Making method of high-fat tendon-free fat beef

A production method, the technology of fattening cattle, is applied in the direction of food ingredients as emulsifiers, food ingredients as thickeners, food ingredients as taste improvers, etc., which can solve the problems of not being tender enough, nutrient loss, and preparation that is not regular and beautiful. Achieve neat appearance, simple manufacturing process, and improve competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

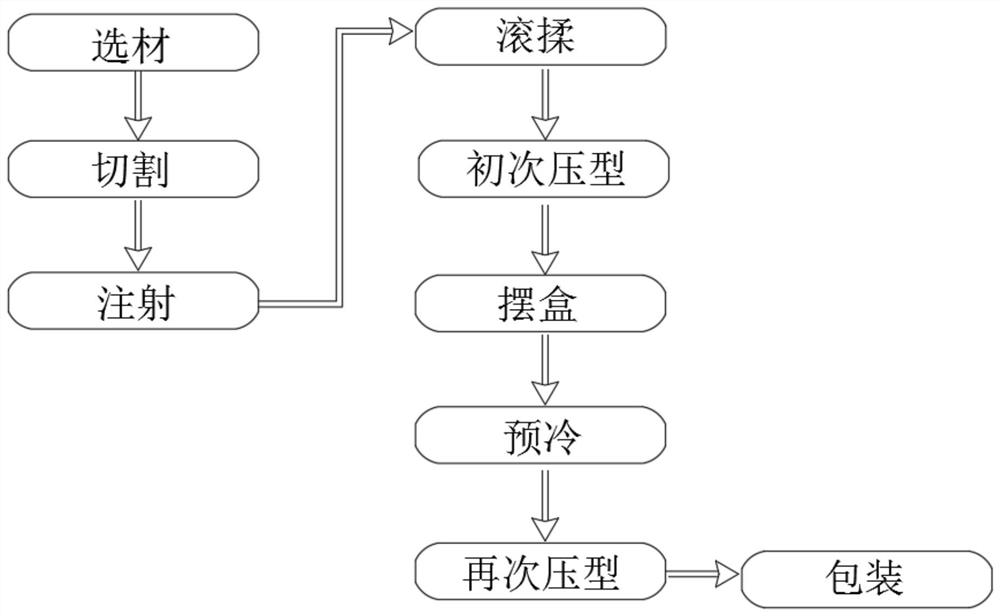

[0032] refer to figure 1 , a preparation method of high-fat gluten-free beef, comprising the following steps:

[0033] S1: Material selection, select high-fat and gluten-free beef brisket, clean it, put the raw material into the buffer zone after cleaning, remove the outer packing box, get the well-packaged beef raw material, and perform acid removal on it For processing, choose beef breast meat when selecting materials, which can ensure that it is high in fat and basically does not contain beef tendon, which improves the taste and lowers the cost. The temperature is not higher than 8 degrees Celsius;

[0034] S2: cutting, the processed beef is cut into regular rectangular parallelepipeds, and the beef is cut into beef slices with a thickness of 4 cm, a length of 20 cm and a width of 12 cm when cutting in S2;

[0035] S3: Injection, put the cut beef slices into the injection machine, and inject the prefabricated liquid;

[0036] S4: tumble and knead, put the injected beef s...

Embodiment 2

[0043] refer to figure 1 , a preparation method of high-fat gluten-free beef, comprising the following steps:

[0044] S1: Material selection, select high-fat and gluten-free beef brisket, clean it, put the raw material into the buffer zone after cleaning, remove the outer packing box, get the well-packaged beef raw material, and perform acid removal on it For processing, choose beef breast meat when selecting materials, which can ensure that it is high in fat and basically does not contain beef tendon, improves the taste, and costs less. The temperature is not higher than 8 degrees Celsius;

[0045] S2: cutting, the processed beef is cut into regular cuboids, and the beef is cut into beef slices with a thickness of 5 cm, a length of 22 cm and a width of 15 cm when cutting in S2;

[0046] S3: Injection, put the cut beef slices into the injection machine, and inject the prefabricated liquid;

[0047] S4: tumble and knead, put the injected beef slices into the tumbler for vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com