Patents

Literature

37results about How to "Meaty flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soup flavorings and production method thereof

InactiveCN101455319AEnhanced interactionPromote absorptionFood preparationMonosodium glutamateFluidized bed

The invention discloses a soup flavoring and production method thereof. The soup flavoring includes raw materials in the following weight parts: salt, sugar, MSG, evaporated fat powders, flavor development material, natural spices, and Chinese herbal medicines, wherein, the Chinese herbal medicines includes dangshen, angelica sinensis, glycyrrhiza, angelia, astragalus or tangerine peel. The production method includes: respectively performing superfine disintegrating to the salt, sugar, monosodium glutamate, natural spices, and Chinese herbal medicines, mixing together, stirring evenly; adding the evaporated fat powders and flavor development material, stirring evenly; granulating through a granulator, drying through a fluidized bed, and then obtaining the completed product after sealed package. All the raw materials of the invention have been superfine disintegrated, thereby intensifying the coactions of raw materials, specifically, the soup will be more delicious after adding flavor development material. Further, the invention has functions of clearing heat and dropping fire, invigorating spleen-stomach and replenishing qi.

Owner:浙江正道生物科技有限公司

Spicy lunch meat can and preparation method thereof

InactiveCN104187759AReduce typesImprove securityFood ingredient functionsFood preparationChemistrySodium triphosphate

The invention discloses a spicy lunch meat can and a preparation method thereof. The spicy lunch meat can is prepared from the following raw materials: pig meat, chicken meat, corn starch, salt, white granulated sugar, I+G, monosodium glutamate, sodium tripolyphosphate, sodium pyrophosphate, xanthan gum, konjac gum, dried chilli powder or fresh red pepper, Chinese jujube powder, D-sodium erythorbate, spice and salt water. The spice is a mixture of semen myristicae and ground pepper according to a ratio of 1:2-4; and the preparation method comprises the steps of pretreating raw materials; pickling; chopping; loading and sterilizing. The spicy lunch meat has the characteristics of tight tissue, smooth cutting surface, high resilience, thick meat fragrance and fine mouthfeel, and can enhance appetite.

Owner:遂宁市三丰食品有限公司

Preparation method of stewed red-hair duck with soy sauce

The invention discloses a preparation method of stewed red-hair duck with soy sauce. The preparation method comprises the following steps: cleaning a slaughtered red-hair duck, removing entrails, cutting into two parts along the central line of the duck back, shaping, seasoning, roasting, and stewing. The spices include star anise, cassia bark, round cardamom, pricklyash peel, Angelica glabra, amomum fruit and bay leaf. The auxiliary ingredients include white granulated sugar, soy sauce, table salt, distilled spirit, monosodium glutamate, dry chili, ginger, fresh shallot and ethyl maltol. Thefood additives include vanillin, D-sodium isoascorbate, monoscus red pigment and sodium nitrite. The preparation method of stewed red-hair duck with soy sauce makes full use of red-hair duck which iseasily available, integrates the three classic cooking methods of stewing, roasting and seasoning, and adopts the unique flavorings and flavoring formula. The product of stewed red-hair duck with soysauce has the characteristics of high lean content, low fat content, mellow meat flavor, dark red color, crisp and fresh taste and moderate spicy taste.

Owner:JIANGXI GUOHONG GRP CO LTD

Preparation method of tea-fragrance dried pork

InactiveCN106901195AIncrease the fragranceHigh level of antioxidantFood scienceGreen teaFermentation

The invention discloses a preparation method of tea-fragrance dried pork. The preparation method comprises the following steps: (1) performing beating and hammering treatment on pork; (2) performing fermentation treatment: mixing 100-150 parts by weight of pork after beating and hammering treatment with 50-100 parts by weight of fermentation liquor, and performing oxygen-free fermentation at the temperature of 4-7 DEG C for 12-20 h so as to obtain pork after fermentation treatment; (3) performing macerating and kneading treatment: putting the pork after fermentation treatment into green tea macerating liquor, performing pickling for 2-4 h, taking out the pickled pork, then applying a layer of green tea powder on the surface of the macerated pork, and then performing kneading at 2-5 DEG C for 45-60 min so as to obtain preprocessed pork; (4) performing baking treatment. According to the tea-fragrance dried pork prepared according to the preparation method disclosed by the invention, meat quality can be sufficiently softened, the elasticity of the meat quality can be maintained, the tea-fragrance dried pork contains rich tea fragrance, the tea-fragrance dried pork with completely new mouth feel can be brought for consumers, and the tea-fragrance dried pork is simple in technology and convenient to process and has broad market popularization prospects.

Owner:广西聚银牧业集团岭南客家陆川猪肉制品有限公司

Processing method of edible-fungus-type whole-bone meat-flavor seasoning

The invention discloses a processing method of an edible-fungus-type whole-bone meat-flavor seasoning. The edible-fungus-type whole-bone meat-flavor seasoning is a compound seasoning prepared by processing the following raw materials: fresh livestock and poultry bones, edible fungi, thick broad-bean paste, and so on. The processing method of the edible-fungus-type whole-bone meat-flavor seasoning specifically comprises the following processes of: performing high-pressure steaming on the fresh livestock and poultry bones so as to prepare a thick bone soup; performing biological enzymatic hydrolysis on bone residues, bone marrow and meat paste so as to obtain a bone-residue enzymatic hydrolyzate; oil-frying broken bones so as to improve aroma, and performing superfine grinding on the oil-fried broken bones so as to prepare aromatic bone powder; stir-frying the thick broad-bean paste so as to improve aroma; adding the thick bone soup, the aromatic bone powder, the bone-residue enzymatic hydrolyzate, superfine edible-fungus powder, a Maillard reaction base material, flavoring spices and so on into the stir-fried thick broad-bean paste; carrying out stewing and a Maillard reaction so as to prepare the edible-fungus-type whole-bone meat-flavor seasoning; and then, carrying out filling when the edible-fungus-type whole-bone meat-flavor seasoning is still hot, and carrying out sterilization by adopting irradiation. The shelf life of the prepared edible-fungus-type whole-bone meat-flavor seasoning is 8 months or longer at room temperature. The edible-fungus-type whole-bone meat-flavor seasoning is a high-end convenient meat-flavor seasoning suitable for dishes and soup.

