Seasoning powder

The technology of seasoning powder and seasoning agent is applied in the field of seasoning to achieve the effects of high color price, enhanced oil solubility and bright red color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

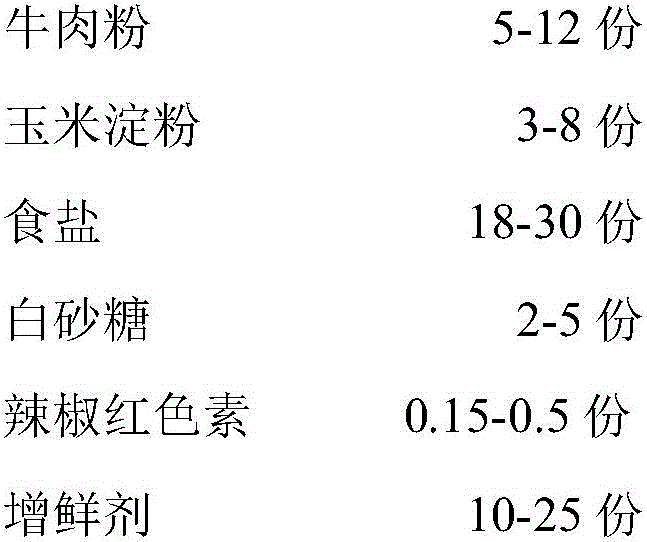

Method used

Image

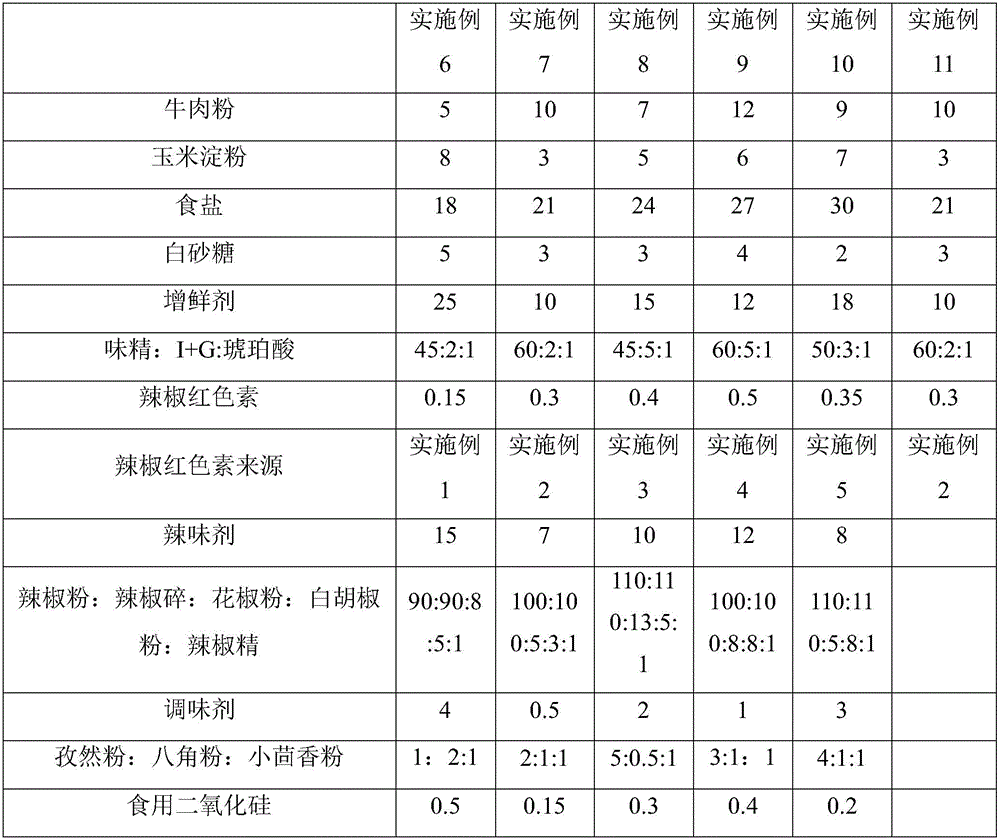

Examples

Embodiment 1

[0037] Step1: Take dried peppers, remove miscellaneous peppers and pepper seeds, dry them at 38-43°C for 1.5-2.5h and then pulverize them. Use n-hexane as the extraction solvent at 55-60°C. The mass-volume ratio is n-hexane: Chili powder=5:1ml / g of n-hexane to reflux extract 20 mesh chili powder for 3-4h, after suction filtration, extract the filter residue, combine the two extracts, and store in a light-shielding seal;

[0038] Step2: Concentrate the crude product obtained in the previous step, carry out column chromatography separation, first use petroleum ether to elute, and then use petroleum ether-ethyl acetate mixed solvent to carry out by volume ratio 40:1, 20:1, 1:1 Gradient elution, the corresponding fractions were collected and concentrated to obtain capsanthin.

Embodiment 2

[0040] Step1: Take dried peppers, remove miscellaneous peppers and pepper seeds, dry them at 38-43°C for 1.5-2.5h and then pulverize them. Use n-hexane as the extraction solvent at 55-60°C. The mass-volume ratio is n-hexane: Chili powder=5:1ml / g of n-hexane to reflux extract 20 mesh chili powder for 3-4h, after suction filtration, extract the filter residue, combine the two extracts, and store in a light-shielding seal;

[0041] Step2: Concentrate the crude product obtained in the previous step, carry out column chromatography separation, first use petroleum ether to elute, and then use petroleum ether-ethyl acetate mixed solvent to carry out by volume ratio 40:1, 20:1, 1:1 Gradient elution, the corresponding fractions were collected and concentrated to obtain capsanthin.

Embodiment 3

[0043] Step1: Take dried peppers, remove miscellaneous peppers and pepper seeds, dry them at 38-43°C for 1.5-2.5h and then pulverize them. Use n-hexane as the extraction solvent at 55-60°C. The mass-volume ratio is n-hexane: Chili powder=5:1ml / g of n-hexane to reflux extract 20 mesh chili powder for 3-4h, after suction filtration, extract the filter residue, combine the two extracts, and store in a light-shielding seal;

[0044] Step2: Concentrate the crude product obtained in the previous step, carry out column chromatography separation, first use petroleum ether to elute, and then use petroleum ether-ethyl acetate mixed solvent to carry out by volume ratio 40:1, 20:1, 1:1 Gradient elution, the corresponding fractions were collected and concentrated to obtain capsanthin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com