Fluid food and preparation method thereof

A liquid and food technology, applied in food preparation, food science, application, etc., can solve the problems of incomplete nutrition and single taste of liquid food, and achieve the effect of attractive color, wide application range, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

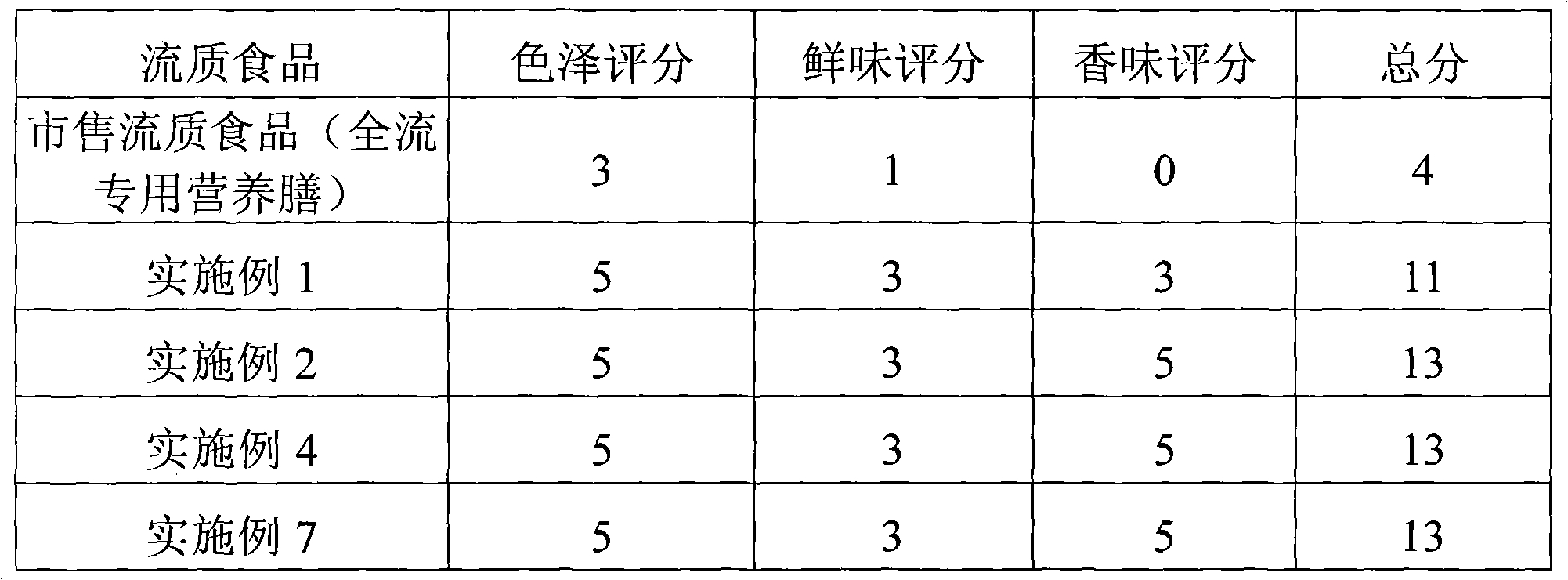

Examples

Embodiment 1

[0031] 1. Chicken soup preparation:

[0032] Wash the whole chicken weighing 1 kg, remove the viscera and head, drain the water, add tap water according to the ratio of whole chicken to water mass of 1:1, heat and boil, the boiling temperature is 70°C, and the boiling time is 6 hours.

[0033] 2. Liquid food formula:

[0034] 75.3% chicken broth prepared in the above step 1, 1.66% salt, 22.16% maltodextrin and 0.88% thickener (carrageenan 50%, gum arabic 50%).

[0035] 3. Liquid food preparation

[0036] (1) Use a shear emulsifier to shear and emulsify 2 / 3 of the chicken broth prepared in step 1, the thickener and maltodextrin according to the recipe, the shear speed is 8000 rpm, and the shear time is 3 minutes .

[0037] (2) According to the formula, the table salt, the remaining part of the chicken soup prepared in step 1 and the feed liquid obtained in step (1) were mixed and put into a mixing heating tank, and heated and stirred at 85° C. for 90 minutes.

[0038] (3) S...

Embodiment 2

[0040] 1. Chicken soup preparation:

[0041] Wash the whole chicken weighing 1.5 kg, remove the viscera and head, drain the water, add tap water according to the ratio of whole chicken to water mass ratio of 1:1.5, heat and boil, the boiling temperature is 80°C, and the boiling time is 4 hours.

[0042] 2. Liquid food formula:

[0043]69.25% chicken broth from step 1, 0.44% salt, 8.99% maltodextrin, 6.93% thickener (gelatin 70%, xanthan gum 20%, acacia gum 10%), 9.11% water, 1% chicken Extract, 1.76% edible spices (20% onion, 10% turmeric, 70% ginger), 1.82% milk powder, 0.2% defoamer (polydimethylsiloxane) and 0.5% food flavor.

[0044] 3. Liquid food preparation

[0045] (1) According to the formula, half of the chicken broth prepared in step 1, the thickener and maltodextrin were sheared and emulsified with a shear emulsifier, the shear speed was 10000 rpm, and the shear time was 2 minutes.

[0046] (2) salt, water, chicken extract, spices, milk powder, defoamer, the rem...

Embodiment 3

[0049] 1. Chicken soup preparation:

[0050] Wash the whole chicken weighing 2.0 kg, remove the viscera and head, drain the water, add tap water according to the ratio of whole chicken to water mass ratio of 1:2, heat and boil, the boiling temperature is 80°C, and the boiling time is 4 hours.

[0051] 2. Liquid food formula:

[0052] 70.1% chicken broth from step 1, 0.6% salt, 16% maltodextrin, 1% thickener (modified starch 70%, carrageenan 30%), 5% water, 4.5% chicken extract, 1.5% milk powder , 0.6% defoamer (polydimethylsiloxane) and 0.7% food flavor.

[0053] 3. Liquid food preparation

[0054] (1) According to the recipe, half of the chicken broth prepared in step 1, the thickener and maltodextrin were sheared and emulsified with a shear emulsifier, the shearing speed was 9000 rpm, and the shearing time was 2 minutes.

[0055] (2) Put salt, water, chicken extract, milk powder, defoamer, the rest of the chicken soup prepared in step 1 and the material liquid obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com