Owner:CHENGDU UNIV

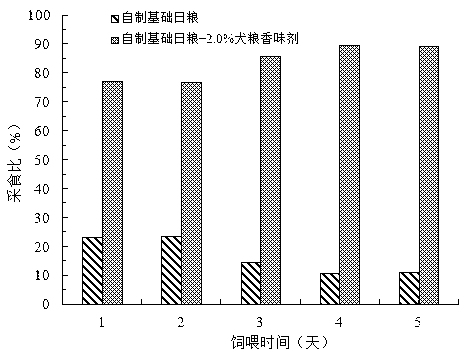

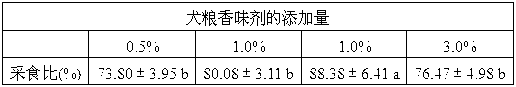

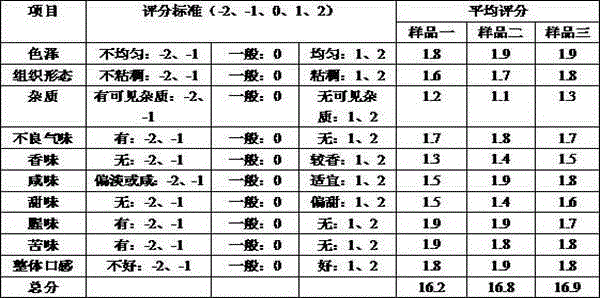

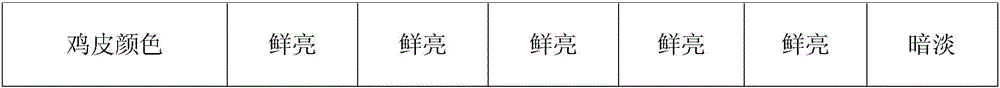

Preparation method for solid powder dog-food flavoring agent

InactiveCN103005155AIncrease profitIncrease added valueAnimal feeding stuffAdditive ingredientHydrolysate

The invention discloses a preparation method for solid powder dog-food flavoring agent, belonging to the technical field of feeding process. The preparation method provided by the invention comprises the following steps of: using chicken breast meat as the main material; using protease to hydrolyze the main material; tracking and determining the degree of hydrolysis of enzymatic hydrolysate; obtaining enzymatic hydrolysate which is rich in amino acid, short-peptide and free of bitter taste; adding D-xylose, L-cysteine hydrochloride and vitamin B1 to the enzymatic hydrolysate for further reacting; adding tara gum and modified starch to mix and homogenize; and finally, spraying and drying to obtain the solid powder dog-food flavoring agent. The solid powder dog-food flavoring agent prepared by the preparation method provided by the invention has strong meat flavor and outstanding delicious taste, improves the utilization rate and additional value of the fresh chicken breast meat, and can cover the bad odor in the materials and the production process by re-dissolving and adding to the dog food. The solid powder is obtained by spraying and drying after being embedded by the tara gum and modified starch, so that the loss of the flavor components in the spraying and drying process is reduced. Compared with the market liquid dog-food flavoring agent, the solid powder dog-food flavoring agent prepared by the preparation method provided by the invention is more convenient to transport and store, and has good market prospect.

Owner:JIANGNAN UNIV

Method for increasing yield of maillard peptide by using enzyme cross-linked action

The invention discloses a method for increasing the yield of maillard peptide by using enzyme cross-linked action, belonging to the field of food additives. The cross linking of peptides is promoted by using the enzyme action so as to increase the content of 1000-5000Da peptide sections of the peptide, thereby the yield of the maillard peptide (a maillard product with 1000-5000Da) in the products is increased and further flavor peptide with a full mellow taste is effectively prepared. The method comprises the specific steps of: adding enzyme into a 5-15 percent (substrate concentration) peptide solution according to the mass percentage of the enzyme to the peptide as 0.1-1.0 percent; carrying out cross linking at the pH value of 5-8 and the temperature of 35-45DEG C for 4.0-6.0h; adding 0.1-0.5g of sugar and 0.05-0.3g of L-cysteine in 6-16g of peptide solution subjected to cross linking, uniformly mixing and reacting at the temperature of 100-130DEG C for 1.5-3.5h; and cooling with icy water to end the reaction, spraying and drying the reaction solution to obtain the flavor peptide. The flavor peptide is powder with shallow yellow color; the content of the maillard peptide is as high as 15-20 percent; and compared with the like products prepared with the conventional method, the yield of the maillard peptide is increased by 17-28 percent. The flavor peptide produced by adopting the method has shallow color and luster, and strong, mellow and full aroma of meat and can be applied to meat seasoning products as an addictive, and the problems that the use of the cysteine results in reduction in color and luster, increase in the aroma of the meat but decrease in the yield of the maillard peptide are effectively solved.

Owner:JIANGNAN UNIV

Composite dried meat floss sauce and making method thereof

InactiveCN105231159ASoft and juicyAchieve the effect of direct consumption of weak thornsFood ingredient as colourFood ingredient as taste affecting agentMonosodium glutamateBiotechnology

The invention discloses a composite dried meat floss sauce and a making method thereof. The composite dried meat floss sauce is made from the following raw materials in parts by weight: 20-24 parts of silver carp meat, 15-18 parts of pig hams, 15-18 parts of Sanhuang chicken leg meat, 15-20 parts of rapeseed oil, 8-10 parts of cooking wine, 2-3 parts of chili, 2-3 parts of a soy sauce, 1-1.5 parts of sugar, 1.5-2 parts of salt, 1-1.5 parts of gourmet powder, 2-4 parts of sesame seeds, 6-8 parts of peanut kernels, 2-4 parts of scallions, 0.5-1.5 parts of ginger, 1-3 parts of garlic, 0.4-0.6 part of star aniseed, 1800-2200 parts of a fishy smell removing solution and 6-8 parts of a black tea. The composite dried meat floss sauce and the making method thereof disclosed by the invention have the beneficial effects that fresh silver carp meat is adopted, and after the fresh silver carp meat is treated through certain steps, the effect that fine fish bones can be directly eaten can be realized; the pig hams are marinated by black tea soup, so that the meat fragrance is rich, and the color is brighter; after the chicken leg meat is baked, two kinds of mouth feel are given, finally a condiment product obtained by mixing three kinds of dried meat flosses is high in layering feeling, and rich in fragrance, and the mouth feel of the condiment product is different from the mouth feel of a traditional dried meat floss and a traditional condiment; after reasonable collocation, the nutrient diet is more balanced, and requirements of consumers are met.

Owner:SHANDONG HUIFA FOODS

Amino acid-containing feed additive

ActiveCN106333081ACompatibility is reasonableSimple manufacturing processAnimal feeding stuffAccessory food factorsBiotechnologyVitamin C

The invention belongs to the field of feed preparation, and discloses an amino acid-containing feed additive, which is prepared from the following raw materials by weight: 3-5 parts of compounded amino acid, 3-5 parts of fish bone powder hydrolyzate, 1-2 parts of kelp powder, 1-2 parts of maltodextrin, 1-2 parts of corn starch, 0.5-0.9 part of a yeast extract, 0.2-0.3 part of zinc sulfate, 0.2-0.3 part of manganese sulfate, 0.1-0.2 part of citric acid, 0.1-0.2 part of magnesium sulfate, 0.1-0.2 part of vitamin C, 0.05-0.1 part of riboflavin, and 0.05-0.1 part of xanthan gum. According to the present invention, the additive does not contain any harmful substances and can effectively replace antibiotics and hormones.

