Method for producing sea-crab seasoner products material

A seasoning and sea crab technology, which is applied in the field of raw materials for sea crab seasoning products, can solve the problems of impure and natural flavor and low quality of seasonings, reduce allergens, have a wide range of uses, and maintain nutrients and unique flavors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

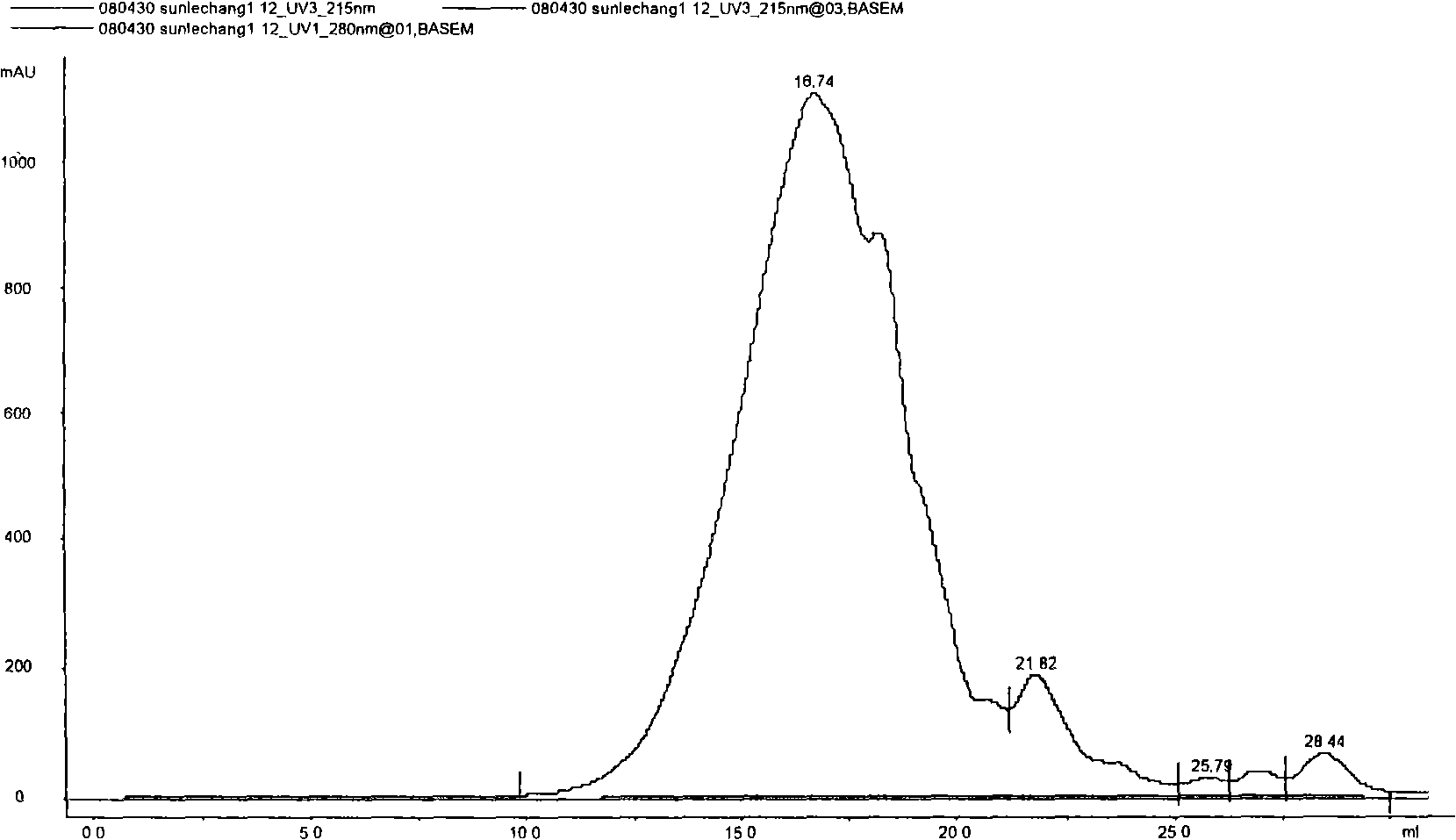

[0033] As shown in table 1, a kind of method that utilizes protease to hydrolyze sea crab leftovers pulverized sample to produce sea crab seasoning product raw material (sea crab albumen liquid), concrete steps are as follows: (1) sea crabs leftovers are broken into pieces, adjust pH value is 5.0, temperature is 60°C, protease amount is 4000U / g, stirring enzymolysis for 4h; (2) Heating to inactivate the enzyme, using a mixed acid treatment of citric acid and malic acid (2:1) (as shown in Table 2) to treat the hydrolyzate After removing the fishy smell and filtering to remove the residue, the obtained hydrolyzate has no obvious bitter smell and allergenicity, but has obvious seafood smell, which is the enzymatic hydrolyzed protein solution of sea crab.

Embodiment 2

[0035] As shown in table 3, a kind of method that utilizes protease to hydrolyze sea crab leftover cooking concentrate to produce sea crab seasoning product raw material (sea crab albumen liquid), concrete steps are as follows: (1) sea crab leftover is processed into concentrate , adjust the pH value to 4.5, the temperature is 45°C, the amount of protease is 3000U / g, and the enzymolysis is stirred for 2 hours; (2) heating is used to inactivate the enzyme, and the hydrolyzate is deodorized by the mixed acid treatment of citric acid and malic acid (2:1), After filtering to remove the residue, the obtained hydrolyzate has no obvious bitter smell and allergenicity, but has obvious seafood smell, which is the enzymatic hydrolyzed protein solution of sea crab.

