Jewellery rose gold surface treatment plating solution, preparation method and electroplating method thereof

A surface treatment and jewelry technology, which is applied in the field of jewelry treatment, can solve the problems of poor corrosion resistance and affect the use effect, and achieve the effect of good corrosion resistance, low preparation cost and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

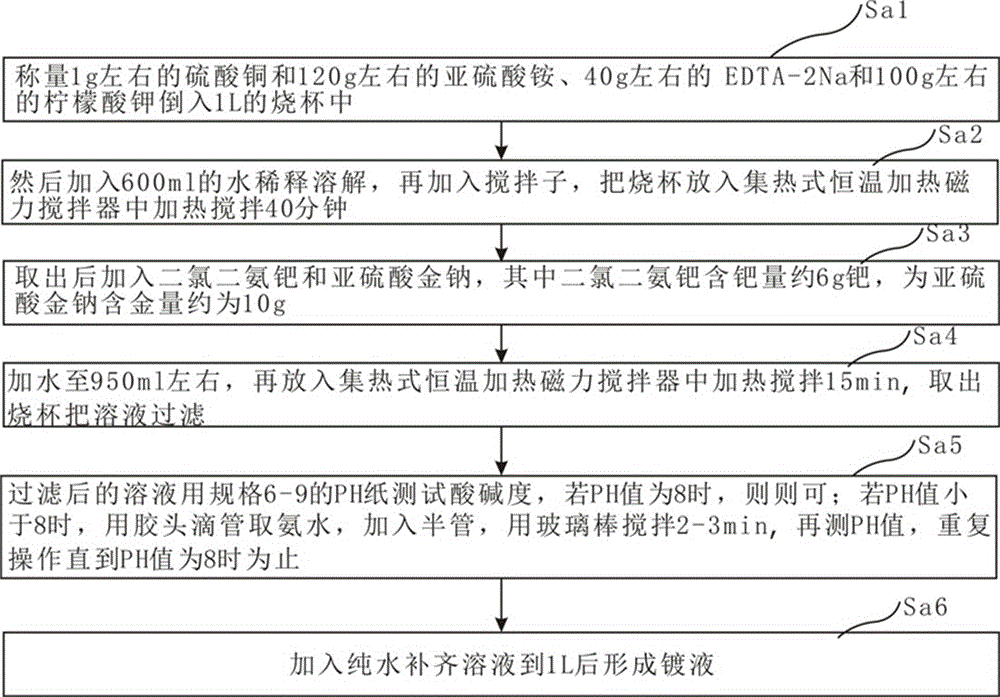

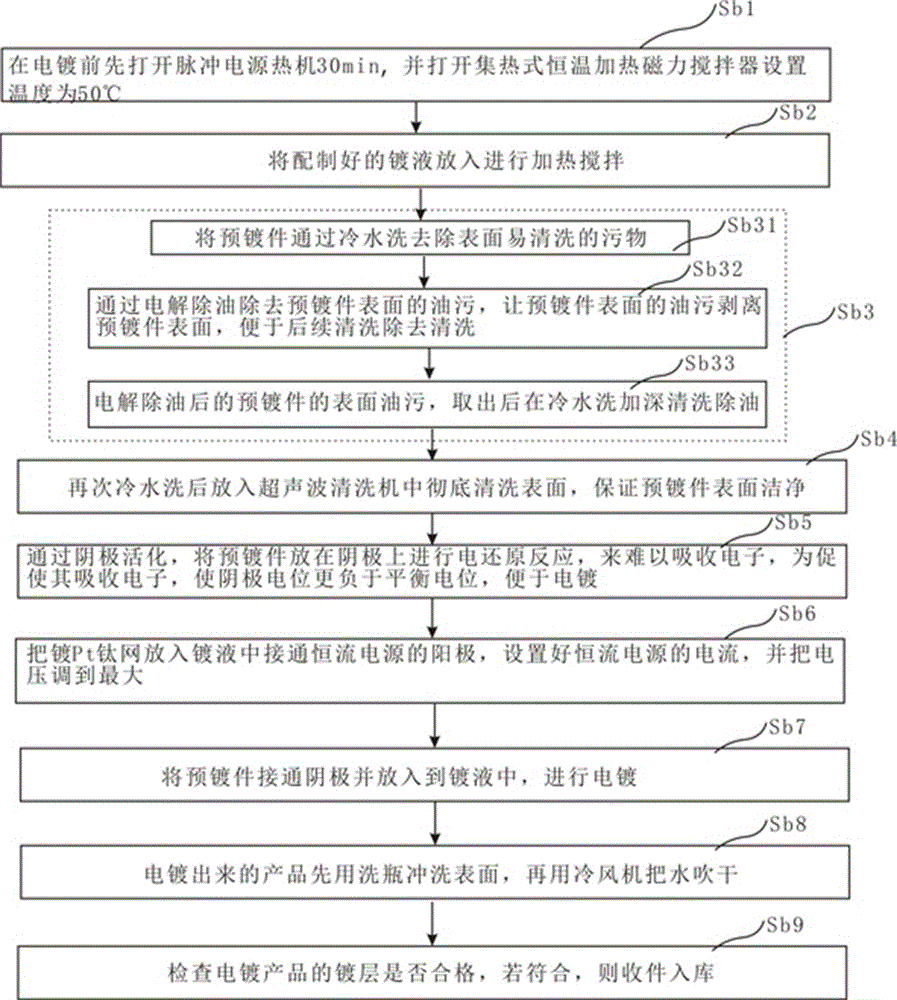

[0033] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0034] The rose gold surface treatment plating solution for jewelry of the present invention comprises the following components: copper sulfate of 0.5-2g, ammonium sulfite of 100-125g, EDTA-2Na of 25-55g, potassium citrate of 85-115g, dichloro Palladium diammonia palladium contains 4-7g of palladium and sodium gold sulfite contains 5-15g of gold.

[0035] see figure 1 , the present invention also provides a kind of preparation method of jewelry rose gold surface treatment plating solution, comprises the following steps:

[0036] Step Sa1, weighing about 1g of copper sulfate and about 120g of ammonium sulfite, about 40g of EDTA-2Na and about 100g of potassium citrate into a 1L beaker;

[0037] Step Sa2, then add 600ml of water to dilute and dissolve, then add a stirrer, put the beaker into a heat-collecting const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com