Low-salt preserved fishes and preparation method thereof

A production method and wax fish technology, which are applied in the preservation of meat/fish, heat preservation of meat/fish, food ingredients as odor modifiers, etc., can solve the problem that low-salt and wax flavor cannot be combined at the same time, surface hardening and cracking, and salt content Advanced problems, achieve good market prospects and market promotion value, reduce salt content, and reduce the amount of edible salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

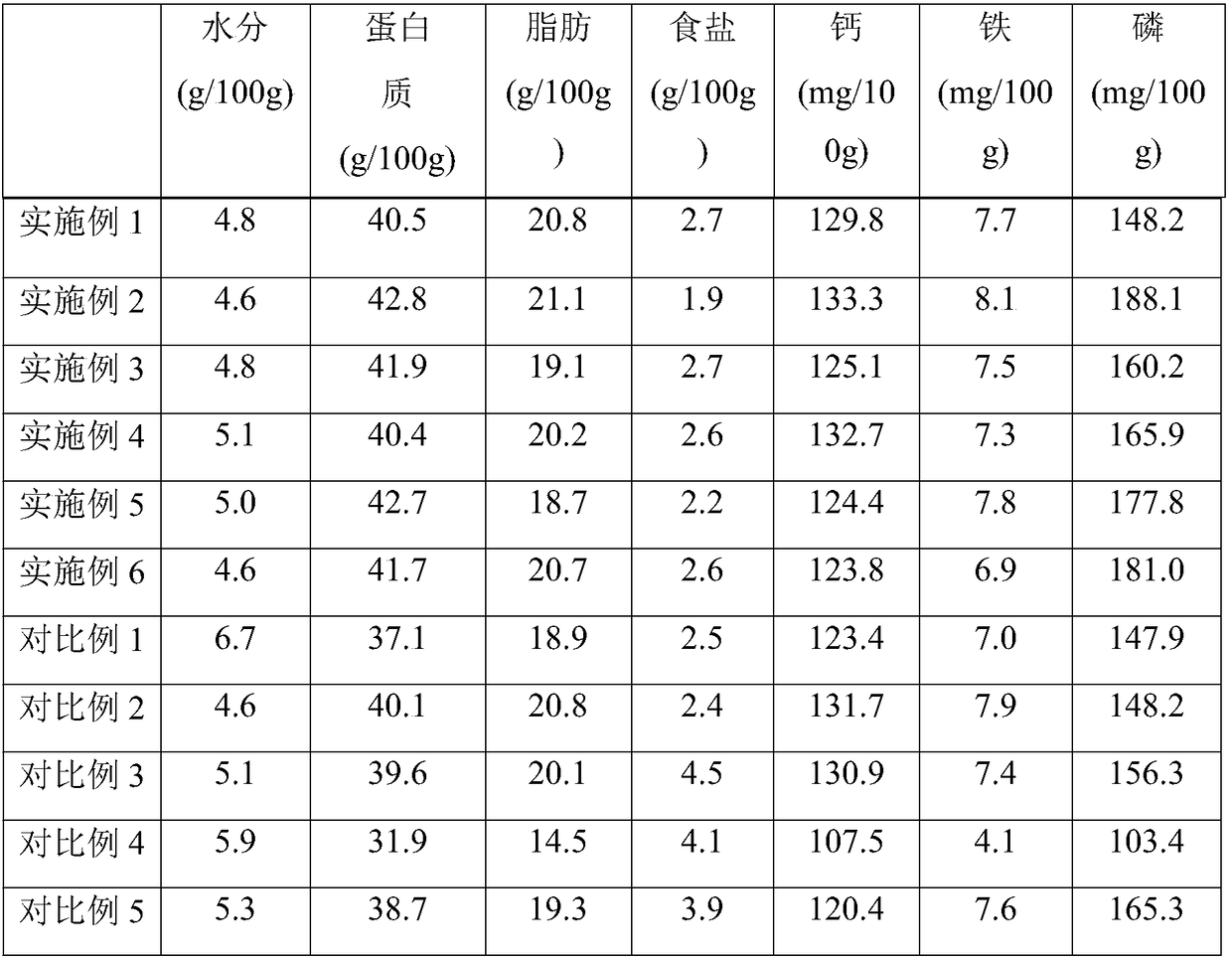

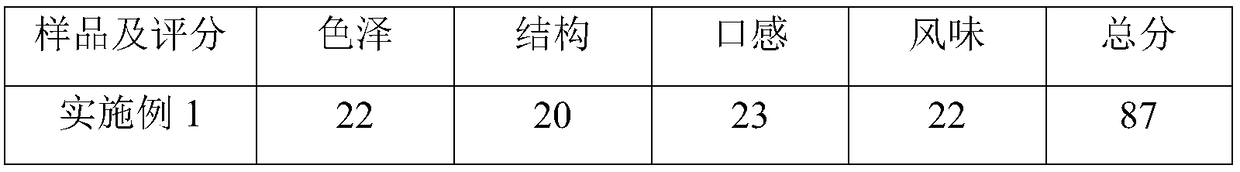

Examples

Embodiment 1

[0048] Embodiment 1: a kind of preparation method of low-salt cured fish, comprises following preparation steps:

[0049] S1. Pretreatment: select fresh live grass carp, remove the scales, cut open along the middle of the back of the fish, remove the main spines of the fish, remove the internal organs, wash clean, remove the tail and fins, and cut into 30*50 pieces with a dicing machine mm uniform fish pieces;

[0050] S2. Pickling: Weigh 0.5 part of salt, 0.5 part of sugar, 0.1 part of white wine, 0.1 part of monosodium glutamate, 0.1 part of dried ginger juice, 0.1 part of pepper juice, 0.5 part of dark soy sauce and 0.1 part of smoked liquid and mix them evenly to prepare for pickling For the material, take the fish pieces obtained in step S1 and add them to the marinade, stir for 0 min, and let stand at a constant temperature of 15°C for 20 hours, and set aside;

[0051] Wherein, the weight ratio of marinade and fish is 1:10;

[0052] S3. Thermal processing: Spread the m...

Embodiment 2

[0056] Embodiment 2: a kind of preparation method of low-salt cured fish, comprises following preparation steps:

