Silicon rubber heat resistant wire for heating coil

A technology of heating coils and silicone rubber, which is applied in the field of electric wires, can solve problems such as easy breakage of terminal contacts, itchy skin of operators, and short service life of electric wires, and achieve good coloring firmness, obvious environmental protection effect, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

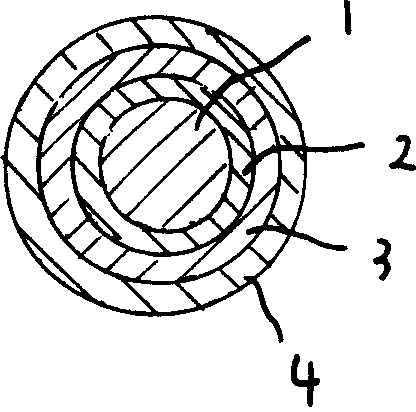

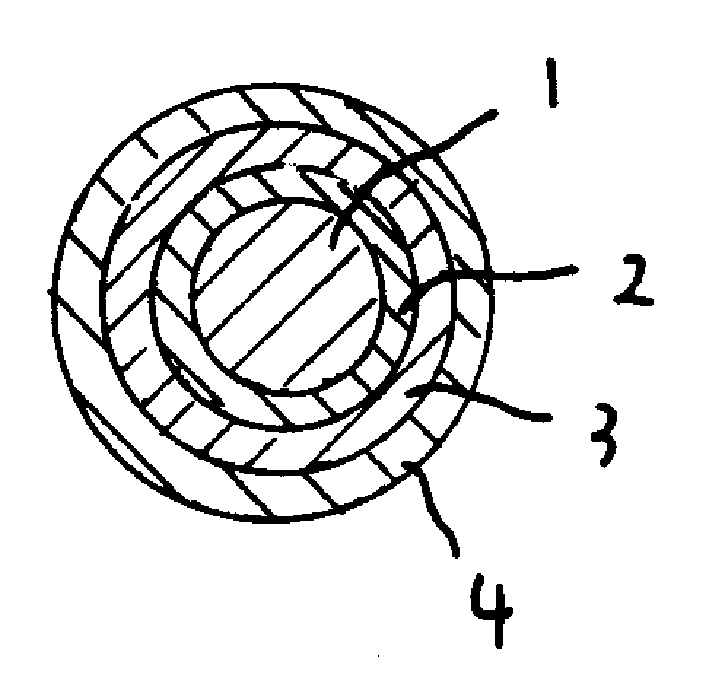

[0016] Such as figure 1 , The invention is a silicone rubber heat-resistant electric wire for a heating coil. Wires used for coil windings and lead wires of microwave oven transformers. It consists of a nickel-plated copper wire core 1, a silicon rubber insulating layer 2, a colored polyester fiber braiding layer 3 and an outer heat-resistant coating 4 from the inside to the outside. The polyester fiber braiding layer is made of red polyester fiber with light fastness: 7-8 grades, temperature resistance: >300°C without discoloration, and migration resistance below 5 grades. The colorant is directly added to the polyester fiber raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com