Owner:内蒙古阜丰生物科技有限公司

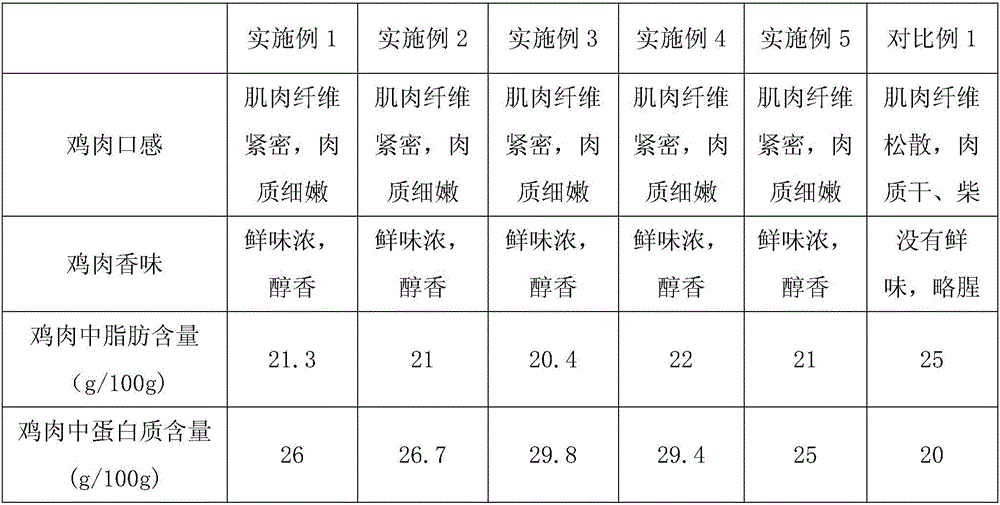

Chicken raising method for improving chicken meat quality

InactiveCN106719409APromote absorptionAbsorb moreFood processingAnimal feeding stuffDiseaseFree range

The invention relates to the technical field of improving chicken meat quality by raising chickens, and particularly to a chicken raising method for improving chicken meat quality. The chicken raising method for improving chicken meat quality comprises a chick stage, a growing chicken stage and an adult chicken stage. In the chick stage, the chicks are in free-range in the forest to enhance the disease resistance of chicks, and are fed with chick fodder to facilitate development of the kidney of chicks and promote the maturation of chicks. In the growing chicken stage, different management is carried out for the growing chickens according to the transformation of the four seasons, and growing chickens are fed with growing chickens assorted feed, so that the immunity of growing chickens can be enhanced and the growing chickens grow healthily. In the adult chicken stage, adult chickens are raised in the forest, and are fed with adult chicken assorted feed to make the quality of chicken fresh better.

Owner:广西睿桂涵农业有限公司

Processing method of ganoderma lucidum fermented rice meal

InactiveCN107439921AMeaty flavorFull of nutritionCultivating equipmentsMushroom cultivationBiologyHorticulture

The invention discloses a processing method of ganoderma lucidum fermented rice meal. The ganoderma lucidum fermented rice meal is processed by inoculating a ganoderma lucidum strain in shelled rice. The ganoderma lucidum fermented rice meal has the advantages of natural fermented fragrance, safety, health, good processability and stable quality.

Owner:广西秀瑶姑生态农业科技有限公司

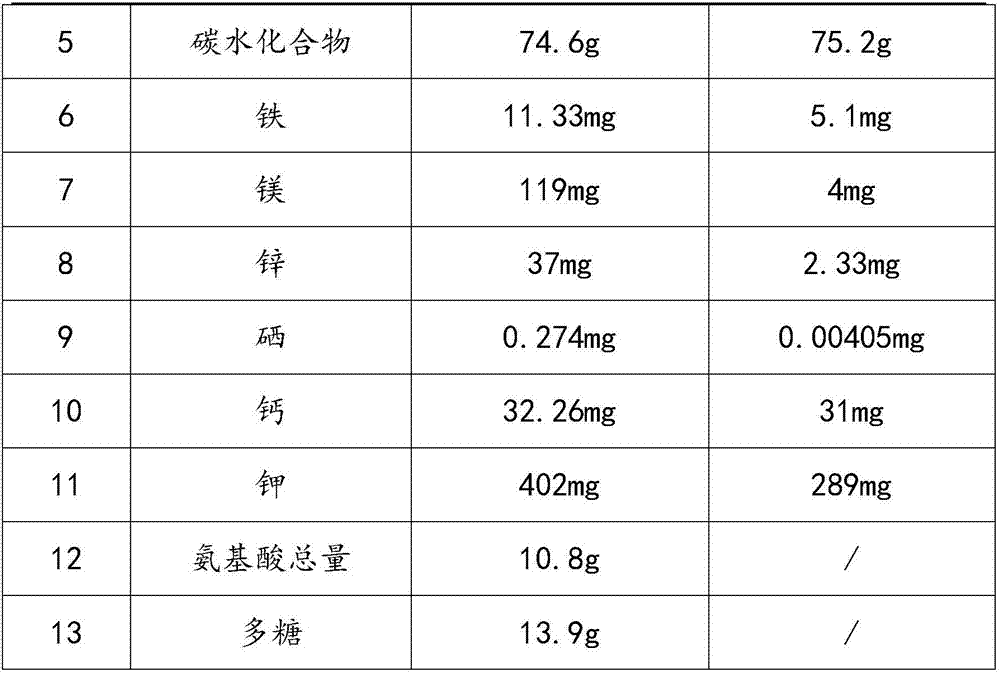

Processing method of beef brisket fat

InactiveCN108294094ANeat appearanceTender meatFood freezingMeat/fish preservation by shapingLean meatBrick

The invention discloses a processing method of beef brisket fat. The method comprises the following steps: selecting beef at different parts which is subjected to acid discharging, conducting weighing, matching brisket fat with lean meat, overlying for shaping, conducting outer packaging with an organic plastic film, placing the packaged meat in a stainless steel mould, conducting rolling for shaping, and conducting quick freezing in a quick freezing storage at a temperature of -40 to -35 DEG C for 3-9 hours, so that the brick-shaped beef fat can be processed. During processing, the beef brisket fat comprises the following main components: beef brisket fat, beef, water, a a stabilizer, an acidity regulator, a thickening agent, an emulsifier, an antioxidant, potassium chloride, edible saltand konjac powder. The invention belongs to the technical field of meat food processing; the preparation technology is simple and quick, short in processing time, high in efficiency and normative in operation; and the processed beef brisket fat is neat in appearance, beautiful in texture, tender in meat quality, bright in meat color, rich in meat aroma and long in shelf life up to 12 months.

