Method for producing yeast extract with high protein content and product

A yeast extract and production method technology, applied in food preparation, food science, application and other directions, can solve the problems of high cost, insufficient protein content, low amino acid nitrogen content, etc., to improve product conversion rate, enhance enzyme Soothing effect, rich taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

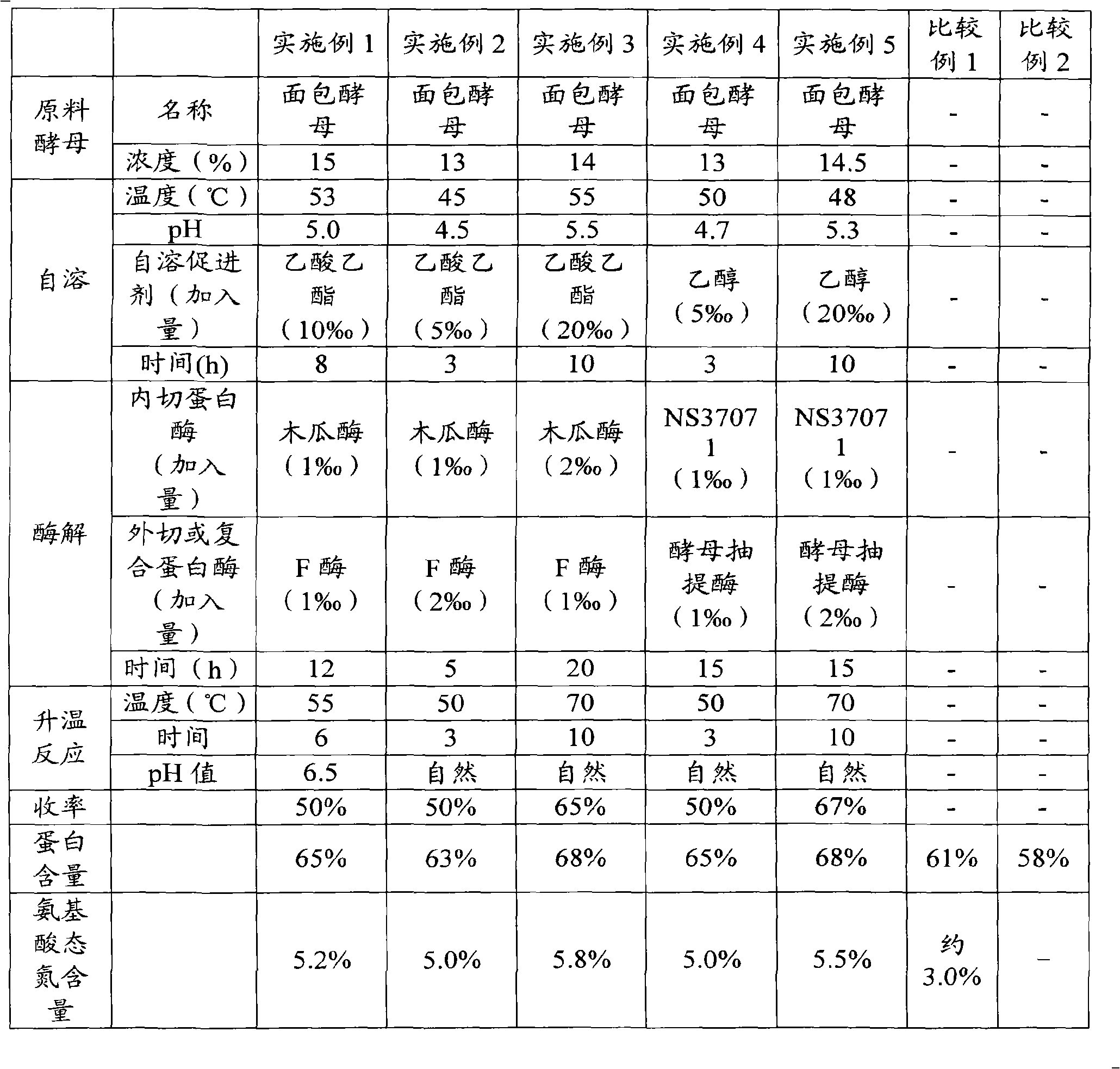

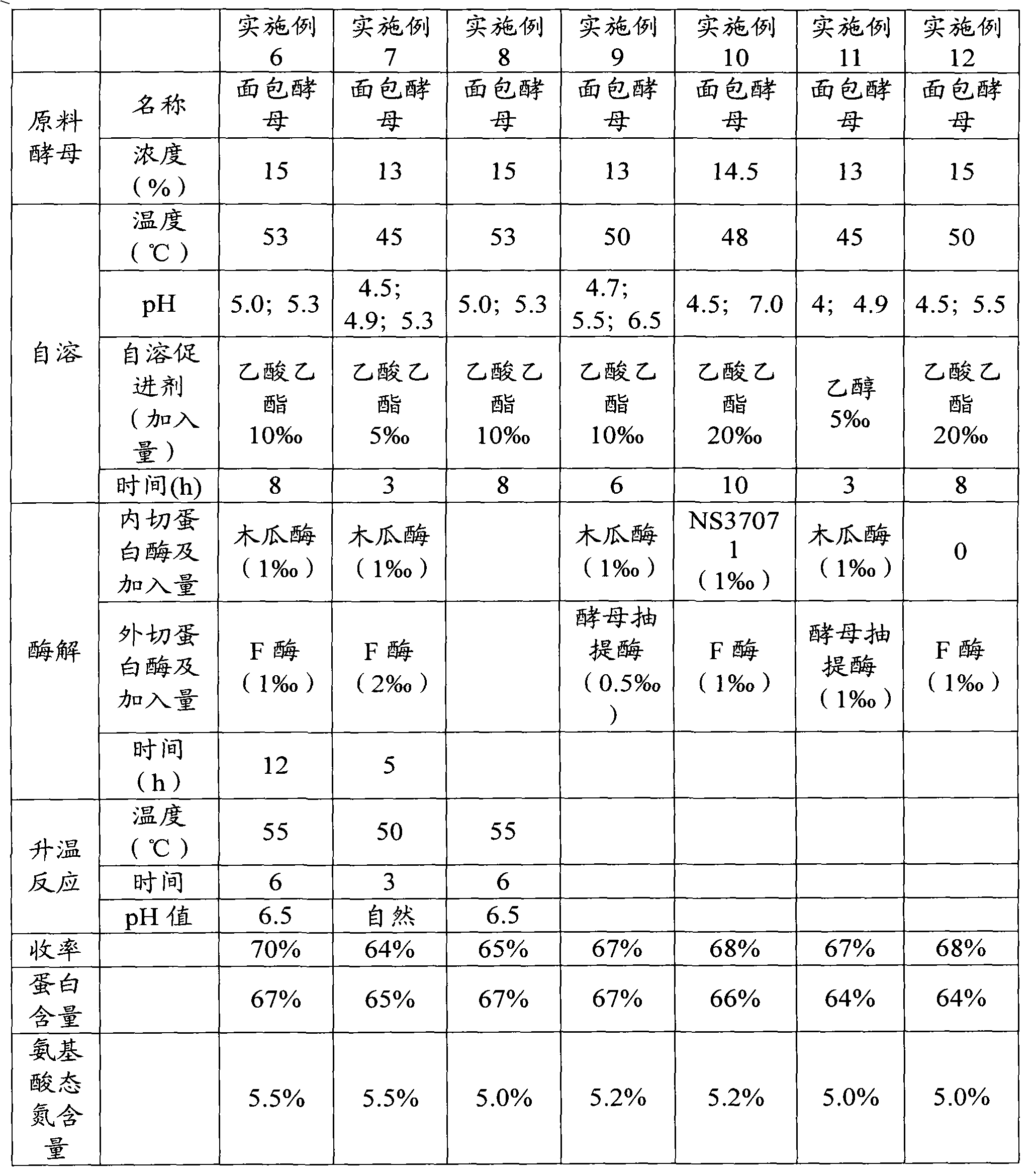

Examples

no. 2 Embodiment approach

[0056] In a second specific embodiment, the method of the present invention comprises the following steps:

[0057] (a) Autolysis: Dilute the raw yeast, keep the pH value from weakly acidic to neutral, and adjust the pH value at least once during the autolysis process;

[0058] (b1) adding the first protease to carry out the first enzymatic hydrolysis step;

[0059] (b2) adding a second protease to perform a second enzymatic hydrolysis step.

[0060] Optionally further include:

[0061] (d) solid-liquid separation;

[0062] (e) sterilization;

[0063] (g) Concentrate into a paste product, or spray and dry into a powder product.

[0064] The preferred conditions in (a) the autolysis step are: the yeast milk is fixedly dissolved to 13%-15%, the temperature is 45-55° C., the pH value is 4-7, and the action is 3-10 hours. Preference is given to adding autolysis promoters.

[0065] In (b1) the first enzymatic hydrolysis step, the preferred conditions are: 45-55° C., adjusting...

no. 3 Embodiment approach

[0070] In a third specific embodiment, the method of the present invention includes the following steps:

[0071] (a) Autolysis: Dilute the raw yeast, keep the pH value from weakly acidic to neutral, and adjust the pH value at least once during the autolysis process;

