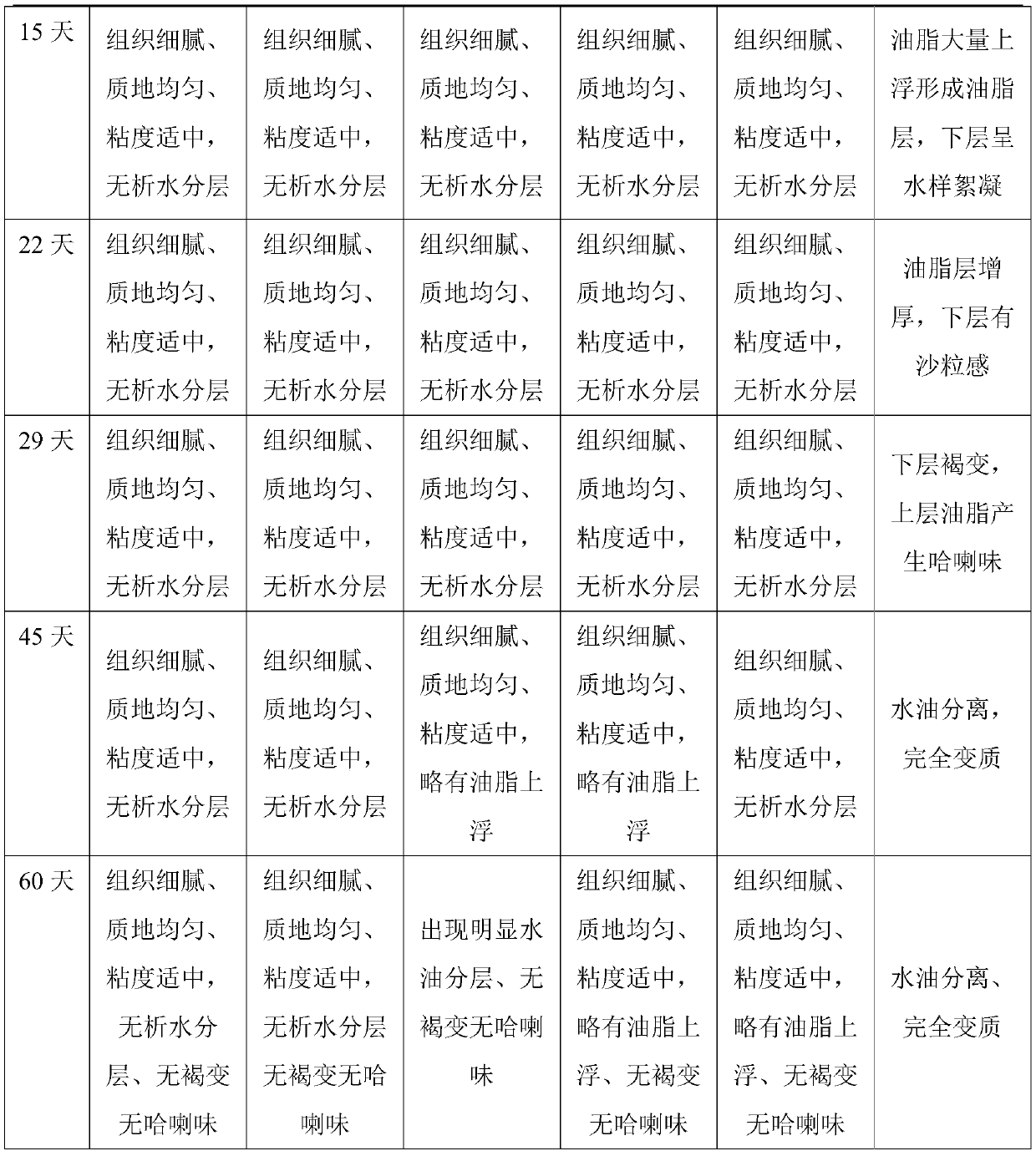

Avocado jam and preparation method thereof

InactiveCN110226728ALower serum total cholesterol levelsNutritious and balancedFood preservationBrowningAntioxidant

