Preparation method of tea-fragrance dried pork

A technology of pork jerky and fragrance, which is applied in the direction of food science, etc., can solve the problems of not being able to meet the needs of consumers with different tastes of pork jerky, and achieve the effects of increasing food desire, increasing anti-oxidation level, and improving aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

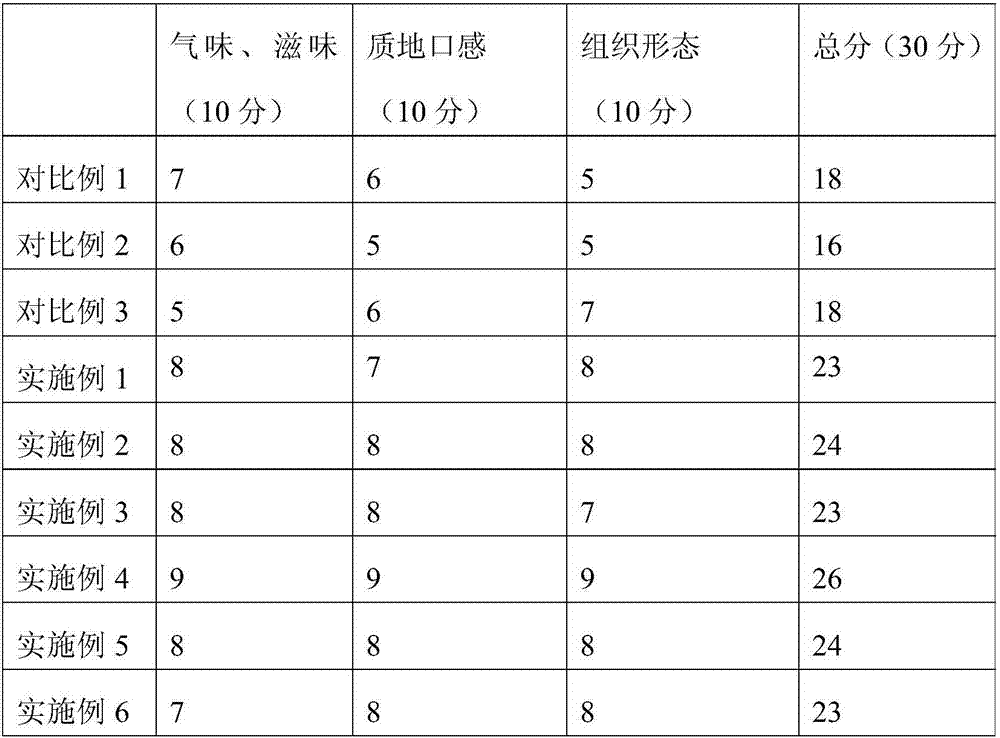

Examples

Embodiment 1

[0041] 1. Preliminary preparation:

[0042] Preparation of fermented liquid: by weight parts, 10 parts concentration is 10 6 Bifidobacterium suspension, 5 parts concentration is 10 6 The Lactobacillus suspension and 15 parts of vegetable juice were evenly mixed, sealed and fermented for 3 hours to obtain a fermented liquid.

[0043] Preparation of green tea powder: In parts by weight, 50 parts of dried green tea leaves and 3 parts of seaweed were mixed, and ground in a stone mill at a speed of 80 r / min for 3 hours to obtain green tea powder.

[0044] Preparation of green tea steeping liquid: by weight, 10 parts of honey, 6 parts of Chinese prickly ash, 3 parts of fragrant leaves, 5 parts of cinnamon, 9 parts of cooking wine, 5 parts of sea salt, 5 parts of mountain yellow bark, 17 parts of green tea powder, 6 parts of 1 part of cheese, 2 parts of lecithin and 55 parts of deionized water are evenly mixed, put into a high-pressure homogenizer, and homogenize for 15 minutes at ...

Embodiment 2

[0053] 1. Preliminary preparation:

[0054] Preparation of fermented liquid: by weight parts, 13 parts concentration is 10 7 Bifidobacterium suspension, 8 parts concentration is 10 8 The Lactobacillus suspension and 20 parts of vegetable juice were evenly mixed, sealed and fermented for 4 hours to obtain a fermented liquid.

[0055] Preparation of green tea powder: In parts by weight, 57 parts of dried green tea leaves and 4 parts of seaweed were mixed, and ground in a stone mill at a speed of 95 r / min for 5 hours to obtain green tea powder.

[0056] Preparation of green tea steeping liquid: by weight, 13 parts of honey, 8 parts of Chinese prickly ash, 3.5 parts of fragrant leaves, 6 parts of cinnamon, 11 parts of cooking wine, 8 parts of sea salt, 6 parts of mountain yellow bark, 20 parts of green tea powder, 8 parts of 1 part of cheese, 2 parts of lecithin and 60 parts of deionized water were evenly mixed, put into a high-pressure homogenizer, and homogenized for 16 minute...

Embodiment 3

[0065] 1. Preliminary preparation:

[0066] Preparation of fermented liquid: by weight parts, 13 parts concentration is 10 8 Bifidobacterium suspension, 7 parts concentration is 10 6 The Lactobacillus suspension and 22 parts of vegetable juice were evenly mixed, sealed and fermented for 5 hours to obtain a fermented liquid.

[0067] Preparation of green tea powder: In parts by weight, 66 parts of dried green tea leaves and 5 parts of seaweed were mixed, and ground in a stone mill at a speed of 85 r / min for 5 hours to obtain green tea powder.

[0068] Preparation of green tea steeping liquid: by weight, 14 parts of honey, 7 parts of Chinese prickly ash, 4 parts of fragrant leaves, 7 parts of cinnamon, 12 parts of cooking wine, 10 parts of sea salt, 6.5 parts of mountain yellow bark, 25 parts of green tea powder, 9 parts of After mixing one part of cheese, two parts of lecithin and 70 parts of deionized water evenly, put them into a high-pressure homogenizer, and homogenize fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com