[0072] (c) Temperature rise reaction.

[0073] Can further include:

[0074] (d) solid-liquid separation;

[0075] (e) sterilization;

[0076] (g) Concentrate into a paste product, or spray and dry into a powder product.

[0077] Among them, (a) the preferred conditions for the autolysis step are: the yeast milk is fixedly dissolved to 3% to 8%, 45 to 55°C, the pH value is adjusted to 4.5 to 7 (phosphoric acid, hydrochloric acid, sulfuric acid, citric acid), and the 8- 26 hours.

[0078] Among them, the preferred conditions for (c) temperature rise reaction are: pH value 4.5-7, temperature rise 50-70°C, action for 4-20 hours.

[0079] The enzymes, acids, bases, and autolysis promoters used are as described...

Embodiment 1

[0085]Dilute the baker's yeast with a protein content of 55% to a yeast content of 15%, adjust the temperature to 53°C, adjust the pH value to 5.0, add 10‰ of the autolysis accelerator ethyl acetate, and act for 8 hours. Keep the pH value in a natural state, that is, without human intervention or adjustment of the pH value, add papain 1‰ (based on the dry weight of the yeast), and Novozymes flavored protease 1‰ (based on the dry weight of the yeast) for 12 hours. Then, the temperature was raised to 55°C, the pH value was 6.5, and the reaction was performed for 6 hours. Adopt centrifugal separation of centrifuge, measure yield (namely centrifuge the yeast liquid of certain quality, dry and weigh centrifugal sedimentation, calculate the percentage m% that precipitated dry matter accounts for total yeast mass, (100%-m%) is yield Rate). Sterilize (sterilization condition: keep at 121° C. for 15 minutes), then adjust the pH value to 7 with potassium hydroxide solution, concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com