Processing method of hericium erinaceus fermented wheat flour

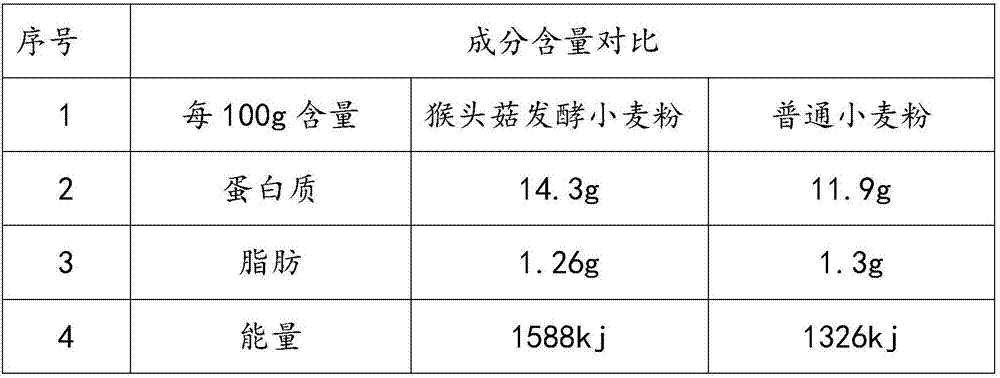

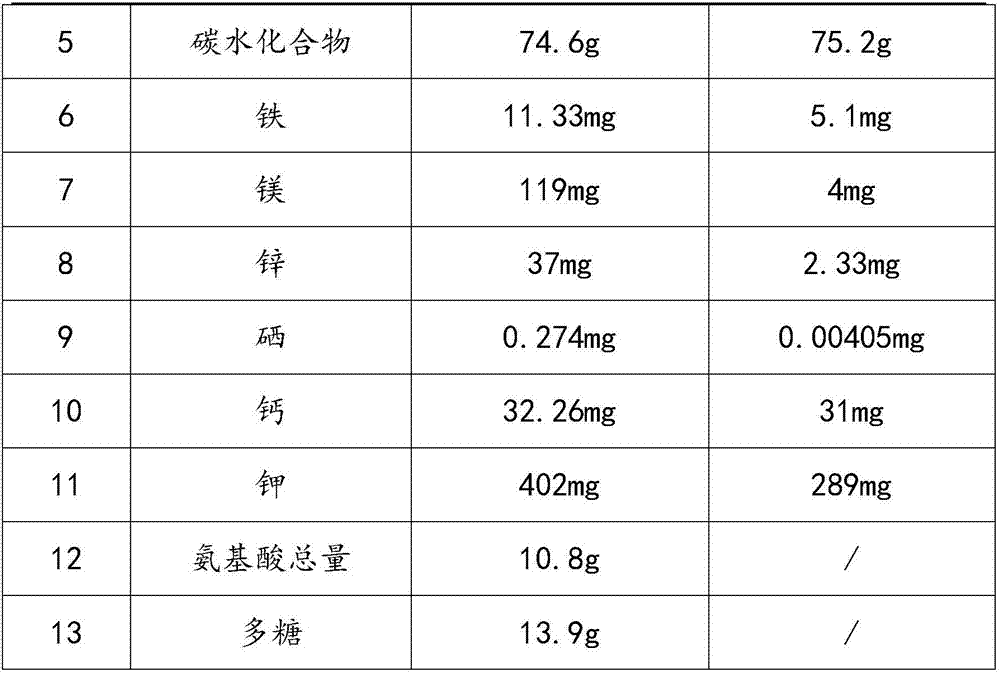

A processing method and wheat flour technology are applied in the processing field of Hericium erinaceus fermented wheat flour to achieve the effects of rich meat flavor, rich nutrition and excellent taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A processing method of Hericium erinaceus fermented wheat flour, specifically comprising the steps of:

[0023] (1) Select high-quality wheat grains and soak them in cold water at 8°C for 28 hours;

[0024] (2) Pack the soaked wheat grains into a sealed bag and seal them;

[0025] (3) Put the sealed bag containing the grains of wheat into the boiler, and cook for 7 hours under normal pressure at 100°C;

[0026] (4) Put the sealed bag containing wheat grains in a natural space to dry, and lower it to 35°C;

[0027] (5) insert Hericium erinaceus bacterial classification into the sealed bag and mix evenly, insert 10g per kilogram of wheat grain, then put into bacteria room;

[0028] (6) Keep the temperature of the bacteria room at 2°C and allow the mycelia to grow for 30 days;

[0029] (7) After the mycelium grows to cover the entire bacterial bag, open the sealed bag and dry the wheat grains until the water content is lower than 12%, and then grind them into powder to ...

Embodiment 2

[0031] A processing method of Hericium erinaceus fermented wheat flour, specifically comprising the steps of:

[0032] (1) Select high-quality wheat grains and soak them in cold water at 10°C for 24 hours;

[0033] (2) Pack the soaked wheat grains into a sealed bag and seal them;

[0034] (3) Put the sealed bag containing the grains of wheat into the boiler, and cook for 8 hours under normal pressure at 100°C;

[0035] (4) Put the sealed bag containing wheat grains in a natural space to dry, and lower it to 35°C;

[0036] (5) insert Hericium erinaceus bacterial classification into the sealed bag and mix evenly, insert 25g per kilogram of wheat grain, then put into bacteria room;

[0037] (6) Keep the temperature of the bacteria room at 23°C, and allow the mycelia to grow for 40 days;

[0038] (7) After the mycelium grows to cover the entire bacterial bag, open the sealed bag and dry the wheat grains until the water content is lower than 12%, and then grind them into powder ...

Embodiment 3

[0040] A processing method of Hericium erinaceus fermented wheat flour, specifically comprising the steps of:

[0041] (1) Select high-quality wheat grains and soak them in cold water at 12°C for 22 hours;

[0042] (2) Pack the soaked wheat grains into a sealed bag and seal them;

[0043] (3) Put the sealed bag containing the grains of wheat into the boiler, and cook at a high pressure of 120°C for 3.5 hours;

[0044] (4) Put the sealed bag containing wheat grains in a natural space to dry, and lower it to 35°C;

[0045] (5) insert Hericium erinaceus bacterial classification into the sealed bag and mix evenly, insert 40g per kilogram of grain of wheat, then put into bacteria room;

[0046] (6) Keep the temperature of the bacteria room at 25°C, and let the mycelia grow for 50 days;

[0047] (7) After the mycelium grows to cover the entire bacterial bag, open the sealed bag and dry the wheat grains until the water content is lower than 12%, and then grind them into powder to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com