[0057] S1. Pretreatment: select fresh live grass carp, remove the scales, cut open along the middle of the back of the fish, remove the main spines of the fish, remove the internal organs, wash clean, remove the tail and fins, and cut into 30*50 pieces with a dicing machine mm uniform fish pieces;

[0058] S2. Pickling: Weigh 1.2 parts of table salt, 2.5 parts of sugar, 0.8 parts of white wine, 0.8 parts of monosodium glutamate, 0.3 parts of dried ginger juice, 0.4 parts of pepper juice, 2 parts of dark soy sauce and 0.2 parts of smoked liquid and mix them evenly to prepare for pickling For the ingredients, take the fish pieces obtained in step S1 and add them to the marinade and stir for 15 minutes, then let stand at a constant temperature of 12°C for 24 hours, and set aside;

[0059] Wherein, the weight ratio of marinade and fish block is 1:13;

[0060] S3. Th...

Embodiment 3

[0064] Embodiment 3: a kind of preparation method of low-salt cured fish, comprises following preparation steps:

[0065] S1. Pretreatment: select fresh live grass carp, remove the scales, cut open along the middle of the back of the fish, remove the main spines of the fish, remove the internal organs, wash clean, remove the tail and fins, and cut into 30*50 pieces with a dicing machine mm uniform fish pieces;

[0066] S2. Pickling: Weigh 5 parts of salt, 8 parts of sugar, 3 parts of white wine, 3 parts of monosodium glutamate, 3 parts of dried ginger juice, 3 parts of pepper juice, 6 parts of dark soy sauce and 2 parts of smoked liquid and mix them evenly to prepare marinated For the ingredients, take the fish pieces obtained in step S1 and add them to the marinade, stir for 20 minutes, and let stand at a constant temperature of 15°C for 48 hours, and set aside;

[0067] Wherein, the weight ratio of marinade and fish block is 1:20;

[0068] S3. Heat processing: Spread the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com