The invention discloses an avocado jam and a preparation method thereof. The avocado jam is prepared from, by weight, 100-200 parts of avocado, 30-60 parts of deep-sea fish meal, 10-20 parts of goosefat liver, 15-35 parts of jackfruit cores, 20-40 parts of durian cores, 50-80 parts of nut powder, 10-25 parts of black seed coat peanuts, 15-30 parts of black sesame, 2-20 parts of an emulsifier, 1-10 parts of a stabilizer, 5-20 parts of antioxidant, and 5-15 parts of a thickening agent. The content of unsaturated fatty acid in the jam can be effectively increased by adding a plurality of nuts and deep-sea fish, so that nutrition can be balanced, the taste of the jam can be improved, and the possibility of jam allergy can be reduced by decomposing macromolecular proteins; the stability of oil-bearing jam can be significantly improved by adding the stabilizer, the emulsifier and the thickening agent during preparation; and the possibility of jam browning and lipid oxidation can be reducedby adopting the antioxidant and inert gas filling and other measures, so that the nutrition and flavor of the product can be guaranteed.

Owner:南京萌萌菌业有限公司

Preparation method of seasoning for steamed pork with rice flour

InactiveCN106036744AImprove fresh tasteHigh nutritional valueFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses a preparation method of seasoning for steamed pork with rice flour, belonging to the technical field of food. The method comprises the steps of A. preparing powdered seasoning: respectively frying rice, millet, sticky rice and spices for 3-8min by using small fire, putting the fried rice, millet and sticky rice, starch, green prickleyash, dried chillis, the spices and black pepper into a crusher for crushing, screening the product by using a 40-60-mesh sieve, adding white granulated sugar and table salt into the screened product, evenly mixing and packaging; B. preparing a sauce package, specifically, grinding dried mushroom and dried bamboo fungus into 60-80 meshes, then adding bean sauce, vegetable oil, soy sauce, chicken essence, rice vinegar, ginger powder and potassium sorbate, evenly stirring, and packaging. The steamed pork with rice flour made by using the seasoning prepared by the method is rich in fresh and delicious taste and high in nutritive value; the seasoning has the advantage of enabling the steamed pork with rice flour to be well tasty.

Owner:CHENGDU JINHUI TECH

Preparation method of capsicum-bean sauce produced by special fermentation agent

InactiveCN107981212ABright colorAvoid churnFood preservationFood ingredient as taste affecting agentAdditive ingredientRapeseed

The invention discloses capsicum-bean sauce produced by a special fermentation agent and a preparation method of the capsicum-bean sauce produced by the special fermentation agent. The method comprises the steps of adding the special fermentation agent into home-made yeast bean sauce, uniformly mixing seven-star peppers, fresh long Sichuan peppers, fresh capsicum frutescens and fried cooled rapeseed oil with raw materials such as sweety bean sauce, crystal sugar and baijiu, then, carrying out natural fermentation for 1 to 2 months in an argil jar, finally, adding garlic essential oil, pericarpium zanthoxyli essential oil, clove lilac essential oil and tea polyphenols, carrying out uniform stirring, and carrying out sealed standing for 24 to 48 hours, thereby obtaining a finished product. The capsicum-bean sauce prepared by the method is short in fermentation cycle, outstanding in fresh fragrance, low in salt content, good in color, luster and taste, full in nutritional ingredients, free of chemical additives and stable in product quality.

