Physical dyeing method for lumber

A dyeing method and wood technology, applied in the fields of wood dyeing and wood physical dyeing, can solve the problems of increasing the difficulty of treating wood dyeing wastewater, uniform dyeing of hard-to-thick wood, and damage to the physical and mental health of the people. The effect of low cost and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

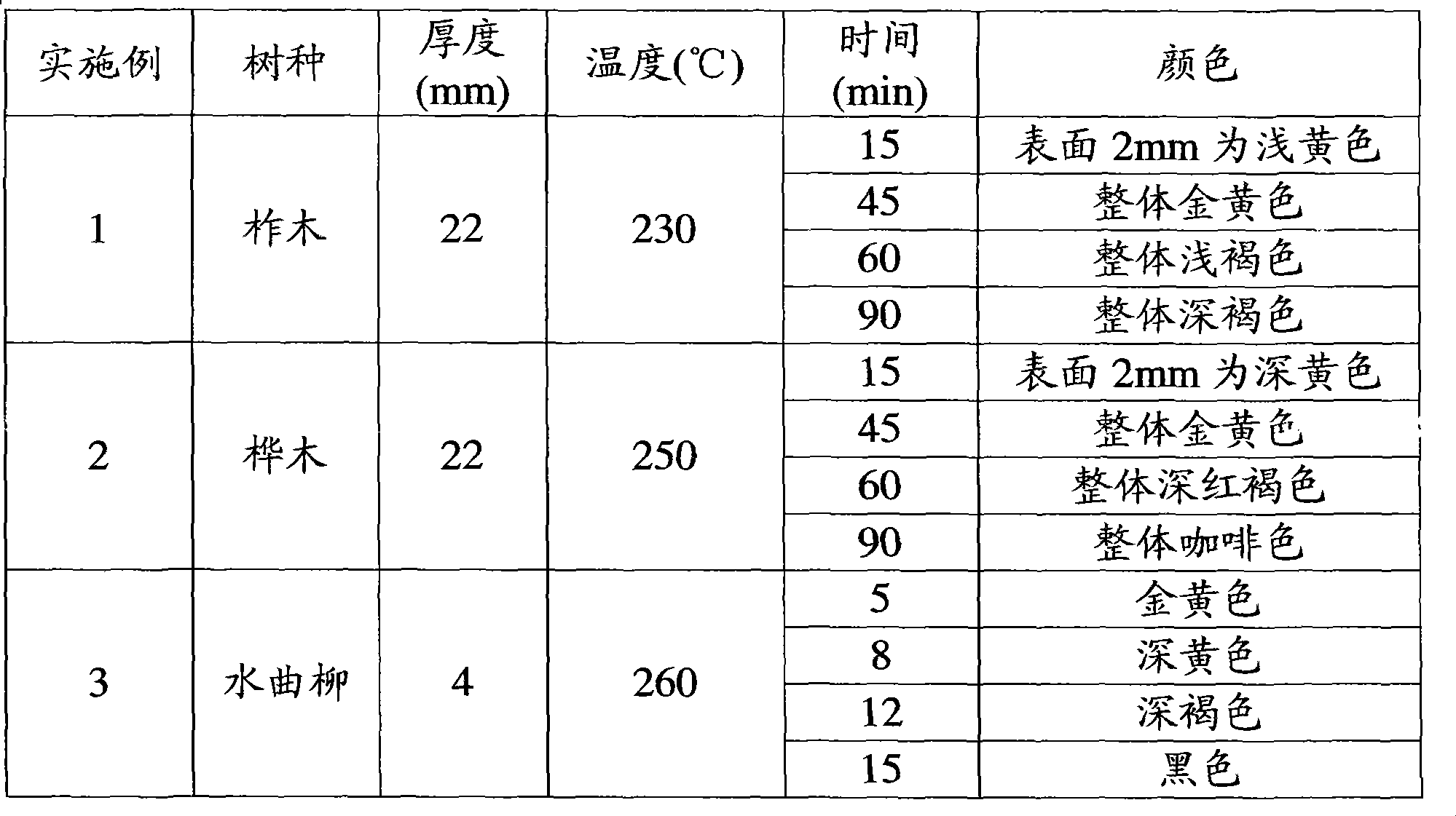

[0017] Take oak wood as an example. When processing, the 25mm thick oak wood with a moisture content of about 12% is first planed and planed. At this time, the thickness of the wood is 22mm; Under the same conditions, keep warm for 15 minutes, 45 minutes, 60 minutes and 90 minutes respectively; then take the wood out of the hot press and cool it down to 60°C in the room; , under the condition that the relative humidity is 75%, the moisture content of the wood can be adjusted to 5-7%. The staining results are shown in Table 1.

Embodiment 2

[0019] Take birch wood, for example. When processing, first control the moisture content of planed birch wood with a thickness of 22mm to about 7-10%; then put the wood into a hot press with a temperature of 250°C, and keep it warm at 250°C for 15 minutes, 45 minutes, 60 minutes and 90 minutes; then the wood is taken out from the hot press and cooled to 60°C indoors; finally, the wood is placed in a temperature-adjusting and humidity-adjusting box at a temperature of 80°C and a relative humidity of 75%. Just adjust the moisture content of the wood to 5-7%. The staining results are shown in Table 1.

Embodiment 3

[0021] Take Ash wood as an example. When processing, first control the moisture content of 4mm-thick planed Ash wood to about 10-15%; Minutes, 12 minutes and 15 minutes; then the wood is taken out from the heat press and cooled to 60°C indoors; finally, the wood is placed in a temperature and humidity control box at a temperature of 80°C and a relative humidity of 75%. Next, adjust the moisture content of the wood to 5-7%. The staining results are shown in Table 1.

[0022] Table 1 Wood staining results

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com