Polyether amine modified waterborne epoxy floor hardener and preparation method thereof

A technology of epoxy flooring and polyether amine, which is applied in the field of building materials, can solve the problems of hardness, adhesion and impact resistance that are difficult to meet the application requirements at the same time, lack of universal applicability, poor water dispersibility, etc., and achieve environmental protection Excellent performance, good water dispersibility, good effect of water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

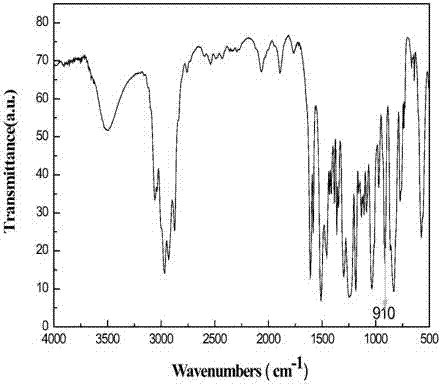

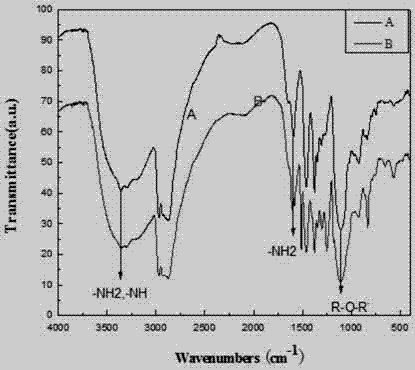

[0039] Among them, R 1 It is a straight chain with 8 to 13 carbon atoms or a straight chain with 8 to 13 atoms formed by combining one or more of oxygen atoms, sulfur atoms and nitrogen atoms with carbon atoms; R 2It is more than one of phenyl, alkoxy and alkyl; it also provides a method for preparing a curing agent for polyether amine modified water-based epoxy floors, using polyether amine and epoxy-terminated glycidyl ether First react, and then react with epoxy resin to prepare polyetheramine modified water-based epoxy floor curing agent, the reaction equation is as follows: Among them, the molar ratio of polyetheramine, epoxy-terminated glycidyl ether and epoxy resin is 2~6:0.5~4.5:0.5~4.5; during the reaction, firstly add polyetheramine into the reactor, and then add terminal ring Oxygen glycidyl ether reacts, after the reaction is complete, add epoxy resin, and finally add deionized water to disperse to obtain a polyether amine modified water-based epoxy floor curing ...

Embodiment 1

[0045] Example 1: Preparation of Polyetheramine Modified Waterborne Epoxy Floor Curing Agent 1

[0046] Add 138g of analytical grade polyetheramine D-400 and a small amount of KH550 into a 500ml four-necked flask equipped with a stirrer, a condenser, a nitrogen conduit and a constant pressure dropping funnel. Stir with nitrogen gas and heat up to a certain temperature (about 70°C). At this temperature, slowly add 60.4g of trimethylolpropane triglycidyl ether dropwise with a constant pressure dropping funnel, and react for 2 hours to obtain a three-branched chain terminal amino group. Then, the temperature was raised to 100° C. to carry out vacuum distillation for 1 hour to distill off excess polyamines. In the second step, 37.4 g of E51 from Shanghai Resin Factory was added dropwise to the four-necked flask after the first step of reaction was completed. React at 80°C for 4 hours to obtain an epoxy-amine addition product, add 101 g of deionized water and disperse at high spe...

Embodiment 2

[0049] Example 2: Preparation of curing agent 2 for polyetheramine modified waterborne epoxy floor

[0050] Add 161g of industrial grade polyetheramine D-403 and a small amount of KH550 into a 500ml four-neck flask equipped with a stirrer, a condenser, a nitrogen conduit and a constant pressure dropping funnel. Stir with nitrogen gas and heat up to a certain temperature (about 80°C). At this temperature, slowly add 44 g of polyethylene glycol diglycidyl ether dropwise with a constant pressure dropping funnel, and react for 3.5 hours to obtain two branched chain terminal amino groups. Then, the temperature was raised to 110° C. to conduct vacuum distillation for 1.5 hours to distill off excess polyamines. In the second step, 37.4 g of E44 was added dropwise to the four-necked flask after the first step of the reaction. React at 90°C for 4.5 hours to obtain an epoxy-amine addition product, add 104 g of deionized water and disperse at high speed for 20 minutes to prepare a polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com