Owner:宋强

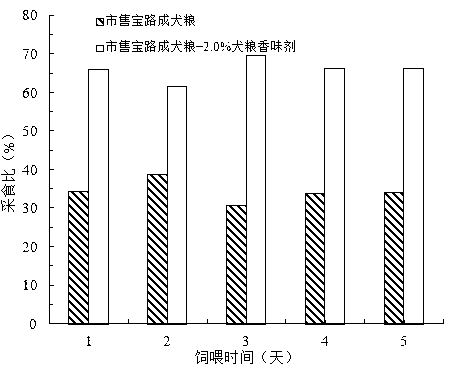

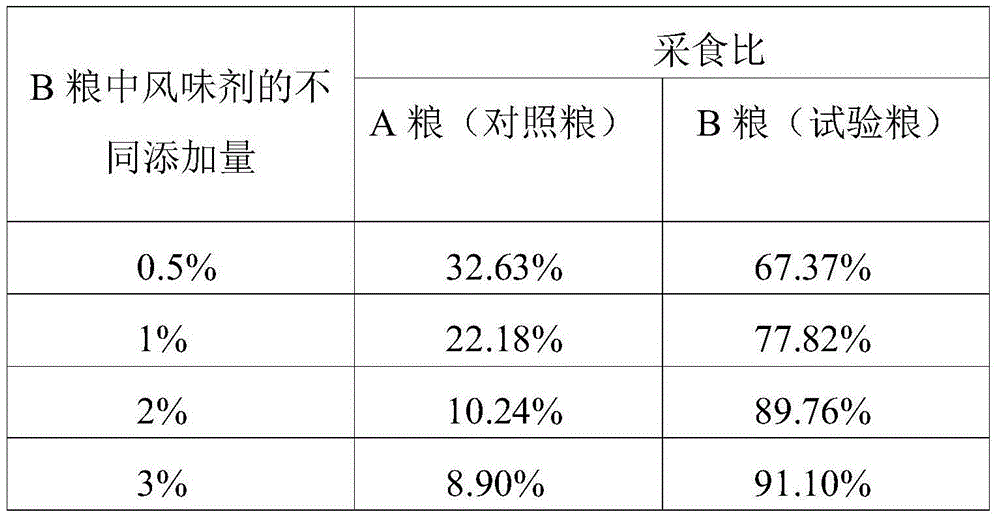

Preparation method for beef-flavor solid powdery flavoring agent used for dog food

The invention discloses a preparation method for a beef-flavor solid powdery flavoring agent used for dog food. The preparation method comprises the following steps: processing meat paste from beef and cow livers; adding water into the meat paste and carrying out full stirring so as to obtain meat slurry; heating the meat slurry to 45 to 60 DEG C, adjusting a pH value to 5.5 to 7.0, adding protease, carrying out a hydrolysis reaction under stirring until the hydrolysis degree of the meat slurry is 23 to 27%, allowing temperature to rise to 92 to 95 DEG C within 30 min and continuing stirring so as to obtain an enzymatic hydrolysis liquid; adding reducing sugar and amino acid into the enzymatic hydrolysis liquid, carrying out uniform mixing under stirring, and carrying out heating at 95 to 110 DEG C for 30 to 50 min so as to obtain an enzymatic hydrolysis product; and adding modified starch into the enzymatic hydrolysis product, carrying out uniform mixing under stirring and then carrying out spray drying so as to obtain the flavoring agent. The invention has the following beneficial effects: since the beef and the cow livers are used as main raw materials, the flavoring agent has low cost and the utilization rate and added value of the beef and the cow livers are effectively improved; and the flavoring agent has rich meat fragrance and protruding characteristic flavor, greatly improves the flavor and palatability of dog food and has good market prospects in application of pet food.

Owner:WING BIOTECH SHANGHAI CO LTD

Food additive containing xanthan gum

InactiveCN106333330AImprove absorption and utilizationCompatibility is reasonableFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFood additiveFood flavorings

The invention belongs to the field of food seasonings, and discloses a food additive containing xanthan gum, and the food additive containing xanthan gum comprises the following raw materials by weight: 1-2 parts of the xanthan gum, 1-2 parts of citric acid, 1-2 parts of white granulated sugar powder, 2-3 parts of yeast extract, 2-3 parts of corn starch, 3-5 parts of maltodextrin, 7-15 parts of kelp powder, 7-15 parts of mussel enzymolysis liquid and 10-20 parts of compound amino acids. The food additive is reasonable in material composition, rich in fresh flavor and good in taste.

Owner:内蒙古阜丰生物科技有限公司

Low-salt preserved fishes and preparation method thereof

InactiveCN109452577AReduce salt contentShorten drying timeFood thermal treatmentMeat/fish preservation by heatingCooking & bakingFreeze-drying

The invention discloses low-salt preserved fishes and a preparation method thereof. Fresh live fishes are selected, pretreated, pickled with pickling materials, then subjected to thermal processing, subjected to baking or freeze drying, and subjected to packaging and sterilization so as to obtain the low-salt preserved fishes with the salt content of 3% or below. According to the invention, the preserved fishes obtained by pickling with the self-made pickling materials not only can restore the fresh and tender meat quality of fresh fishes, but also retain various nutrient components in the fresh fishes, wherein the content of vitamin A is particularly high, and the contents of elements such as phosphorus, calcium and iron are very high. The preserved fishes prepared by the method have theadvantages of low salt content, uniform color, sanitation, health, convenience for eating and traditional smoking flavor, are a healthy fish product, and have good market prospect and market popularization value.

