Method for preparing flavored black tea

A technology for black tea and flavor, applied in the field of preparation of flavored black tea, can solve the problems of affecting the color and taste of black tea soup, long fermentation time, low processing efficiency, etc., so as to make up for defects in taste and efficacy, low cost and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

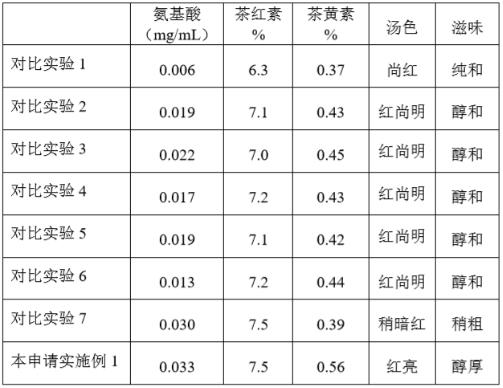

Examples

Embodiment 1

[0020] Embodiment 1: a kind of preparation method of local flavor black tea, comprises the following steps:

[0021] (1) Evenly mix alkaline protease and papain with an enzyme activity of 200,000 U / g at a mass ratio of 1.3:1 to obtain a mixed enzyme;

[0022] (2) Weigh the mixed enzyme to prepare a mixed enzyme solution with a mass concentration of 2.3% for later use;

[0023] (3) Weigh a certain amount of L-cysteine and add it to the mixed enzyme solution, so that the concentration of L-cysteine in the mixed enzyme solution is 0.8mmol / L, and the obtained mixed enzyme solution is ready for use;

[0024] (4) Spread the fresh leaves evenly by 3cm on the withering curtain, wither for 12 hours, turn over and spray the mixed enzyme solution every 2 hours, the total amount of the mixed enzyme solution sprayed is 12% of the mass of the fresh leaves, and the withering temperature is 28-30°C , using fans for forced ventilation, so that the moisture content of the withered leaves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com