Owner:SICHUAN UNIV

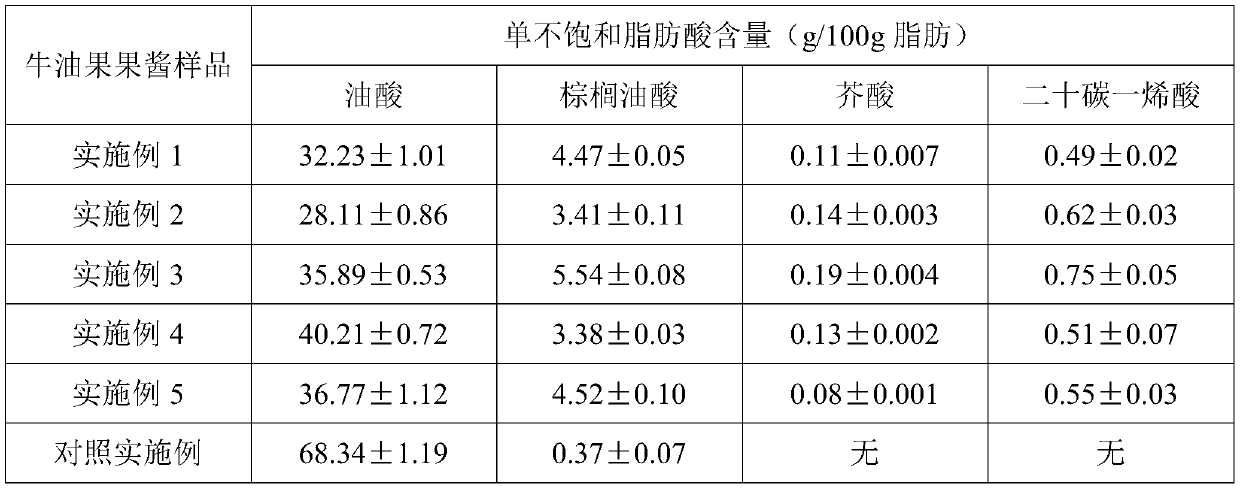

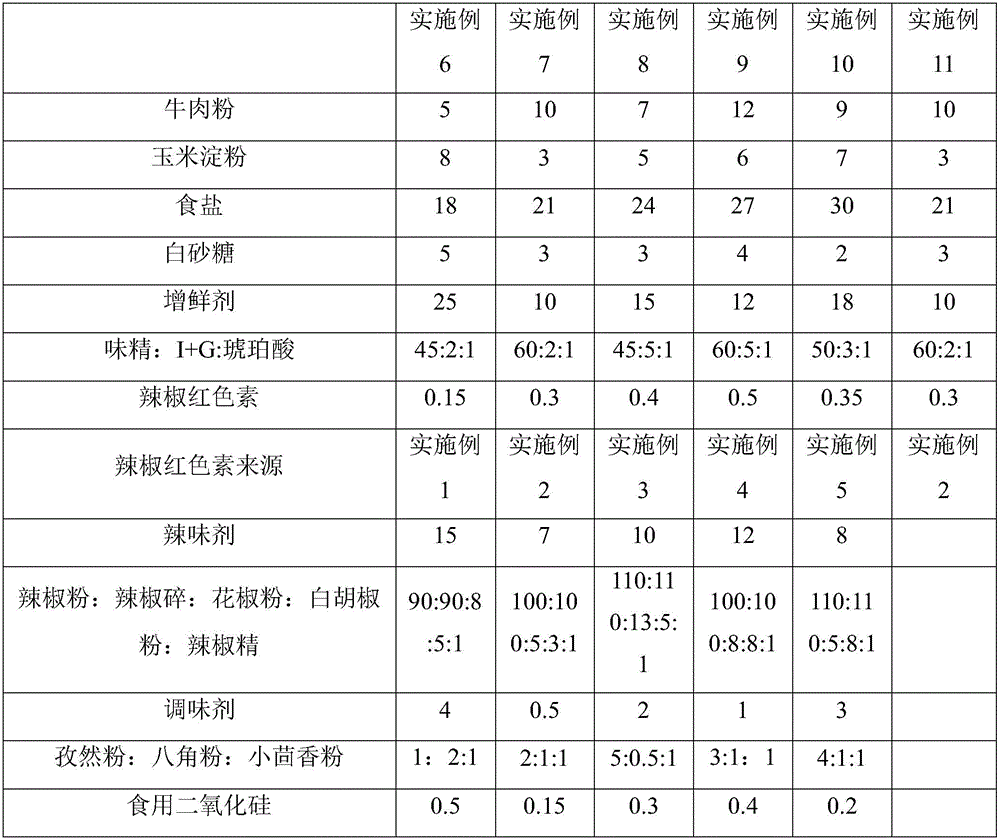

Seasoning powder

The invention discloses a seasoning powder, which comprises the following components in parts by weight: 5-12 parts of beef powder, 3-8 parts of cornstarch, 18-30 parts of table salt, 2-5 parts of white sugar, and 0.15-parts of capsanthin 0.5 parts, freshness enhancer 10‑25 parts. The freshness enhancer includes monosodium glutamate, I+G and succinic acid, and according to parts by weight, the monosodium glutamate: I+G:succinic acid=45-60:2-5:1. Beneficial effects of the invention: the seasoning powder is bright red in color and delicious in flavor, and has good coloring effect.