Owner:湖南唐人神肉制品有限公司

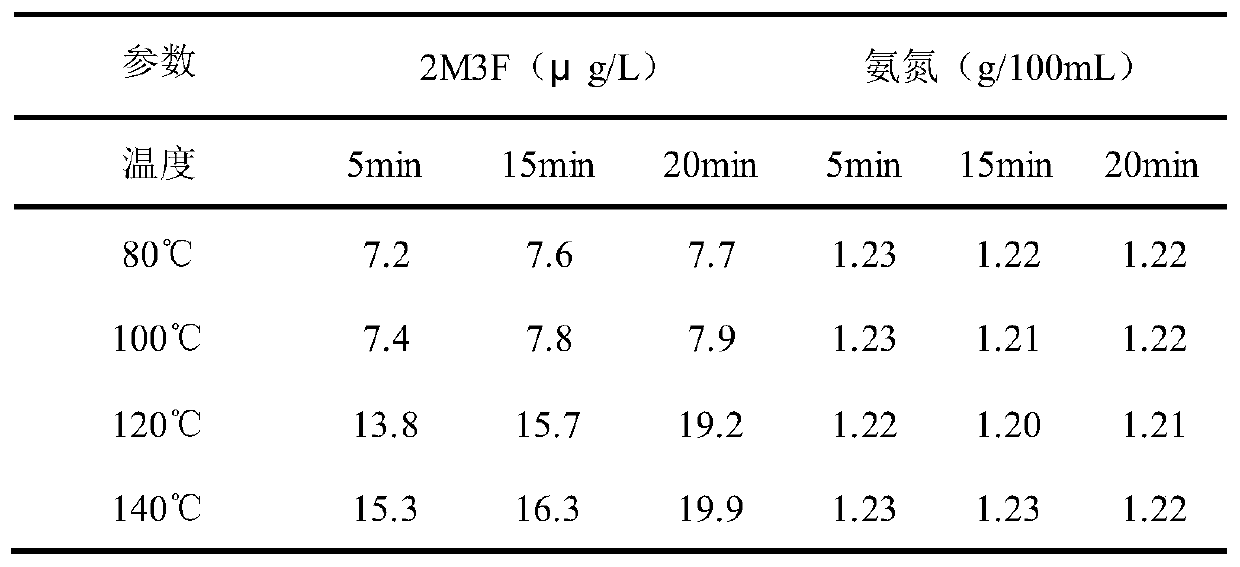

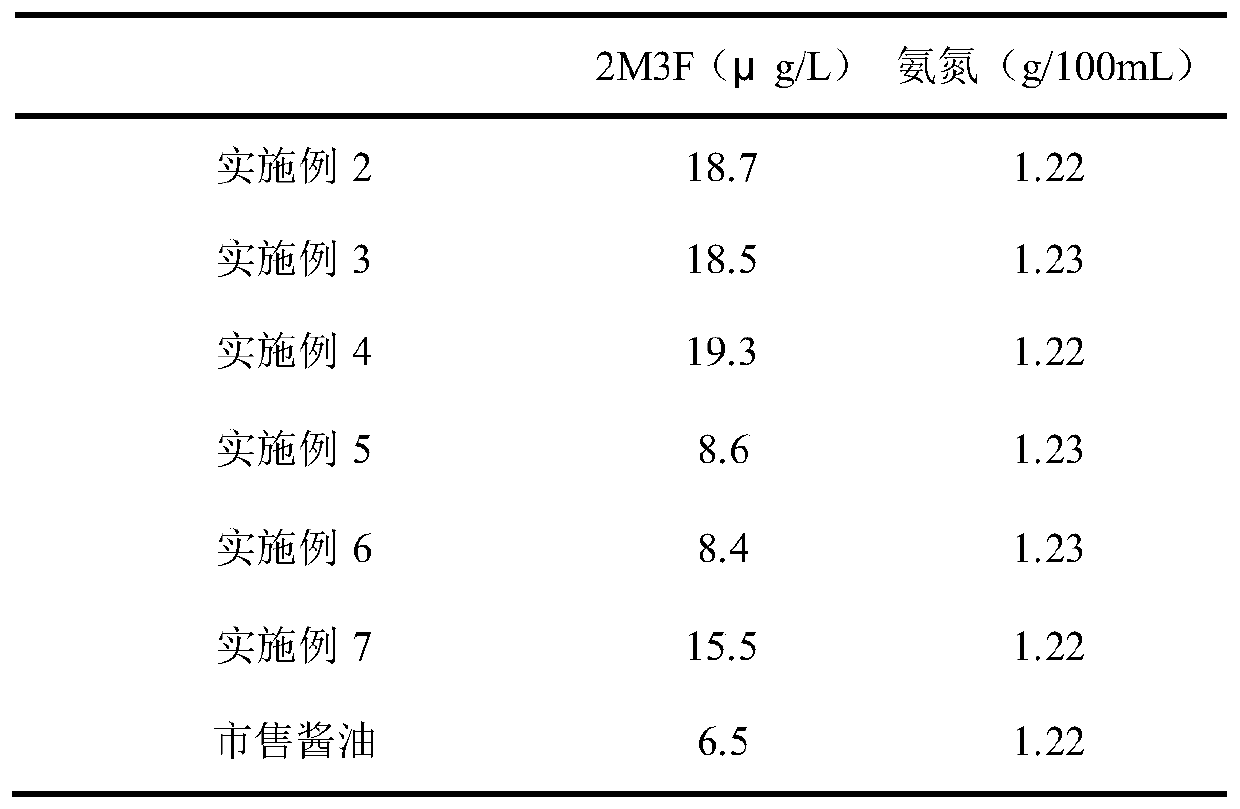

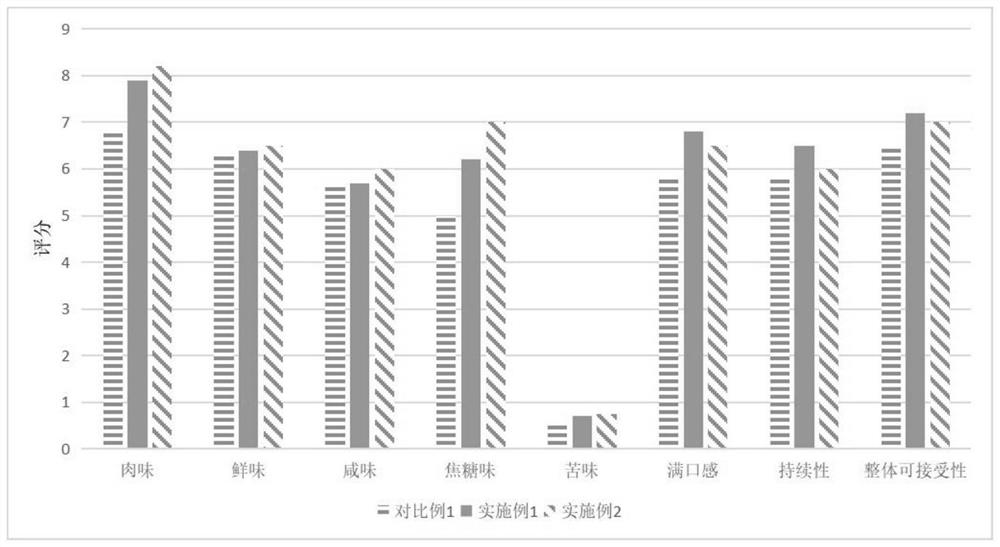

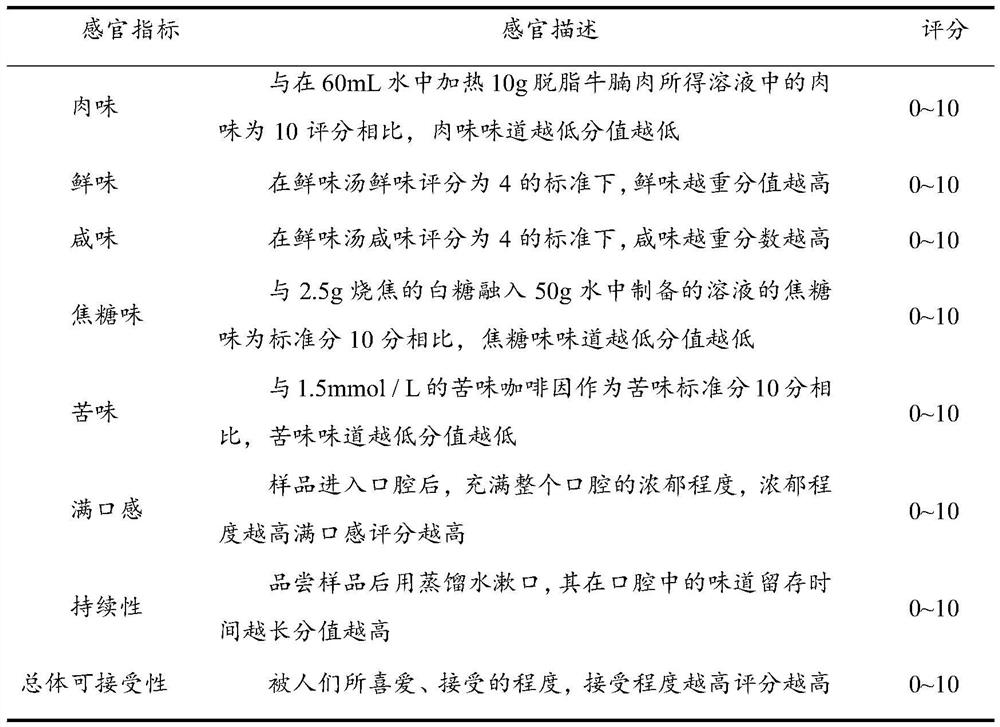

Method capable of increasing soy sauce 2M3F content and application of method

ActiveCN109907293A2M3F content is highMeaty flavorFood scienceClimate change adaptationChemistrySalt water

The invention discloses a method capable of increasing soy sauce 2M3F content and application of the method. The method includes the steps of firstly, mixing soybean and wheat to produce yeast; secondly, fermenting, to be more specific, adding salt water and hemicellulase into the yeast obtained in the first step, and fermenting in a tank to obtain a fermentation culture medium; thirdly, inoculating a yeast seed solution into the fermentation culture medium, continuously fermenting for 5-6 months, and squeezing after the fermenting to obtain raw soy sauce; fourthly, adding methionine and / or cysteine into the raw soy sauce, and performing sealed and temperature-controlled sterilizing to obtain the soy sauce. The soy sauce produced by the method has the advantages that the 2-methyl-3-furanthiol content of the soy sauce is evident higher than that of existing soy sauce, the soy sauce is rich in meat fragrance, and the quality of the soy sauce is better than that of traditional fermented soy sauce.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Flavor-enhancing composition and preparation method and application thereof

PendingCN111616348AHigh nutritional valueMeaty flavorDough treatmentBakery productsBiotechnologyNutritive values

The invention relates to a flavor-enhancing composition and a preparation method and application thereof. The flavor-enhancing composition includes a first composition and a second composition, wherein the first composition is prepared from 20-100 parts of Chinese yam powder and 0.5-2 parts of wood sugar, and the second composition is prepared from 2.5-7.5 parts of alanine, 0.25-0.75 part of cysteine, and 2.5-7.5 parts of wood sugar. The flavor-enhancing composition has the advantages of higher nutritional value, naturalness, safety, strong meat flavor, and delicious taste.

Owner:合肥华恒生物工程有限公司

Tea-flavored duck meat preparation technology

The invention discloses a tea-flavored duck meat preparation technology in the field of food processing. The tea-flavored duck meat preparation technology includes chopping a duck into small pieces, deep-frying the chopped duck, taking out the deep-dried chopped duck and draining off oil; putting withered fresh tea leaves into a wok, heating to stir-fry for 30-40 minutes, adding the deep-fried chopped duck, braising the mixture for 50-60 minutes at 95-100 DEG C, taking out the mixture, and separating the tea leaves from the chopped duck; adding clear water into the wok, heating the clear water to boil, adding rice to boil for 5-8 minutes, adding the braised chopped