[0036] Step (1) The steps of processing the leftovers of sea crabs into a concentrated liquid are: washing the leftovers of sea crabs→cleaning→crushing→cooking→heating and concentrating the soup stock→obtaining a concentrated...

Embodiment 3

[0038] A method for producing sea crab seasoning product raw material (sea crab protein powder), which comprises the following steps: (1) smashing the sea crab leftovers, adjusting the pH value to 6.4, the temperature at 64°C, the amount of protease at 4000U / g, Stir enzymolysis for 4 hours; or use sea crabs to process and cook the concentrated solution of soup stock (i.e. crab juice), adjust the pH value to 6.4, temperature 60°C, protease amount 3500U / g, and stir enzymolysis for 2 hours; (2) Heat to inactivate the enzyme, Use the mixed acid treatment of citric acid and malic acid (2:1) to remove the fishy smell from the hydrolyzate, filter to remove the residue, the obtained hydrolyzate has no obvious bitter smell and allergenicity, and has obvious seafood smell, and is further concentrated at low temperature and sprayed Dried to make sea crab protein powder.

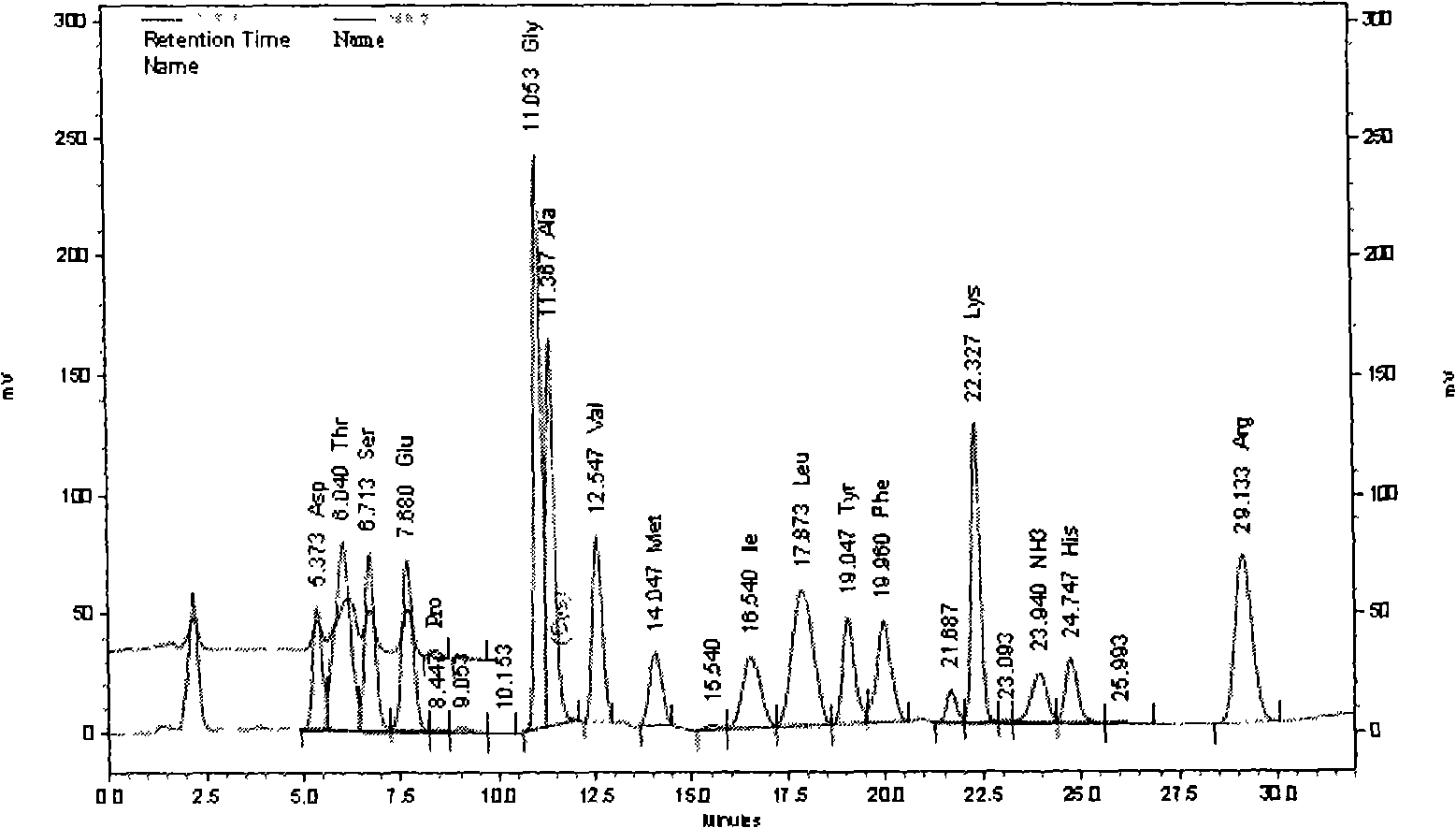

[0039] Two, the raw material component analysis of the sea crab seasoning product of the present invention.

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com