Owner:SUZHOU MEIJIAHUI FOOD TECH CO LTD

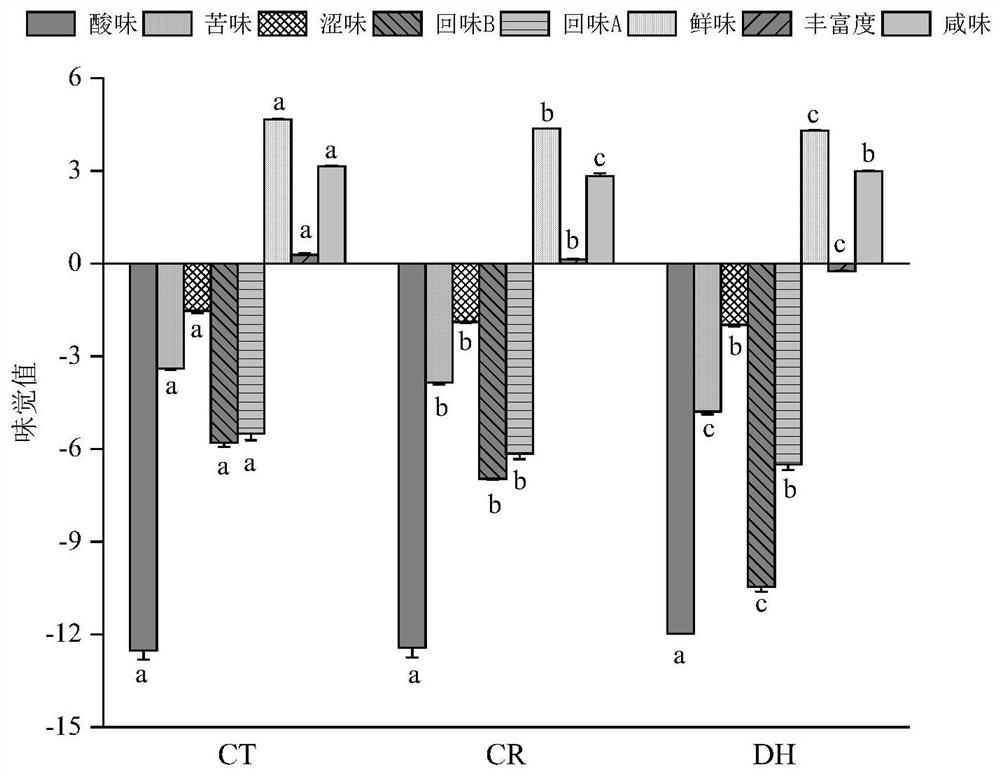

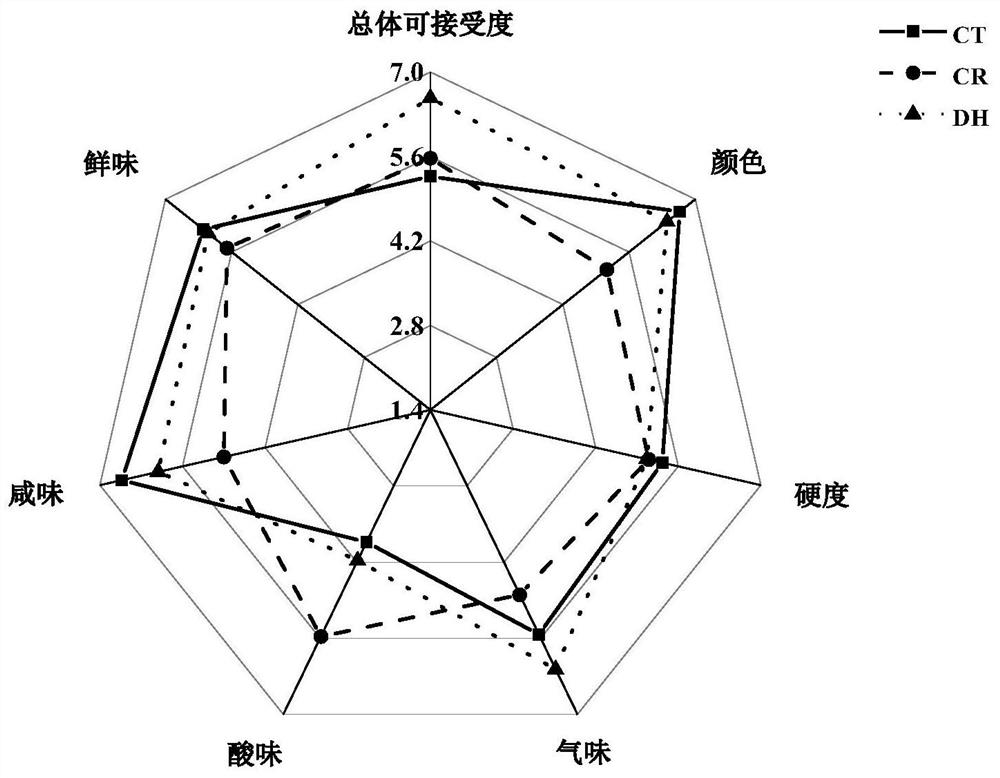