duck for 5-8 minutes and taking out the mixture; spreading the braised tea leaves in a baking tray, covering the surfaces of the tea leaves with gauze, spreading the boiled chopped duck on the gauze, brushing edible oil on the chopped duck, putting the baking tray in an oven, controlling the internal temperature of the oven at 100-105 DEG C, braking for 12-14 minutes, and taking the baking tray out. The tea-flavored duck meat preparation technology has the advantages that through synergistic effect of all the steps, oily smell of duck meat is removed effectively, the duck meat is endowed with delicate tea aroma, and the duck meat is fresher and tenderer, strong in aroma and high in palatability.

Owner:遵义市俊丰食品有限责任公司

Preparation process of compound xanthan gum additive

InactiveCN106307449ASimple manufacturing processCompatibility is reasonableFood scienceBiotechnologyFood additive

The invention belongs to the technical field of preparation of food additives and discloses a preparation process of a compound xanthan gum additive. The preparation process comprises the following steps: (1) preparing a yeast extract; (2) preparing kelp powder; (3) preparing mussel enzymatic hydrolysate; (4) preparing compound amino acid; (5) weighing the raw materials in parts by weight; (6) premixing; (7) mixing, and granulating; and (8) drying, and sieving. The preparation process is simple and feasible, and the prepared additive has stable performance, uniform appearance, striking delicate flavor and complete nutrition.

Owner:内蒙古阜丰生物科技有限公司

Ham pork can and preparation method thereof

InactiveCN110122788AImprove securityGood colorFood ingredient as colourFood ingredient for microbe protectionFood additiveCarrageenan

The invention discloses a ham pork can which comprises the following raw materials in parts by weight: 70-75 parts of pork, 4-8 parts of corn starch, 1-1.5 parts of edible salt, 0.5-1.5 parts of whitegranulated sugar, 0.01-0.03 part of sodium glutamate, 0.1-0.2 part of sodium tripolyphosphate, 0.1-0.2 part of sodium pyrophosphate, 0.2-0.5 part of carrageenan, 0.04-0.06 part of D-sodium isoascorbate, 0.03-0.06 part of spice, 10-14 part of flake ice, 0.1-0.5 part of ganoderan, 0.1-0.6 part of polysaccharides from Gastrodia Elata Blume and 0.1-0.8 part of astragalus polysaccharide. The food additive disclosed by the invention is few in type, the content is far lower than the upper limit value specified by the state, nitrite is not added, and the safety is high; the added spice is a mixture of semen myristicae and ground pepper, the addition types are less, the addition amount is small, the original flavor of a meat product is kept to the maximum extent, and the taste is pure; and dry chilli powder is particularly added, the color of the meat product is improved, vitamins required by human bodies are supplemented, meanwhile, the taste of ham pork is enriched, and the appetite of people is improved.

