Chili soy sauce and preparation method thereof

A production method and chili technology, which are applied in the field of condiment production technology, can solve the problems of no production technology and records, etc., and achieve the effect of convenient and quick eating, rich nutrition, and full-bodied spicy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

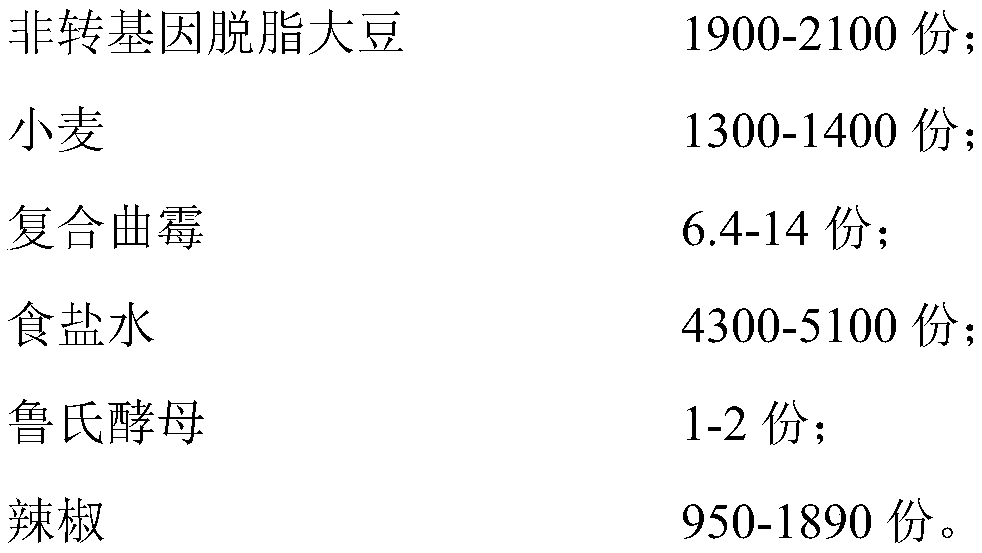

[0028] A kind of chili soy sauce, is made up of the material of following mass parts:

[0029]

[0030]

[0031] The composite Aspergillus is a composite of Shanghai Niang 3.042 Aspergillus oryzae and AS3.350 Aspergillus niger, and the mass ratio of the two is 3:1.

[0032] The concentration of the salt water is 25.5g / 100ml.

[0033] Follow the steps below to prepare:

[0034] 1) Weigh the components in mass proportion, preheat the non-transgenic defatted soybeans at 78±2°C for 5 minutes, cook them at a pressure of 0.15 MPa for 6 minutes; fry the wheat at 200°C for 3 minutes, and then grind them to wait use;

[0035] 2) After cleaning the fresh peppers, boil them in 100°C boiling water for 3 minutes;

[0036] 3) Mix the cooked non-transgenic defatted soybeans with wheat flour, insert compound Aspergillus, and send them into a disc koji making machine, control the temperature at 29±3°C, and make koji for 40 hours;

[0037] 4) Mix the prepared koji and boiled chili eve...

Embodiment 2

[0044] A kind of chili soy sauce, is made up of the material of following mass parts:

[0045]

[0046] The compound Aspergillus is a compound of Shanghai Shuang 3.042 Aspergillus oryzae and AS3.350 Aspergillus niger, and the mass ratio of the two is 5:1.

[0047] The concentration of the salt water is 28g / 100ml.

[0048] Follow the steps below to prepare:

[0049] 1) Weigh the components in mass proportion, preheat the non-transgenic defatted soybeans at 78±2°C for 10 minutes, cook them at a pressure of 0.18MPa for 4 minutes; fry the wheat at 300°C for 2 minutes, and then grind them to wait use;

[0050] 2) After cleaning the fresh peppers, boil them in 100°C boiling water for 5 minutes;

[0051] 3) Mix the cooked non-transgenic defatted soybeans with wheat flour, insert compound Aspergillus, and send them into a disc koji making machine, control the temperature at 29±3°C, and make koji for 48 hours;

[0052] 4) Mix the prepared koji and boiled chili evenly, mix it wit...

Embodiment 3

[0059] A kind of chili soy sauce, is made up of the material of following mass parts:

[0060]

[0061] The composite Aspergillus is a composite of Shanghai Niang 3.042 Aspergillus oryzae and AS3.350 Aspergillus niger, and the mass ratio of the two is 4:1.

[0062] The concentration of the salt water is 27g / 100ml.

[0063] Follow the steps below to prepare:

[0064] 1) Weigh the components in mass proportion, preheat the non-transgenic defatted soybeans at 78±2°C for 5 minutes, cook them at a pressure of 0.16MPa for 4 minutes; fry the wheat at 250°C for 3 minutes, and then grind them to wait use;

[0065] 2) After cleaning the fresh peppers, boil them in 100°C boiling water for 3 minutes;

[0066] 3) Mix the cooked non-transgenic defatted soybeans with wheat flour, insert compound Aspergillus, and send them into a disc koji making machine, control the temperature at 29±3°C, and make koji for 46 hours;

[0067]4) Mix the prepared koji and boiled chili evenly, mix it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com