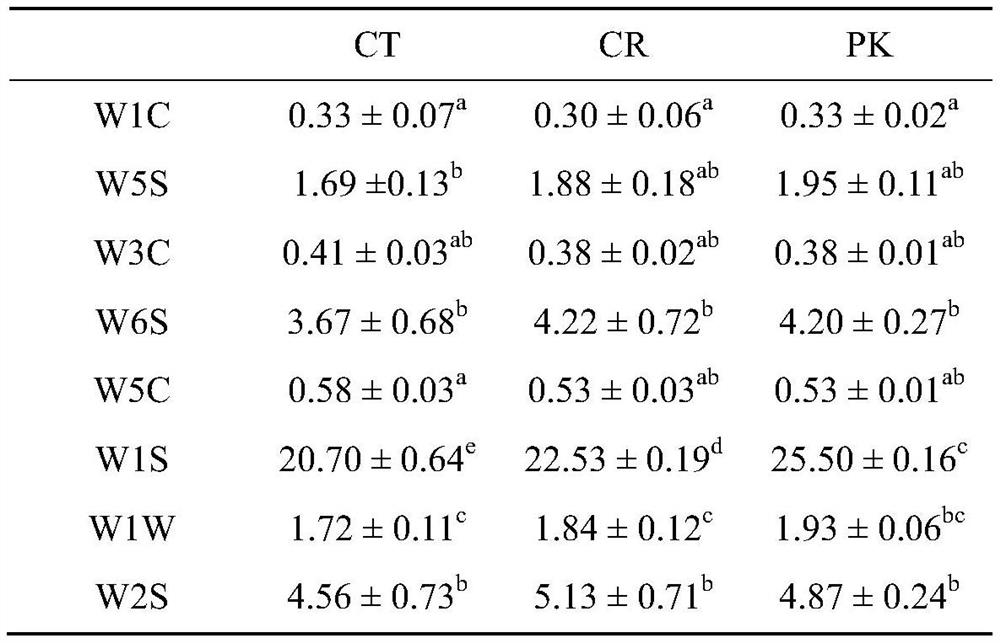

Debaryomyces hansenii SH4 with salt increasing effect and application thereof in low-salt air-dried sausage