Owner:四川飘香远大食品有限公司

Borneol beef food

InactiveCN103549469BReduce lossesPromote absorptionFood ingredient functionsFood preparationMonosodium glutamateFood flavor

The invention discloses a borneol beef food which is prepared from the following raw materials in parts by weight: 100 parts of beef, 2-3 parts of salt, 1-2 parts of white sugar, 1-2 parts of monosodium glutamate, 1-2 parts of a borneol distilled solution, 1-3 parts of borneol extracting oil and 1-2 parts of sesame oil. A preparation method for the borneol beef food comprises the following steps: processing the raw materials, extracting borneol, rolling, salting, drying, roasting, stirring and seasoning. According to the borneol beef food, the beef with the high nutrition and the borneol with the excellent penetrating capacity and medicinal value are combined for providing the leisure borneol beef food which has the clean aroma of the borneol and a flavor of the beef, has special medicinal effects of bacteria and inflammation resistance and the like of the borneol, and is peculiar, and the nutrition of the borneol beef food can be very easily absorbed.

Owner:新晃嘉信食品有限公司

Soup flavorings and production method thereof

InactiveCN101455319BEnhanced interactionPromote absorptionFood preparationFlavorMonosodium glutamate

The invention discloses a soup flavoring and production method thereof. The soup flavoring includes raw materials in the following weight parts: salt, sugar, MSG, evaporated fat powders, flavor development material, natural spices, and Chinese herbal medicines, wherein, the Chinese herbal medicines includes dangshen, angelica sinensis, glycyrrhiza, angelia, astragalus or tangerine peel. The production method includes: respectively performing superfine disintegrating to the salt, sugar, monosodium glutamate, natural spices, and Chinese herbal medicines, mixing together, stirring evenly; addingthe evaporated fat powders and flavor development material, stirring evenly; granulating through a granulator, drying through a fluidized bed, and then obtaining the completed product after sealed package. All the raw materials of the invention have been superfine disintegrated, thereby intensifying the coactions of raw materials, specifically, the soup will be more delicious after adding flavor development material. Further, the invention has functions of clearing heat and dropping fire, invigorating spleen-stomach and replenishing qi.

Owner:浙江正道生物科技有限公司

Preparation technology of food additive containing xanthan gum

ActiveCN106262617AImprove absorption and utilizationSimple manufacturing processFood scienceFood additiveFood flavor

The invention belongs to the technical field of food additive preparation and discloses a preparation technology of a food additive containing xanthan gum. The preparation technology is characterized by comprising the following steps of 1, weighing raw materials; 2, performing premixing; 3, performing mixing and granulating; 4, performing drying and screening. The preparation technology of the food additive is simple and feasible, raw materials are reasonably compatible, the delicate flavor is enough and the taste is good.

Owner:内蒙古阜丰生物科技有限公司

Method for increasing yield of maillard peptide by using enzyme cross-linked action

The invention discloses a method for increasing the yield of maillard peptide by using enzyme cross-linked action, belonging to the field of food additives. The cross linking of peptides is promoted by using the enzyme action so as to increase the content of 1000-5000Da peptide sections of the peptide, thereby the yield of the maillard peptide (a maillard product with 1000-5000Da) in the productsis increased and further flavor peptide with a full mellow taste is effectively prepared. The method comprises the specific steps of: adding enzyme into a 5-15 percent (substrate concentration) peptide solution according to the mass percentage of the enzyme to the peptide as 0.1-1.0 percent; carrying out cross linking at the pH value of 5-8 and the temperature of 35-45DEG C for 4.0-6.0h; adding 0.1-0.5g of sugar and 0.05-0.3g of L-cysteine in 6-16g of peptide solution subjected to cross linking, uniformly mixing and reacting at the temperature of 100-130DEG C for 1.5-3.5h; and cooling with icy water to end the reaction, spraying and drying the reaction solution to obtain the flavor peptide. The flavor peptide is powder with shallow yellow color; the content of the maillard peptide is as high as 15-20 percent; and compared with the like products prepared with the conventional method, the yield of the maillard peptide is increased by 17-28 percent. The flavor peptide produced by adopting the method has shallow color and luster, and strong, mellow and full aroma of meat and can be applied to meat seasoning products as an addictive, and the problems that the use of the cysteine results in reduction in color and luster, increase in the aroma of the meat but decrease in the yield of the maillard peptide are effectively solved.

Owner:JIANGNAN UNIV

Preparation method of stewed red-hair duck with soy sauce

Owner:JIANGXI GUOHONG GRP CO LTD

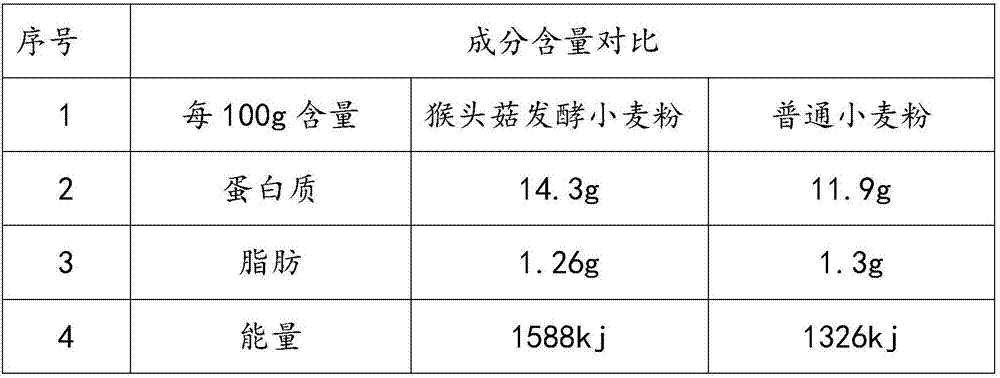

Processing method of hericium erinaceus fermented wheat flour

The invention discloses a processing method of hericium erinaceus fermented wheat flour. The hericium erinaceus fermented wheat flour is processed through inoculating wheat with hericium erinaceus strains. The hericium erinaceus fermented wheat flour has the advantages of being natural in fermentation fragrance, safe, healthy, good in processing properties and stable in quality.

