High-temperature-resistant olive modified polyamide fiber and preparing method thereof

A technology of nylon fiber and high temperature resistance, applied in the direction of microsphere preparation, fiber chemical characteristics, microcapsule preparation, etc., can solve problems that have not been seen, and achieve good sphericity and dispersion, good heat storage performance, and good antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

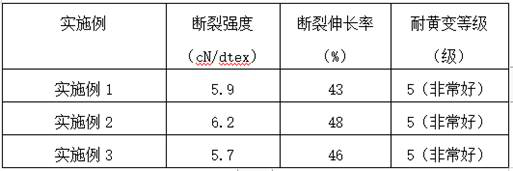

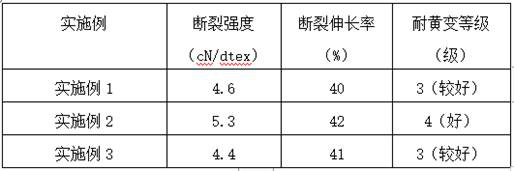

Examples

Embodiment 1

[0048] Embodiment 1 A preparation method of high temperature resistant olive modified nylon fiber includes:

[0049] 1. Preparation of olive leaf modified bilayer microcapsules

[0050] (1) Preparation of the first reaction solution:

[0051] The olive leaf extract was added to a 50% ethanol solution to dissolve for 20min, the temperature was raised to 32°C, then aminopropyltrimethoxysilane, dimethyl carbonate, and vegetable oil were added for stirring, and the stirring speed was 600r / min, and then the temperature was maintained for 10min. to obtain the first reaction solution;

[0052] The mass ratio of aminopropyltrimethoxysilane, dimethyl carbonate and vegetable oil is: 2:1:10; the addition of aminopropyltrimethoxysilane is 10% of the olive leaf extract;

[0053] The vegetable oil is a mixture of safflower seed oil and camellia oil, and the mass ratio is 1:1; the added amount of the vegetable oil is 2 times the quality of the olive leaf extract;

[0054] (2) Preparation ...

Embodiment 2

[0074] Embodiment 2 A preparation method of high temperature resistant olive modified nylon fiber includes:

[0075] 1. Preparation of olive leaf modified bilayer microcapsules

[0076] (1) Preparation of the first reaction solution:

[0077] Add olive leaf extract to 55% ethanol solution to dissolve for 20min, heat up to 30℃, then add aminopropyltrimethoxysilane, dimethyl carbonate, vegetable oil and dispersant to stir, stirring speed is 1000r / min, after Incubate for 10min to obtain the first reaction solution;

[0078] The mass ratio of aminopropyltrimethoxysilane, dimethyl carbonate, vegetable oil and dispersant is: 4:3:15:1;

[0079] The addition of aminopropyltrimethoxysilane is 15% of the olive leaf extract;

[0080] The vegetable oil is safflower seed oil; the added amount of the vegetable oil is 2 times the quality of the olive leaf extract;

[0081] (2) Preparation of the second reaction solution:

[0082] Continue to heat up the prepared first reaction solution ...

Embodiment 3

[0100] Embodiment 3 A preparation method of high temperature resistant olive modified nylon fiber includes:

[0101] 1. Preparation of olive leaf modified bilayer microcapsules

[0102] (1) Preparation of the first reaction solution:

[0103] Add olive leaf extract to 60% ethanol solution to dissolve for 30min, heat up to 30℃, then add aminopropyltrimethoxysilane, dimethyl carbonate, vegetable oil, dispersant and stir, stirring speed is 1500r / min, after Incubate for 10min to obtain the first reaction solution;

[0104] The mass ratio of aminopropyltrimethoxysilane, dimethyl carbonate, vegetable oil, and dispersant is: 2:1:20:0.5;

[0105] The addition of aminopropyltrimethoxysilane is 10% of the olive leaf extract; the vegetable oil is olive oil; the addition of the vegetable oil is 3 times the quality of the olive leaf extract;

[0106] (5) Preparation of the second reaction solution:

[0107] Continue to heat up the prepared first reaction solution to 60°C, slowly add me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com