PendingCN113969241AReduce bitternessSalt-taste compensating effect confirmedFungiYeast food ingredientsBiotechnologyAlkane

The invention provides a Debaryomyces hansenii SH4 with a salt increasing effect, and belongs to the technical field of microorganisms. The strain is named Debaryomyces hansenii SH4, and is preserved in China General Microbiological Culture Collection Center on May 12, 2021, and the preservation number is CGMCC No. 22507. After the Debaryomyces hansenii SH4 is inoculated into a low-salt air-dried sausage (the addition amount of salt is reduced by 30%) for fermentation for 12 days, the bitterness and astringency of the low-salt air-dried sausage can be inhibited, the saline taste can be improved, and more aromatic hydrocarbons, nitrogen oxides, alkane compounds, sulfides and long-chain alkane substances can be generated. Sensory evaluation results show that the total acceptability is the best, and the air-dried sausage can be softer in texture and stronger in smell. Compared with a low-salt control group, the Debaryomyces hansenii SH4 has higher delicate flavor and color score and moderate sourness, and improves the quality and flavor of the low-salt air-dried sausage. The strain can be used as a novel salt reduction means as a fermentation agent, makes up for the flavor defects of low-salt fermented meat products, and has a better development prospect.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

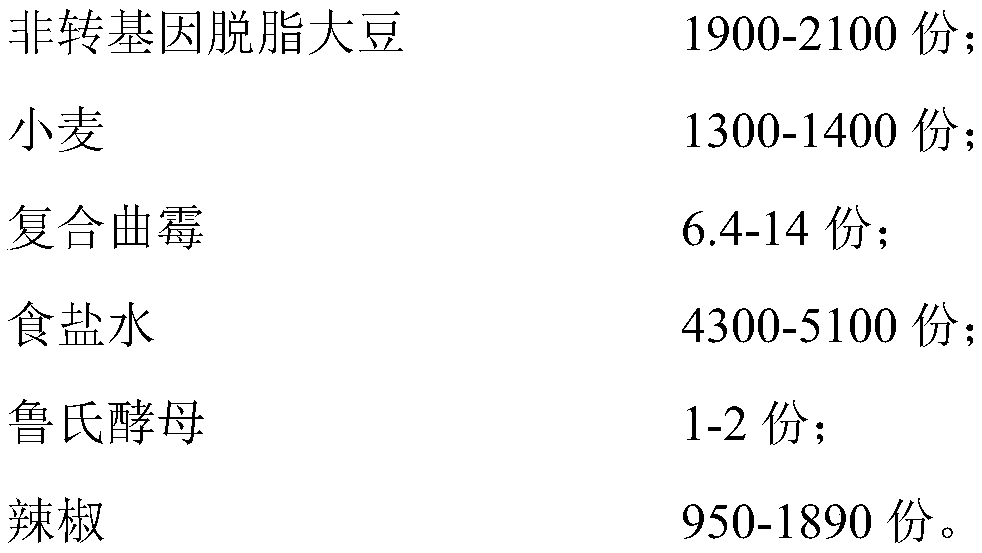

Chili soy sauce and preparation method thereof

InactiveCN109222046ABright red colorSpicy and mellowFood ingredient functionsCapsicum annuumSaccharomyces rouxii

The invention relates to a chili soy sauce and a preparation method thereof, and belongs to the technical field of seasoning production process. The chili soy sauce is prepared from the following massfractions: 1900-2100 parts of non-GMO defatted soybean; 1300-1400 parts of wheat; 6.4-14 parts of composite aspergillus; 4,300-5,100 parts of saline solution; 1-2 parts of saccharomyces rouxii; 950-1,890 parts of chili. The produced soy sauce has a rich sauce flavor, ester flavor and spicy flavor of chili. With full spicy flavor, the umami is more prominent; with the rich flavor and nutrition, the chili soy sauce has the unique flavor of chili and soy sauce. The invention also provides a production method thereof, comprising 7 steps. The method is scientific and reasonable, simple and easy.

Owner:ZIBO QIAOXIFU FOOD SHANDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com