Self-decorating recycled aggregate permeable concrete product and preparation method thereof

A technology of permeable concrete and recycled aggregates, which is applied to pavements paved with prefabricated blocks, roads, side ditches/curbs, etc., can solve the problem of low resource utilization rate of construction waste, shortage of sandstone aggregates for construction, Natural colored sand is not easy to collect and other problems, to achieve the effect of obvious self-decoration effect, natural surface decoration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

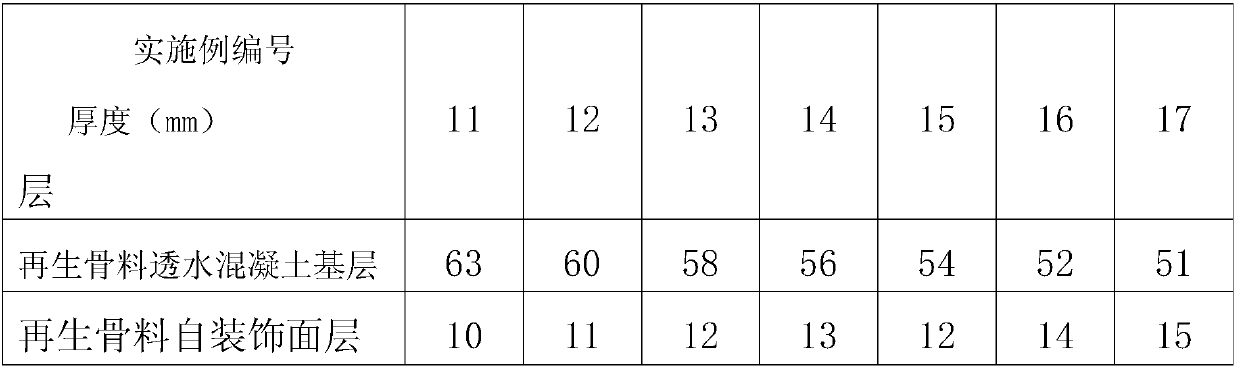

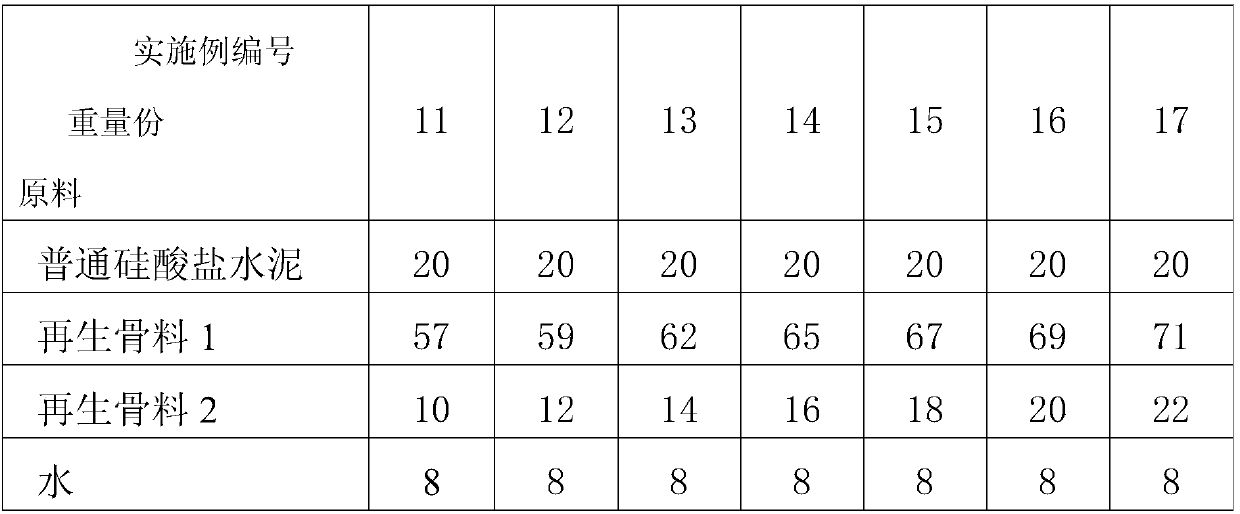

[0028] A self-decorating recycled aggregate permeable concrete product comprises a recycled aggregate permeable concrete base layer and a recycled aggregate self-decorating surface layer. The recycled aggregate permeable concrete base consists of 20 parts by weight of ordinary Portland cement, 2.36mm~9.5mm concrete, 56 parts by weight of mortar-type construction waste recycled aggregate, ≤2.36mm concrete, and 24 parts by weight of mortar-type construction waste recycled aggregate 8 parts by weight of water and 8 parts by weight of raw materials; wherein the self-decorating surface layer of recycled aggregate is composed of 20 parts by weight of white cement, ≤2.36mm sintered bricks and tiles, 100 parts by weight of recycled decorative aggregate of glass and ceramic construction waste and 10 parts by weight of water The components and raw materials in parts by weight are mixed to form.

[0029] The preparation method of self-decorating recycled aggregate pervious concrete produ...

Embodiment 2

[0036] A self-decorating recycled aggregate permeable concrete product comprises a recycled aggregate permeable concrete base layer and a recycled aggregate self-decorating surface layer. The recycled aggregate permeable concrete base is composed of 20 parts by weight of ordinary Portland cement, 2.36mm~9.5mm concrete, 64 parts by weight of mortar type construction waste recycled aggregate, ≤2.36mm concrete, 16 weight parts of mortar type construction waste recycled aggregate 8 parts by weight of water and 8 parts by weight of raw materials; wherein the self-decorating surface layer of recycled aggregate is composed of 20 parts by weight of white cement, ≤2.36mm sintered bricks and tiles, 100 parts by weight of recycled decorative aggregate of glass and ceramic construction waste and 10 parts by weight of water The components and raw materials in parts by weight are mixed to form.

[0037] The preparation method of self-decorating recycled aggregate pervious concrete product i...

Embodiment 3

[0044] A self-decorating recycled aggregate permeable concrete product comprises a recycled aggregate permeable concrete base layer and a recycled aggregate self-decorating surface layer. The recycled aggregate permeable concrete base consists of 20 parts by weight of ordinary Portland cement, 2.36mm-9.5mm concrete, 72 parts by weight of mortar-type construction waste recycled aggregate, ≤2.36mm concrete, and 8 weight parts of mortar-type construction waste recycled aggregate 8 parts by weight of water and 8 parts by weight of raw materials; wherein the self-decorating surface layer of recycled aggregate is composed of 20 parts by weight of white cement, ≤2.36mm sintered bricks and tiles, 100 parts by weight of recycled decorative aggregate of glass and ceramic construction waste and 10 parts by weight of water The components and raw materials in parts by weight are mixed to form.

[0045] The preparation method of self-decorating recycled aggregate pervious concrete product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com