Owner:广西秀瑶姑生态农业科技有限公司

Method for raising geese on farmland after autumn harvest

The invention discloses a method for raising geese on farmland after autumn harvest and relates to the technical field of poultry raising. The method comprises steps as follows: a proper raising field is selected; the farmland after autumn harvest is cleared up and prepared, the periphery of the selected farmland is fenced, and a goose house is constructed; geese which are more than six months old and suitable for field survival are selected; plant ash mixed with lime is applied to the farmland periodically, steps including sterilization and epidemic prevention measures and the like are well done, goose dung discharged by the geese increases organic fertilizer for the farmland, fattening of the land is facilitated, usage of chemical fertilizer is reduced, and environmental protection and food safety are facilitated; the geese are prevented from being fed with synthetic feed, food of the geese mainly comprises fallen grain, farmland weeds, crop stubbles and farmland insects after autumn harvest, the vacant farmland is reasonably utilized, fallen grain is prevented from being wasted, meanwhile, farmland pests in the next year are reduced, insecticide usage is avoided, environmental protection and food safety are facilitated, meanwhile, meat is better flavored, and the economic benefit is better.

Owner:四川喜亚动物药业有限公司

A kind of preparation method of amino acid compound feed additive

ActiveCN106333082BCompatibility is reasonableSimple manufacturing processAnimal feeding stuffAccessory food factorsBiotechnologyNutrition

The invention belongs to the field of feed preparation, and discloses an amino acid composite feed additive preparation method, which comprises: 1) weighing, 2) pre-mixing, 3) mixing and granulation, and 4) drying and screening. The amino acid composite feed additive preparation method is simple and feasible, and the prepared feed additive has characteristics of sufficient flavor, complete nutrition, and immunity improving.

Owner:内蒙古阜丰生物科技有限公司

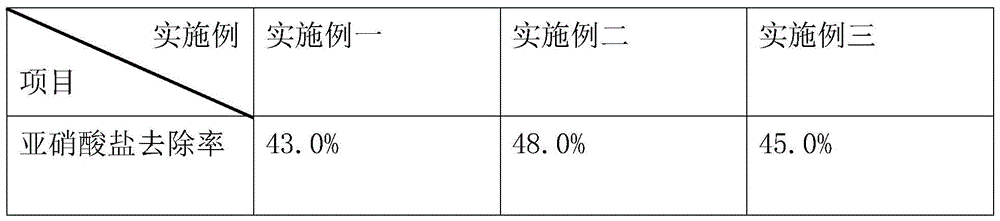

Methods to Eliminate Nitrite in Salted Fish

InactiveCN104256730BReduce contentTaking into account anti-corrosion and fresh-keeping effectFood scienceNitriteHydrogen

The invention discloses a method for eliminating nitrite in salted fish. The salted fish is washed with clean water to remove the surface salt, divided into blocks, soaked in dilute hydrochloric acid, and then the block-shaped salted fish is washed and drained; The washed block salted fish is soaked in deionized water, and centrifuged; the treated salted fish is soaked in a conditioner, and ultrasonic treatment is performed while soaking; the treated salted fish is put into a pool, and the Autotrophic denitrifying bacteria are inoculated on the surface, and inorganic sulfur is used as a substrate to provide hydrogen and passive sources; oxidants are put into the pool to remove nitrite. On the premise of ensuring the characteristics of traditional salted fish, the present invention can greatly eliminate the nitrite produced in the pickling process of salted fish through the regulator combined with ultrasonic treatment, reduce the possibility of the danger of nitrite in salted fish to the human body, and obtain Salted fish products with low salt content also take into account the antiseptic and fresh-keeping effect of salted fish under low-salt conditions, maintaining a strong meaty aroma and a soft and smooth taste.

Owner:BOHAI UNIV

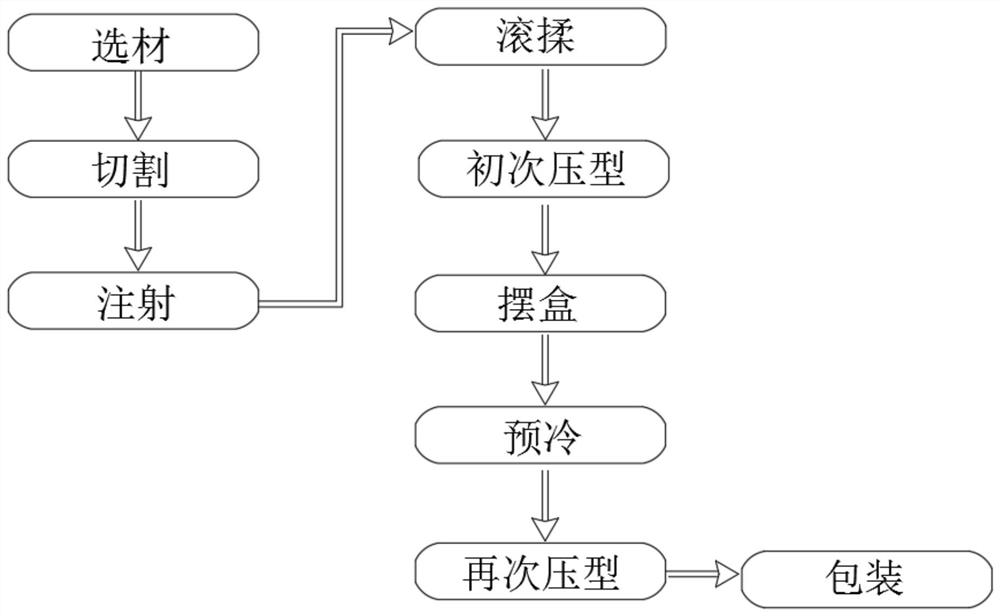

Making method of high-fat tendon-free fat beef

PendingCN114568649AGreat tasteLow costFood freezingFood ingredient as thickening agentBiotechnologyAnimal science

The invention relates to the technical field of fat beef making, and discloses a making method of high-fat tendon-free fat beef, which comprises the following steps: S1, material selection: selecting high-fat tendon-free beef breast meat, cleaning the selected high-fat tendon-free beef breast meat, putting the cleaned raw material into a slow melting area, removing an outer packaging box to obtain a well-packaged fat beef raw material, and carrying out acid discharge treatment on the well-packaged fat beef raw material; s2, performing cutting: performing cutting treatment on the treated beef, and cutting the beef into regular cuboids; s3, injection: putting the cut beef slices into an injection machine, and injecting the pre-prepared liquid; s4, tumbling: putting the beef slices subjected to injection treatment into a tumbling machine, and carrying out vacuum tumbling treatment; and S5, primary profiling is carried out. The preparation technology is simple and rapid, the processing time is short, the efficiency is high, the situation that the whole quality is affected due to the fact that the fat cattle melts during box arrangement can be prevented by limiting the box arrangement time, the shape of the fat cattle can be more attractive and neat through secondary profiling treatment, and the competitiveness is improved.

Owner:国澳(福建)食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com