Methods to Eliminate Nitrite in Salted Fish

A nitrite and salted fish technology, applied in the field of nitrite treatment, can solve the problems of difficult operation, ineffective effect, and inability to greatly reduce the content of nitrate and nitrite in salted fish, and achieve strong meat flavor, Soft and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

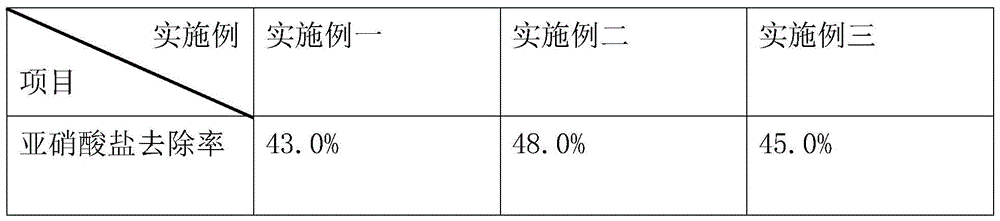

Examples

Embodiment 1

[0027] The method for eliminating nitrite in salted fish of the present invention comprises the following steps:

[0028] (1) Rinse the salted fish with clean water to remove the surface salt, divide it into blocks, place it in 8% dilute hydrochloric acid, soak it for about 18 hours, then wash and drain the block salted fish, repeat twice;

[0029] (2) Soak the washed massive salted fish in deionized water at 50°C for 1 hour, and perform centrifugation, repeating 4 times;

[0030] (3) Soak the processed salted fish in the conditioner for 10 minutes, and perform ultrasonic treatment while soaking. The ultrasonic power is 180-220W, the ultrasonic frequency is 35KHZ, and the treatment time is 18 minutes, then pick up and drain;

[0031] (4) Put the treated salted fish into the pool, inoculate autotrophic denitrifying bacteria on it, use inorganic sulfur as the substrate, provide hydrogen and inorganic carbon sources, and denitrifying bacteria use NO under anaerobic conditions 3 ...

Embodiment 2

[0040] The method for eliminating nitrite in salted fish of the present invention comprises the following steps:

[0041] (1) Rinse the salted fish with clean water to remove the surface salt, divide it into blocks, put it in 10% dilute hydrochloric acid, soak it for about 22 hours, then wash and drain the block salted fish, repeat twice;

[0042] (2) Soak the washed massive salted fish in deionized water at 70°C for 1 hour, and perform centrifugation, repeating 5 times;

[0043](3) Soak the processed salted fish in the conditioner for 20 minutes, and perform ultrasonic treatment while soaking. The ultrasonic power is 200W, the ultrasonic frequency is 40KHZ, and the treatment time is 20 minutes, then picked up and drained;

[0044] (4) Put the treated salted fish into the pool, inoculate autotrophic denitrifying bacteria on it, use inorganic sulfur as the substrate, provide hydrogen and inorganic carbon sources, and denitrifying bacteria use NO under anaerobic conditions 3 -...

Embodiment 3

[0053] The method for eliminating nitrite in salted fish of the present invention comprises the following steps:

[0054] (1) Rinse the salted fish with clean water to remove the surface salt, divide it into blocks, put it in 15% dilute hydrochloric acid, soak it for about 28 hours, then wash and drain the block salted fish, repeat 3 times;

[0055] (2) Soak the washed massive salted fish in deionized water at 85°C for 2 hours, and perform centrifugation, repeating 6 times;

[0056] (3) Soak the processed salted fish in the conditioner for 30 minutes, and perform ultrasonic treatment while soaking. The ultrasonic power is 220W, the ultrasonic frequency is 45KHZ, and the treatment time is 25 minutes, then picked up and drained;

[0057] (4) Put the treated salted fish into the pool, inoculate autotrophic denitrifying bacteria on it, use inorganic sulfur as a substrate, provide hydrogen and inorganic carbon sources, and denitrifying bacteria use NO under anaerobic conditions 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com